设计简介

轮轨式移动提升机传动系统设计及车架部件设计

摘要:随着我国经济的快速发展和对矿山资源需求的高速增长,对矿山生产技术提出了越来越高的要求。矿井提升机是矿山的大型固定设备之一,是联系井下与地面的主要运输工具。大幅度提高劳动生产率,实现工业现代化的一项战略措施。综合机械化不仅产量大,效率高,成本低,而且能减轻笨重的体力劳动,改善作业环境,是工业技术的发展方向。矿井提升工作是整个采矿过程中的重要环节。从地下采出的煤炭、矿石必须提升至地面才有实际应用价值。废石的提升,工作人员、材料及设备的升降等都要靠提升工作来完成。

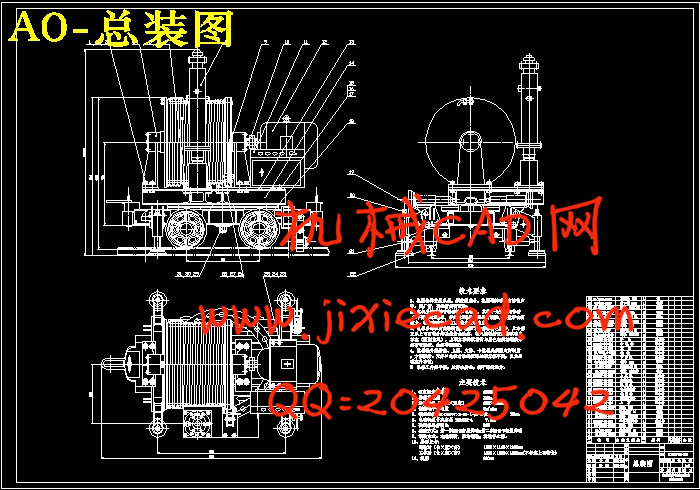

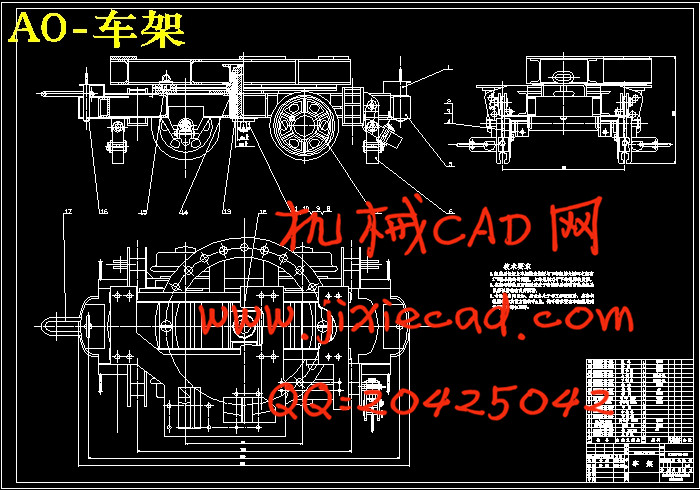

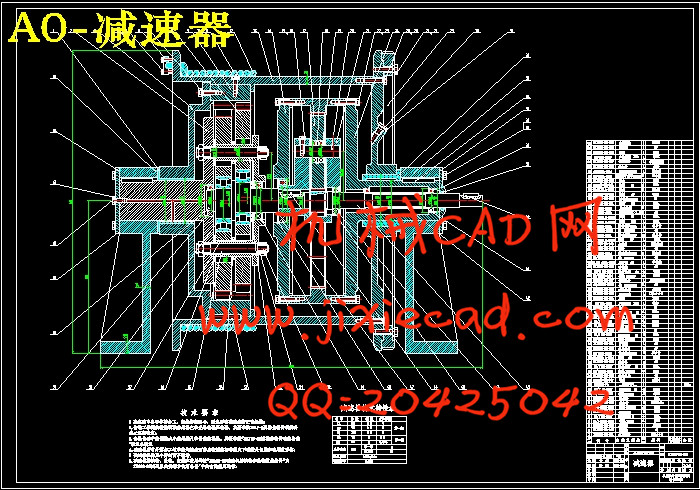

本设计根据生产实际和预选的数据,以提升机的车架设备为核心,经过科学的计算和分析,设计、选择了一套矿井提升机的传动系统设备,并设计了矿井提升机电动机。矿井提升机主要由以下几个基本部分组成:顶柱,车架,卡轨器,滑轮,卷筒,电动机,减速器。设计要遵从支护性能好、强度高、移架速度快、安全可靠等原则。

关键词:电动机;减速器;车架;顶柱

The designing of wheel and rail-mobile hoist transmission system and frame part

Abstract:As China's rapid economic development of mining resources and the rapid growth of demand, mine production technology to the growing demands. Mine mine hoist is one of the major fixed equipment, underground contact with the ground is the main means of transport. A substantial increase labor productivity, and achieve industrial modernization of a strategic measures. Integrated not only mechanized production, high efficiency, low cost, but also reduce the heavy manual work, improve the operating environment, industrial technology development direction. Mine upgrade the entire mining work is an important link in the process. From the ground to coal mining, ore must be raised to the ground before the actual value. Waste rock the upgrade, staff, materials and equipment movements and so must rely on upgrading work to complete.

According to the design and actual production of pre-selection data to hoist equipment at the core of the frame, after a scientific calculation and analysis, design, select a mine hoist the transmission equipment, and design a mine hoist motor. Mine Hoist mainly by the following basic components: Top-chu, trailers, rail card, the pulley, drum, motor, reducer. Designed to comply with the support of good, high-intensity, fast-shifting, the principles of safe and reliable.

Key words: motor;reducer;frame;top columns

目 录

1绪论 1

1.1提升设备研究背景及意义 2

1.2提升设备工作原理 2

1.3矿井提升设备的分类及基本组成 3

1.4 提升机发展概况 5

2传动方案设计 6

3工作装置的设计计算 8

3.1钢丝绳 8

3.2滑轮 15

3.3卷筒 19

4动力装置的设计计算 26

4.1电动机的工作制 26

4.2电动机的选择与校验 28

5传动装置的设计计算 31

5.1确定总的传动比 31

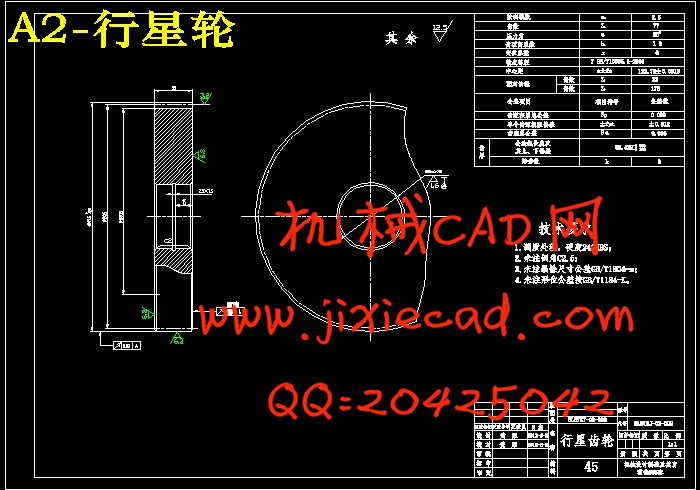

5.2多级复合轮系减速器的设计计算 32

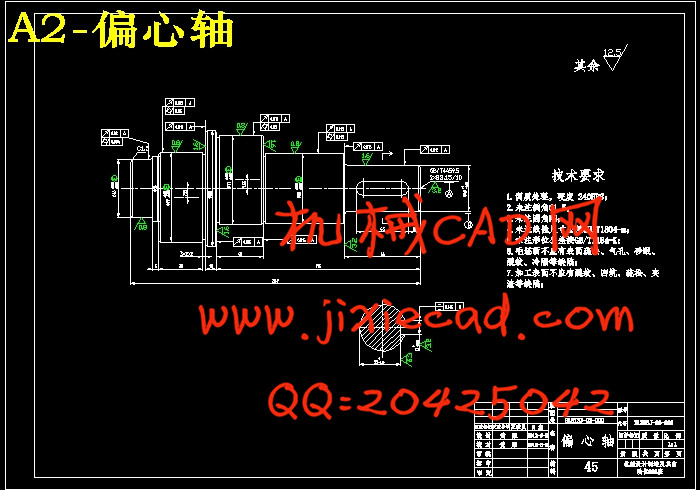

5.3轴的结构及其轴上零件的布置 48

6车轮、卡轨器部件的设计 55

6.1车轮设计 55

6.2卡轨器设计 58

参考文献 63

谢 辞 64

摘要:随着我国经济的快速发展和对矿山资源需求的高速增长,对矿山生产技术提出了越来越高的要求。矿井提升机是矿山的大型固定设备之一,是联系井下与地面的主要运输工具。大幅度提高劳动生产率,实现工业现代化的一项战略措施。综合机械化不仅产量大,效率高,成本低,而且能减轻笨重的体力劳动,改善作业环境,是工业技术的发展方向。矿井提升工作是整个采矿过程中的重要环节。从地下采出的煤炭、矿石必须提升至地面才有实际应用价值。废石的提升,工作人员、材料及设备的升降等都要靠提升工作来完成。

本设计根据生产实际和预选的数据,以提升机的车架设备为核心,经过科学的计算和分析,设计、选择了一套矿井提升机的传动系统设备,并设计了矿井提升机电动机。矿井提升机主要由以下几个基本部分组成:顶柱,车架,卡轨器,滑轮,卷筒,电动机,减速器。设计要遵从支护性能好、强度高、移架速度快、安全可靠等原则。

关键词:电动机;减速器;车架;顶柱

The designing of wheel and rail-mobile hoist transmission system and frame part

Abstract:As China's rapid economic development of mining resources and the rapid growth of demand, mine production technology to the growing demands. Mine mine hoist is one of the major fixed equipment, underground contact with the ground is the main means of transport. A substantial increase labor productivity, and achieve industrial modernization of a strategic measures. Integrated not only mechanized production, high efficiency, low cost, but also reduce the heavy manual work, improve the operating environment, industrial technology development direction. Mine upgrade the entire mining work is an important link in the process. From the ground to coal mining, ore must be raised to the ground before the actual value. Waste rock the upgrade, staff, materials and equipment movements and so must rely on upgrading work to complete.

According to the design and actual production of pre-selection data to hoist equipment at the core of the frame, after a scientific calculation and analysis, design, select a mine hoist the transmission equipment, and design a mine hoist motor. Mine Hoist mainly by the following basic components: Top-chu, trailers, rail card, the pulley, drum, motor, reducer. Designed to comply with the support of good, high-intensity, fast-shifting, the principles of safe and reliable.

Key words: motor;reducer;frame;top columns

目 录

1绪论 1

1.1提升设备研究背景及意义 2

1.2提升设备工作原理 2

1.3矿井提升设备的分类及基本组成 3

1.4 提升机发展概况 5

2传动方案设计 6

3工作装置的设计计算 8

3.1钢丝绳 8

3.2滑轮 15

3.3卷筒 19

4动力装置的设计计算 26

4.1电动机的工作制 26

4.2电动机的选择与校验 28

5传动装置的设计计算 31

5.1确定总的传动比 31

5.2多级复合轮系减速器的设计计算 32

5.3轴的结构及其轴上零件的布置 48

6车轮、卡轨器部件的设计 55

6.1车轮设计 55

6.2卡轨器设计 58

参考文献 63

谢 辞 64