设计简介

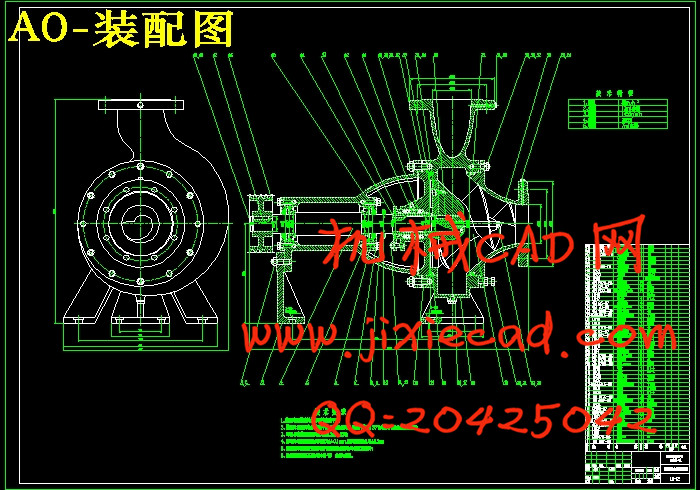

螺旋离心泵的设计

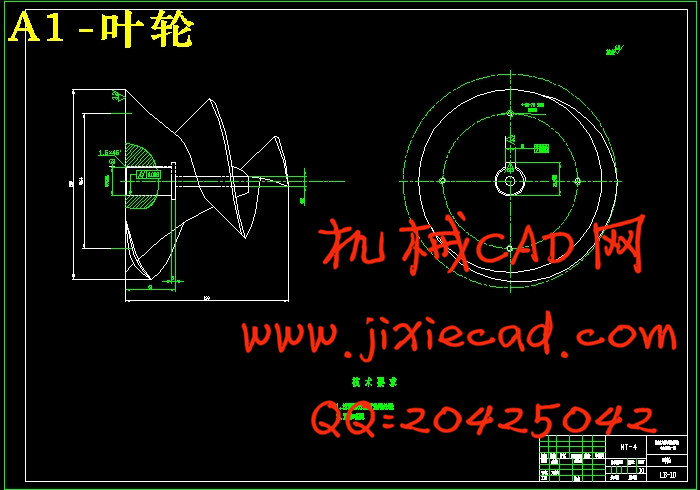

摘要:此说明书设计了一台用于输送固液两相流体的螺旋离心泵。本文的设计重点和难点是螺旋离心泵特有的是三维螺旋叶轮的设计。因此,叶轮设计是以何希杰和劳学苏提出的螺旋离心泵叶轮叶片工作面和负压面空间曲线方程为依据进行的设计,叶轮叶片型线为对数螺旋线。根据设计参数和工作条件的要求,在设计上采用固液两相流理论对叶轮、背叶片、压出室等泵过流部件进行水力设计。说明书从螺旋离心泵的结构设计开始,分别进行了叶轮的设计与绘形、压水室及吸水室的设计、轴向力极其平衡、主要通用零部件的选择、V型带传动设计和离心泵主要零部件的强度计算。

本文为设计高效螺旋离心泵提供了一个重要的参考依据。

关键词:固液两相流 螺旋离心泵 三维螺旋叶轮 空间曲线 对数螺旋线

Spiral centrifugal pump design

Abstract :The article designs a screw centrifugal pump used to transport the mix flows of solid and liquid. The emphases and difficulty of the article is the design of three dimensional screw impeller owned by screw centrifugal pump. So, the design of impeller is designed with the space curve screw equation of impeller vane work surface of screw centrifugal pump and minus pressure surface raised by Xue su LAO and Xi jie HE. I take it as the gist of design. The impeller vane line is logarithm screw curve. Accord to the design parameter and the require of work condition, on the design , we do waterpower design to impeller , back vane, press out house and some flow over parts with the theory of the mix flows of solid and liquid. The article starts with structure design of screw centrifugal pump, and design the calculation and drawing of impeller, pressure out house and off water house, the force of direction of axis and its balance, the choice of the main parts in common use, the transmission design of V strip and intensity calculation of the parts of screw centrifugal pump.

The article provides an important reference for designing the high efficiency screw centrifugal pump

Key words:the mix flows of solid and liquid screw centrifugal pump three dimensional screw impeller the space the curve logarithm screw curve

目

第一章 绪论 1

1.2螺旋离心泵概述 1

1.2离心泵主要零部件及结构形式 1

第二章总体方案的确定 3

2.1 设计参数 3

2.2 方案的确定 3

2.3原动机的选择 3

2.4水力设计 4

第三章 叶轮的设计 6

3.1概述 6

3.2叶轮主要参数的确定 6

3.3背叶片设计 14

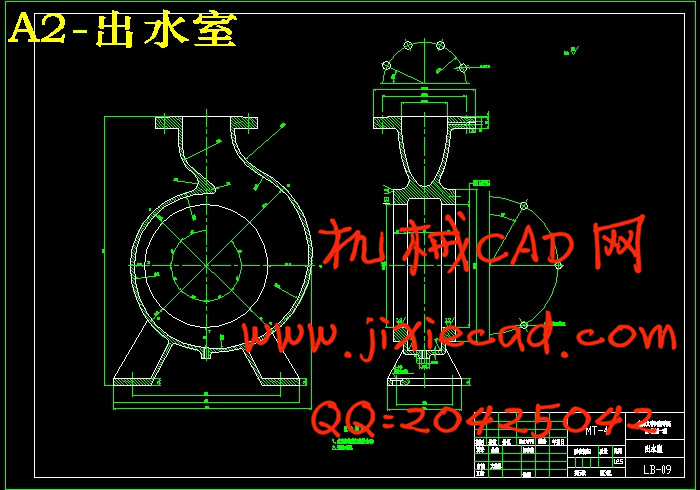

第四章 压水室及吸水室的设计 15

4.1压水室的用途及分类 15

4.2压水室的设计 15

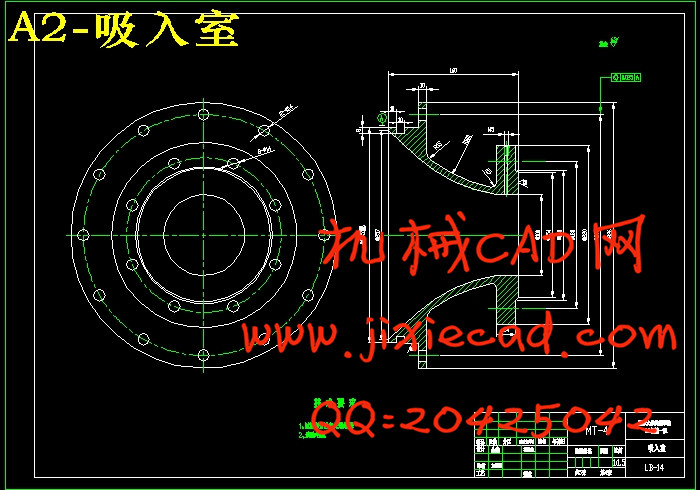

4.3吸水室的设计 16

第五章 轴向力及其平衡 18

5.1产生轴向力的主要原因 18

5.2轴向力计算 18

5.3轴向力平衡方法 18

第六章 主要通用零部件选择 20

6.1正确选用通用零部件的重要性 20

6.2轴封结构选择 20

6.3轴承部件选择 22

第七章 离心泵主要零部件的强度计算 23

7.1泵体强度计算 23

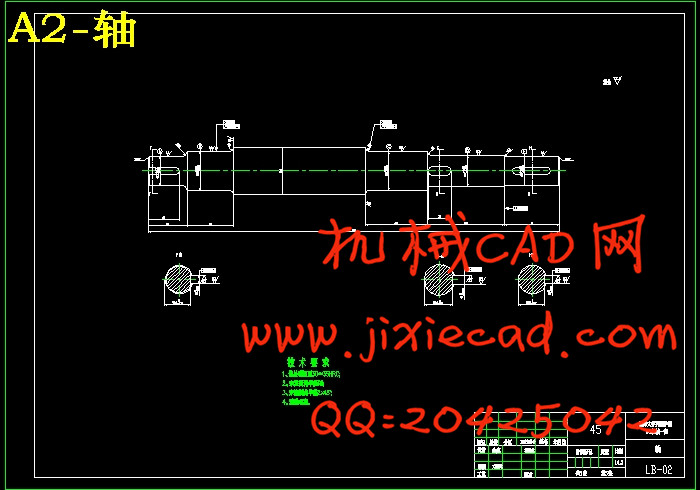

7.2泵轴校核 23

7.3轴承校核 25

总结 27

致 谢 28

参考文献 29

摘要:此说明书设计了一台用于输送固液两相流体的螺旋离心泵。本文的设计重点和难点是螺旋离心泵特有的是三维螺旋叶轮的设计。因此,叶轮设计是以何希杰和劳学苏提出的螺旋离心泵叶轮叶片工作面和负压面空间曲线方程为依据进行的设计,叶轮叶片型线为对数螺旋线。根据设计参数和工作条件的要求,在设计上采用固液两相流理论对叶轮、背叶片、压出室等泵过流部件进行水力设计。说明书从螺旋离心泵的结构设计开始,分别进行了叶轮的设计与绘形、压水室及吸水室的设计、轴向力极其平衡、主要通用零部件的选择、V型带传动设计和离心泵主要零部件的强度计算。

本文为设计高效螺旋离心泵提供了一个重要的参考依据。

关键词:固液两相流 螺旋离心泵 三维螺旋叶轮 空间曲线 对数螺旋线

Spiral centrifugal pump design

Abstract :The article designs a screw centrifugal pump used to transport the mix flows of solid and liquid. The emphases and difficulty of the article is the design of three dimensional screw impeller owned by screw centrifugal pump. So, the design of impeller is designed with the space curve screw equation of impeller vane work surface of screw centrifugal pump and minus pressure surface raised by Xue su LAO and Xi jie HE. I take it as the gist of design. The impeller vane line is logarithm screw curve. Accord to the design parameter and the require of work condition, on the design , we do waterpower design to impeller , back vane, press out house and some flow over parts with the theory of the mix flows of solid and liquid. The article starts with structure design of screw centrifugal pump, and design the calculation and drawing of impeller, pressure out house and off water house, the force of direction of axis and its balance, the choice of the main parts in common use, the transmission design of V strip and intensity calculation of the parts of screw centrifugal pump.

The article provides an important reference for designing the high efficiency screw centrifugal pump

Key words:the mix flows of solid and liquid screw centrifugal pump three dimensional screw impeller the space the curve logarithm screw curve

目

第一章 绪论 1

1.2螺旋离心泵概述 1

1.2离心泵主要零部件及结构形式 1

第二章总体方案的确定 3

2.1 设计参数 3

2.2 方案的确定 3

2.3原动机的选择 3

2.4水力设计 4

第三章 叶轮的设计 6

3.1概述 6

3.2叶轮主要参数的确定 6

3.3背叶片设计 14

第四章 压水室及吸水室的设计 15

4.1压水室的用途及分类 15

4.2压水室的设计 15

4.3吸水室的设计 16

第五章 轴向力及其平衡 18

5.1产生轴向力的主要原因 18

5.2轴向力计算 18

5.3轴向力平衡方法 18

第六章 主要通用零部件选择 20

6.1正确选用通用零部件的重要性 20

6.2轴封结构选择 20

6.3轴承部件选择 22

第七章 离心泵主要零部件的强度计算 23

7.1泵体强度计算 23

7.2泵轴校核 23

7.3轴承校核 25

总结 27

致 谢 28

参考文献 29