设计简介

螺旋式压榨机的设计

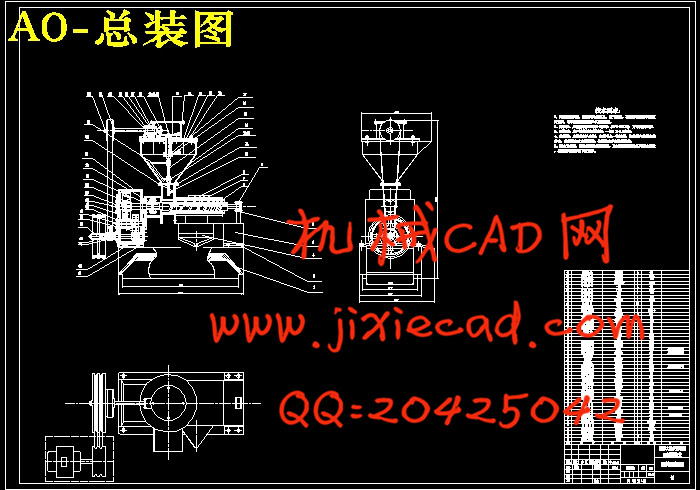

摘要:螺旋榨油机过去是现在仍然是油脂生产中的一台主机。就是在近代的浸出法制油中队高含油份油料大多采用还是预榨—— 浸出工艺方法来制备油脂,所以预榨机——螺旋榨油机仍然是油脂工业生产中的重要部件。螺旋榨油机的结构直接影响到油脂生产的数量和质量。而榨油机的工作部分是螺旋轴和榨笼构成,料胚经过螺旋轴和榨笼之间的空间——炸膛,而受到压榨。所以它们是榨油机的“心脏”,它们的结构直接影响到榨油机的性能。本文通过了解压榨机的资料,然后比对压榨机的结构,设计其结构,螺杆的设计是整个设计的主体,通过对压榨物质和生产量的取定,得出螺旋杆的设计过程,本文的传动采用两级减速传动,使机器运作稳定。通过对整机功率,转矩,最后定出电机。还要对整个设计重要部件做出校核,能够让机器正常运作。

关键词: 榨油机;榨笼;;生产量;校核

The design spiral presser

Abstract: Screw press in the past and is still oil production in a host. Leaching in the modern legal system is the oil companies of most of the high fuel oil were used or pre-press - leaching method to prepare the oil, so pre-press machine - oil screw press is still important components of industrial production. Screw press of the structure of a direct impact on oil production quantity and quality. The press of work is the screw axis and the pressing part of the cage structure, material embryo axis and squeezed This text through the spiral space between the cage - bombing bore, and being squeezed. So they press of the "heart", which directly affects the structure of oil press performance. In this paper, the information about press machine, and then compared presser structure, design its structure, the screw design is the design of the main body, squeezing through on the amount of substance and production are constant, obtained screw design process, This text slow down the drive with two transmission, the machine operates in a stable. On machine power, torque, and finally set the motor. Also an important part of the whole design and make check, allowing the normal operation of the machine。

Keywords: oil press;pressed cage;production;check

目录

摘要……………………………………………………………………3

一、 绪论……………………………………………………………..5

1.1 螺旋式压榨机的工作原理………………………………………………...5

1.2 设计压榨机的程序……………………………………..………………….6

1.3 准备阶段……………………………………………………………..….…6

1.4 方案设计阶段………………………………………………………………6

1.5 技术设计阶段……………………………………………………..6

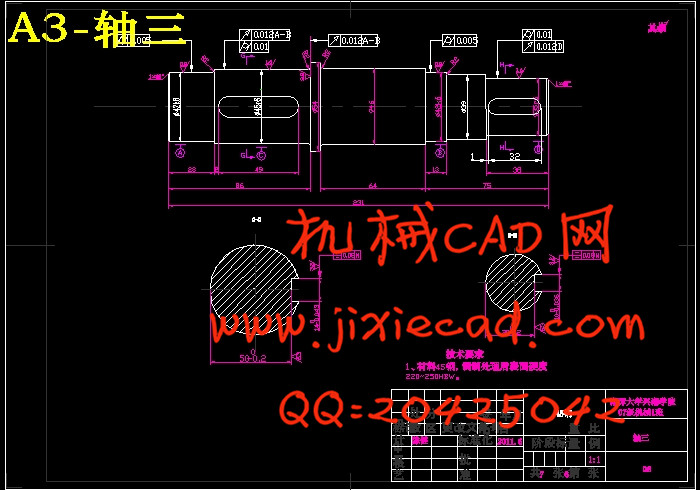

二、 螺旋压榨机的结构设计………………………………..……….8

2.1 榨螺轴的设计………………………………………………………………8

2.2 榨笼的构造…………………………………………………………………8

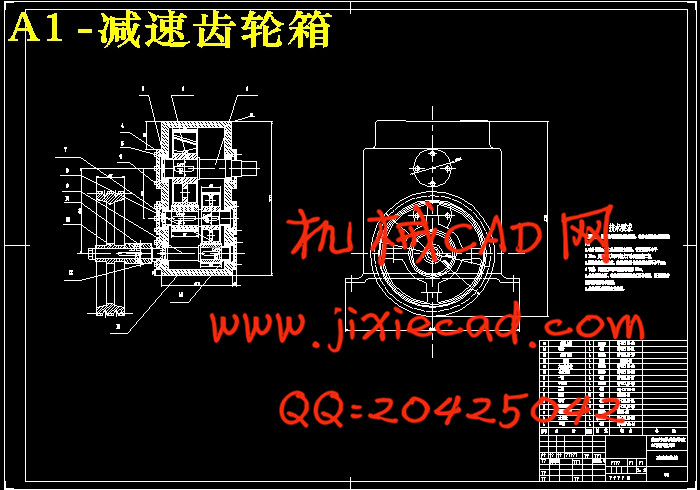

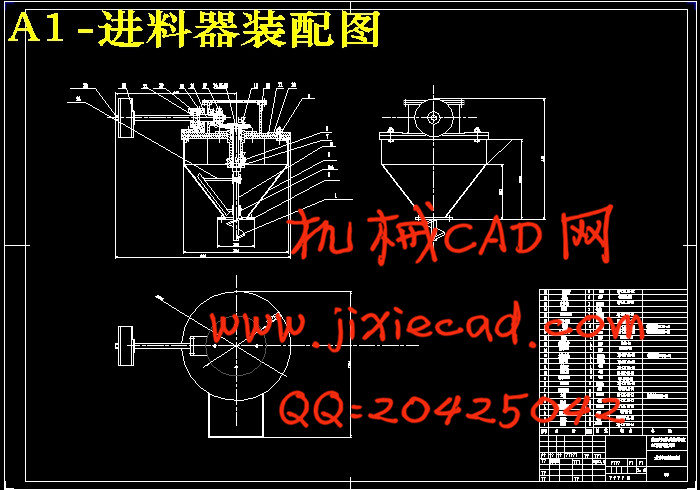

2.3 齿轮箱的构造及入料器的构造……………………………………………8

2.4 调节装置的设计…………………………………….…………...…8

三、 螺旋压榨机的主要参数的确定……………..………………....9

3.1 螺杆的设计及其校核……………………………………………………….9

3.2 带传动的设计计算…………………………………………………………17

3.2.1 平行带轮的设计………………………………………………………..…..17

3.2.2 三角带轮的结构设计……………………………………………………….18

四、 减速器的设计……………………………………..………..…..21

4.1 电动机的选择………………………………………………………….......21

4.2 传动装置的运动和动力参数………………………………………………22

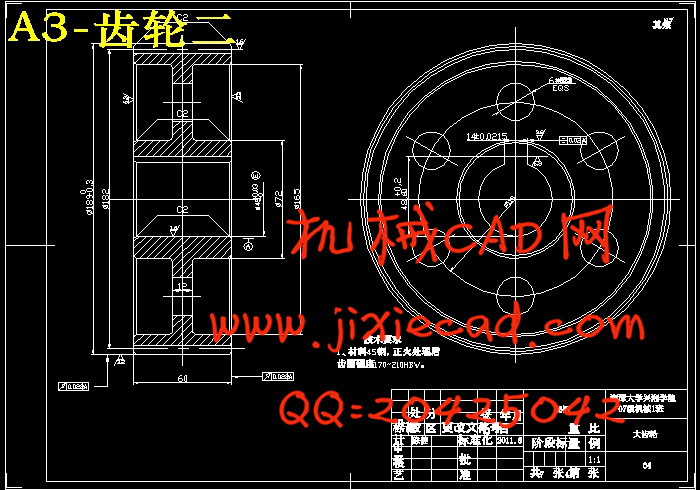

4.3 齿轮传动的设计及校核…………………………………………………....23

4.4 低级减速齿轮的设计…………………………………………………..…..26

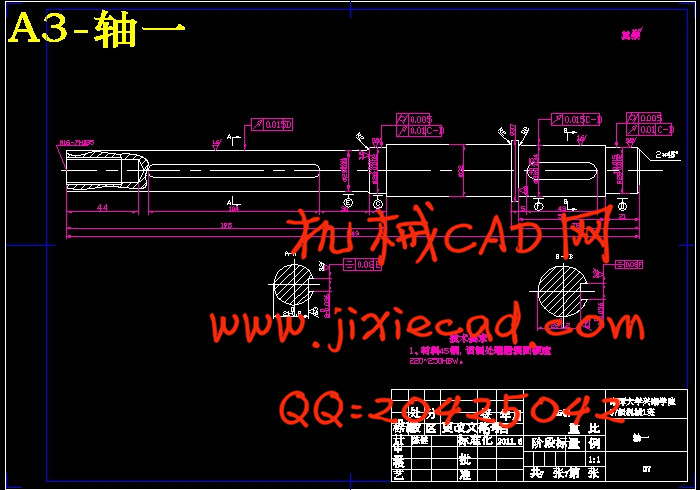

4.5 轴的设计…………………………………………………………….……...31

4.1.1 低速轴的设计…………………………………………………….…….…31

4.1.2 中间轴的设计…………………………………………………….……….34

4.1.3 高速轴的设计………………………………………………………..……34

4.6 校核……………………………………………………………..………...35

五、 结束语…………………………………………………………37

参考文献……………………………………..………………………38

摘要:螺旋榨油机过去是现在仍然是油脂生产中的一台主机。就是在近代的浸出法制油中队高含油份油料大多采用还是预榨—— 浸出工艺方法来制备油脂,所以预榨机——螺旋榨油机仍然是油脂工业生产中的重要部件。螺旋榨油机的结构直接影响到油脂生产的数量和质量。而榨油机的工作部分是螺旋轴和榨笼构成,料胚经过螺旋轴和榨笼之间的空间——炸膛,而受到压榨。所以它们是榨油机的“心脏”,它们的结构直接影响到榨油机的性能。本文通过了解压榨机的资料,然后比对压榨机的结构,设计其结构,螺杆的设计是整个设计的主体,通过对压榨物质和生产量的取定,得出螺旋杆的设计过程,本文的传动采用两级减速传动,使机器运作稳定。通过对整机功率,转矩,最后定出电机。还要对整个设计重要部件做出校核,能够让机器正常运作。

关键词: 榨油机;榨笼;;生产量;校核

The design spiral presser

Abstract: Screw press in the past and is still oil production in a host. Leaching in the modern legal system is the oil companies of most of the high fuel oil were used or pre-press - leaching method to prepare the oil, so pre-press machine - oil screw press is still important components of industrial production. Screw press of the structure of a direct impact on oil production quantity and quality. The press of work is the screw axis and the pressing part of the cage structure, material embryo axis and squeezed This text through the spiral space between the cage - bombing bore, and being squeezed. So they press of the "heart", which directly affects the structure of oil press performance. In this paper, the information about press machine, and then compared presser structure, design its structure, the screw design is the design of the main body, squeezing through on the amount of substance and production are constant, obtained screw design process, This text slow down the drive with two transmission, the machine operates in a stable. On machine power, torque, and finally set the motor. Also an important part of the whole design and make check, allowing the normal operation of the machine。

Keywords: oil press;pressed cage;production;check

目录

摘要……………………………………………………………………3

一、 绪论……………………………………………………………..5

1.1 螺旋式压榨机的工作原理………………………………………………...5

1.2 设计压榨机的程序……………………………………..………………….6

1.3 准备阶段……………………………………………………………..….…6

1.4 方案设计阶段………………………………………………………………6

1.5 技术设计阶段……………………………………………………..6

二、 螺旋压榨机的结构设计………………………………..……….8

2.1 榨螺轴的设计………………………………………………………………8

2.2 榨笼的构造…………………………………………………………………8

2.3 齿轮箱的构造及入料器的构造……………………………………………8

2.4 调节装置的设计…………………………………….…………...…8

三、 螺旋压榨机的主要参数的确定……………..………………....9

3.1 螺杆的设计及其校核……………………………………………………….9

3.2 带传动的设计计算…………………………………………………………17

3.2.1 平行带轮的设计………………………………………………………..…..17

3.2.2 三角带轮的结构设计……………………………………………………….18

四、 减速器的设计……………………………………..………..…..21

4.1 电动机的选择………………………………………………………….......21

4.2 传动装置的运动和动力参数………………………………………………22

4.3 齿轮传动的设计及校核…………………………………………………....23

4.4 低级减速齿轮的设计…………………………………………………..…..26

4.5 轴的设计…………………………………………………………….……...31

4.1.1 低速轴的设计…………………………………………………….…….…31

4.1.2 中间轴的设计…………………………………………………….……….34

4.1.3 高速轴的设计………………………………………………………..……34

4.6 校核……………………………………………………………..………...35

五、 结束语…………………………………………………………37

参考文献……………………………………..………………………38