设计简介

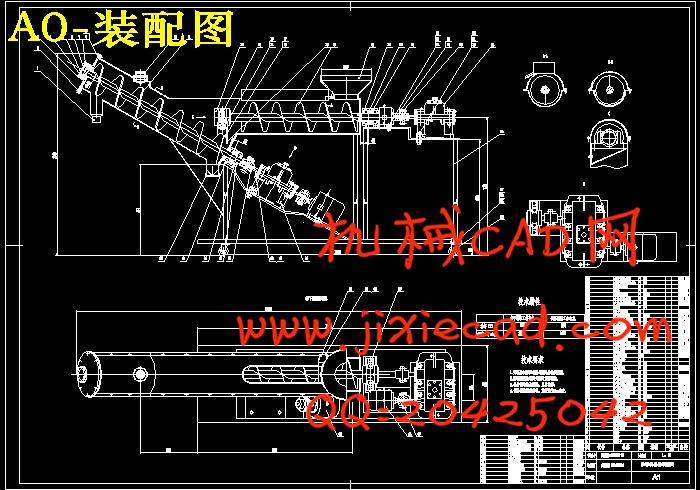

摘要:为适应食堂、大型饭店、快餐中心、现代化饮食企业应用等的需要,本文设计了一种螺旋输送式连续洗米机,该机由料斗、水平螺旋、倾斜螺旋、机架、动力装置、喷水装置等部分组成。洗米时,大米由料斗加入,经过水平螺旋的输送进行揉搓洗涤,大米中的漂浮杂质在此过程中漂出,与洗涤的浊水一起从溢流口排出。大米经过水平螺旋输送洗涤完后,进入倾斜螺旋,在倾斜螺旋的入口处,沉降速度较快的沙石则被沉降在沙石沉积槽内(,大米则随着倾斜螺旋的转动,被进一步揉搓洗涤并往上输送,最后经过喷水装置以上的沥干段沥干后从排料口排出,完成洗米操作。

该新型连续式洗米机结构简单、占地面积小、集搓米、洗米、除去漂浮杂质、沙石等于一体,除用于洗米外,也能用于黄豆,小麦,碗豆的洗涤及输送.它还适合于米制品厂,豆类制品厂等的原料洗涤,是食堂、大型饭店、快餐中心及酿造、豆类加工作业中较为理想的粮食洗涤机械。

关键词: 连续式 洗米机 原理 结构设计

Abstract:In order to meet the canteens, large restaurants, fast food centers, enterprise application modernization dietsuch, the need, the paper designs of a washing, it consists of a hopper, the level of spiral, helix tilt, rack,power devices, such as sprinkler parts .Rice machine work, adding the rice from the hopper through the level of the conveyor screw to rub washing, floating rice in Impurity in the process of bleaching, and washing with Choshui discharged from the overflow port.After the level of rice after washing spiral conveyor, spiral into the tilt in the tilt of the helix at the entrance, a faster settling velocity of sand deposition was deposited in the gravel bed,Of rice along with the tilt of the rotating spiral, further washing and rubbing up delivery, and finally, after more than sprinklers Drain Drain paragraph after the discharge from the mouth nesting complete washing rice operation.

.The new continuous type washes the rice hulling machine structure simply, the area small, the collection rubs the hands the rice, washes the rice, except the float impurity, the grit was equal to a body, this type besides uses in washing the rice, also can use in the soybean, the wheat, the bowl bean lavation and the transportation. It also suits in the rice production factory, the legumes production factory and so on raw material lavation, is the cafeteria, the large-scale hotel, the fast-food center and brews, the legumes processes in the work the more ideal grain lavation machinery.

Keywords: continuous,washing rice machine,principle,structural design

目录

1 前言.............................................(1)

2 螺旋输送式连续洗米机设计的原理.....................(2)

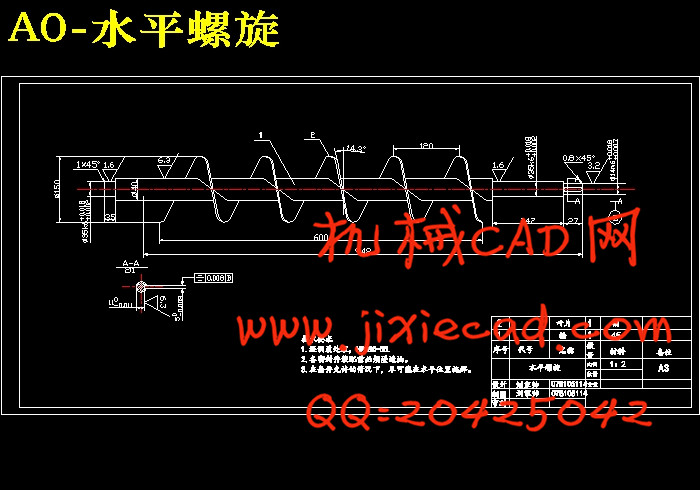

3 水平及倾斜螺旋设计及计算.........................(3)

3.1 水平螺旋直径,转速及长度 (3)

3.2 倾斜螺旋直径、转速及长度 (4)

3.3 功率计算及电机的选型 (4)

3.4 水平及倾斜螺旋校核计算 (5)

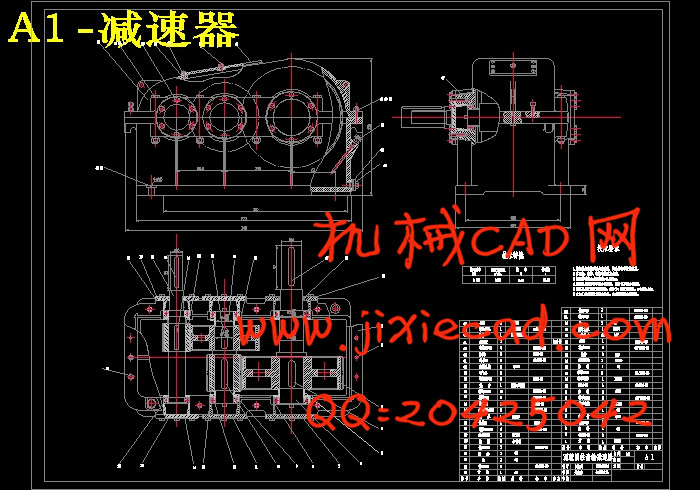

4 水平螺旋减速器设计 (8)

4.1 水平减速器总体设计 (8)

4.2 水平螺旋减速器高速级齿轮设计 (10)

4.3 水平螺旋减速器低速级齿轮设计 (15)

4.4 各轴的结构设计与较核 (19)

5 倾斜螺旋减速器设计 (30)

5.1 倾斜减速器总体设计 (30)

5.2 倾斜螺旋减速器高速级齿轮设计 (32)

5.3 倾斜螺旋减速器低速级齿轮设计 (36)

5.4 各轴的结构设计与较核 (40)

6 全文总结 (51)

6.1 本文完成的主要工作 (51)

6.2 设计小结 (51)

参考文献 (52)

致谢 (53)

该新型连续式洗米机结构简单、占地面积小、集搓米、洗米、除去漂浮杂质、沙石等于一体,除用于洗米外,也能用于黄豆,小麦,碗豆的洗涤及输送.它还适合于米制品厂,豆类制品厂等的原料洗涤,是食堂、大型饭店、快餐中心及酿造、豆类加工作业中较为理想的粮食洗涤机械。

关键词: 连续式 洗米机 原理 结构设计

Abstract:In order to meet the canteens, large restaurants, fast food centers, enterprise application modernization dietsuch, the need, the paper designs of a washing, it consists of a hopper, the level of spiral, helix tilt, rack,power devices, such as sprinkler parts .Rice machine work, adding the rice from the hopper through the level of the conveyor screw to rub washing, floating rice in Impurity in the process of bleaching, and washing with Choshui discharged from the overflow port.After the level of rice after washing spiral conveyor, spiral into the tilt in the tilt of the helix at the entrance, a faster settling velocity of sand deposition was deposited in the gravel bed,Of rice along with the tilt of the rotating spiral, further washing and rubbing up delivery, and finally, after more than sprinklers Drain Drain paragraph after the discharge from the mouth nesting complete washing rice operation.

.The new continuous type washes the rice hulling machine structure simply, the area small, the collection rubs the hands the rice, washes the rice, except the float impurity, the grit was equal to a body, this type besides uses in washing the rice, also can use in the soybean, the wheat, the bowl bean lavation and the transportation. It also suits in the rice production factory, the legumes production factory and so on raw material lavation, is the cafeteria, the large-scale hotel, the fast-food center and brews, the legumes processes in the work the more ideal grain lavation machinery.

Keywords: continuous,washing rice machine,principle,structural design

目录

1 前言.............................................(1)

2 螺旋输送式连续洗米机设计的原理.....................(2)

3 水平及倾斜螺旋设计及计算.........................(3)

3.1 水平螺旋直径,转速及长度 (3)

3.2 倾斜螺旋直径、转速及长度 (4)

3.3 功率计算及电机的选型 (4)

3.4 水平及倾斜螺旋校核计算 (5)

4 水平螺旋减速器设计 (8)

4.1 水平减速器总体设计 (8)

4.2 水平螺旋减速器高速级齿轮设计 (10)

4.3 水平螺旋减速器低速级齿轮设计 (15)

4.4 各轴的结构设计与较核 (19)

5 倾斜螺旋减速器设计 (30)

5.1 倾斜减速器总体设计 (30)

5.2 倾斜螺旋减速器高速级齿轮设计 (32)

5.3 倾斜螺旋减速器低速级齿轮设计 (36)

5.4 各轴的结构设计与较核 (40)

6 全文总结 (51)

6.1 本文完成的主要工作 (51)

6.2 设计小结 (51)

参考文献 (52)

致谢 (53)