设计简介

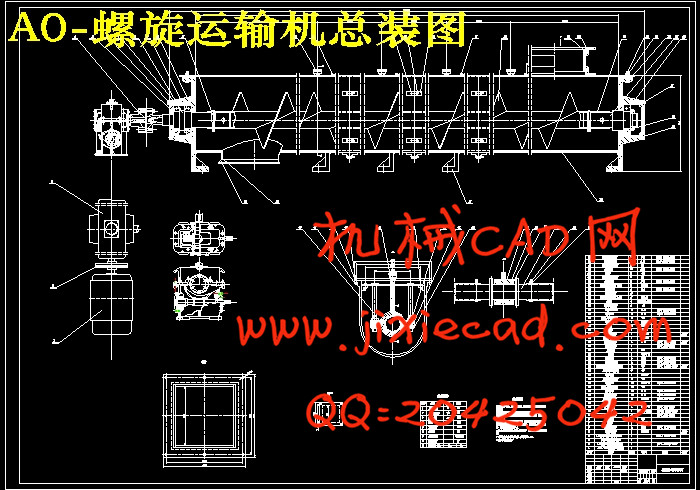

螺旋运输机的设计

摘要:螺旋输送机具有结构简单,制做成本低,密封性强、操作安全方便等优点,中间可多点装、卸料。广泛用于化工、 建材、冶金、粮食等部门,在倾角β< 20 °的情况下,输送粘度不大、不易变质、不蝗结块的粉状、颗粒状和小块物料。螺旋机广泛应用于各行业,如建材、化工、电力、冶金、煤矿炭、粮食等行业,适用于水平或倾斜输送粉状、粒状和小块状物料,如煤矿、灰、渣、水泥、粮食等,物料温度小于200℃。螺旋机不适于输送易变质的、粘性大的、易结块的物料。在混凝土搅拌站中,螺旋输送机的作用得到了最大的体现.由驱动装置封闭槽箱和螺旋组成借螺旋转动将槽箱内的煤推移输出。

关键词:螺旋输送机,卸料,物料,驱动装置,螺旋

Screw conveyor design

Abstract: The screw conveyor is simple in structure, low cost production, tightness, and the advantages of safe and convenient operation, the middle point can be loaded, discharge. Widely used in chemical industry, building materials, metallurgy, food and other departments, in the angle β <20 °, the transmission is not the viscosity, non-perishable, non-caking powder locusts, and small granular materials. Screw machine is widely used in various industries, such as building materials, chemical industry, electric power, metallurgy, coal mine, food and other industries, applied to horizontal or inclined conveyor powder, granulated and small lump materials, such as coal, ash, slag, cement , food, etc., material temperature is less than 200 ℃. Not suitable for screw machine perishable transport, and viscous large, easy caking materials. In the concrete mixing stations, the role of screw conveyor of the embodiment of the largest. By drive me and the spiral groove formed by the rotation of spiral groove box over the output of coal.

Keywords: screw conveyor, discharge, materials, drives, spiral

目 录

摘要

第一章 绪论…………………………………………………………… 1

1.1螺旋运输机的原理与特点 …………………………………… 1

1.2螺旋运输机的主要现状 ……………………………………… 1

1.3螺旋运输机的发展趋势 ……………………………………… 2

1.4煤矿螺旋运输机的技术发展趋势 …………………………… 5

第二章 结构方案拟定 ……………………………………………… 6

2.1设计要求 ……………………………………………………… 6

2.2设计原理 ……………………………………………………… 6

第三章 主要参数确定 ……………………………………………… 8

3.1功率计算与驱动装置的选择 ………………………………… 8

3.2螺旋直径与转数确定 ………………………………………… 9

3.3驱动装置的设计 ……………………………………………… 11

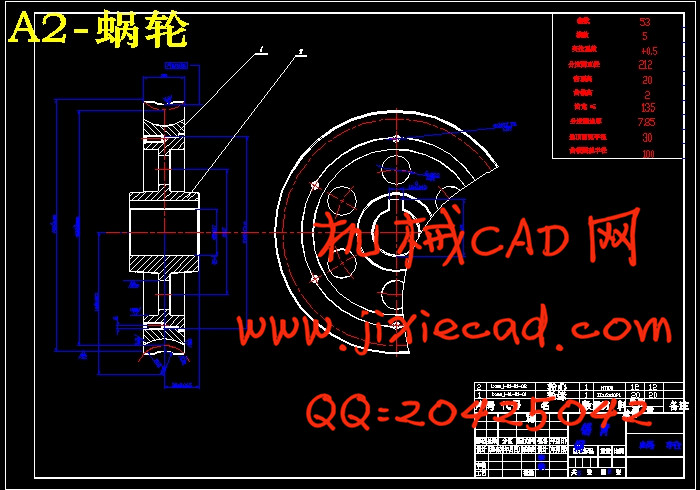

3.4传动零件的设计计算 ………………………………………… 14

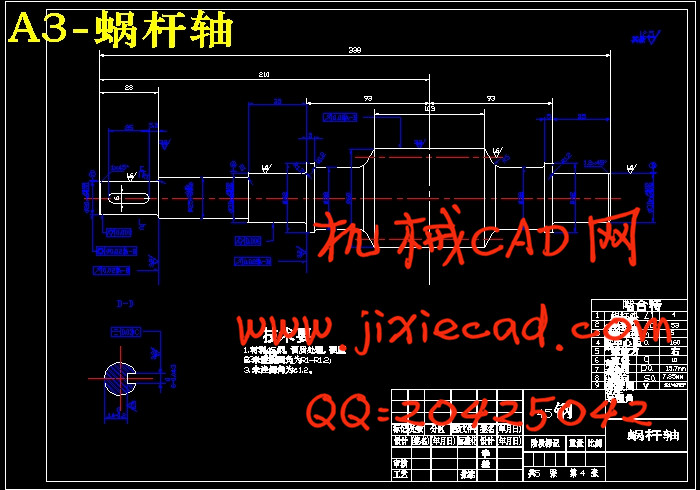

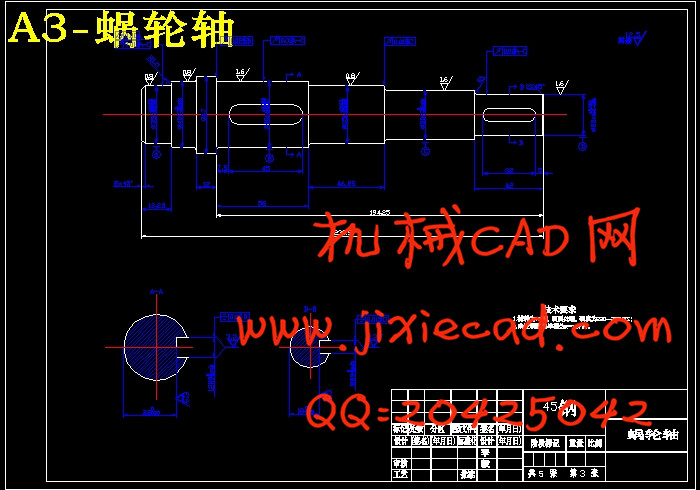

3.5轴的设计 ……………………………………………………… 19

3.6轴承及联轴器的校核 ………………………………………… 25

3.7箱体结构的设计 ……………………………………………… 28

3.8减速器其他零件的选择 ……………………………………… 30

3.9减速器的润滑 ………………………………………………… 33

设计心得 ……………………………………………………………… 34

参考文献 ……………………………………………………………… 35

摘要:螺旋输送机具有结构简单,制做成本低,密封性强、操作安全方便等优点,中间可多点装、卸料。广泛用于化工、 建材、冶金、粮食等部门,在倾角β< 20 °的情况下,输送粘度不大、不易变质、不蝗结块的粉状、颗粒状和小块物料。螺旋机广泛应用于各行业,如建材、化工、电力、冶金、煤矿炭、粮食等行业,适用于水平或倾斜输送粉状、粒状和小块状物料,如煤矿、灰、渣、水泥、粮食等,物料温度小于200℃。螺旋机不适于输送易变质的、粘性大的、易结块的物料。在混凝土搅拌站中,螺旋输送机的作用得到了最大的体现.由驱动装置封闭槽箱和螺旋组成借螺旋转动将槽箱内的煤推移输出。

关键词:螺旋输送机,卸料,物料,驱动装置,螺旋

Screw conveyor design

Abstract: The screw conveyor is simple in structure, low cost production, tightness, and the advantages of safe and convenient operation, the middle point can be loaded, discharge. Widely used in chemical industry, building materials, metallurgy, food and other departments, in the angle β <20 °, the transmission is not the viscosity, non-perishable, non-caking powder locusts, and small granular materials. Screw machine is widely used in various industries, such as building materials, chemical industry, electric power, metallurgy, coal mine, food and other industries, applied to horizontal or inclined conveyor powder, granulated and small lump materials, such as coal, ash, slag, cement , food, etc., material temperature is less than 200 ℃. Not suitable for screw machine perishable transport, and viscous large, easy caking materials. In the concrete mixing stations, the role of screw conveyor of the embodiment of the largest. By drive me and the spiral groove formed by the rotation of spiral groove box over the output of coal.

Keywords: screw conveyor, discharge, materials, drives, spiral

目 录

摘要

第一章 绪论…………………………………………………………… 1

1.1螺旋运输机的原理与特点 …………………………………… 1

1.2螺旋运输机的主要现状 ……………………………………… 1

1.3螺旋运输机的发展趋势 ……………………………………… 2

1.4煤矿螺旋运输机的技术发展趋势 …………………………… 5

第二章 结构方案拟定 ……………………………………………… 6

2.1设计要求 ……………………………………………………… 6

2.2设计原理 ……………………………………………………… 6

第三章 主要参数确定 ……………………………………………… 8

3.1功率计算与驱动装置的选择 ………………………………… 8

3.2螺旋直径与转数确定 ………………………………………… 9

3.3驱动装置的设计 ……………………………………………… 11

3.4传动零件的设计计算 ………………………………………… 14

3.5轴的设计 ……………………………………………………… 19

3.6轴承及联轴器的校核 ………………………………………… 25

3.7箱体结构的设计 ……………………………………………… 28

3.8减速器其他零件的选择 ……………………………………… 30

3.9减速器的润滑 ………………………………………………… 33

设计心得 ……………………………………………………………… 34

参考文献 ……………………………………………………………… 35