设计简介

摘要

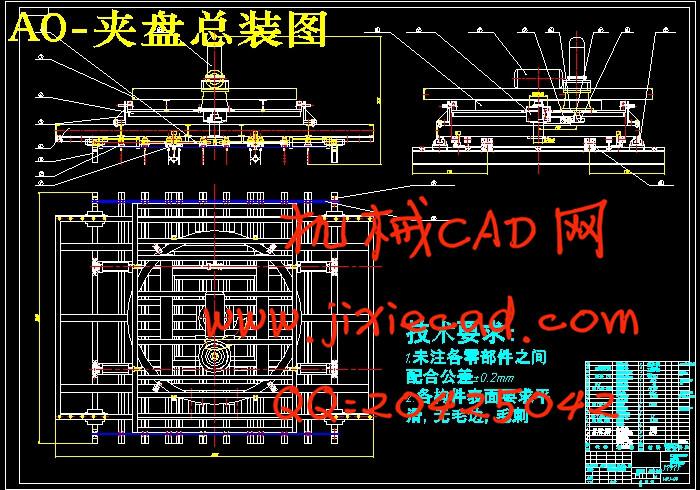

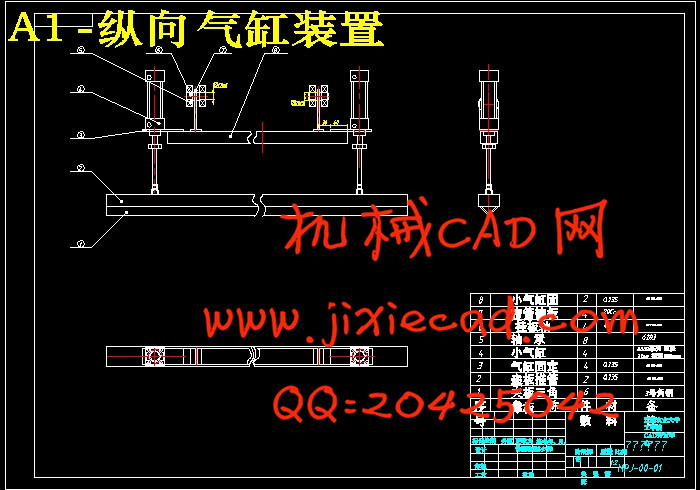

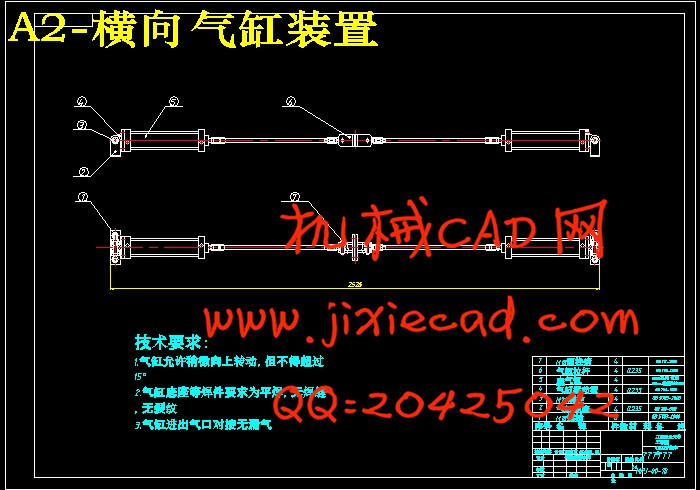

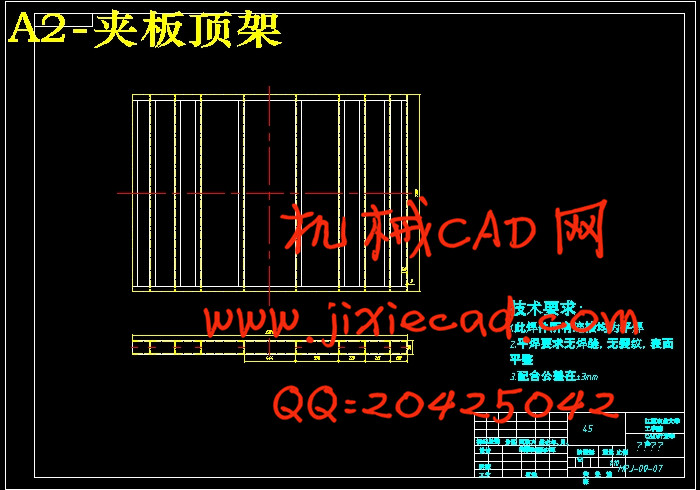

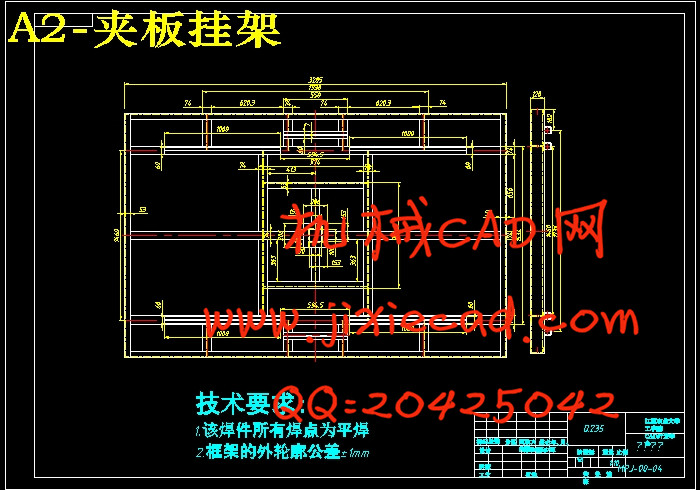

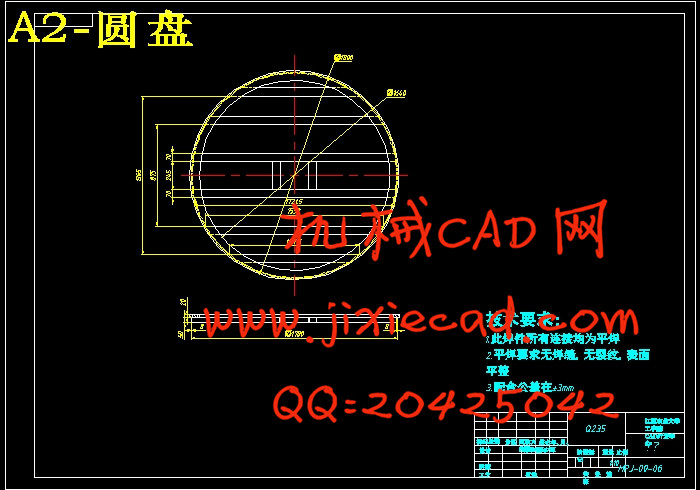

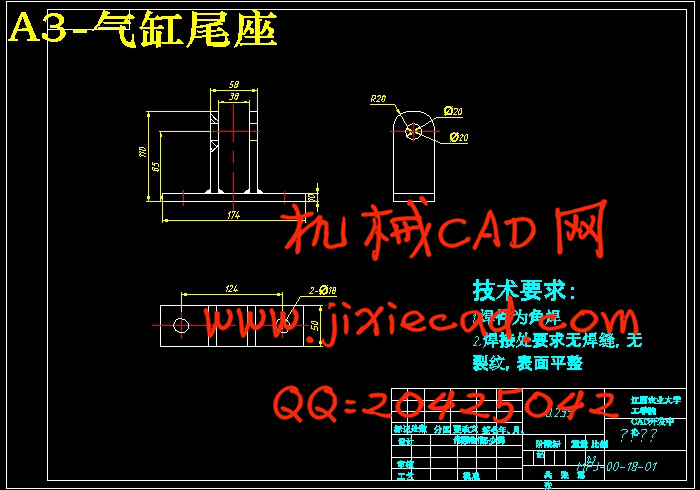

目前,常见码坯机夹盘机构有自动夹坯机构、先进机械手机构以及半自动半手动夹坯机构等多种形式。一般多采用半自动半手动机构设计,当坯条由切坯机切出并有传送带运送至夹盘正下方,夹盘在手动按钮的控制下,开始下降,到达一定高度后停止下降,并在电机传动和气缸传动控制下,横向气缸装置向中心推动,带动夹板加紧,同时纵向气缸装置向竖直方向推动,由焊接在下方的方管推动两侧的角铁从而同时将夹板加紧,达到夹坯的效果,然后由升降机构将夹盘提起并移送至烘烧轨道,依次循环。整个夹盘机构由夹板,纵横气缸装置,中心旋转轴架装置,夹板挂架装置,电动气动装置以及其他焊件装置构成。夹板两侧为直线导轨引导的侧板方管,承受压力大,并且直线性能好,摩擦力小,平稳性能好,有利于夹坯。纵向气缸装置也为加紧机构增加横向作用力,更大程度上有利于砖坯的夹紧。本文就是通过各方面考虑,综合对比传统的夹坯机构,获取整机各零件的参数,并且通过计算,论证了该设计方案的可行性。

关键词:码坯机;夹盘;夹坯原理

Abstract

At present, a common code base machine chuck mechanism has automatic blank clamping mechanism, advanced mechanical hand mechanism and a semi-automatic manual blank clamping mechanism and so on many kinds of forms. The general use of semi automatic and manual mechanism design, when the strip by cutting machine cut out and the conveyor to the chuck is below, chuck in the manual button control, began to decline, reaches a certain height to halt the decline, and in motor drive and a cylinder driving control, horizontal cylinder device to the center push, drive the splint intensified, while a longitudinal cylinder device to a vertical drive, at the bottom of the tube driven by welding on both sides of the angle iron and at the same time to reach the splint, blank clamping effect, and then by the lifting mechanism to chuck up and transferred to bake track, followed by cycle. The clamp mechanism consists of a splint, vertical and horizontal cylinder device, a center rotating shaft frame device, clamping plate rack device, electric pneumatic device and other welding device. Two sides of the splint is a linear guide rail guide plates of the square tube, large bearing pressure, and the straight line performance, small friction force, stable performance, is conducive to the blank clamping. Longitudinal cylinder device for clamping mechanism to increase the transverse force, more conducive to the clamping tile. This paper is through the aspects to consider, comprehensive comparison of traditional blank clamping mechanism, acquiring the various parameters of parts, and through calculation, it proves the feasibility of design scheme.

Key words :Setting machine ; Chuck mechanism ;Principle of Folder blank

目录

目录 I

摘要 II

Abstract III

1 绪论 1

1.1 砖的主要特点及功用 1

1.2 码坯机在国内外的发展现状 1

1.3 码坯机的概述 2

1.3.1 码坯机工作原理及运动流程 2

1.3.2 码坯机未来发展的影响因素 3

2 码坯机夹盘机构设计 3

2.1 夹盘机构总体设计方案 3

2.1.1夹盘机构设计要求 4

2.1.2 夹盘各功能板块 4

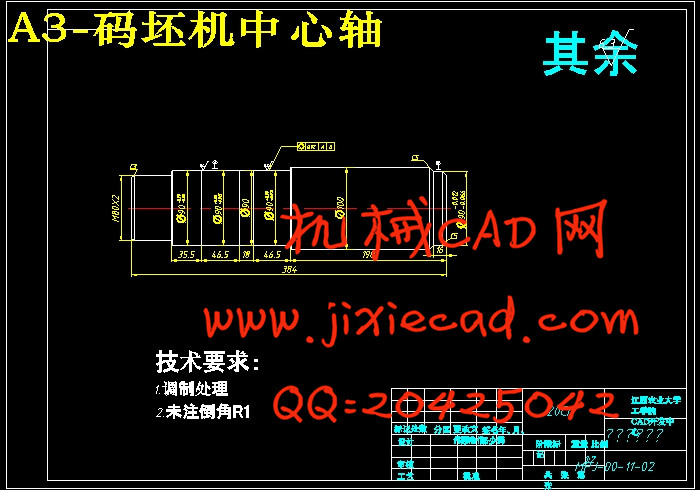

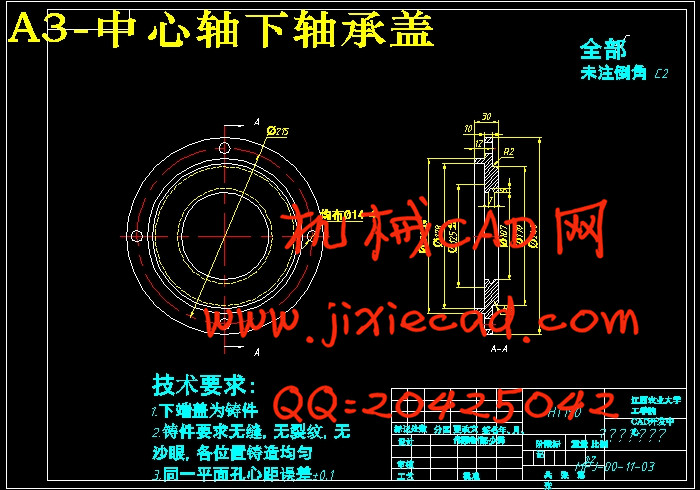

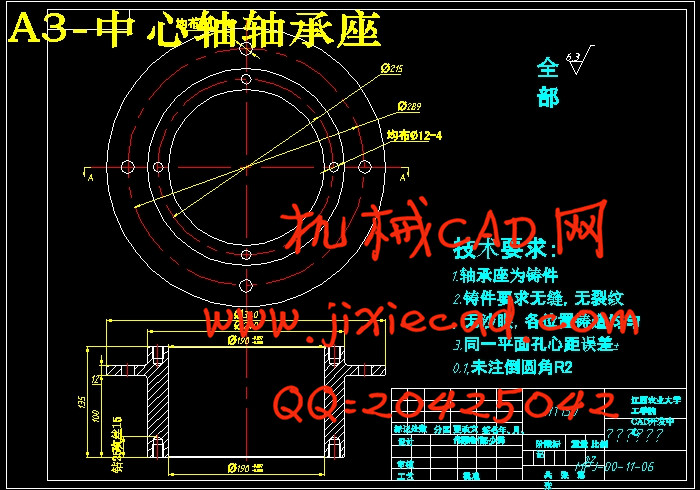

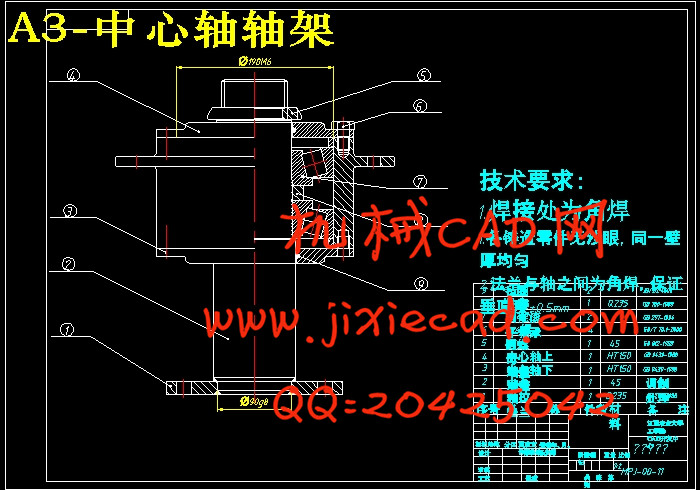

3 转动机构的设计 5

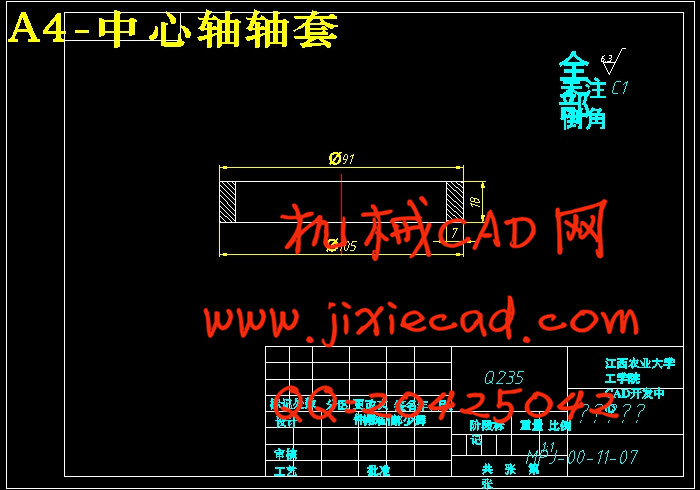

3.1 轴的校核计算 5

3.1.2 轴承的校核 6

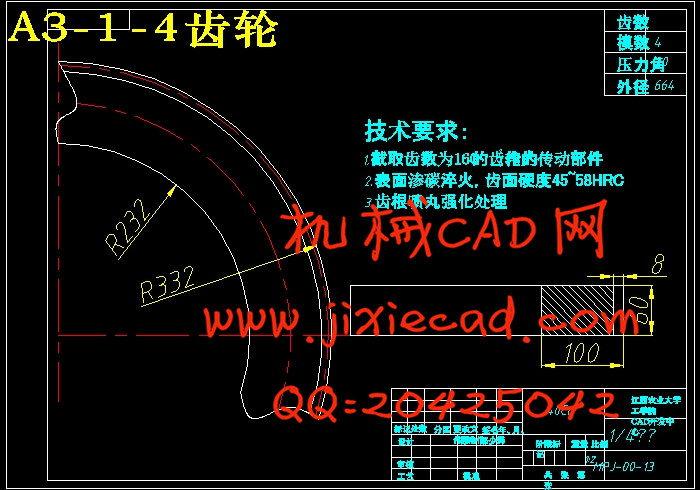

3.2 大小齿轮的校核计算和选用 7

3.2.1 选精度等级、材料及齿数材料及热处理 8

3.2.2 初步设计齿轮传动的主要尺寸 8

3.2.3 按齿根弯曲强度设计 10

3.2.4 几何尺寸计算 11

3.2.5 轴上键连接的选择及校核 12

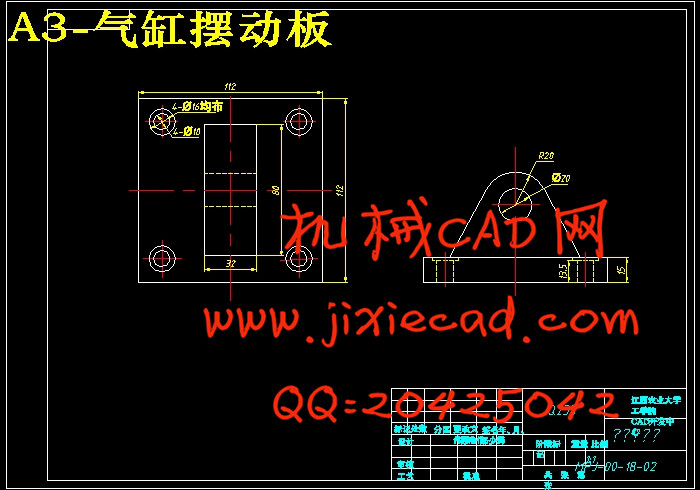

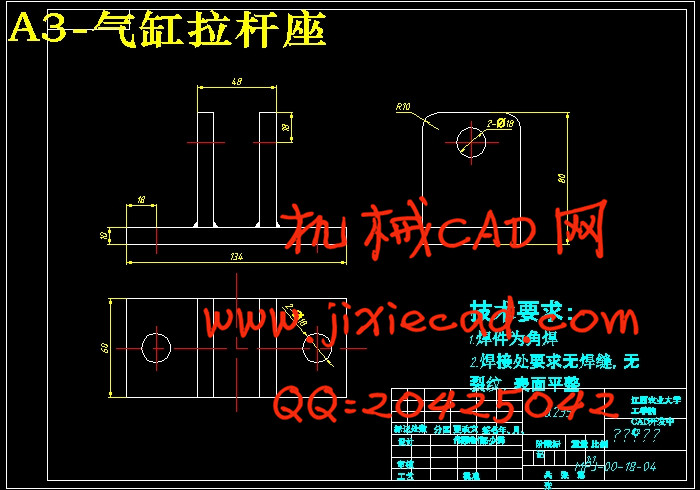

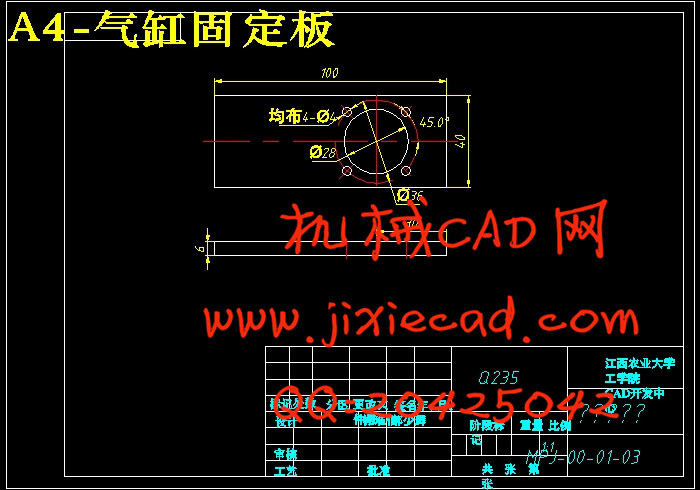

4 气压传动机构的选用 12

4.1 横向气压装置的选用 12

4.2 纵向气压装置的选用 13

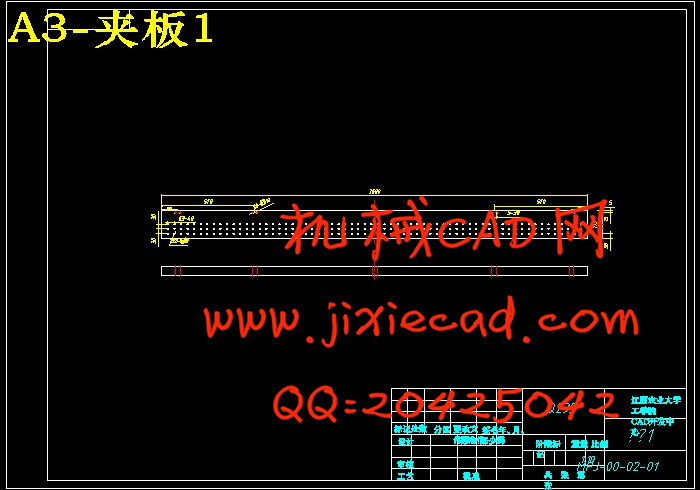

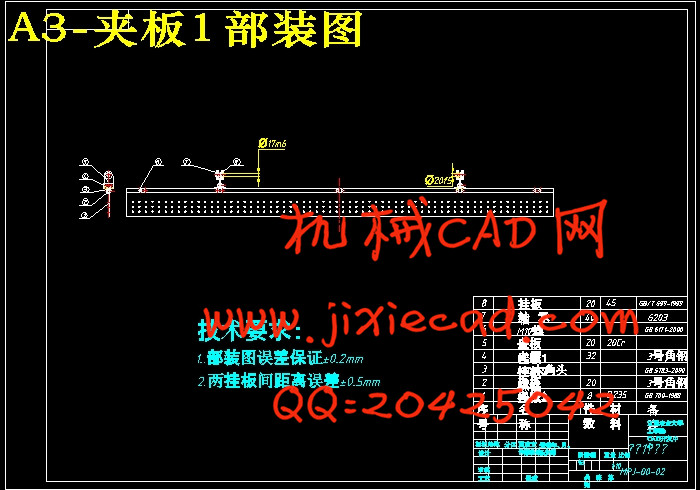

5 夹板机构的设计 13

5.1 夹板的整体设计 13

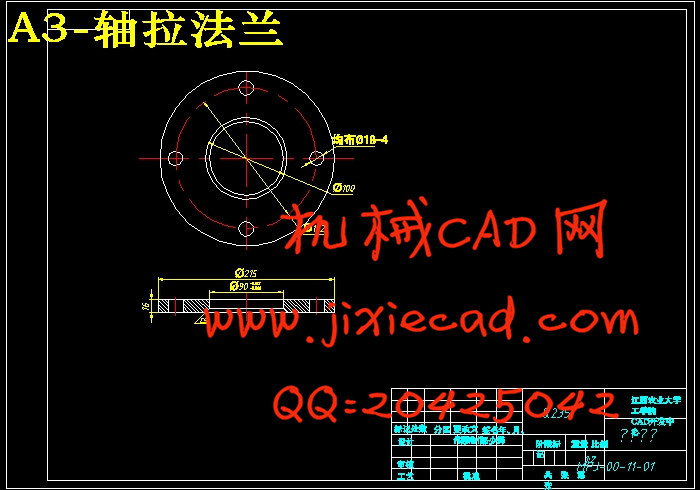

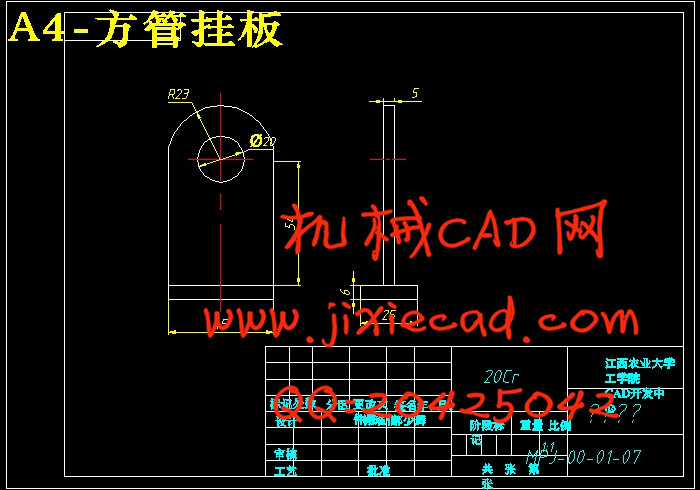

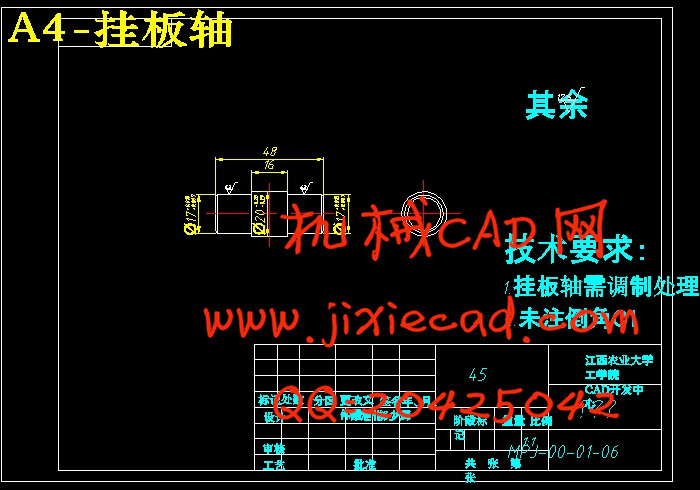

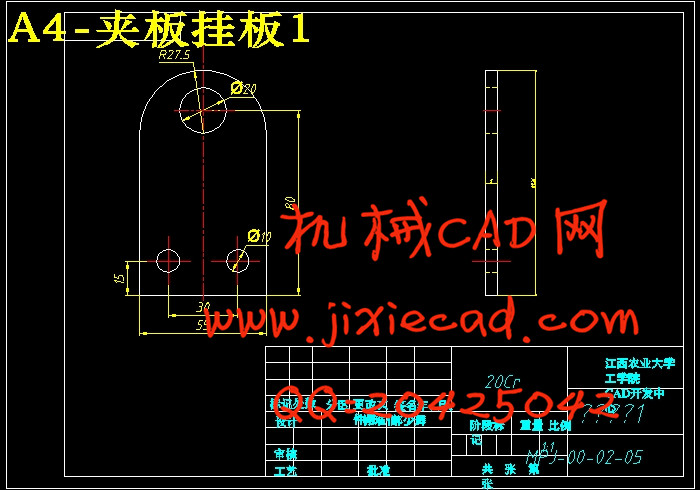

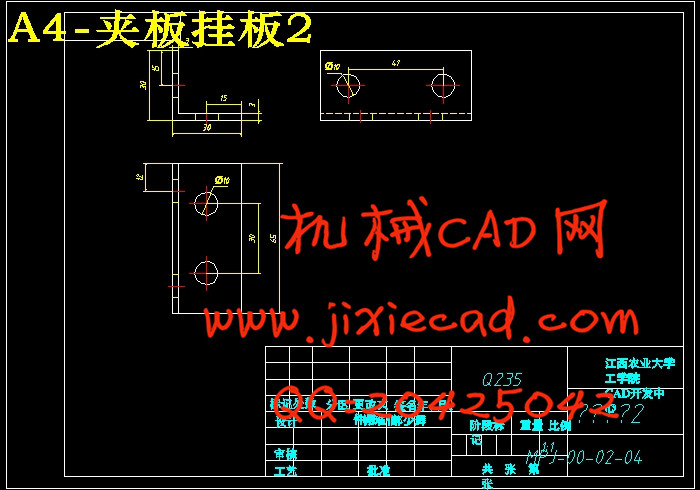

5.1.1 挂板轴的校核和设计 14

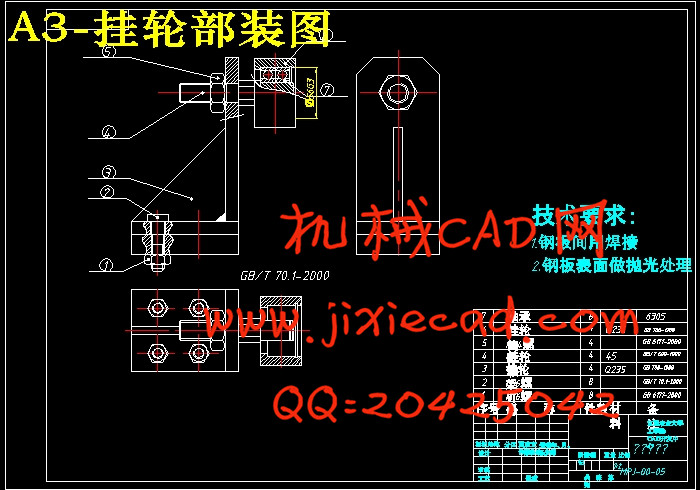

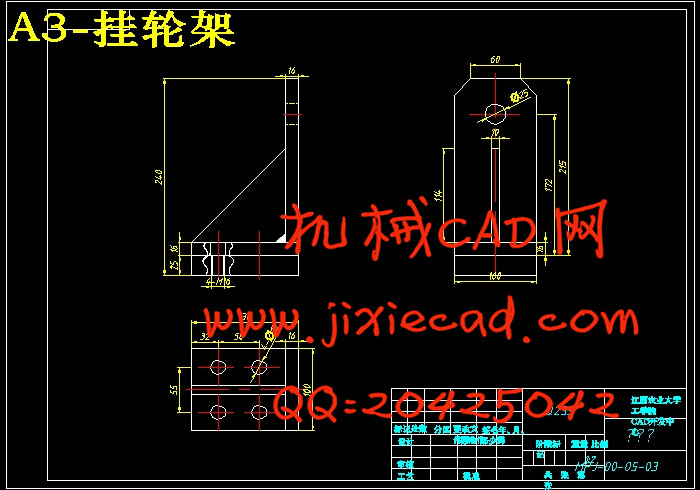

6 挂轮的设计 17

6.1 挂轮的整体设计 17

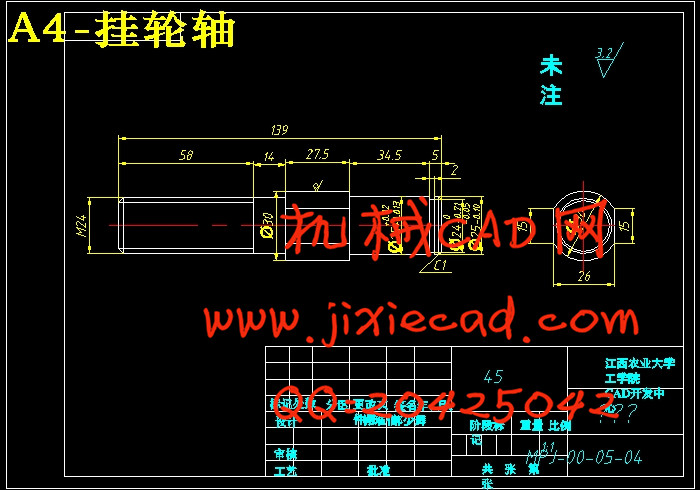

6.1.1 挂轮轴的校核和设计 17

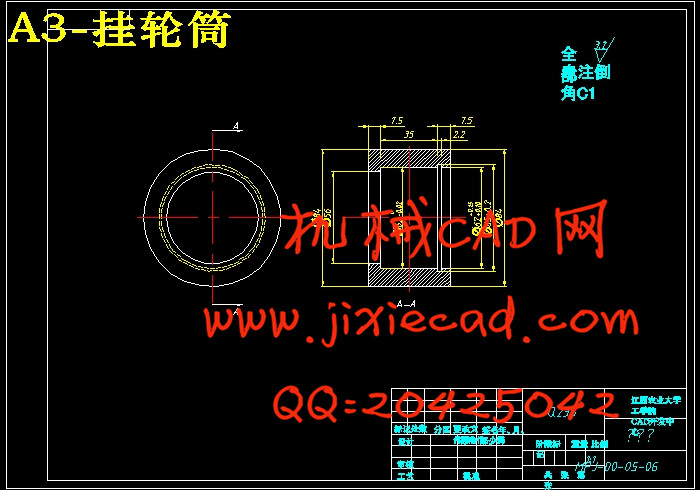

6.1.2 轴承的选用 19

6.1.3 挂轮筒的设计 19

7 框架及各焊接件的作用和选用 20

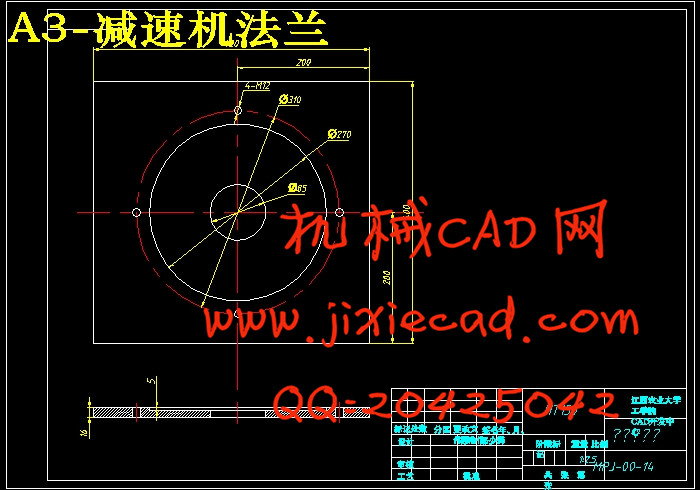

8 电机和减速器的选用 20

参考文献 22

致谢 23