设计简介

在许多场合,微细电解加工有着独立的优势,如高的加工效率,良好的成形精度,适合加工的材料范围广,不需考虑工件材料的强度,硬度等机械特性,加工过程工具无摩擦,工件上不产生应力等优点。

本文研究的是微细电解加工中的电解射流加工,其加工表面可达到无裂纹、无变质层、无残余应力的“三无”效果,其工艺技术具有可达性好、表面不产生金相缺陷、深径比大等优点。

本文将介绍电解射流加工的基本机理和基本方法,以及脉冲电解射流加工实验装置系统的基本组成及基本设计方法,研究高压喷射电解液束的射流结构,设计制造出能用于工艺试验的喷射装置,并结合相关工艺进行试验和优化。并通过实际试验验证装置的可行性。最后利用所设计的喷射装置进行相关的工艺试验,并进一步试验探索相关加工参数的影响。

关键词 电解射流加工 喷射液束 微尺度 喷嘴设计 表面质量

关键词 电解射流加工 喷射液束 微尺度 喷嘴设计 表面质量

Abstract

In many cases, micro-electrochemical machining has unique advantages, such as high processing efficiency, forming good accuracy shape, suitable for processing a wide range of materials, Without considering the strength of workpiece material, hardness and Hardness and other mechanical properties,

No tool wear process, The workpiece does not produce stress.

This Paper is to study the electrochemical jet machining belonged to the micro-electrochemical machining. Its surface can be achieved without micro-cracks, non-metamorphic layer, without residual stress about "three noes" effect, and its process technology with up to good, no metallographic surface defects, deep-diameter ratio advantages.

The paper will say the basic mechanism of electrolytic jet machining and basic methods, Grasp Pulse electrolytic jet machining test equipment system and the basic design elements, Studying of Jet beam jet structure of electrolyte , Able to design and manufacture jet device for process test, Combined with related Technology Test validation and optimization process, And through the actual test to verify the feasibility of devices,it can design of injection devices based on the optimal. Finally, Using the injection devices to carry out the technology-related experiments, And I will make furtherly explore to get the related processing parameters.

Keywords micro electrochemical jet machining jet beam liquid microscale nozzle design surface quality

目 次

1 绪论………………………………………………………………………………… 1

1.1 微细加工技术…………………………………………………………………… 1

1.2 电解加工………………………………………………………………………… 1

2 微尺度电解加工…………………………………………………………………… 3

2.1 电液束加工工艺研究…………………………………………………………… 3

2.2电解射流加工……………………………………………………………………… 4

3 电解射流加工的系统装置设计…………………………………………………… 7

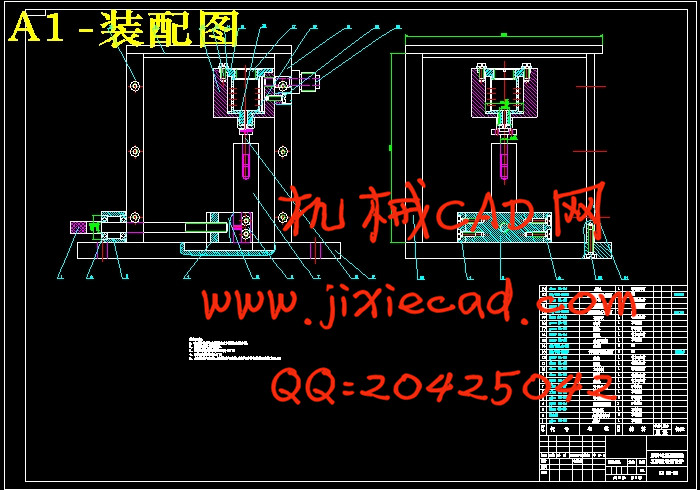

3.1总体系统设计………………………………………………………………………7

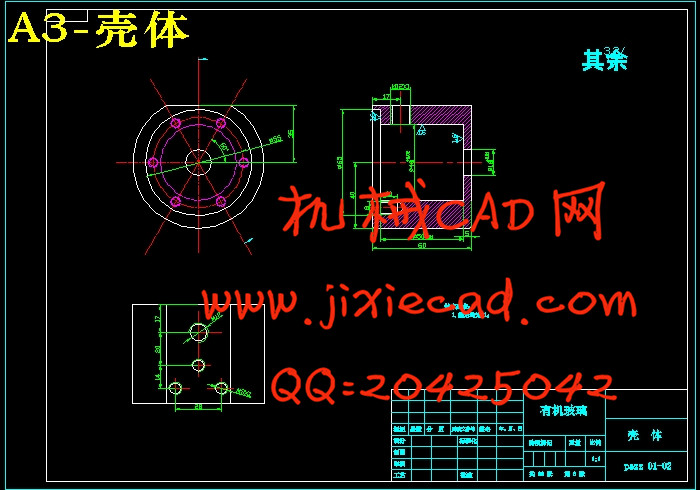

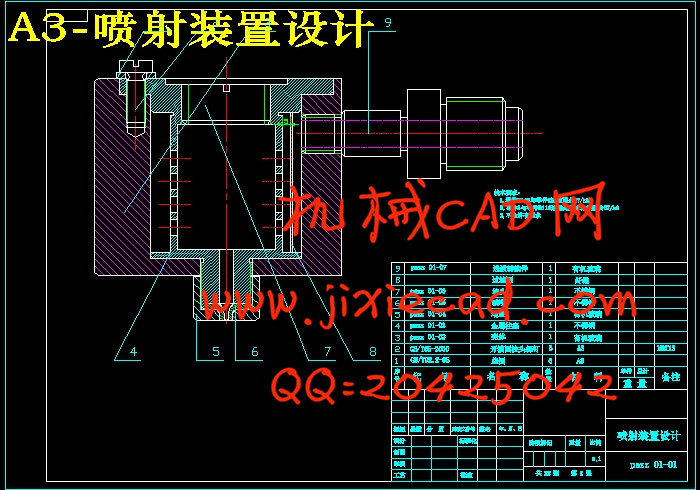

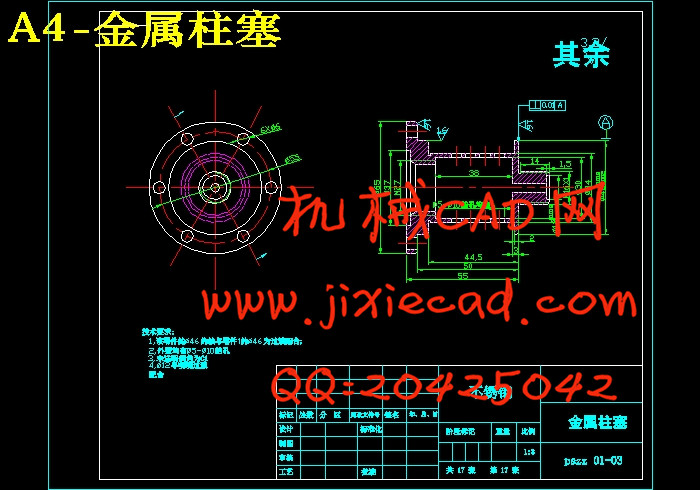

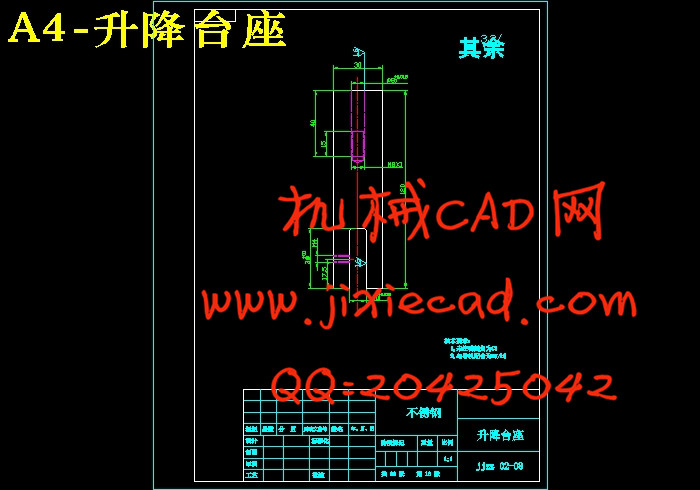

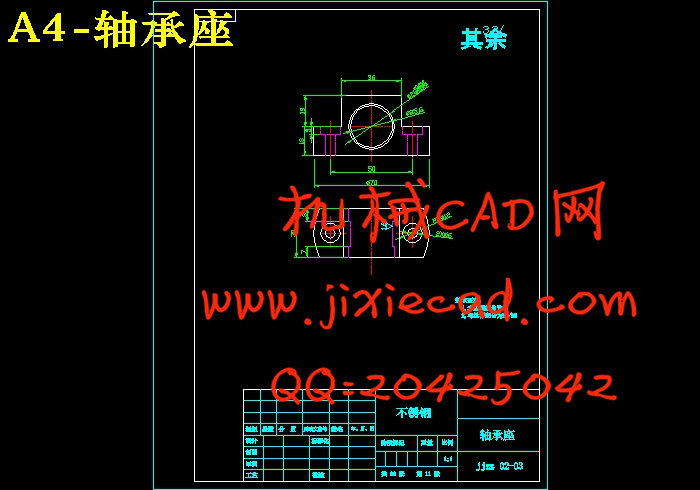

3.2 喷射装置设计…………………………………………………………………… 8

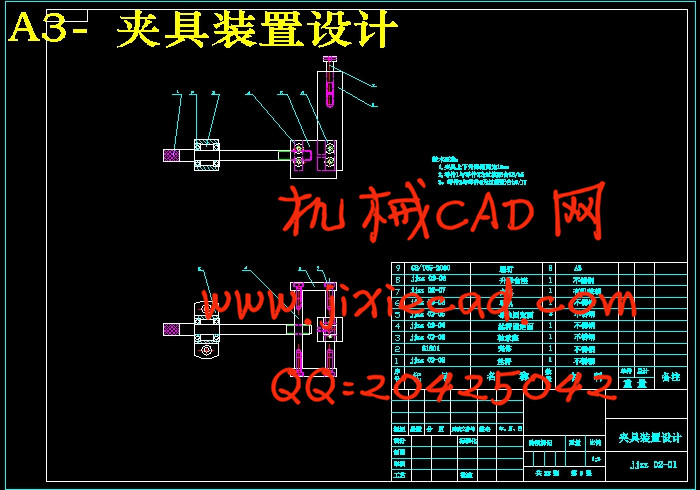

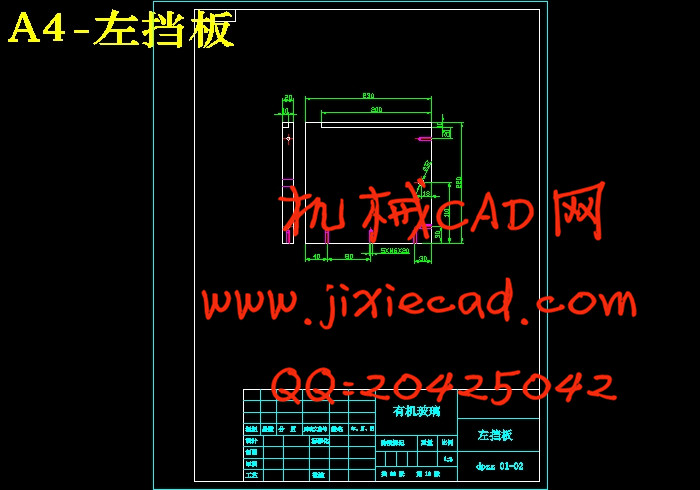

3.3工装夹具的设计………………………………………………………………… 17

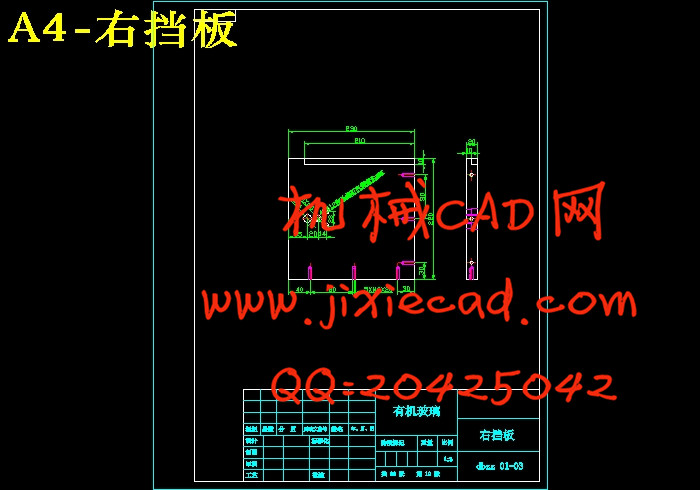

3.4防护装置设计…………………………………………………………………… 19

3.5电解液的选择及循环系统设计………………………………………………… 19

3.6电源选择及参数………………………………………………………………… 20

3.7装置挡板设计实物………………………………………………………………… 21

4 可行性试验研究………………………………………………………………… 21

4.1射流破碎长度与哪些因素有关………………………………………………… 21

4.2材料强度的可行性分析……………………………………………………… 23

4.3喷射系统试验及参数测试……………………………………………………… 24

总结…………………………………………………………………………………… 29

致谢…………………………………………………………………………………… 31

参考文献……………………………………………………………………………… 32

本文研究的是微细电解加工中的电解射流加工,其加工表面可达到无裂纹、无变质层、无残余应力的“三无”效果,其工艺技术具有可达性好、表面不产生金相缺陷、深径比大等优点。

本文将介绍电解射流加工的基本机理和基本方法,以及脉冲电解射流加工实验装置系统的基本组成及基本设计方法,研究高压喷射电解液束的射流结构,设计制造出能用于工艺试验的喷射装置,并结合相关工艺进行试验和优化。并通过实际试验验证装置的可行性。最后利用所设计的喷射装置进行相关的工艺试验,并进一步试验探索相关加工参数的影响。

Abstract

In many cases, micro-electrochemical machining has unique advantages, such as high processing efficiency, forming good accuracy shape, suitable for processing a wide range of materials, Without considering the strength of workpiece material, hardness and Hardness and other mechanical properties,

No tool wear process, The workpiece does not produce stress.

This Paper is to study the electrochemical jet machining belonged to the micro-electrochemical machining. Its surface can be achieved without micro-cracks, non-metamorphic layer, without residual stress about "three noes" effect, and its process technology with up to good, no metallographic surface defects, deep-diameter ratio advantages.

The paper will say the basic mechanism of electrolytic jet machining and basic methods, Grasp Pulse electrolytic jet machining test equipment system and the basic design elements, Studying of Jet beam jet structure of electrolyte , Able to design and manufacture jet device for process test, Combined with related Technology Test validation and optimization process, And through the actual test to verify the feasibility of devices,it can design of injection devices based on the optimal. Finally, Using the injection devices to carry out the technology-related experiments, And I will make furtherly explore to get the related processing parameters.

Keywords micro electrochemical jet machining jet beam liquid microscale nozzle design surface quality

目 次

1 绪论………………………………………………………………………………… 1

1.1 微细加工技术…………………………………………………………………… 1

1.2 电解加工………………………………………………………………………… 1

2 微尺度电解加工…………………………………………………………………… 3

2.1 电液束加工工艺研究…………………………………………………………… 3

2.2电解射流加工……………………………………………………………………… 4

3 电解射流加工的系统装置设计…………………………………………………… 7

3.1总体系统设计………………………………………………………………………7

3.2 喷射装置设计…………………………………………………………………… 8

3.3工装夹具的设计………………………………………………………………… 17

3.4防护装置设计…………………………………………………………………… 19

3.5电解液的选择及循环系统设计………………………………………………… 19

3.6电源选择及参数………………………………………………………………… 20

3.7装置挡板设计实物………………………………………………………………… 21

4 可行性试验研究………………………………………………………………… 21

4.1射流破碎长度与哪些因素有关………………………………………………… 21

4.2材料强度的可行性分析……………………………………………………… 23

4.3喷射系统试验及参数测试……………………………………………………… 24

总结…………………………………………………………………………………… 29

致谢…………………………………………………………………………………… 31

参考文献……………………………………………………………………………… 32