设计简介

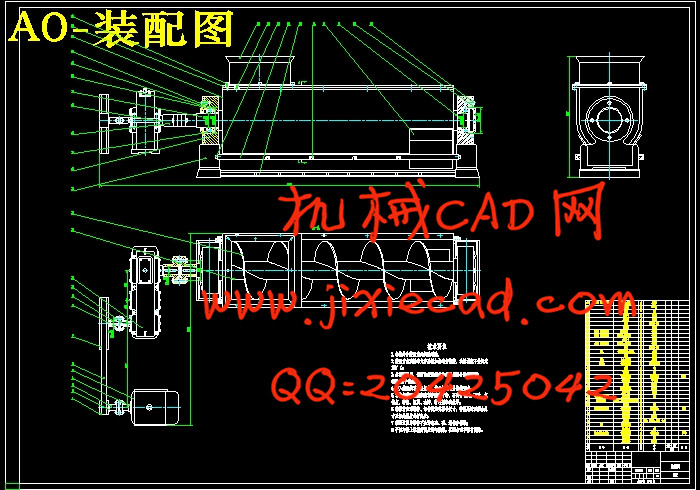

摘 要:本设计主要介绍了螺旋输送机的选型设计过程,包括有电动机的选型、V带传动的设计、减速器的设计计算、螺旋输送机缸体及配套驱动装置的选用和螺旋输送机的安装与调整四大部分。而主要部分则是减速器部件的设计,输送缸体内螺旋直径及螺旋轴转速的计算和功率计算,求出所需的选型数据,然后以此选型数据为依据,以螺旋输送机设计手册为主,以其他相关工具书和资料为辅,选出符合要求的螺旋输送机的外形及安装尺寸、长度组合数据和主要组成部件的相关尺寸,以及相配套驱动装置的安装尺寸及其相关数据,最终完成该螺旋输送机的选型设计。

关键词:V带传动;减速器;螺旋输送机;配套驱动装置;

Abstract:This design mainly introduces the selection and design process of screw conveyor in which four parts are included:motor selection,the design of V belt transmission ,the design calculation of gear reducer,the selection of screw conveyor and accessory drive cylinder body and the installation and adjustment of screw conveyor.In calculating, the screw diameter in the delivery cylinder and the rotate speed together with the power of spiral shaft will be chiefly concerned, so as to reach a collection of required data for model selection. Based on these data, with screw conveyor design manual as guidance and other related reference books and information as complement, the shape and mounting dimensions, the related data and size of the main components as well as the actuating devices that all conform to the requirements of screw conveyor will be worked out. Finally, the tutor will accomplish the model selection and design process of screw conveyor.

Key words:V belt drive; Gear reducer; Screw conveyor of coal;Form a complete set of device drivers

目 录

摘要………………………………………………………………………………1

关键词…………………………………………………………………………1

1前言……………………………………………………………………………2

1.1输送机的历史和发展趋势…………………………………………………2

1.2螺旋输送机简介……………………………………………………………3

1.3螺旋输送机主要特点………………………………………………………3

1.4螺旋输送机的结构特点……………………………………………………3

1.5螺旋输送机的运行原理……………………………………………………3

2 拟定设计方案…………………………………………………………………4

2.1传动方案的拟定……………………………………………………………4

2.2工作参数的拟定……………………………………………………………4

3电动机的选择…………………………………………………………………5

3.1类型和结构形式的选择……………………………………………………5

3.2电动机功率的确定…………………………………………………………5

3.2.1计算电动机所需功率 ………………………………………………5

………………………………………………5

3.2.2确定电动机转速…………………………………………………………5

4V带的设计…………………………………………………………………… 6

4.1确定计算功率………………………………………………………………6

4.2V带的带型确定与带速的验算…………………………………………… 6

4.2.1确定带轮的基准直径……………………………………………………6

4.2.2验算V带速度……………………………………………………………6

4.2.3确定中心距a,并选择V带的基准长度Ld……………………………6

4.2.4验算小带轮上的包角a1…………………………………………………7

4.2.5确定带的根数Z………………………………………………………… 7

4.2.6确定带的初拉力F0与压轴力FP…………………………………………7

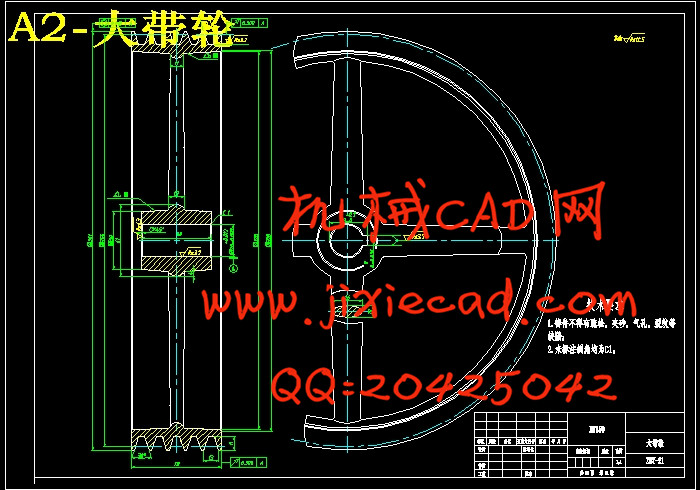

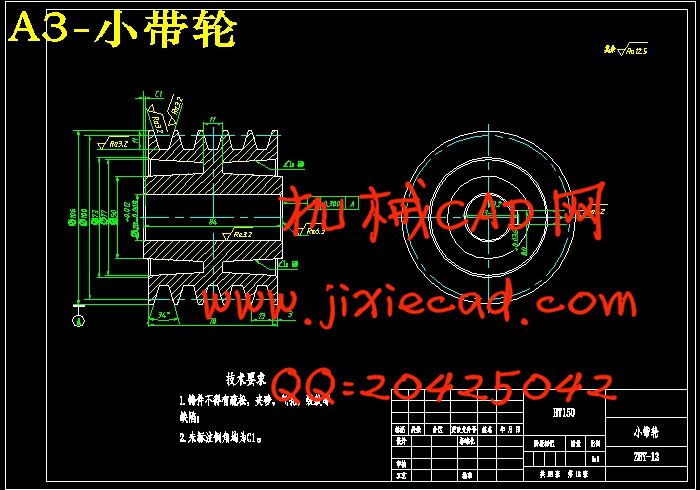

4.3V带轮的设计……………………………………………………………… 8

4.3.1V带轮的材料…………………………………………………………… 8

4.3.2V带轮的结构尺寸……………………………………………………… 8

5确定传动装置的总传动比和分配传动比…………………………………………… 9

5.1计算传动装置的动力参数………………………………………………………… 9

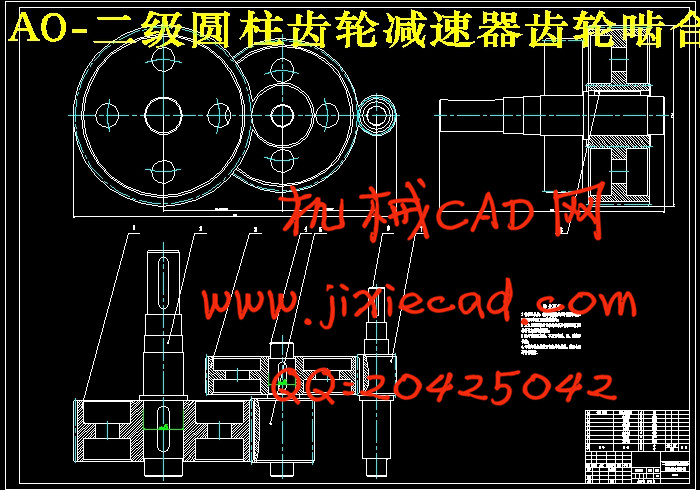

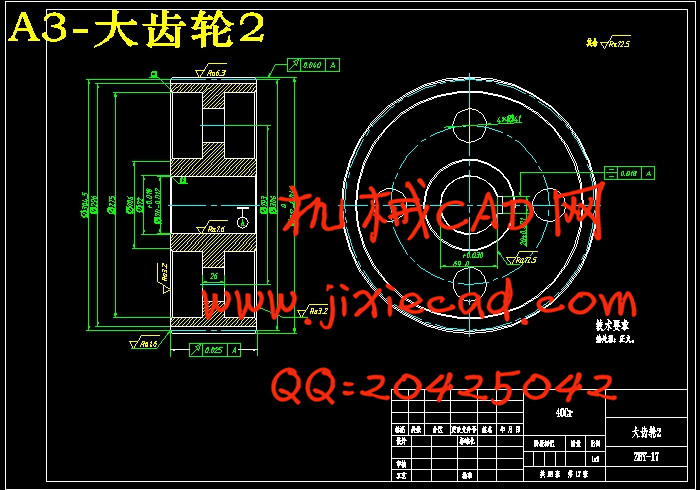

6减速器的设计与计算………………………………………………………………10

6.1减速器结构设计……………………………………………………………10

6.1.1机体结构…………………………………………………………………10

6.1.2铸铁减速器箱体主要结构尺寸…………………………………………10

6.1.3减速器中各轴运动及动力参数计算…………………………………10

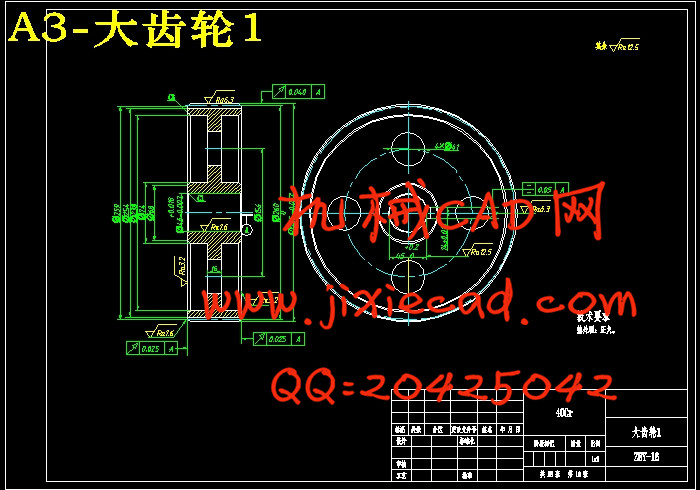

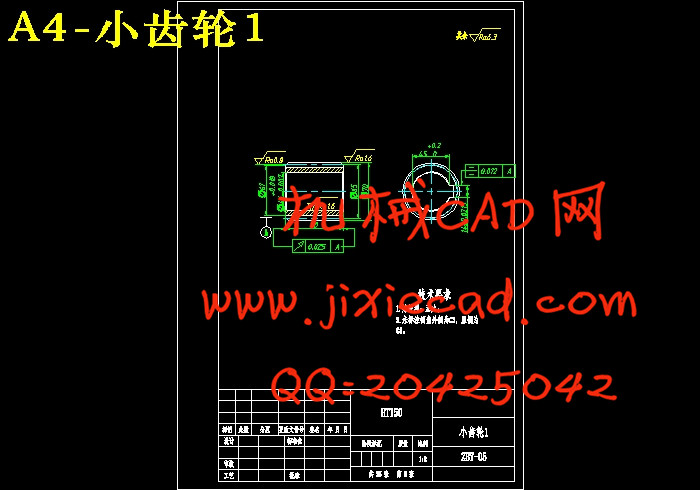

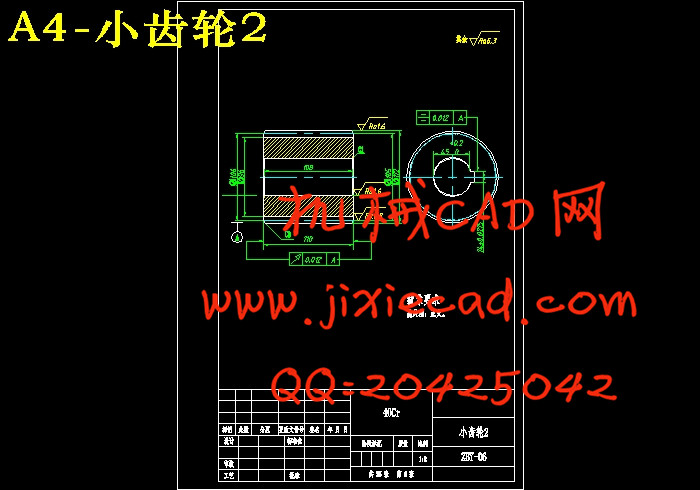

6.1.4齿轮传动的设计与计算……………………………………………… 10

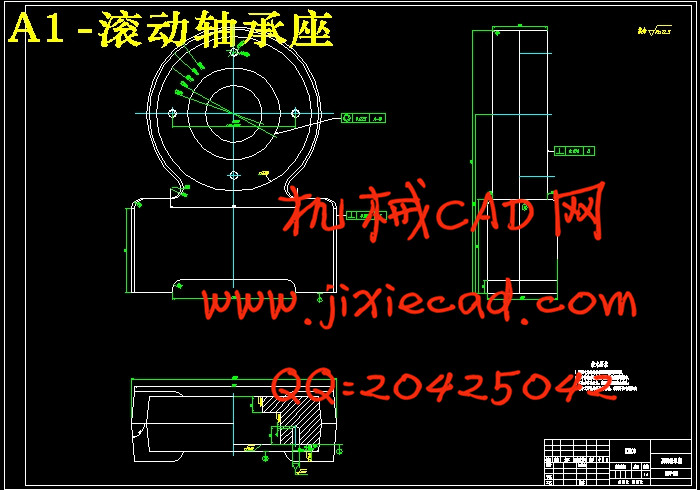

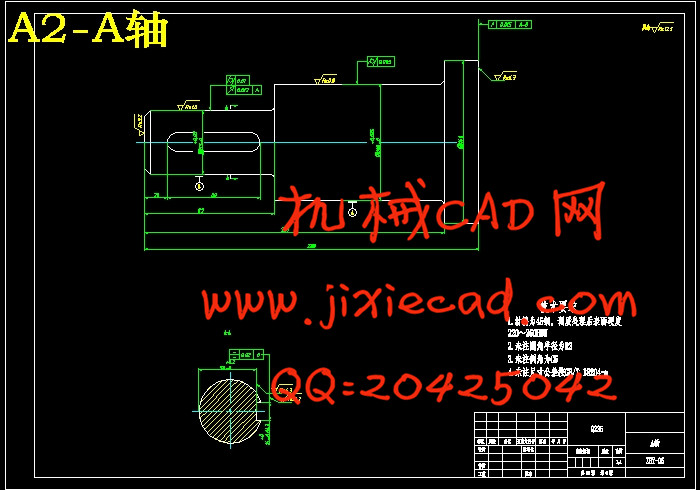

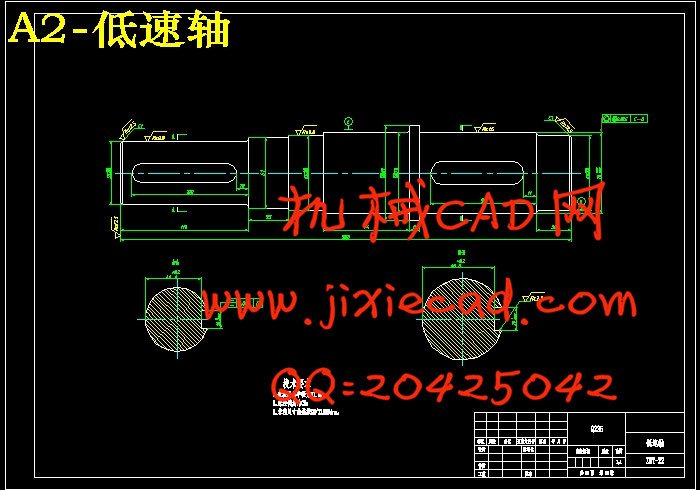

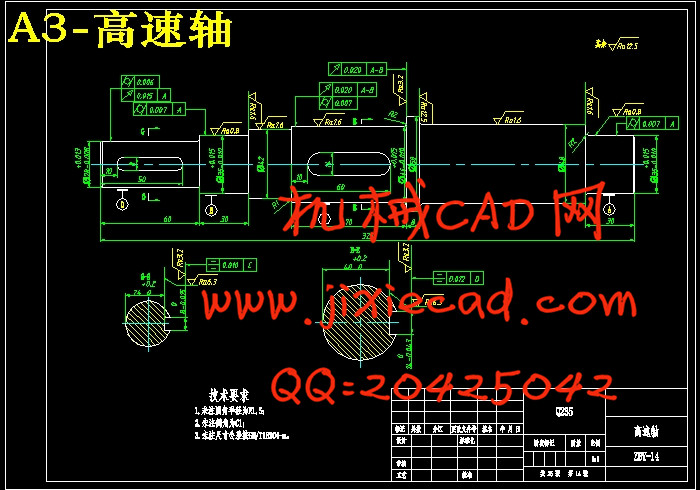

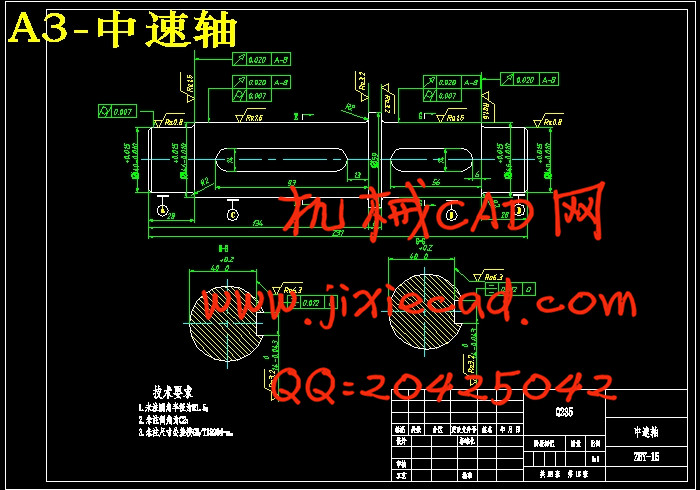

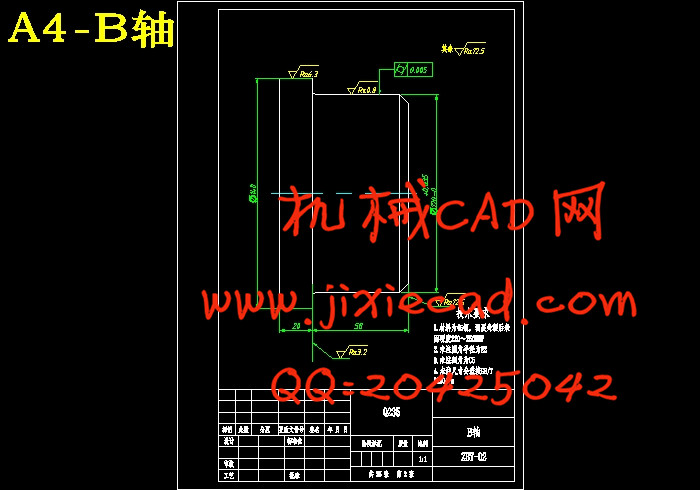

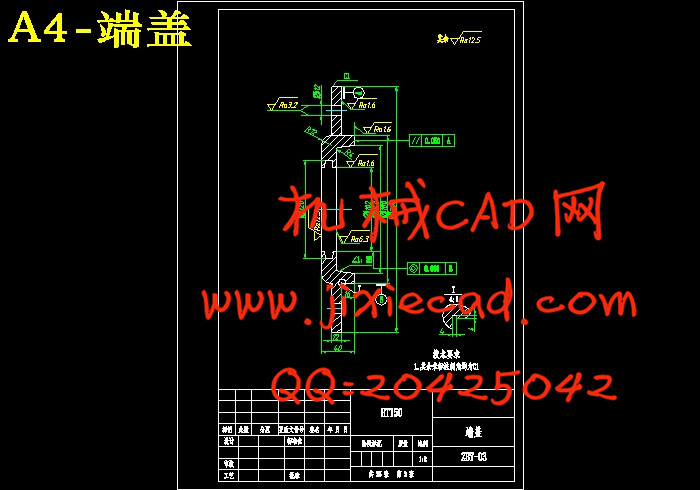

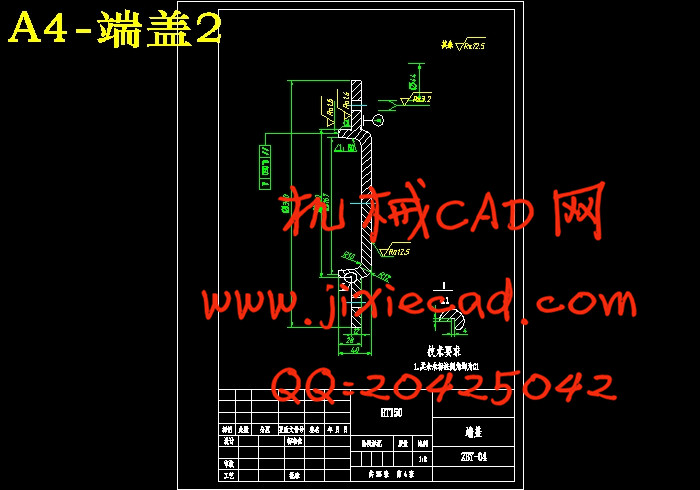

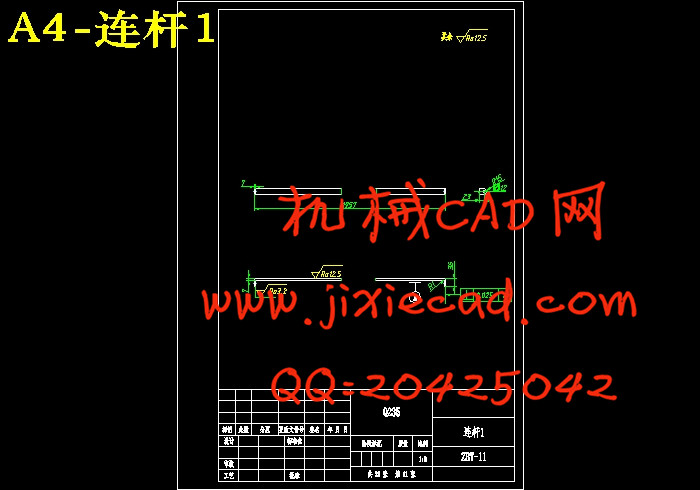

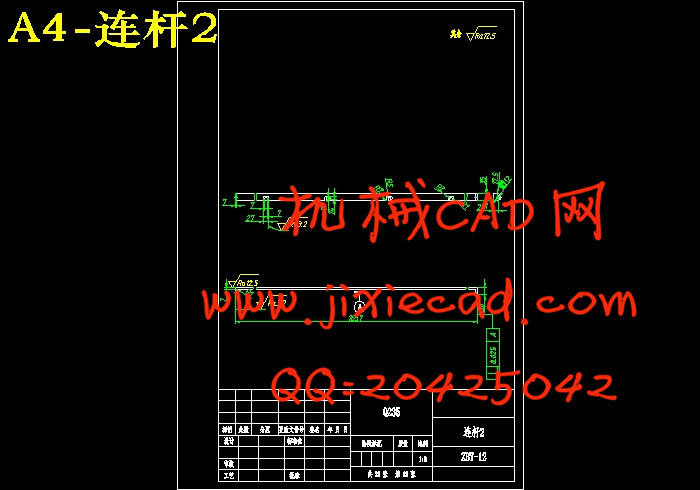

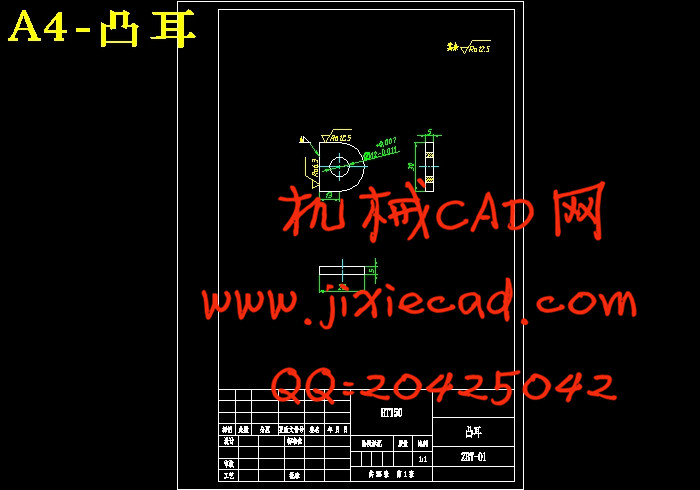

6.1.5轴的设计计算…………………………………………………………18

6.1.6箱体内键联接的选择………………………………………………… 23

6.1.7减速器附件的选择…………………………………………………… 24

7螺旋输送机的设计………………………………………………………… 24

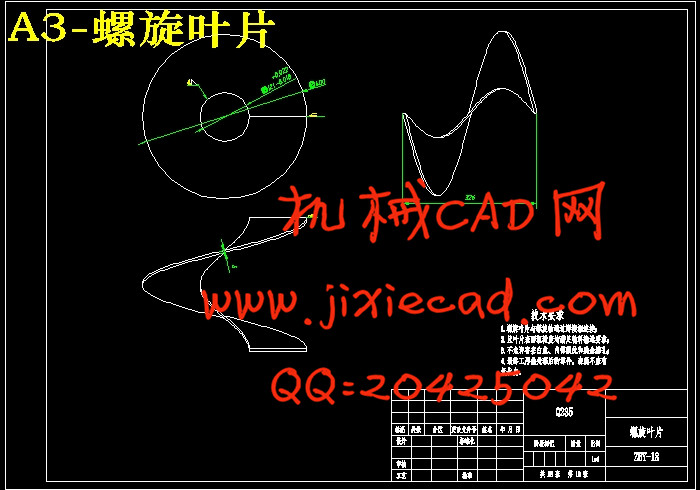

7.1螺旋输送机的选型……………………………………………………… 24

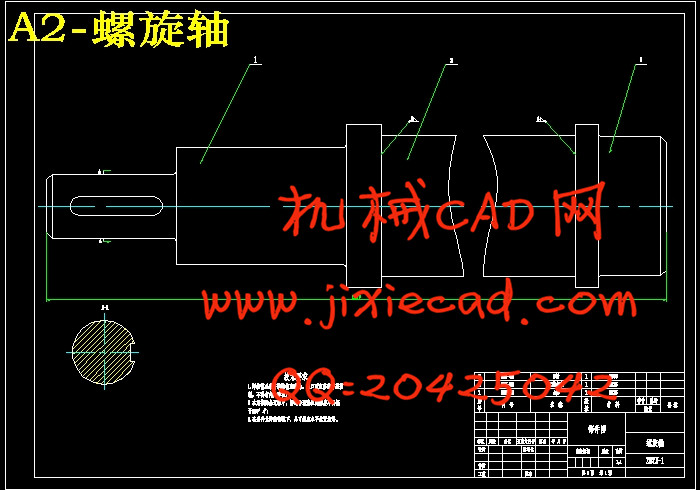

7.2螺旋输送部件的设计…………………………………………………… 25

7.2.1螺旋输送机的主要参数计算………………………………………… 26

7.2.2螺旋直径的确定…………………………………………………………26

7.2.3螺距与螺旋轴转速的确定…………………………………………… 26

7.2.4实体型螺旋叶片的展开尺寸………………………………………… 29

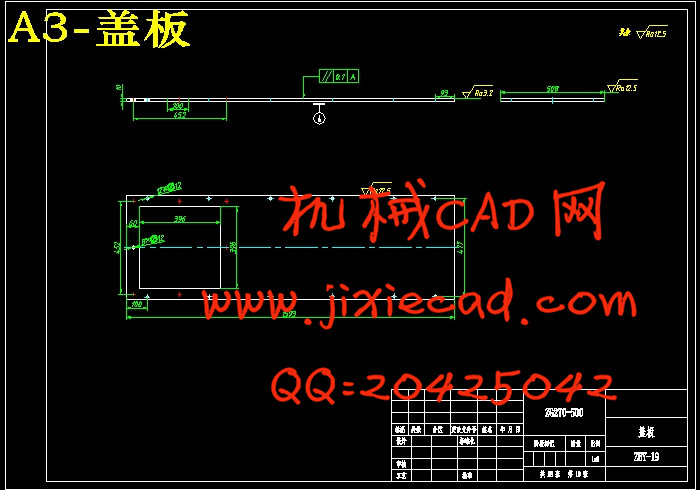

7.3螺旋输送机机体的设计………………………………………………… 29

7.3.1机体主要部件的介绍……………………………………………………30

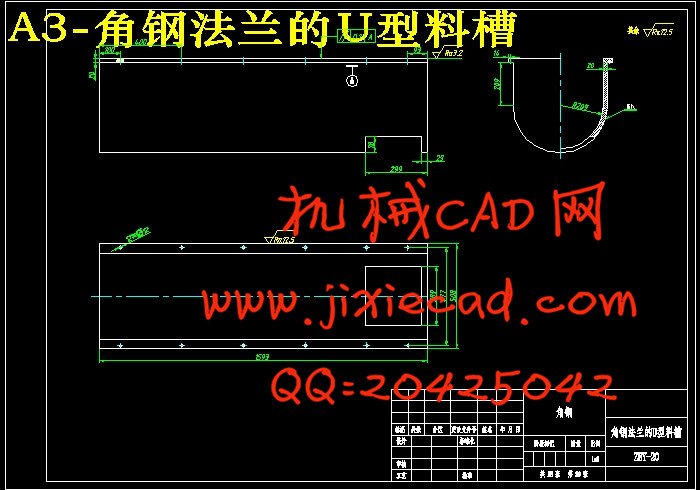

7.3.2料槽的确定…………………………………………………………… 31

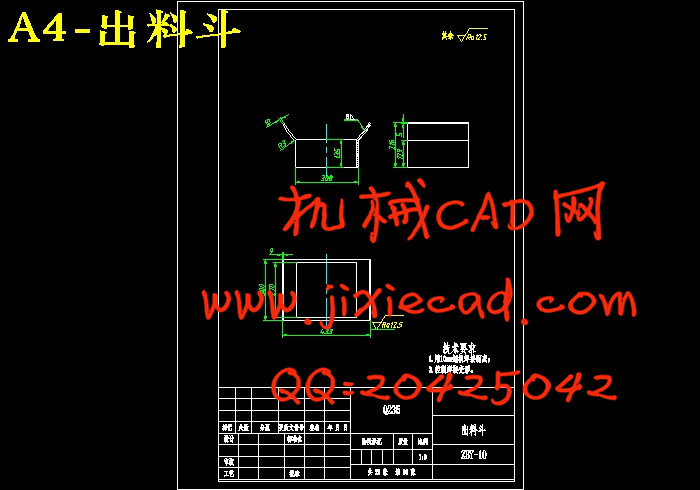

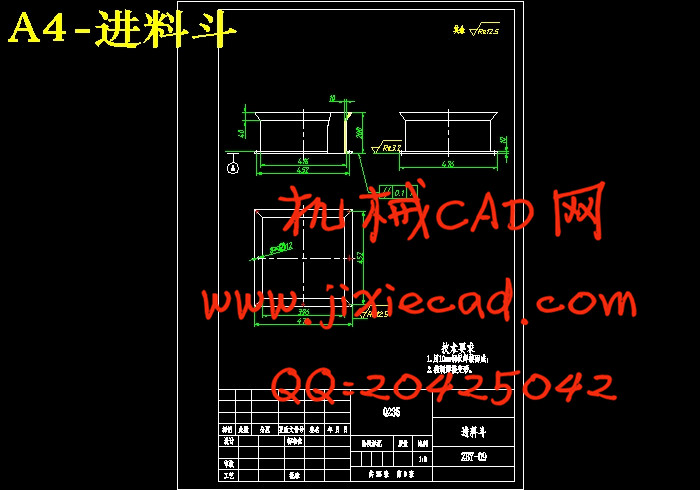

7.4进出料口的设计………………………………………………………… 32

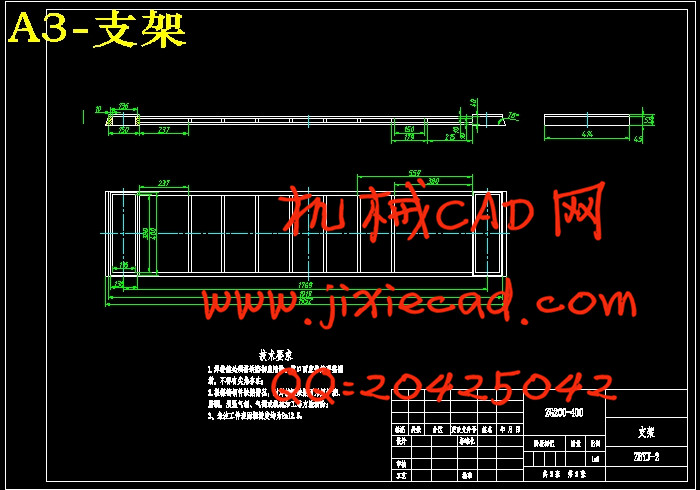

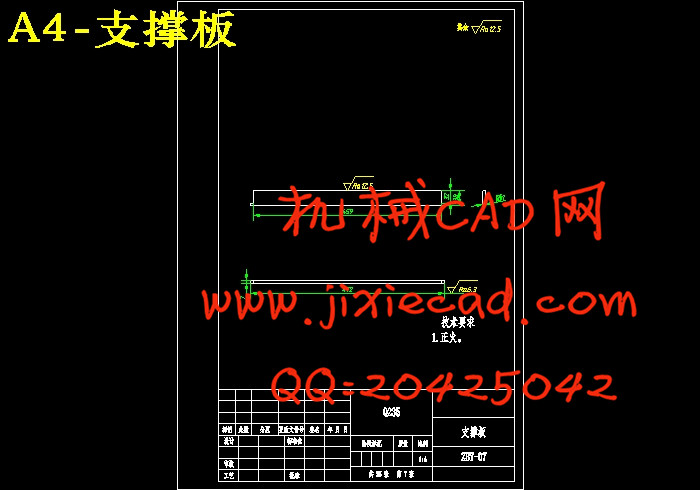

7.5输送缸体支架的设计………………………………………………………………33

7.6轴承的密封…………………………………………………………………………34

8螺旋输送机机体的安装条件、使用及维护……………………………… 34

8.1螺旋输送机的安装条件………………………………………………… 34

8.2螺旋输送机的使用及维护……………………………………………… 35

9结论………………………………………………………………………… 36

参考文献……………………………………………………………………… 36

致谢………………………………………………………………………… 37

附录…………………………………………………………………………… 37

关键词:V带传动;减速器;螺旋输送机;配套驱动装置;

Abstract:This design mainly introduces the selection and design process of screw conveyor in which four parts are included:motor selection,the design of V belt transmission ,the design calculation of gear reducer,the selection of screw conveyor and accessory drive cylinder body and the installation and adjustment of screw conveyor.In calculating, the screw diameter in the delivery cylinder and the rotate speed together with the power of spiral shaft will be chiefly concerned, so as to reach a collection of required data for model selection. Based on these data, with screw conveyor design manual as guidance and other related reference books and information as complement, the shape and mounting dimensions, the related data and size of the main components as well as the actuating devices that all conform to the requirements of screw conveyor will be worked out. Finally, the tutor will accomplish the model selection and design process of screw conveyor.

Key words:V belt drive; Gear reducer; Screw conveyor of coal;Form a complete set of device drivers

目 录

摘要………………………………………………………………………………1

关键词…………………………………………………………………………1

1前言……………………………………………………………………………2

1.1输送机的历史和发展趋势…………………………………………………2

1.2螺旋输送机简介……………………………………………………………3

1.3螺旋输送机主要特点………………………………………………………3

1.4螺旋输送机的结构特点……………………………………………………3

1.5螺旋输送机的运行原理……………………………………………………3

2 拟定设计方案…………………………………………………………………4

2.1传动方案的拟定……………………………………………………………4

2.2工作参数的拟定……………………………………………………………4

3电动机的选择…………………………………………………………………5

3.1类型和结构形式的选择……………………………………………………5

3.2电动机功率的确定…………………………………………………………5

3.2.1计算电动机所需功率

3.2.2确定电动机转速…………………………………………………………5

4V带的设计…………………………………………………………………… 6

4.1确定计算功率………………………………………………………………6

4.2V带的带型确定与带速的验算…………………………………………… 6

4.2.1确定带轮的基准直径……………………………………………………6

4.2.2验算V带速度……………………………………………………………6

4.2.3确定中心距a,并选择V带的基准长度Ld……………………………6

4.2.4验算小带轮上的包角a1…………………………………………………7

4.2.5确定带的根数Z………………………………………………………… 7

4.2.6确定带的初拉力F0与压轴力FP…………………………………………7

4.3V带轮的设计……………………………………………………………… 8

4.3.1V带轮的材料…………………………………………………………… 8

4.3.2V带轮的结构尺寸……………………………………………………… 8

5确定传动装置的总传动比和分配传动比…………………………………………… 9

5.1计算传动装置的动力参数………………………………………………………… 9

6减速器的设计与计算………………………………………………………………10

6.1减速器结构设计……………………………………………………………10

6.1.1机体结构…………………………………………………………………10

6.1.2铸铁减速器箱体主要结构尺寸…………………………………………10

6.1.3减速器中各轴运动及动力参数计算…………………………………10

6.1.4齿轮传动的设计与计算……………………………………………… 10

6.1.5轴的设计计算…………………………………………………………18

6.1.6箱体内键联接的选择………………………………………………… 23

6.1.7减速器附件的选择…………………………………………………… 24

7螺旋输送机的设计………………………………………………………… 24

7.1螺旋输送机的选型……………………………………………………… 24

7.2螺旋输送部件的设计…………………………………………………… 25

7.2.1螺旋输送机的主要参数计算………………………………………… 26

7.2.2螺旋直径的确定…………………………………………………………26

7.2.3螺距与螺旋轴转速的确定…………………………………………… 26

7.2.4实体型螺旋叶片的展开尺寸………………………………………… 29

7.3螺旋输送机机体的设计………………………………………………… 29

7.3.1机体主要部件的介绍……………………………………………………30

7.3.2料槽的确定…………………………………………………………… 31

7.4进出料口的设计………………………………………………………… 32

7.5输送缸体支架的设计………………………………………………………………33

7.6轴承的密封…………………………………………………………………………34

8螺旋输送机机体的安装条件、使用及维护……………………………… 34

8.1螺旋输送机的安装条件………………………………………………… 34

8.2螺旋输送机的使用及维护……………………………………………… 35

9结论………………………………………………………………………… 36

参考文献……………………………………………………………………… 36

致谢………………………………………………………………………… 37

附录…………………………………………………………………………… 37