设计简介

摘 要

本文以“门架式专用工业机械手设计”为题目,设计了一个多自由度固定机械手,使其具有水平旋转、上下摆动、并抓取一组物体等功能。在先期工作中,对机械手进行功能原理分解。设计可行性方案并进行对比,选出最优方案。本文的重点有二个方面:

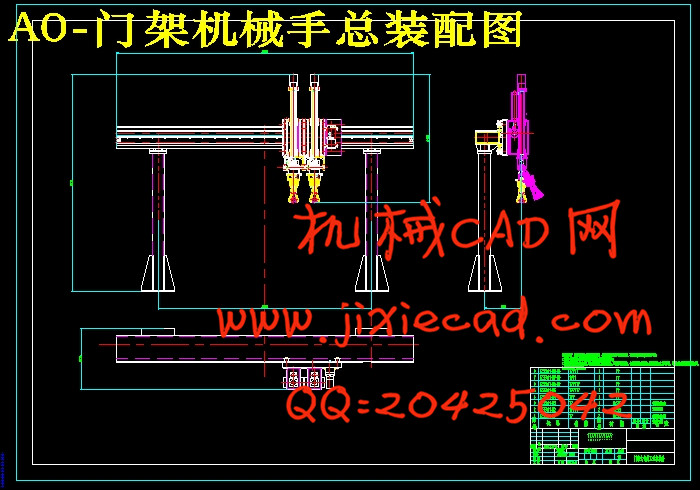

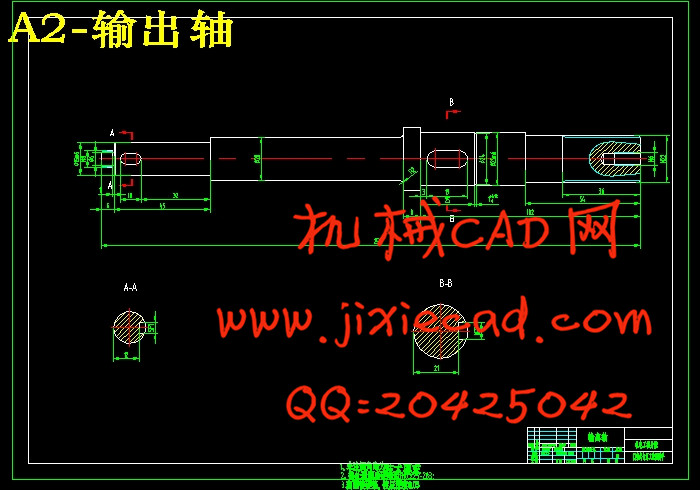

文中设计了机械手的机械结构部分,使用CAD和CATIA完成机械手的总体装配图和非标零件的设计,并结合力学知识对各非标零件进行校核计算。其中包括外观改进和结构优化。

结合设计参数和实践需要,对机械手的传动方案——液压传动进行设计,运用CAD绘制原理图。结合机械实体结构布置液压系统。

关键词:微型件 机械手 门架式

ABTRACT

This paper takes the project “The designing of a machinery manipulator for auto polishing of miniature parts” as the study background, designs a fixed manipulator which it has freedom 11.The manipulator has some functions, that it can turn in horizontal plane, swing in vertical plane and capture many miniature parts.In the authors prior work, the manipulator of function is decomposed. Some of reasonable plans are designed. They are contrasted and the best plan is took. The focus of the paper is on three aspects:

At first, this paper designs the manipulator of machinery structure, use CAD and CATIA to finishes its Auto CAD and non-standard parts in mechanics. This part of the paper is consist of outward appearance and machinery construction, that they are improved and optimized.

The second, the paper designs a plan of manipulator’s transmission----hydraulic pressure transmission by parameters of design and practice of demand and finishes the schematic diagram in CAD. The system of hydraulic pressure is designed according the machinery structure.

At last, the paper finally puts forward the electric control strategy of the manipulator, and use the CAD and CATIA to finish the schematic diagram of electric control.

Keywords: Miniature parts Manipulator Polishing

目录

绪 论 1

1机械手发展状况 1

2课题背景及研究意义 1

第一章 设计任务及方案评价 3

1.1设计目标与功能原理分析 3

1.2机械手的配置和工作原理 3

1.3解决原理 4

1.4方案的分析和决策 5

第二章 结构评价设计 7

2.1门架式专用工业机械手总体方案 7

2.2机械手的部件设计 8

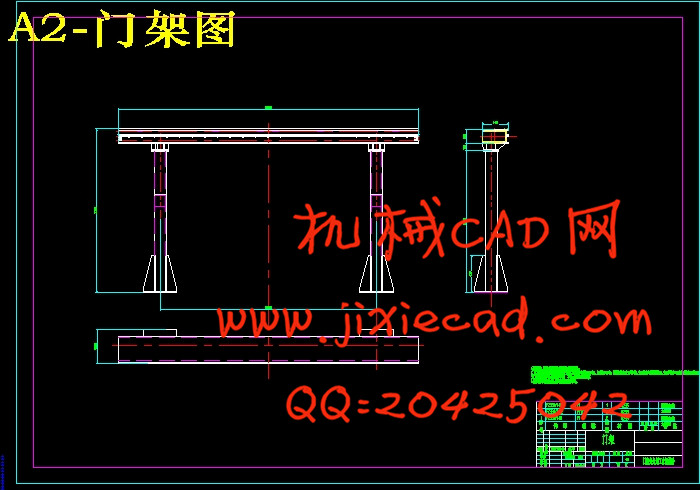

2.2.1机械手的机架设计 8

2.2.2小车的设计 10

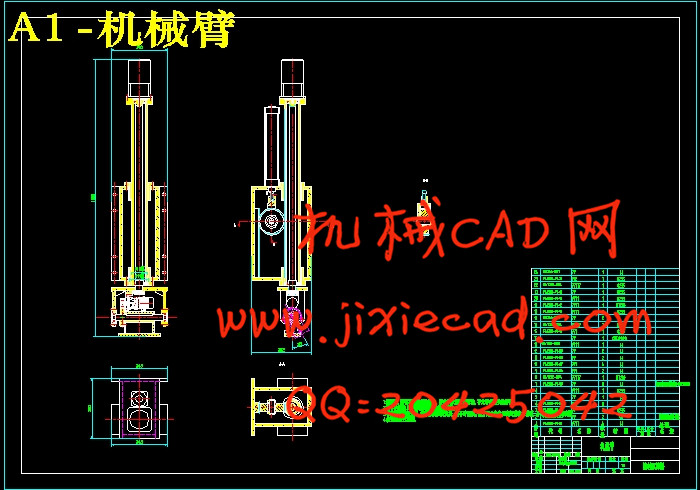

2.2.3机械手臂 12

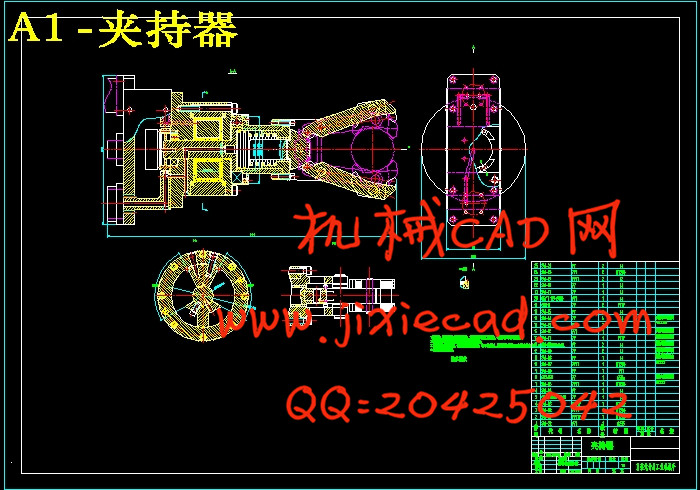

2.2.4夹持器设计 13

第三章 部件计算与校核 15

3.1横梁的计算 15

3.2小车计算 17

3.2.1 小车速度计算 17

3.2.2 小车精度计算 17

3.2.3 小车电机功率计算 18

3.2.4 小车零件计算 18

3.3手臂计算 21

3.3.1 手臂汽缸计算 21

3.3.2 手手腕处摆动减速电机计算 21

3.4夹持器计算 24

第四章 气动原理设计 28

4.1驱动方式 28

4.2工作原理 28

4.2.1手臂升降汽缸 28

4.2.2手臂回转汽缸 29

4.2.3夹紧缸 30

4.2.4气源处理 30

第五章 机械手的控制设计 32

5.1基本设计思路 32

5.2单片机的选择 32

5.3驱动芯片的选择 34

5.4流程图 36

5.5汇编程序 37

总结 40

参考文献 41

致 谢 42