设计简介

摘 要

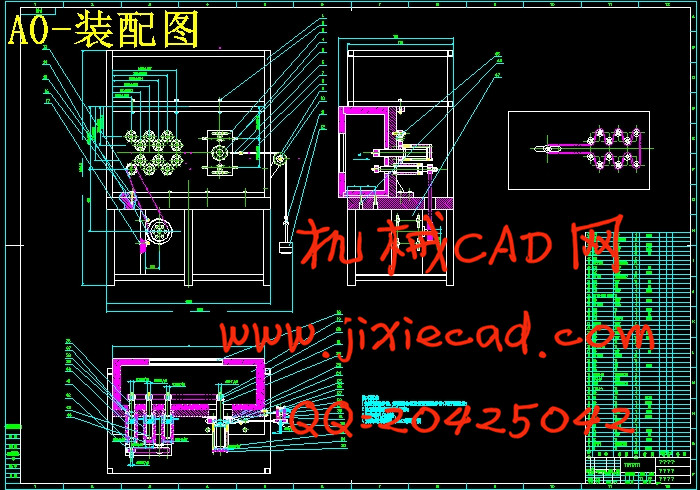

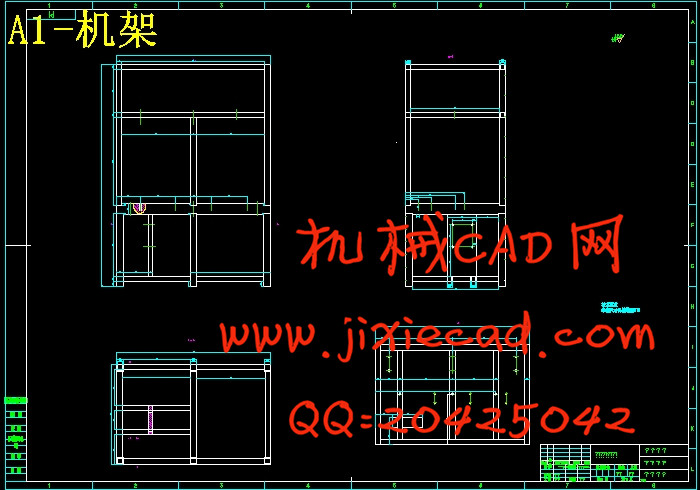

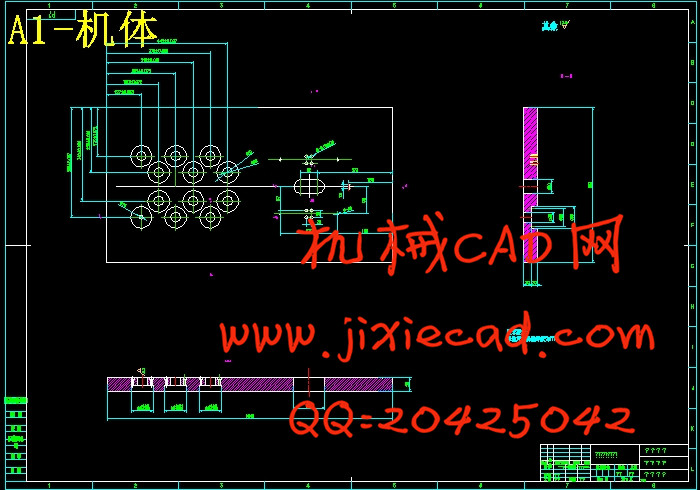

本文详细论述了多楔带传动轮系优化试验台的硬件及软件设计方案。试验台的开发是围绕模拟附件轮系的实际运转,同时又能调整各个附件负载大小及各个附件的位置来进行的。论文针对的这些特殊性能要求,设计了具有独创性的台架结构,包括模拟机体部分,移动导轨部分,转向泵的工况模拟部分,测功机模拟空调压缩机作为负载工作等等。多楔带轮系优化试验台测控系统的硬件部分以计算机为核心,配以外围接口电路,信号调理单元和传感器,构成闭环控制系统,主要完成附件轮系主轴转速、主轴扭矩、空压机轴转速、空压机轴扭矩、转向泵轴转速、转向泵轴扭矩、系统噪声、系统振动频率、皮带轮垂直带面振幅、皮带轮测向振幅、减振皮带轮扭转角、减振皮带轮轮面振幅、自动张紧轮轴承温度等参数的采集和处理,同时实现对模拟附件负载大小以及主动电机运转情况的控制。

关键词:多楔带; 轮系; 台架

Abstract

This article presents the design plan of software and hardware of testbench for optimizing design of the poly rib driving wheel system in detail. The development of test-bed centers on imitating actual operation of wheel system and changing load size and position of each accessory at the same time. Aiming at these special demand of performance, I have designed the innovative structure of test-bed, including simulation engine gear box, the part of moving guiding tracks, the simulation part often steering pump, the part of dynamometer simulating compressor as load etc. Computer is the core of poly rib belt driving wheel system test bench’s hardware, equipped with the interface circuit, signal processing unit and sensor. All those parts constitute a close loop control system to realize the signal collection and process, including the rotate speed and torque of main shaft ,rotate speed and torque of the shaft of compressor, rotate speed and torque of the shaft of the steering pump, systematic noise, systematic vibration frequency, the amplitude of surface of poly rib belt, the torsion angle and amplitude of damping pulley, bearing temperature of auto tension wheel, etc.. At the same time we can control the load size of each accessories and operation of electrical machinery by the control system.

Keywords: Poly rib belt; wheel system;

本文详细论述了多楔带传动轮系优化试验台的硬件及软件设计方案。试验台的开发是围绕模拟附件轮系的实际运转,同时又能调整各个附件负载大小及各个附件的位置来进行的。论文针对的这些特殊性能要求,设计了具有独创性的台架结构,包括模拟机体部分,移动导轨部分,转向泵的工况模拟部分,测功机模拟空调压缩机作为负载工作等等。多楔带轮系优化试验台测控系统的硬件部分以计算机为核心,配以外围接口电路,信号调理单元和传感器,构成闭环控制系统,主要完成附件轮系主轴转速、主轴扭矩、空压机轴转速、空压机轴扭矩、转向泵轴转速、转向泵轴扭矩、系统噪声、系统振动频率、皮带轮垂直带面振幅、皮带轮测向振幅、减振皮带轮扭转角、减振皮带轮轮面振幅、自动张紧轮轴承温度等参数的采集和处理,同时实现对模拟附件负载大小以及主动电机运转情况的控制。

关键词:多楔带; 轮系; 台架

Abstract

This article presents the design plan of software and hardware of testbench for optimizing design of the poly rib driving wheel system in detail. The development of test-bed centers on imitating actual operation of wheel system and changing load size and position of each accessory at the same time. Aiming at these special demand of performance, I have designed the innovative structure of test-bed, including simulation engine gear box, the part of moving guiding tracks, the simulation part often steering pump, the part of dynamometer simulating compressor as load etc. Computer is the core of poly rib belt driving wheel system test bench’s hardware, equipped with the interface circuit, signal processing unit and sensor. All those parts constitute a close loop control system to realize the signal collection and process, including the rotate speed and torque of main shaft ,rotate speed and torque of the shaft of compressor, rotate speed and torque of the shaft of the steering pump, systematic noise, systematic vibration frequency, the amplitude of surface of poly rib belt, the torsion angle and amplitude of damping pulley, bearing temperature of auto tension wheel, etc.. At the same time we can control the load size of each accessories and operation of electrical machinery by the control system.

Keywords: Poly rib belt; wheel system;

目 录

第1章 绪 论 2

1.1 本课题研究的目的与意义 2

1.2 发展现状 2

1.2.3 技术要求 5

第2章 机构总体设计方案 6

2.1 机构原理 6

2.2 功能原理方案设计 7

2.3.1动力源选取 9

2.3.2传动装置设计 9

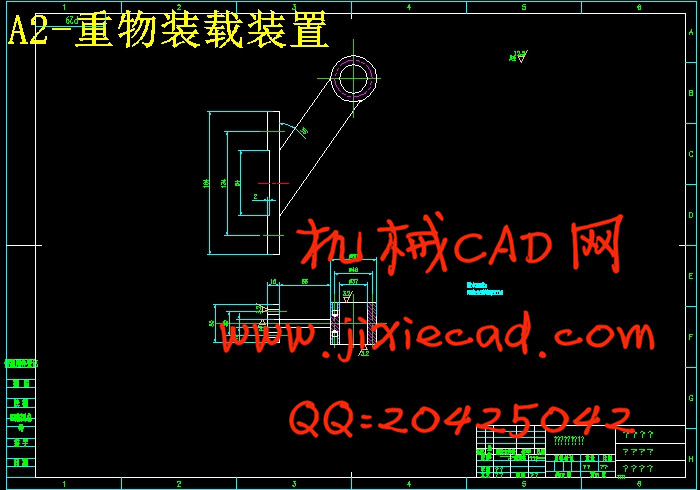

2.3.3 加载装置 10

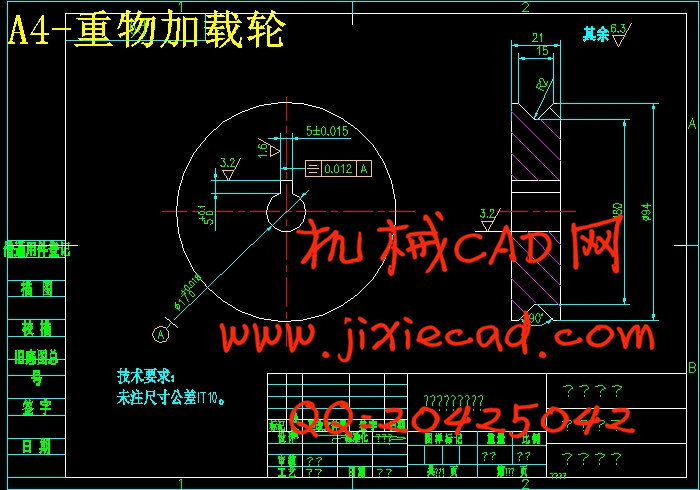

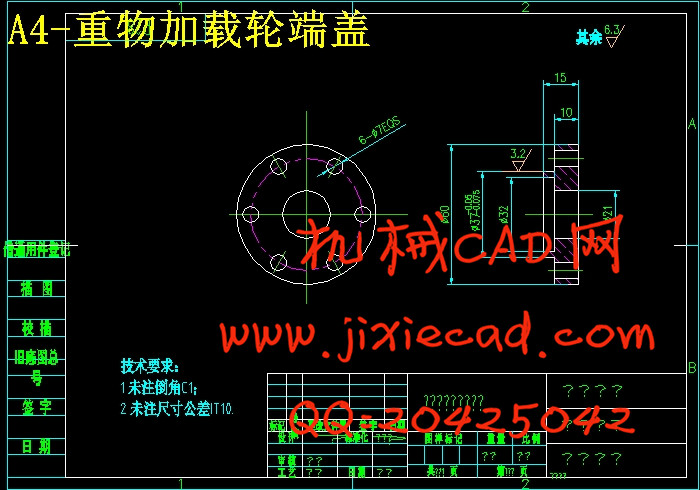

第3章 疲劳试验机各部分计算 11

3.1 多楔带疲劳试验机设计计算 11

3.2 同步带传动的设计计算 12

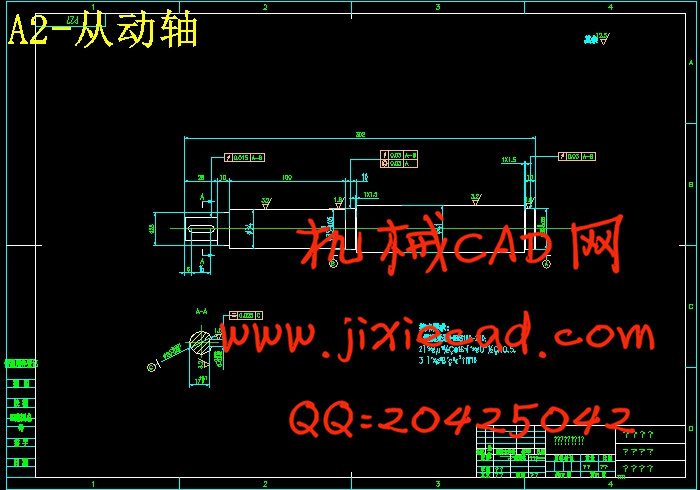

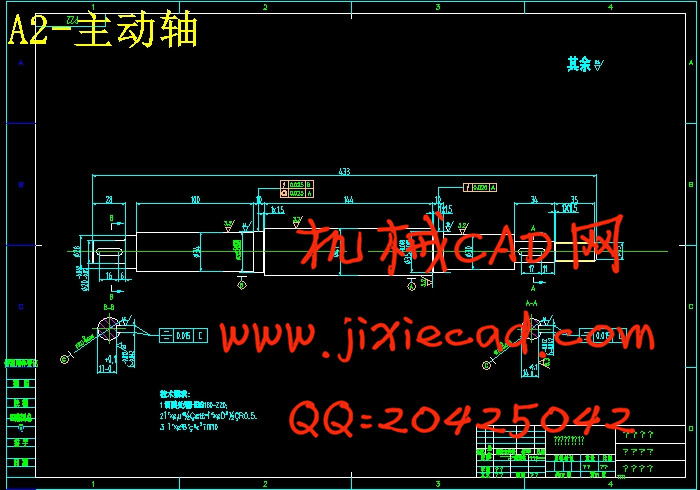

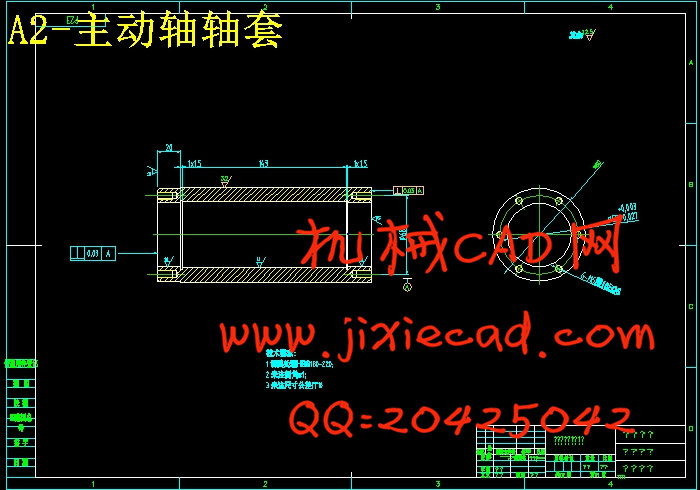

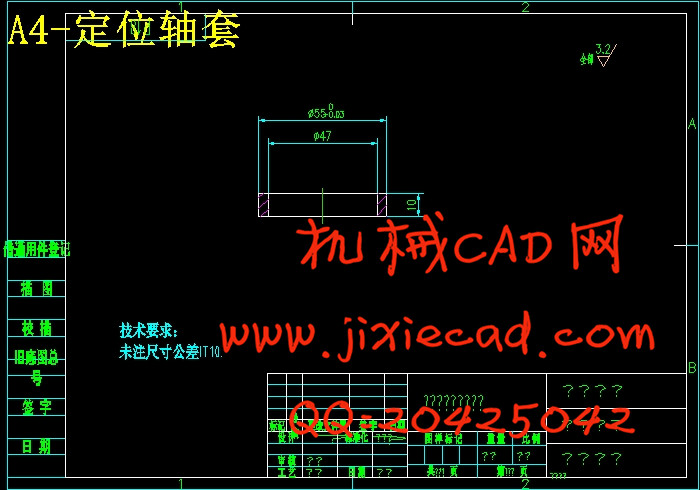

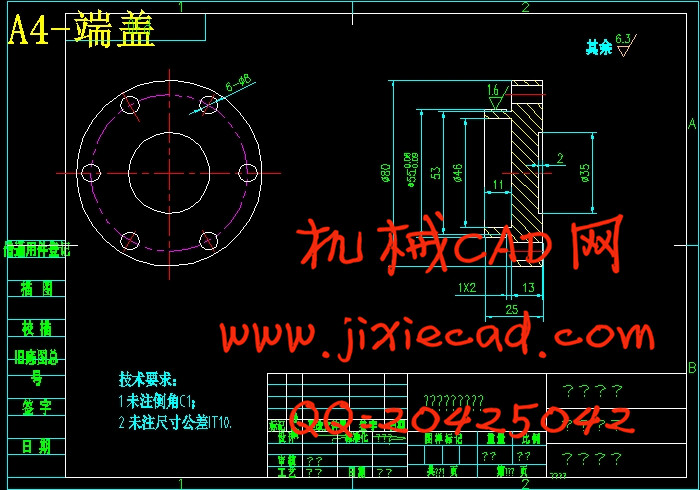

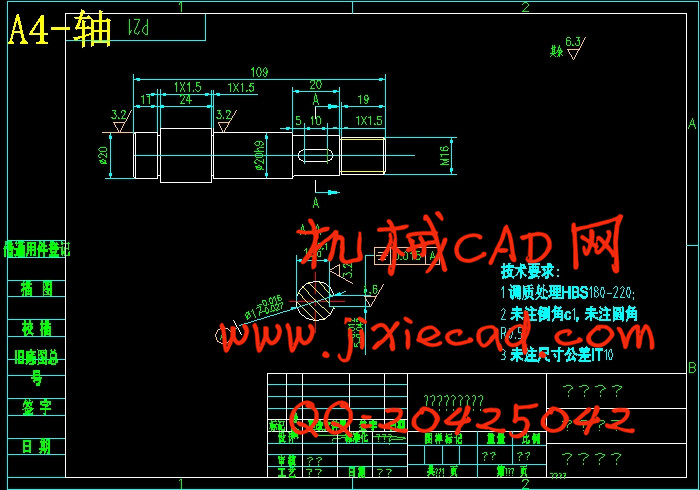

3.3 轴的设计与计算 15

3.4 主动轴轴承设计计算 19

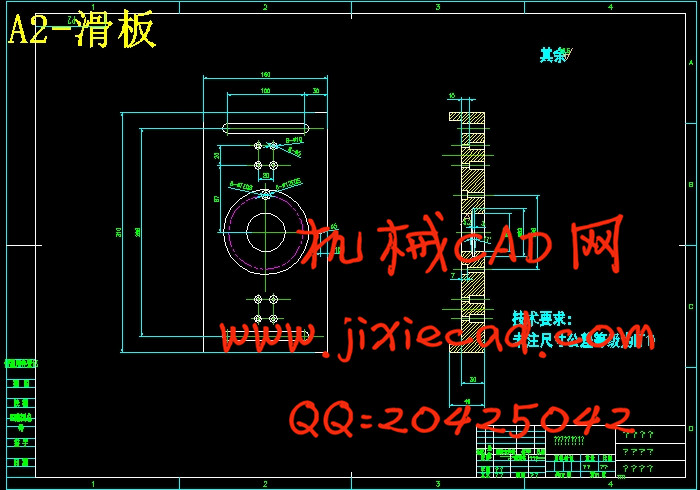

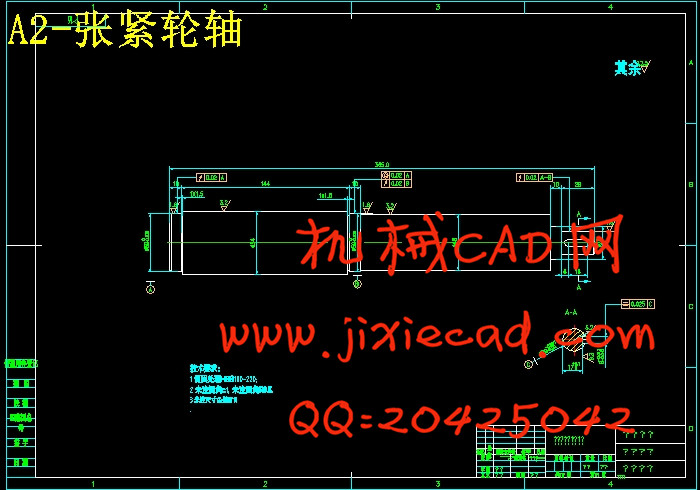

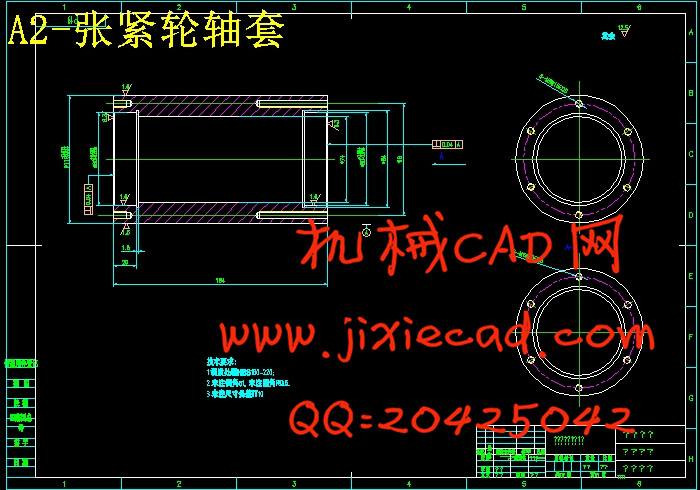

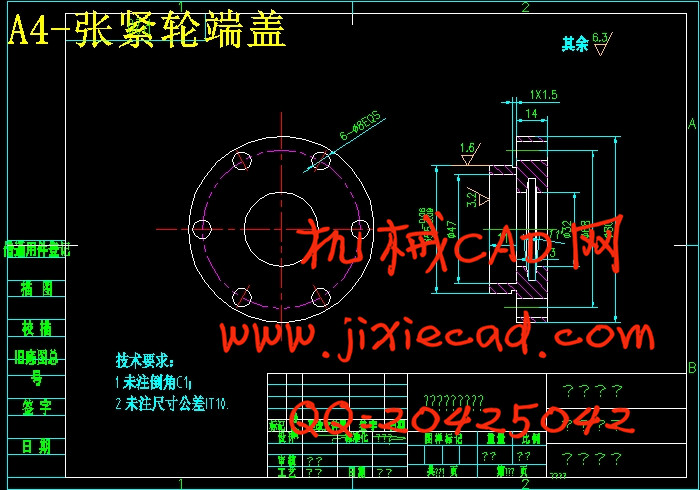

3.5 张紧轮轴的结构设计与计算 19

第4章 设计与人机工程学 21

4.1 根据人体尺度确定设备的合理尺寸 21

4.2 根据人体的力参数合理设计操纵装置 21

总 结 22

参考文献 23

致 谢 24