设计简介

摘要:减震器又称缓冲器,是安装在摩托车悬挂装置上的一个重要零件。摩托车悬挂装置不仅决定了乘坐的舒适度,而且还是决定其运动性能的重要部件。而减震器的功能就是缓和由于路面不平引起的冲击,衰减摩托车的振动;提高乘坐舒适性,保护货载;减低车体各部分的运应力,增加零件的寿命;加强轮胎的附着性,有助于摩托车的操纵性、稳定性。

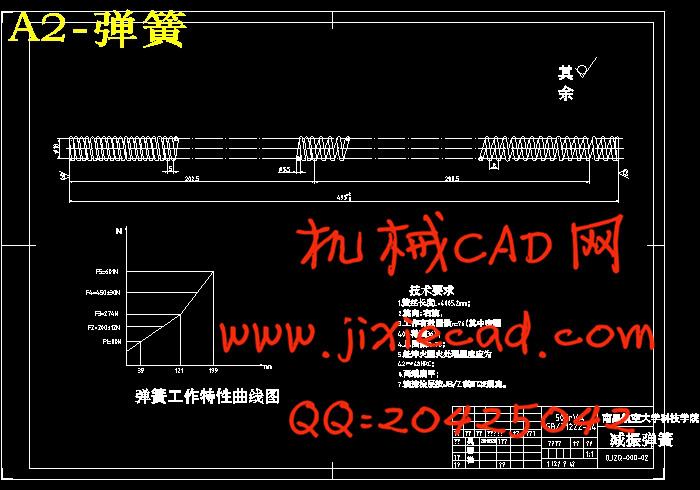

本文所设计的摩托车前减震器采用液力式减震方式,其工作行程为50 mm。通过弹簧减震为主。设计时减震弹簧采用组合式弹簧,由两段节距不同的等节距圆柱弹簧组成。在通常振动范围内,弹簧柔软,当车辆受到冲击时,弹簧变硬,有足够的能力吸收这种冲击能量。减震器的机能是利用流体通过减震杆上的孔、隙产生的粘性阻力。和固体摩托减震相比,利用液体紊流阻力的减震器,在一定阻尼力和吸收能量的条件下,质量小,尺寸小,并在相当的范围内具有能任意规定阻尼力对工作速度的关系等优点。

mm。通过弹簧减震为主。设计时减震弹簧采用组合式弹簧,由两段节距不同的等节距圆柱弹簧组成。在通常振动范围内,弹簧柔软,当车辆受到冲击时,弹簧变硬,有足够的能力吸收这种冲击能量。减震器的机能是利用流体通过减震杆上的孔、隙产生的粘性阻力。和固体摩托减震相比,利用液体紊流阻力的减震器,在一定阻尼力和吸收能量的条件下,质量小,尺寸小,并在相当的范围内具有能任意规定阻尼力对工作速度的关系等优点。

在设计过程中对前减震器的工作原理进行了说明,并确定了工作部分主要零件的相关参数,在已知条件的前提下分别对减震弹簧直径和自由高度,阻尼孔的数量和直径等进行设计计算。

关键词:前减震器 弹簧 阻尼 设计

Abstract : Dampers also known as buffer , is the installation of the hoisting device an important component . Motorcycle hoisting device will not only decide the ride comfort, but also to determine their performance movement of important parts . And the function of a shock absorber is easing due to the road surface uneven, the effect of vibration attenuation motorcycle; improveing ride comfort, Protection of cargo; reduceing the stress of the body operation, increaseing the life expectancy of components; strengthen tire adhesion. helping manipulation and stability of Motorcycle.

In this paper , motorcycle before shock absorber and the overall program analysis and design is the main content. Useing hydraulic shock absorber, its itinerary to 50 mm . Mainly through the spring damping, supplemented dampers. Damping spring design using modular spring,the combination of spring two such different pitchs pitch cylindrical spring,. In the normal range of vibration, soft spring, when the vehicles to be shocked, springs stiffen and have sufficient capacity to absorb the impact energy . Damper function use the fluid through the Absorption of shock pole on the hole, the gap viscous resistance . And compared to solid motorized damping, the use of liquid turbulent resistance dampers, to a certain damping force and absorb energy conditions, Quality small, size small, and the lack of scale with arbitrary requirements damping force on the relationship between the pace of work and so on.

mm . Mainly through the spring damping, supplemented dampers. Damping spring design using modular spring,the combination of spring two such different pitchs pitch cylindrical spring,. In the normal range of vibration, soft spring, when the vehicles to be shocked, springs stiffen and have sufficient capacity to absorb the impact energy . Damper function use the fluid through the Absorption of shock pole on the hole, the gap viscous resistance . And compared to solid motorized damping, the use of liquid turbulent resistance dampers, to a certain damping force and absorb energy conditions, Quality small, size small, and the lack of scale with arbitrary requirements damping force on the relationship between the pace of work and so on.

In the process of designing,there are a note On the before shock absorber working principle , and to identify the major components of the work of the relevant parameters, Respectively damping springs, which includes determination and free height of the damping spring, Damping hole quantity and determination for the design and rehabilitation of resistance

Keywords :before the shock absorber damping spring damper design

目 录

1 绪论………………………………………………………………………………(1)

2 总体方案设计

2.1 研究内容及实验方案…………………………………………………………(3)

2.2 工作原理………………………………………………………………………(3)

3 摩托车减震器的功能和结构形式

3.1 减震器的功能…………………………………………………………………(5)

3.2 摩托车前减震器的结构形式…………………………………………………(5)

3.2.1 弹簧空气式…………………………………………………………………(5)

3.2.2 单筒伸缩式…………………………………………………………………(5)

3.2.3 双筒伸缩式…………………………………………………………………(6)

3.2.4 油—汽伸缩式………………………………………………………………(6)

3.2.5 防下沉伸缩式前减震器……………………………………………………(7)

4 摩托车后减震器的主要特性

4.1 摩托车减震器的弹簧特性……………………………………………………(8)

4.1.1 摩托车悬挂装置的挠度……………………………………………………(8)

4.1.2 摩托车悬挂装置的理想弹簧特性…………………………………………(9)

4.2 摩托车减震弹簧的材料及工艺………………………………………………(10)

4.2.1 弹簧材料的种类……………………………………………………………(10)

4.2.2弹簧制造工艺………………………………………………………………(11)

4.3 摩托车减震器的阻尼特性……………………………………………………(11)

4.3.1 阻力——速度特性…………………………………………………………(11)

4.3.2 阻力——位移特性…………………………………………………………(13)

4.4 摩托车减震器的阻尼力………………………………………………………(14)

4.4.1 复原行程阻尼力计算………………………………………………………(14)

4.4.2 压缩行程阻尼力计算………………………………………………………(16)

4.4.3 减震器额定阻力……………………………………………………………(17)

4.4.4 示功图………………………………………………………………………(17)

5 摩托车后减震器的结构设计

5.1 减震器的主要零件结构参数…………………………………………………(19)

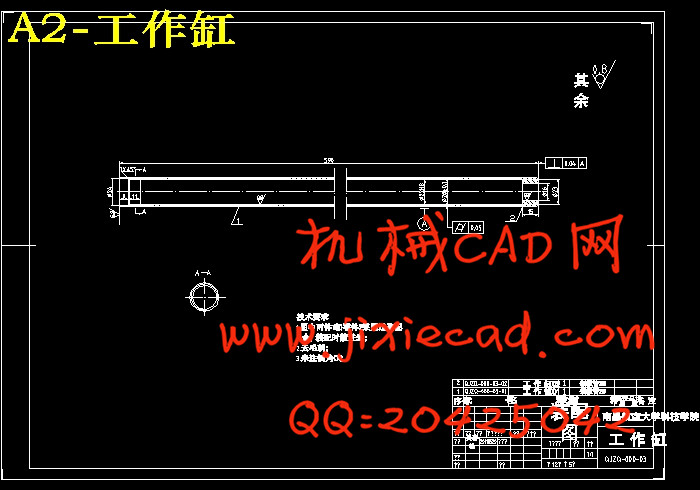

5.1.1 工作缸径的确定……………………………………………………………(19)

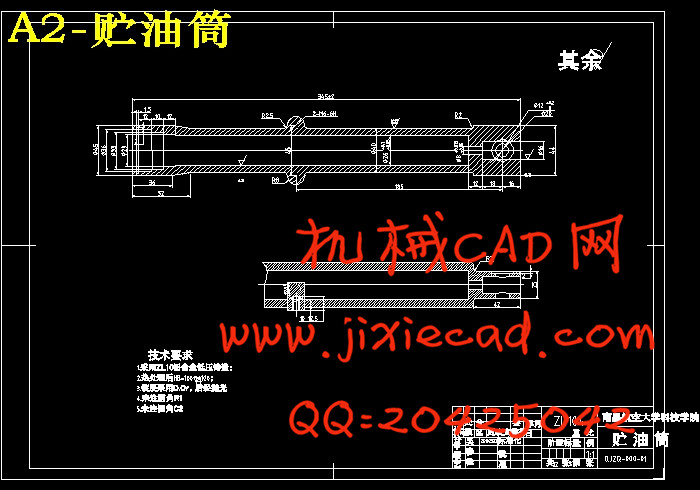

5.1.2 贮油筒径的确定……………………………………………………………(19)

5.1.3 减震器基长的确定…………………………………………………………(20)

5.1.4 工作行程……………………………………………………………………(20)

5.2 摩托车后减震器主要零件的结构设计………………………………………(21)

5.2.1 弹簧的结构尺寸设计和计算………………………………………………(21)

5.2.2 减震弹簧按实际工作状态绘图的优点……………………………………(24)

5.2.3 减震器减震杆杆的设计……………………………………………………(24)

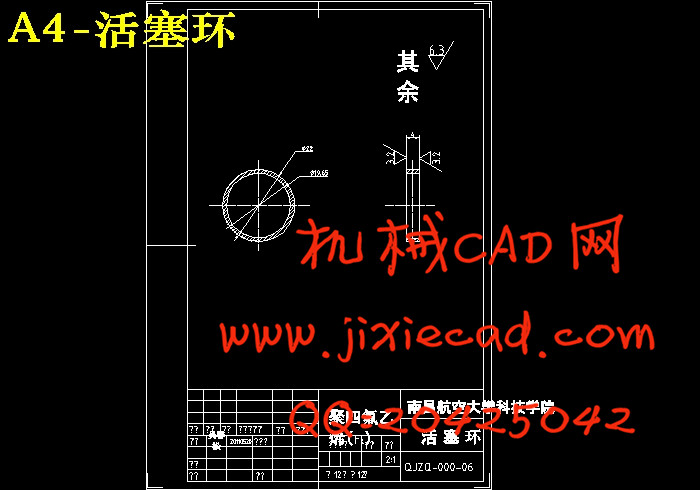

5.2.4 活塞环设计计算……………………………………………………………(26)

5.2.5 贮 油 筒……………………………………………………………………(29)

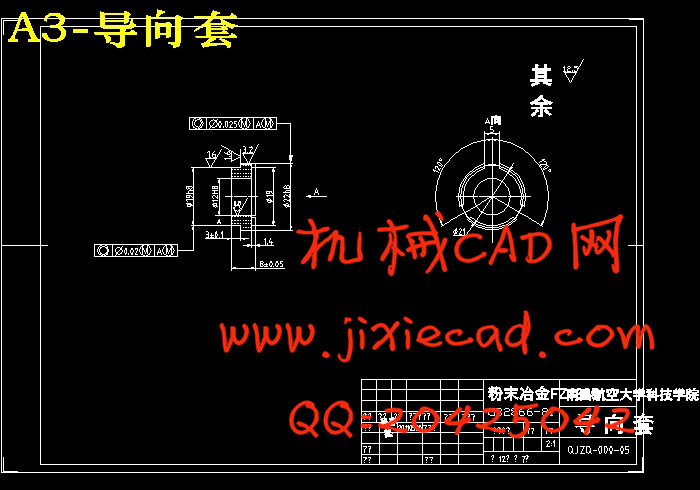

5.2.6 导向套(衬套)……………………………………………………………(30)

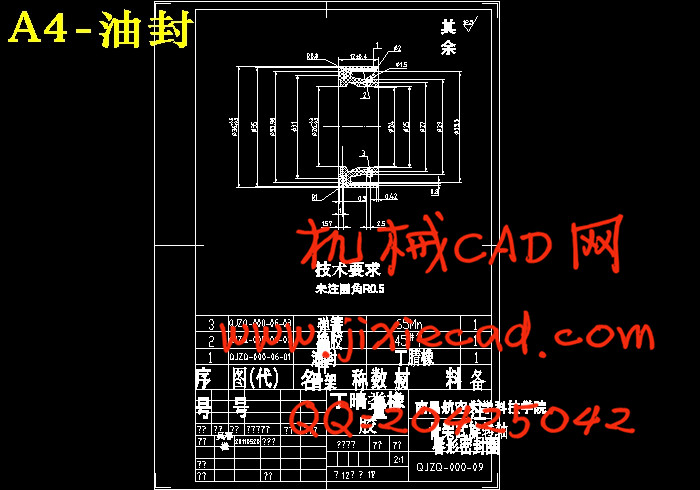

5.2.7 油封…………………………………………………………………………(31)

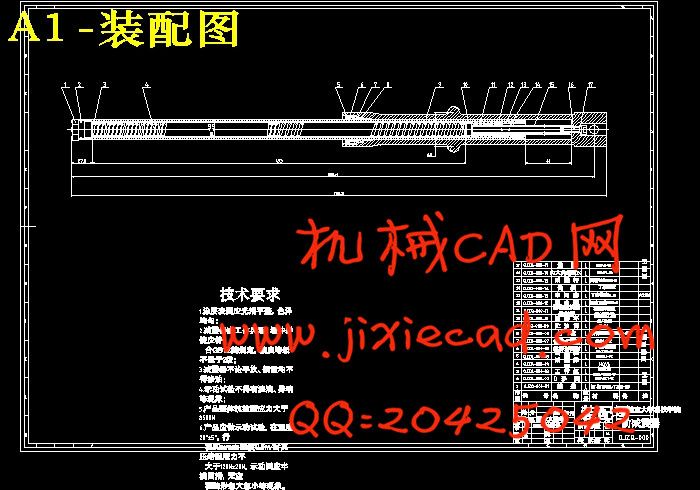

6 摩托车减震器主要零部件的组装工艺

6.1 装配工艺原则…………………………………………………………………(34)

6.2 装配工艺流程…………………………………………………………………(34)

6.2.1 活塞、活塞杆的装配………………………………………………………(34)

6.2.2 前减震器总成装配…………………………………………………………(35)

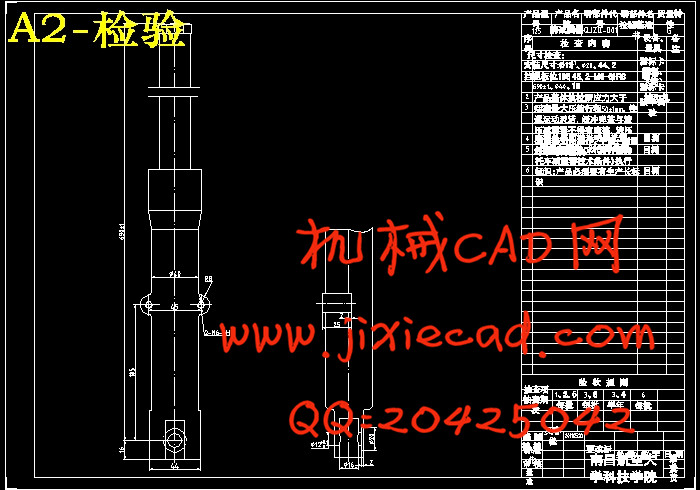

7 摩托车后减震器的检验与质量评定

7.1 出厂检验………………………………………………………………………(36)

7.2 减震器型式检验………………………………………………………………(36)

7.3 减震器质量等级评定方法……………………………………………………(37)

8 总结………………………………………………………………………………(38)

参考文献……………………………………………………………………………(39)

致 谢……………………………………………………………………………(40)

本文所设计的摩托车前减震器采用液力式减震方式,其工作行程为50

在设计过程中对前减震器的工作原理进行了说明,并确定了工作部分主要零件的相关参数,在已知条件的前提下分别对减震弹簧直径和自由高度,阻尼孔的数量和直径等进行设计计算。

关键词:前减震器 弹簧 阻尼 设计

Abstract : Dampers also known as buffer , is the installation of the hoisting device an important component . Motorcycle hoisting device will not only decide the ride comfort, but also to determine their performance movement of important parts . And the function of a shock absorber is easing due to the road surface uneven, the effect of vibration attenuation motorcycle; improveing ride comfort, Protection of cargo; reduceing the stress of the body operation, increaseing the life expectancy of components; strengthen tire adhesion. helping manipulation and stability of Motorcycle.

In this paper , motorcycle before shock absorber and the overall program analysis and design is the main content. Useing hydraulic shock absorber, its itinerary to 50

In the process of designing,there are a note On the before shock absorber working principle , and to identify the major components of the work of the relevant parameters, Respectively damping springs, which includes determination and free height of the damping spring, Damping hole quantity and determination for the design and rehabilitation of resistance

Keywords :before the shock absorber damping spring damper design

目 录

1 绪论………………………………………………………………………………(1)

2 总体方案设计

2.1 研究内容及实验方案…………………………………………………………(3)

2.2 工作原理………………………………………………………………………(3)

3 摩托车减震器的功能和结构形式

3.1 减震器的功能…………………………………………………………………(5)

3.2 摩托车前减震器的结构形式…………………………………………………(5)

3.2.1 弹簧空气式…………………………………………………………………(5)

3.2.2 单筒伸缩式…………………………………………………………………(5)

3.2.3 双筒伸缩式…………………………………………………………………(6)

3.2.4 油—汽伸缩式………………………………………………………………(6)

3.2.5 防下沉伸缩式前减震器……………………………………………………(7)

4 摩托车后减震器的主要特性

4.1 摩托车减震器的弹簧特性……………………………………………………(8)

4.1.1 摩托车悬挂装置的挠度……………………………………………………(8)

4.1.2 摩托车悬挂装置的理想弹簧特性…………………………………………(9)

4.2 摩托车减震弹簧的材料及工艺………………………………………………(10)

4.2.1 弹簧材料的种类……………………………………………………………(10)

4.2.2弹簧制造工艺………………………………………………………………(11)

4.3 摩托车减震器的阻尼特性……………………………………………………(11)

4.3.1 阻力——速度特性…………………………………………………………(11)

4.3.2 阻力——位移特性…………………………………………………………(13)

4.4 摩托车减震器的阻尼力………………………………………………………(14)

4.4.1 复原行程阻尼力计算………………………………………………………(14)

4.4.2 压缩行程阻尼力计算………………………………………………………(16)

4.4.3 减震器额定阻力……………………………………………………………(17)

4.4.4 示功图………………………………………………………………………(17)

5 摩托车后减震器的结构设计

5.1 减震器的主要零件结构参数…………………………………………………(19)

5.1.1 工作缸径的确定……………………………………………………………(19)

5.1.2 贮油筒径的确定……………………………………………………………(19)

5.1.3 减震器基长的确定…………………………………………………………(20)

5.1.4 工作行程……………………………………………………………………(20)

5.2 摩托车后减震器主要零件的结构设计………………………………………(21)

5.2.1 弹簧的结构尺寸设计和计算………………………………………………(21)

5.2.2 减震弹簧按实际工作状态绘图的优点……………………………………(24)

5.2.3 减震器减震杆杆的设计……………………………………………………(24)

5.2.4 活塞环设计计算……………………………………………………………(26)

5.2.5 贮 油 筒……………………………………………………………………(29)

5.2.6 导向套(衬套)……………………………………………………………(30)

5.2.7 油封…………………………………………………………………………(31)

6 摩托车减震器主要零部件的组装工艺

6.1 装配工艺原则…………………………………………………………………(34)

6.2 装配工艺流程…………………………………………………………………(34)

6.2.1 活塞、活塞杆的装配………………………………………………………(34)

6.2.2 前减震器总成装配…………………………………………………………(35)

7 摩托车后减震器的检验与质量评定

7.1 出厂检验………………………………………………………………………(36)

7.2 减震器型式检验………………………………………………………………(36)

7.3 减震器质量等级评定方法……………………………………………………(37)

8 总结………………………………………………………………………………(38)

参考文献……………………………………………………………………………(39)

致 谢……………………………………………………………………………(40)