设计简介

摘 要

绝大多数的物体都有热胀冷缩这一特性,而在磨床生产过程中,由于磨具的高速旋转和被加工产品的来回移动,双方在接触的过程中产生大量的热,使被加工产品受热膨胀,导致被加工产品的生产不精确,从而产生了次品废品.这就需要我们设计一种能根据被加工产品的温度来控制磨床砂轮进给的自动装置,来提高生产的精确度.这就是我们要设计的磨床温度补偿器. 磨床温度补偿系统的开发和研究,有着重大的社会效益和经济效益。随着工业的发展,科技的进步,改革步伐进一步加大,各个企业为了适应市场的变化,都在不断的进行着技术改革。同时,国际国内市场的积累竞争都不断的要求我们提高产品的质量,但为了保证我们的利益,各生产厂家都在谋求以最小的投入换取最大的收益。磨床温度补偿系统就是为了适应这一变化而提出的研究课题。

关键词: 温度补偿,硬件设计,软件编程

Abstract

The objects of the great majority all have the hot bulge the cold Contract this chara -cteristic, but in the grinding machine production line, revolve and is process the return am -bulation of the product because of the high speed that whet to have, the both parties produ -ce a great deal of heat in contiguous process, make is process the product is subjected to t -he hot inflation, cause drive process the production of the product not accurate, this produ -ced an article to discard the article.This need we design a kind of ability according to is pr -ocess product of temperature to control the grinding machine emery wheel enter to of auto device, raise the accuracy of the production.This is the grinding machine temperature that we want to design to compensate the machine. The grinding machine temperature compen -sates the development and researches of the system, having the important social performa -nce and economic performances.Along with the development, technological advance of the industry, the reform step further enlargement, each business enterprise for the sake of orientation the variety of the market, all at carry on the technique reform continuously.At the same time, backlog competitions of the international local market all request the quan -tity that we raise the product continuously, but for guaranteeing our benefits, each produc -tion factory houses are all at seek to exchange the biggest income with the minimum dev -otion.In expiation of system of the grinding machine temperature be for the sake of the research topic that adapt this variety but put forward.

Keywords: The temperature compensate,The hardware design,software programming

目 录

绪论…………………………………………………………………………………1

1 磨床温度补偿器的设计原理和技术要求………………………………2

1.1 磨床温度补偿器的设计思想和原理………………………………………2

1.2 磨床温度补偿器的技术要求………………………………………………3

2 磨床温度补偿器的硬件设计…………………………………………4

2.1 热电偶的选择………………………………………………………………4

2.2 线性化器件的选择…………………………………………………………5

2.3 放大器的选择………………………………………………………………6

2.4 A/D转化器的选择…………………………………………………………6

2.4.1 转换器AD574A简介…………………………………………………7

2.4.2 AD574A 在独立运行模式下的电路设计与工作原理………………8

2.4.3 设计中应注意的问题………………………………………………10

2.5 单片机的选择……………………………………………………………10

2.5.1 主要特性……………………………………………………………10

2.5.2 管脚说明……………………………………………………………11

2.5.3 芯片擦除……………………………………………………………12

2.5.4 各主要部分电路简述 ………………………………………………13

2.6 步进电机起动及加/减速控制方案……………………………………15

2.7 并行I/O口的扩展……………………………………………………………… 18

3 磨床温度补偿器的软件支持和编程……………………………………19

3.1 显示子程序设计…………………………………………………………19

3.2 键盘设计…………………………………………………………………20

4 结论 …………………………………………………………………………21

致谢 ………………………………………………………………………………22

附录 ………………………………………………………………………………23

参考文献…………………………………………………………………………36

绝大多数的物体都有热胀冷缩这一特性,而在磨床生产过程中,由于磨具的高速旋转和被加工产品的来回移动,双方在接触的过程中产生大量的热,使被加工产品受热膨胀,导致被加工产品的生产不精确,从而产生了次品废品.这就需要我们设计一种能根据被加工产品的温度来控制磨床砂轮进给的自动装置,来提高生产的精确度.这就是我们要设计的磨床温度补偿器. 磨床温度补偿系统的开发和研究,有着重大的社会效益和经济效益。随着工业的发展,科技的进步,改革步伐进一步加大,各个企业为了适应市场的变化,都在不断的进行着技术改革。同时,国际国内市场的积累竞争都不断的要求我们提高产品的质量,但为了保证我们的利益,各生产厂家都在谋求以最小的投入换取最大的收益。磨床温度补偿系统就是为了适应这一变化而提出的研究课题。

关键词: 温度补偿,硬件设计,软件编程

Abstract

The objects of the great majority all have the hot bulge the cold Contract this chara -cteristic, but in the grinding machine production line, revolve and is process the return am -bulation of the product because of the high speed that whet to have, the both parties produ -ce a great deal of heat in contiguous process, make is process the product is subjected to t -he hot inflation, cause drive process the production of the product not accurate, this produ -ced an article to discard the article.This need we design a kind of ability according to is pr -ocess product of temperature to control the grinding machine emery wheel enter to of auto device, raise the accuracy of the production.This is the grinding machine temperature that we want to design to compensate the machine. The grinding machine temperature compen -sates the development and researches of the system, having the important social performa -nce and economic performances.Along with the development, technological advance of the industry, the reform step further enlargement, each business enterprise for the sake of orientation the variety of the market, all at carry on the technique reform continuously.At the same time, backlog competitions of the international local market all request the quan -tity that we raise the product continuously, but for guaranteeing our benefits, each produc -tion factory houses are all at seek to exchange the biggest income with the minimum dev -otion.In expiation of system of the grinding machine temperature be for the sake of the research topic that adapt this variety but put forward.

Keywords: The temperature compensate,The hardware design,software programming

目 录

绪论…………………………………………………………………………………1

1 磨床温度补偿器的设计原理和技术要求………………………………2

1.1 磨床温度补偿器的设计思想和原理………………………………………2

1.2 磨床温度补偿器的技术要求………………………………………………3

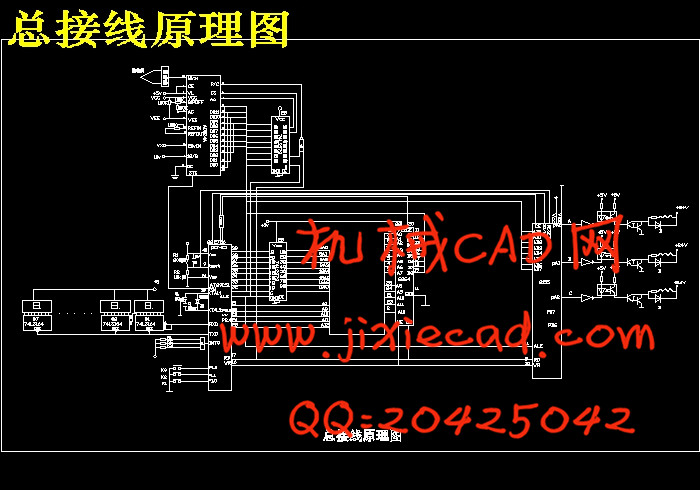

2 磨床温度补偿器的硬件设计…………………………………………4

2.1 热电偶的选择………………………………………………………………4

2.2 线性化器件的选择…………………………………………………………5

2.3 放大器的选择………………………………………………………………6

2.4 A/D转化器的选择…………………………………………………………6

2.4.1 转换器AD574A简介…………………………………………………7

2.4.2 AD574A 在独立运行模式下的电路设计与工作原理………………8

2.4.3 设计中应注意的问题………………………………………………10

2.5 单片机的选择……………………………………………………………10

2.5.1 主要特性……………………………………………………………10

2.5.2 管脚说明……………………………………………………………11

2.5.3 芯片擦除……………………………………………………………12

2.5.4 各主要部分电路简述 ………………………………………………13

2.6 步进电机起动及加/减速控制方案……………………………………15

2.7 并行I/O口的扩展……………………………………………………………… 18

3 磨床温度补偿器的软件支持和编程……………………………………19

3.1 显示子程序设计…………………………………………………………19

3.2 键盘设计…………………………………………………………………20

4 结论 …………………………………………………………………………21

致谢 ………………………………………………………………………………22

附录 ………………………………………………………………………………23

参考文献…………………………………………………………………………36