设计简介

摘要:装载机属于铲土运输机械类,是一种通过安装在前端一个完整的铲斗支撑结构和连杆,随机器向前运动进行装载或挖掘,以及提升、运输和卸载的自行式机械。它广泛用于公路、铁路、建筑、水电、港口和矿山等工程建设。装载机具有作业速度快、效率高、机动性好、操作轻便等优点,因此成为工程建设中土石方施工的主要机种之一,对于加快工程建设速度,减轻劳动强度,提高工程质量,降低工程成本都发挥着重要的作用,是现代机械化施工中不可缺少的装备之一。

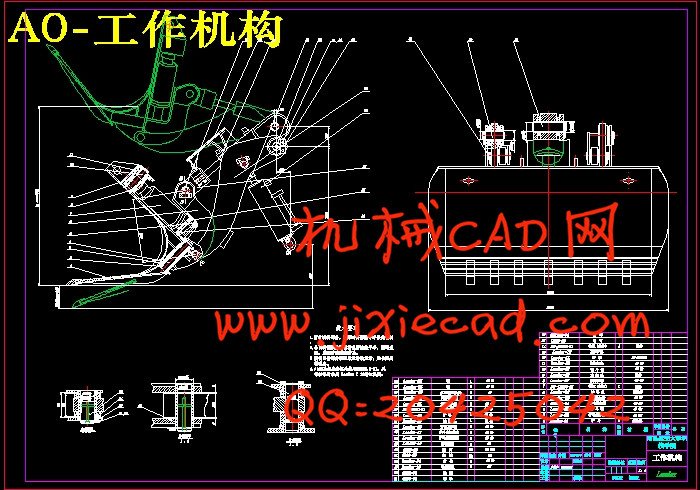

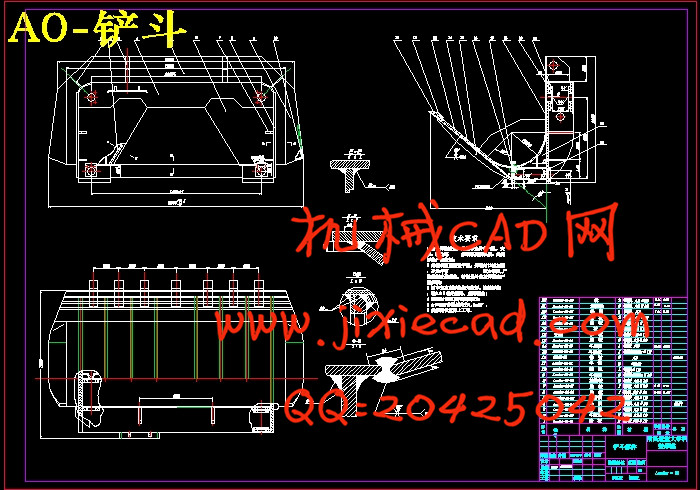

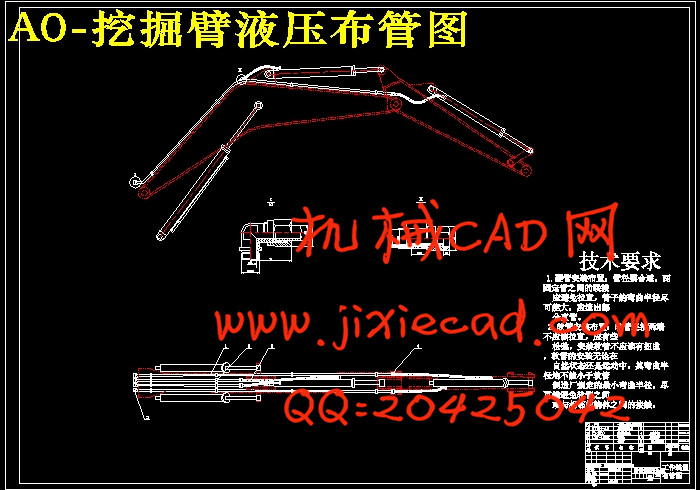

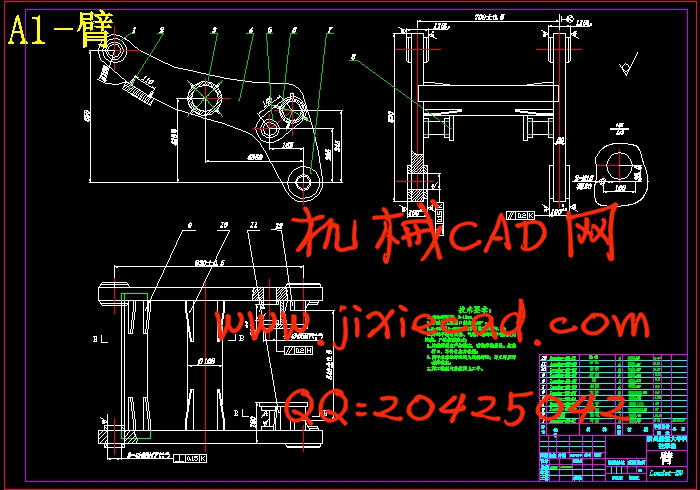

这次设计先介绍了装载机的工作机构利用AUTOCAD2007对装载机的工作机构进行了初步设计,然后对这种轮式装载机工作机构进行了总体设计到零部件设计。主要包括轮式装载机工作机构的关键零部件,如铲斗、连杆机构以及转斗油缸、举升油缸等,并对重要零件进行了刚度、强度分析,以验证设计合理性。

关键词: 装载机; 机械化; 工作装置;

Abstract: Loader ofsoil belonging to the transport machinery, through the installation of a front-end in a bucket full support structure and linkage, random forward movement for loading or excavation, and the upgrading, transportation and unloading of self-propelled machinery. It widely used in highway, railway, construction, utilities, ports and mines and other projects. Loader is operating speed, high efficiency, good flexibility, the advantages of operating the light, so as the construction of earth and stone in the construction of one of the main machine, to speed up the construction speed, reduce labor intensity, improve project quality, reduce project cost plays an important role in the construction of a modern mechanized, one of indispensable equipment.

This design introduced the first loader working mechanism based on AUTOCAD2007loader working mechanism was discussed in detail, and then the loader working mechanism design to design components. Wheel loader work includes mechanism of key parts and components, such as a bucket, and the bucket rotating oil cylinder link mechanism, a lifting oil cylinder, and the important parts of the stiffness, strength analysis, in order to verify the reasonableness of the design.

Keywords:Loader; Mechanization; Work-Equipment;

目 录

1. 前言 1

1.1设计课题 1

1.2 装载机的发展历史 1

1.3 装载机工作机构的特点 1

1.4装载机工作机构的用途 2

2. 装载机装载过程分析 3

2.1装载过程描述: 3

2.2装载机的装载阻力计算 4

3. 装载机工作机构的设计 7

3.1工作机构对铲斗运动的要求 7

3.2 铲斗的机构设计 7

3.3 斗容的计算和尺寸确定 8

3.4工作机构杆件系统的配制与设计 10

4. 装载机工作机构受力分析 14

4.1工作机构的最大受力工况与最大外载荷的确定 14

4.2工作机构最大铲取力与铲斗臂最大举升的确定 14

5. 工作机构稳定性能分析 22

5.1 稳定性指标 22

5.2机器纵向稳定性能分析 23

5.3 装载机横向稳定性分析 25

6. 液压缸设计计算 29

6.1 铲斗上的侧卸油缸设计 29

6.2 拉伸油缸的设计 30

总结 33

参考资料 34

致谢 35

这次设计先介绍了装载机的工作机构利用AUTOCAD2007对装载机的工作机构进行了初步设计,然后对这种轮式装载机工作机构进行了总体设计到零部件设计。主要包括轮式装载机工作机构的关键零部件,如铲斗、连杆机构以及转斗油缸、举升油缸等,并对重要零件进行了刚度、强度分析,以验证设计合理性。

关键词: 装载机; 机械化; 工作装置;

Abstract: Loader ofsoil belonging to the transport machinery, through the installation of a front-end in a bucket full support structure and linkage, random forward movement for loading or excavation, and the upgrading, transportation and unloading of self-propelled machinery. It widely used in highway, railway, construction, utilities, ports and mines and other projects. Loader is operating speed, high efficiency, good flexibility, the advantages of operating the light, so as the construction of earth and stone in the construction of one of the main machine, to speed up the construction speed, reduce labor intensity, improve project quality, reduce project cost plays an important role in the construction of a modern mechanized, one of indispensable equipment.

This design introduced the first loader working mechanism based on AUTOCAD2007loader working mechanism was discussed in detail, and then the loader working mechanism design to design components. Wheel loader work includes mechanism of key parts and components, such as a bucket, and the bucket rotating oil cylinder link mechanism, a lifting oil cylinder, and the important parts of the stiffness, strength analysis, in order to verify the reasonableness of the design.

Keywords:Loader; Mechanization; Work-Equipment;

目 录

1. 前言 1

1.1设计课题 1

1.2 装载机的发展历史 1

1.3 装载机工作机构的特点 1

1.4装载机工作机构的用途 2

2. 装载机装载过程分析 3

2.1装载过程描述: 3

2.2装载机的装载阻力计算 4

3. 装载机工作机构的设计 7

3.1工作机构对铲斗运动的要求 7

3.2 铲斗的机构设计 7

3.3 斗容的计算和尺寸确定 8

3.4工作机构杆件系统的配制与设计 10

4. 装载机工作机构受力分析 14

4.1工作机构的最大受力工况与最大外载荷的确定 14

4.2工作机构最大铲取力与铲斗臂最大举升的确定 14

5. 工作机构稳定性能分析 22

5.1 稳定性指标 22

5.2机器纵向稳定性能分析 23

5.3 装载机横向稳定性分析 25

6. 液压缸设计计算 29

6.1 铲斗上的侧卸油缸设计 29

6.2 拉伸油缸的设计 30

总结 33

参考资料 34

致谢 35