设计简介

自动垂直提升仓储系统是集光、机、电、微机控制、数据库为一体的新型产品。自动垂直提升仓储系统主要用于电子元器件、标准件、标准工具、数控机床刀柄和小型货物的储存和管理。具有外形美观,占地面积小,存储量大,存取操作方便,便于管理等特点。是一些具有一定经济实力的企业改造首选设备。自动化仓储系统是由电脑控制处理设备,记忆物料存放的位置,利用自动化控制系统、自动存取臂与条形码扫描设备,不需人工拣货或上架,通过电脑控制可自动存取货物的系统。其优点为节省空间和人力,为提高作业效率 。是一些具有一定经济实力的企业改造首选设备。

。是一些具有一定经济实力的企业改造首选设备。

关键词仓储系统 产品结构总体 垂直升降机构 托盘组件 拨叉运动

Abstract

Automatic vertical storage system upgrade is a light, mechanical, electrical, computer the database is one of the new product. Automatic vertical storage system is mainly used to enhance electronic components, standard parts, standard tool, numerical control machine tool holder and small cargo storage and management. Has beautiful shape, small size, storage capacity, access to convenient operation, easy management. Some with a certain economic strength of enterprise transformation device of choice into account. Automated warehousing system is computer-controlled processing equipment, memory storage location of materials, use of automatic control system, automatic access to arms and bar code scanning equipment, without manual picking or shelves, and through the computer control system of automatic access to the goods. The advantages of saving space and manpower, to improve operating efficiency. Some have a certain economic strength of first choice for business transformation.

Keywords Storage Systems Overall product structure Vertical lifting mechanism Pallet components Fork movement

目录

1 引言..................................................................2

2 现状..................................................................2

3 发展趋势..............................................................3

4 国内外自动仓储系统的研究..............................................3

4.1 国外自动仓储系统的研究..............................................3

4.2 国内自动仓储系统的研究..............................................4

5 产品简介..............................................................4

5.1 仓储系统的主要功能..................................................4

5.2 自动垂直提升仓储系统组成............................................5

6 产品结构总体..........................................................5

6.1 各机构的动作顺序....................................................5

6.1.1 取货物............................................................5

6.1.2 存放货物..........................................................6

6.2 主体................................................................6

6.3 垂直升降机构........................................................6

6.4 水平存取机构........................................................6

6.5 关开门机构..........................................................7

6.6 托盘组件............................................................7

6.7 刀架组件............................................................7

6.8 产品结构总体设计中主要的难题和解决方法..............................7

6.8.1 拨叉运动的实现....................................................7

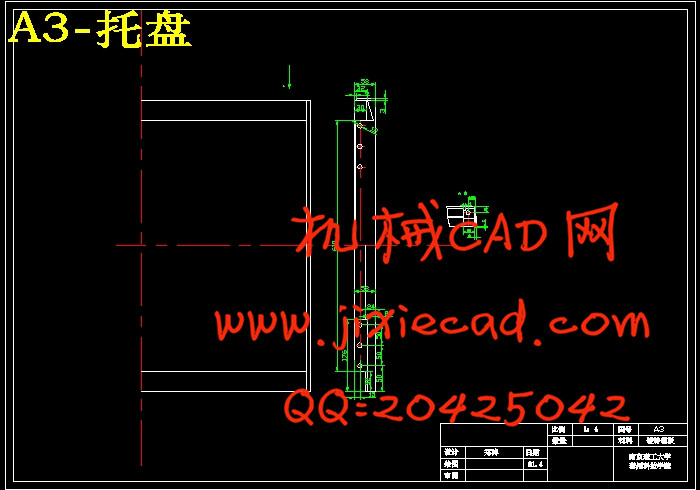

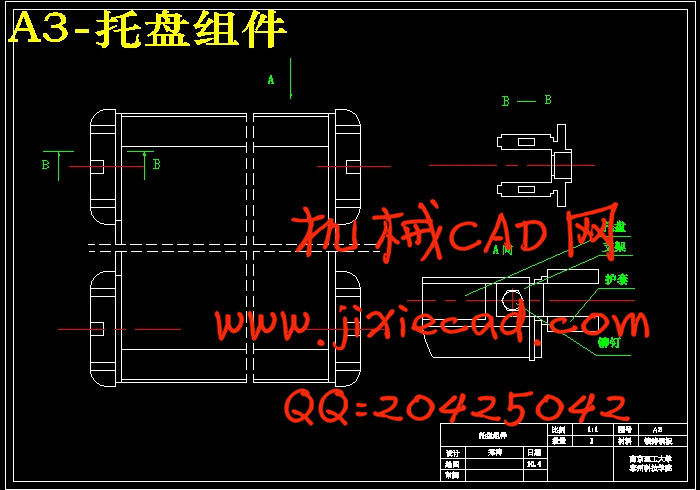

6.8.2 托盘组件的设计..................................................11

7 关键零部件的设计与校核..............................................12

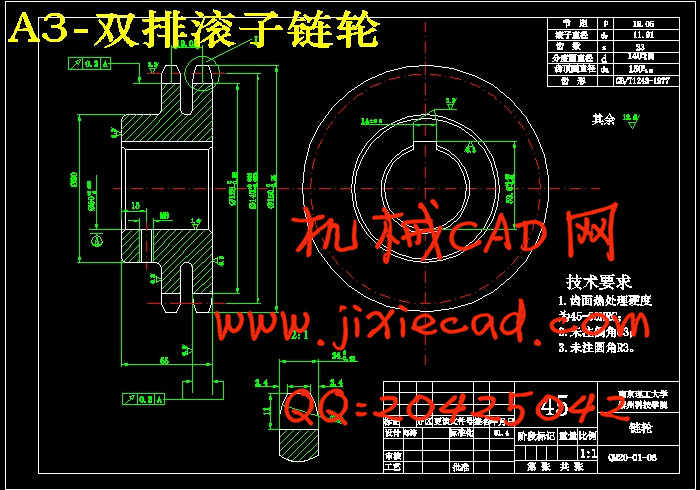

7.1 链轮的设计与校核..................................................12

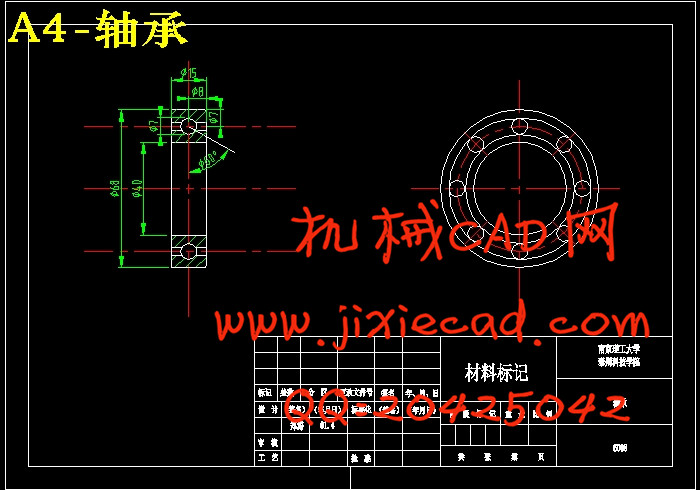

7.2 轴的设计与校核....................................................15

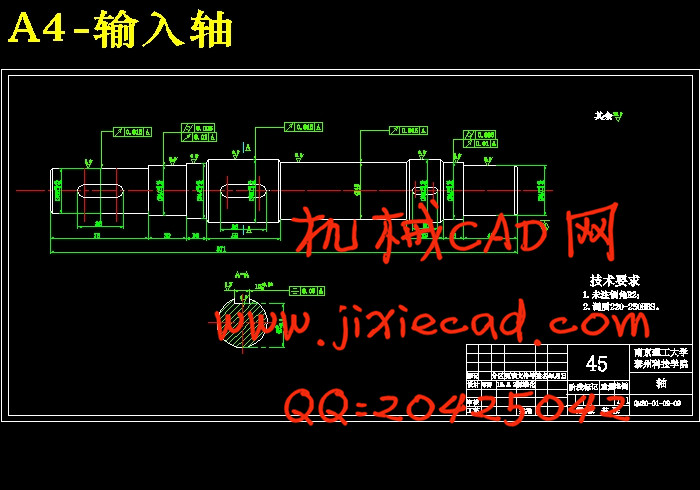

7.2.1 输入轴的设计.....................................................15

7.2.2 输入轴的校核.....................................................17

总结...................................................................25

致谢...................................................................26

参考文献...............................................................27

关键词仓储系统 产品结构总体 垂直升降机构 托盘组件 拨叉运动

Abstract

Automatic vertical storage system upgrade is a light, mechanical, electrical, computer the database is one of the new product. Automatic vertical storage system is mainly used to enhance electronic components, standard parts, standard tool, numerical control machine tool holder and small cargo storage and management. Has beautiful shape, small size, storage capacity, access to convenient operation, easy management. Some with a certain economic strength of enterprise transformation device of choice into account. Automated warehousing system is computer-controlled processing equipment, memory storage location of materials, use of automatic control system, automatic access to arms and bar code scanning equipment, without manual picking or shelves, and through the computer control system of automatic access to the goods. The advantages of saving space and manpower, to improve operating efficiency. Some have a certain economic strength of first choice for business transformation.

Keywords Storage Systems Overall product structure Vertical lifting mechanism Pallet components Fork movement

目录

1 引言..................................................................2

2 现状..................................................................2

3 发展趋势..............................................................3

4 国内外自动仓储系统的研究..............................................3

4.1 国外自动仓储系统的研究..............................................3

4.2 国内自动仓储系统的研究..............................................4

5 产品简介..............................................................4

5.1 仓储系统的主要功能..................................................4

5.2 自动垂直提升仓储系统组成............................................5

6 产品结构总体..........................................................5

6.1 各机构的动作顺序....................................................5

6.1.1 取货物............................................................5

6.1.2 存放货物..........................................................6

6.2 主体................................................................6

6.3 垂直升降机构........................................................6

6.4 水平存取机构........................................................6

6.5 关开门机构..........................................................7

6.6 托盘组件............................................................7

6.7 刀架组件............................................................7

6.8 产品结构总体设计中主要的难题和解决方法..............................7

6.8.1 拨叉运动的实现....................................................7

6.8.2 托盘组件的设计..................................................11

7 关键零部件的设计与校核..............................................12

7.1 链轮的设计与校核..................................................12

7.2 轴的设计与校核....................................................15

7.2.1 输入轴的设计.....................................................15

7.2.2 输入轴的校核.....................................................17

总结...................................................................25

致谢...................................................................26

参考文献...............................................................27