设计简介

某药筒尺寸自动测量设备开发

摘要:本篇文章主要是关于某型号药筒尺寸的自动测量设备的开发研究,本文详细阐述了每个待测尺寸的测量方法,结合并借鉴其他机械测量的方法,应用LVDT气电内径测量系统、气动系统、差动式位移传感器测长系统、激光测径系统等等,实现对药筒总长、底厚、内外径等尺寸的自动化测量。首先通过对总长的测量,其次对底厚的测量,然后对内径的测量,再次对外径的测量和最后对药筒是否合格的检测以及此次系统的可靠性与可行性,可得出本药筒尺寸自动测量设备具有可行性和高效率性的结论。

本文所完成的主要工作如下所示:

(1)了解药筒测量技术在国内外发展水平现状,尤其是一些关于药筒测量的相关检测技巧和方法,同时针对药筒所要测量的尺寸进行研究。

(2)描述了关于药筒的各种尺寸的测量方法,并对相应的测量原理和测量工具进行详细的介绍,为系统的设计提供了理论依据。

(3)根据药筒需要测量的关键尺寸的结构要求,将待测尺寸分为5个步骤进行测量和检验,为了实现自动测量,设计药筒抓手实现其药筒的移动。

(4)根据药筒所要测量的尺寸的结构,对比选择较合适的测量仪器,并根据测量控制要求,完成对测量系统的控制方案设计。

(5)针对每个测量仪器所得出的测量数据的特点,设计每个所要测量测尺寸的分析方法,使之尽可能的满足测量要求。

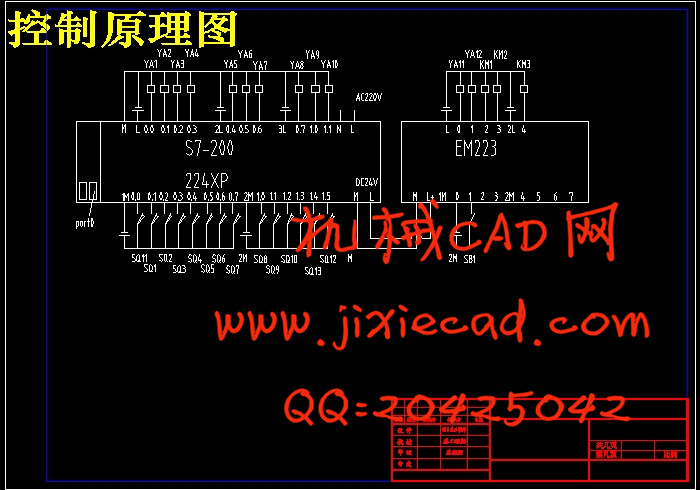

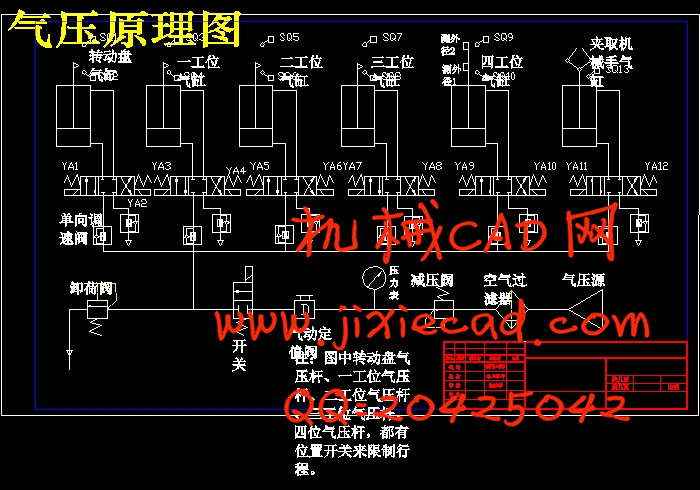

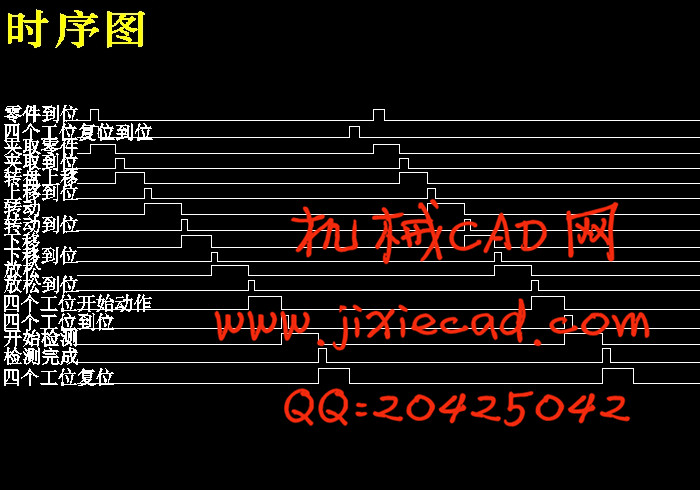

(6)本设计进行了药筒尺寸自动测量设备控制系统设计的开发,根据系统的需求,通过s7 - 200 PLC控制整个系统,形成一套完整的控制方案设计和相应的控制程序来控制外围继电器回路,控制气动控制回路、步进电机的操作,料斗振动电机。本检测系统的控制主要包括:升降平台气缸的控制、各检测工位气缸及气动夹爪的控制,以及相关电机的控制。本文具体设计了气压控制系统和PLC控制程序设计。

摘要:本篇文章主要是关于某型号药筒尺寸的自动测量设备的开发研究,本文详细阐述了每个待测尺寸的测量方法,结合并借鉴其他机械测量的方法,应用LVDT气电内径测量系统、气动系统、差动式位移传感器测长系统、激光测径系统等等,实现对药筒总长、底厚、内外径等尺寸的自动化测量。首先通过对总长的测量,其次对底厚的测量,然后对内径的测量,再次对外径的测量和最后对药筒是否合格的检测以及此次系统的可靠性与可行性,可得出本药筒尺寸自动测量设备具有可行性和高效率性的结论。

本文所完成的主要工作如下所示:

(1)了解药筒测量技术在国内外发展水平现状,尤其是一些关于药筒测量的相关检测技巧和方法,同时针对药筒所要测量的尺寸进行研究。

(2)描述了关于药筒的各种尺寸的测量方法,并对相应的测量原理和测量工具进行详细的介绍,为系统的设计提供了理论依据。

(3)根据药筒需要测量的关键尺寸的结构要求,将待测尺寸分为5个步骤进行测量和检验,为了实现自动测量,设计药筒抓手实现其药筒的移动。

(4)根据药筒所要测量的尺寸的结构,对比选择较合适的测量仪器,并根据测量控制要求,完成对测量系统的控制方案设计。

(5)针对每个测量仪器所得出的测量数据的特点,设计每个所要测量测尺寸的分析方法,使之尽可能的满足测量要求。

(6)本设计进行了药筒尺寸自动测量设备控制系统设计的开发,根据系统的需求,通过s7 - 200 PLC控制整个系统,形成一套完整的控制方案设计和相应的控制程序来控制外围继电器回路,控制气动控制回路、步进电机的操作,料斗振动电机。本检测系统的控制主要包括:升降平台气缸的控制、各检测工位气缸及气动夹爪的控制,以及相关电机的控制。本文具体设计了气压控制系统和PLC控制程序设计。

关键词:药筒,总长测量,外径测量,内径测量,自动控制,S7-200,气压控制,程序

Automatic sizes measuring equipment developed

of a cartridge

Abstract:This paper is a study of the development of a certain type of cartridge the size of an equipment, measurement methods described in detail for size, combined with the reference method for measurement of other machinery, gas-electric applications LVDT inner diameter of the measuring system, pneumatic system, poor fixed displacement sensor length measurement systems, laser diameter measurement systems, etc., to achieve the total length of the cartridge, thick bottom, inner and outer diameter and other dimensions of automated testing. First, by measuring the total length, followed by measurement of the thickness of the bottom, then the measurement of the inner diameter, outer diameter was measured again and the last cartridge eligibility detect far more than the feasibility and reliability of the system, the drug can be drawn tube size automatic measuring equipment having a viable, high efficiency characteristics.

The main complete as follows:

(1) The level of understanding of domestic and international development status of the cartridge measurement technology, especially related to the detection cartridge measurement methods and techniques, and study for the test cartridge size.

(2) Describes the measurement method cartridge of various sizes, and the corresponding measurement principle and measurement tools in detail, for the design of the system provides a theoretical basis.

(3) According to the requirements of the critical dimensions of the structure to be measured of the cartridge to be tested is divided into five steps and inspection, in order to achieve automatic measurement, the cartridge design which lever for moving the cartridge.

(4) The structure of the test cartridge size, contrast selection Johnson appropriate

measuring instruments, according to the measurement and control requirements, the completion of the measurement system control design.

(5) For details of each measurement instrument characteristic measurement data, making it possible to meet the measurement requirements.

(6)This design were bullet size automatic measuring equipment control system design development, according to the demand of the system, through the S7 - 200 PLC control system as a whole, form a set of complete control scheme is designed and the corresponding control program to control the external relay circuit, gas control pneumatic control circuit, stepper motor operation, hopper vibration motor. The control of the detection system mainly includes: the control of the lifting platform cylinder, the control of the cylinder and the pneumatic clamping, and the control of the motor. The design of air pressure control system and PLC control program is designed in this paper.

Keywords:Cartridge, length measurement, diameter measurement, diameter measurement, automatic control, pressure control, S7-200 program

(5) For details of each measurement instrument characteristic measurement data, making it possible to meet the measurement requirements.

(6)This design were bullet size automatic measuring equipment control system design development, according to the demand of the system, through the S7 - 200 PLC control system as a whole, form a set of complete control scheme is designed and the corresponding control program to control the external relay circuit, gas control pneumatic control circuit, stepper motor operation, hopper vibration motor. The control of the detection system mainly includes: the control of the lifting platform cylinder, the control of the cylinder and the pneumatic clamping, and the control of the motor. The design of air pressure control system and PLC control program is designed in this paper.

Keywords:Cartridge, length measurement, diameter measurement, diameter measurement, automatic control, pressure control, S7-200 program

目 录

摘要……………………………………………………………………………I

Abstract………………………………………………………………………II

目录……………………………………………………………………………III

1 绪论…………………………………………………………………………1

1.1课题的研究背景…………………………………………………………1

1.2测量技术的国内外研究现状……………………………………………1

1.3研究的内容及意义………………………………………………………2

1.3.1研究的内容……………………………………………………………2

1.3.2研究的意义……………………………………………………………2

2 药筒尺寸自动测量整体方案………………………………………………4

2.1药筒尺寸的主要测量内容………………………………………………4

2.2药筒尺寸的检测方案……………………………………………………4

2.2.1内径的测量方法………………………………………………………4

2.2.2长度的测量方法………………………………………………………6

2.2.3外径的测量方法………………………………………………………7

2.3药筒尺寸的整体方案……………………………………………………8

3可编程器简介………………………………………………………………9

3.1 PLC的基本结构…………………………………………………………9

3.2 扩展模块…………………………………………………………………9

3.3 S7-200系列PLC元件功能………………………………………………10

3.4 程序编辑器………………………………………………………………10

4气动控制系统设计…………………………………………………………15

4.1气动控制系统的组成……………………………………………………15

4.2气动控制系统的设计……………………………………………………15

摘要……………………………………………………………………………I

Abstract………………………………………………………………………II

目录……………………………………………………………………………III

1 绪论…………………………………………………………………………1

1.1课题的研究背景…………………………………………………………1

1.2测量技术的国内外研究现状……………………………………………1

1.3研究的内容及意义………………………………………………………2

1.3.1研究的内容……………………………………………………………2

1.3.2研究的意义……………………………………………………………2

2 药筒尺寸自动测量整体方案………………………………………………4

2.1药筒尺寸的主要测量内容………………………………………………4

2.2药筒尺寸的检测方案……………………………………………………4

2.2.1内径的测量方法………………………………………………………4

2.2.2长度的测量方法………………………………………………………6

2.2.3外径的测量方法………………………………………………………7

2.3药筒尺寸的整体方案……………………………………………………8

3可编程器简介………………………………………………………………9

3.1 PLC的基本结构…………………………………………………………9

3.2 扩展模块…………………………………………………………………9

3.3 S7-200系列PLC元件功能………………………………………………10

3.4 程序编辑器………………………………………………………………10

4气动控制系统设计…………………………………………………………15

4.1气动控制系统的组成……………………………………………………15

4.2气动控制系统的设计……………………………………………………15

4.3气动控制系统具体设计内容……………………………………………15

5.系统控制与设计……………………………………………………………185.1控制系统控制方式确定…………………………………………………18

5.2 控制系统设计流程………………………………………………………18

5.3 控制任务分析……………………………………………………………18

5.4 电气系统设计……………………………………………………………23

总结……………………………………………………………………………26

致谢……………………………………………………………………………27

参考文献………………………………………………………………………28