设计简介

摘 要

带式输送机,又称作是“胶带运输机”。俗称“皮带输送机”。是现今最重要的散装物料运输设备,具有输送能力大、耗电量小、连续运输能力、运输阻力小、且运行平稳等优点。所以,被广泛应用于矿井巷道内采用带式输送机运送煤炭、矿石等物料,对建设现代化矿井有重要作用,在国民经济的各个行业中很常见。

带式输送机是一种摩擦驱动以连续方式运输物料的机械。其主要由机架、输送皮带、皮带辊筒、张紧装置、传动装置等组成。它可以将物料在一定的输送线上,从最初的供料点到最终的卸料点间形成一种物料的输送流程。它既可以进行碎散物料的输送,也可以进行成件物品的输送。除进行纯粹的物料输送外,还可以与各工业企业生产流程中的工艺过程的要求相配合,形成有节奏的流水作业运输线。

带式输送机可以用于水平运输或倾斜运输,使用非常方便,广泛应用于现代化的各种工业企业中。在煤矿中,带式输送机主要用于运输平巷及斜井,也常用于地面生产系统和选煤厂中。

本文根据笔者多年的学习经历、社会实践以及

关键词:带式输送机 原理 设计计算 滚筒托辊 安装维护

Abstract

Belt conveyor, also known as" adhesive tape conveyer". Commonly known as the" belt conveyor". Nowadays the most important bulk material transportation equipment, strong conveying capacity, low power consumption, continuous transport capacity, transport small resistance, and stable operation and the like. So, is widely used in mine roadway with belt conveyor for transporting coal, ores and other materials, on the construction of modern mine has an important role in the national economy, the various industry is very common.

Belt conveyor is a kind of friction drive by the continuous mode transportation machinery materials. It is mainly composed of a machine frame, conveying belt, a belt roller, tensioning device, transmission device. It can be the material in certain transportation line, from the initial material to the final point of discharge is formed between a material conveying process. It not only can be broken loose material conveying, can also be carried into pieces of goods transportation. In addition to the pure material handling, but also with various industrial enterprise production process in process requirements are matched, formation of rhythmic flow transport line.

Belt conveyor can be used for horizontal transport or incline transportation, use very convenient, widely used in modern industrial enterprises. In the coal mine, belt conveyor is mainly used for the transport level and inclined shaft, also used in surface production system and coal preparation plant.

In this paper, according to the years of learning experiences, social practice and CAD technology, combined with their own learned in school and related professional knowledge, the related mechanical discipline comprehensive summary, description of the design of a belt conveyor. And introduced the TD belt conveyor drum roller structure, working principle, design process, installation operation and maintenance and related security protection technology.

Key words: principles of design calculation of belt conveyor drum roller installation and maintenance

目 录

摘 要 1

Abstract 2

前 言 5

1. 概述 7

1.2 通用带式输送机的结构 9

1.2.1输送带 10

1.2.2 驱动装置 19

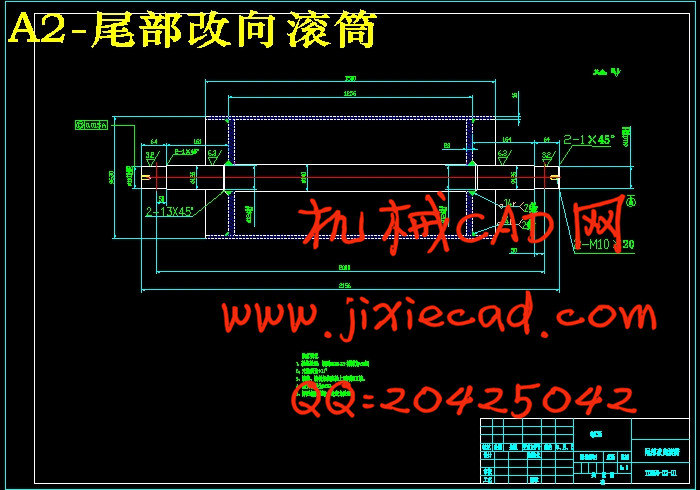

1.2.3 托辊 22

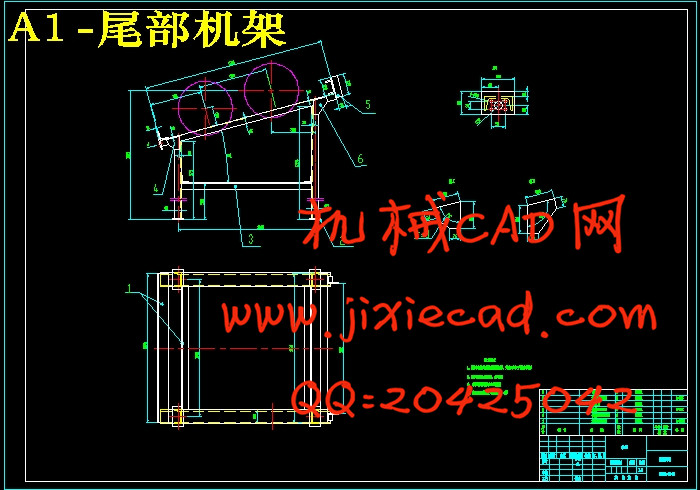

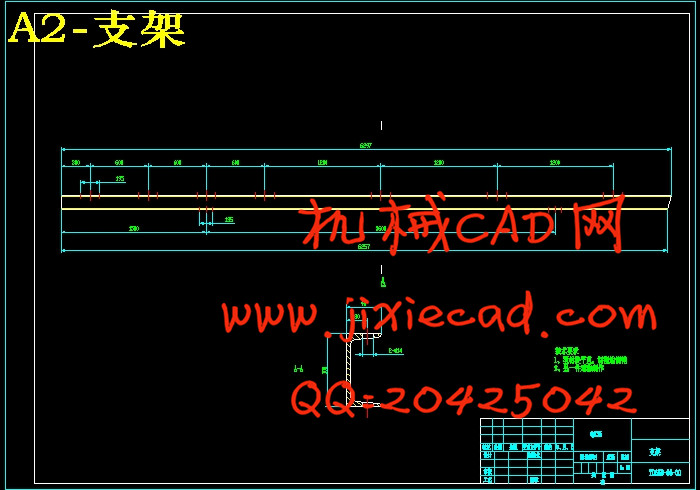

1.2.4 机架 25

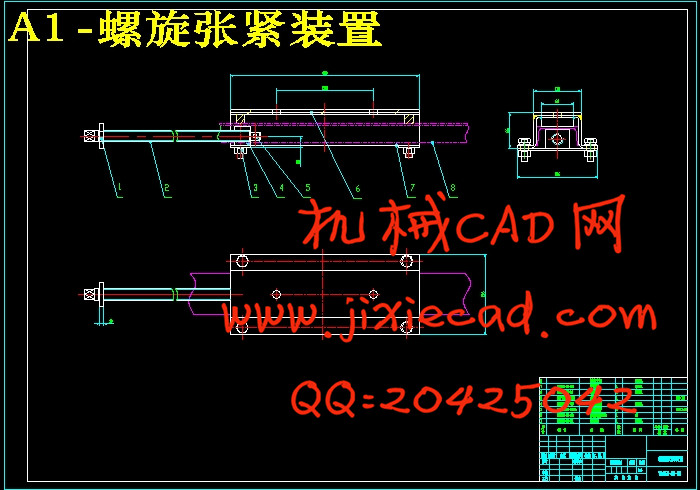

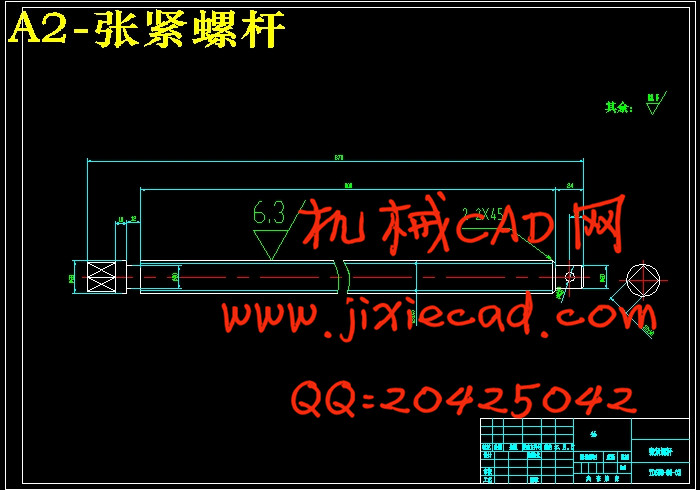

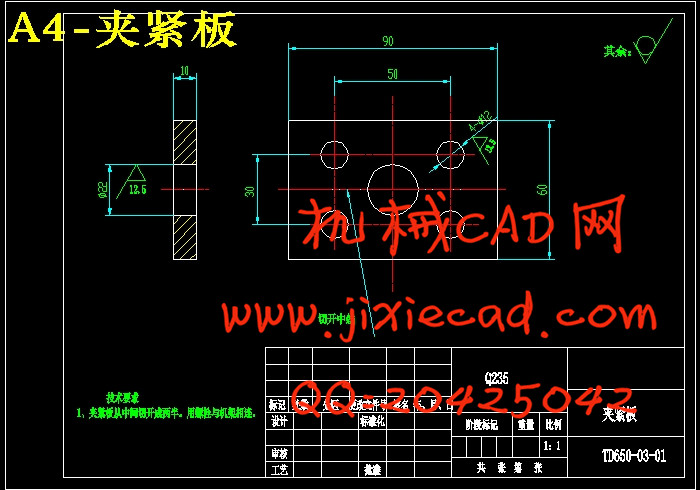

1.2.5 拉紧装置 26

2. 带式输送机摩擦传动理论 30

2.1 摩擦传动理论 30

2.2 提高牵引力的途径 31

3 带式输送机的设计计算选型 32

3.1 带式输送机选型设计的依据及要求 32

3.2 带式输送机的工艺布置 32

3.3 零部件设计计算及选择 34

3.3.1 计算标准、符号和单位 34

3.3.2 原始数据及工作条件 35

3.3.3 输送能力和输送带宽度的计算 37

3.3.4 计算圆周驱动力和传动功率计算 40

3.3.5 张力计算 44

3.3.6 输送带选择计算 48

3.3.7 拉紧装置计算 54

3.3.8 托辊的选择 54

4 带式输送机的操作、维护和安装 57

4.1 启动和停机 57

4.2 带式输送机的维护 58

4.3 带式输送机的安装 62

致 谢 64

参考文献 65

带式输送机,又称作是“胶带运输机”。俗称“皮带输送机”。是现今最重要的散装物料运输设备,具有输送能力大、耗电量小、连续运输能力、运输阻力小、且运行平稳等优点。所以,被广泛应用于矿井巷道内采用带式输送机运送煤炭、矿石等物料,对建设现代化矿井有重要作用,在国民经济的各个行业中很常见。

带式输送机是一种摩擦驱动以连续方式运输物料的机械。其主要由机架、输送皮带、皮带辊筒、张紧装置、传动装置等组成。它可以将物料在一定的输送线上,从最初的供料点到最终的卸料点间形成一种物料的输送流程。它既可以进行碎散物料的输送,也可以进行成件物品的输送。除进行纯粹的物料输送外,还可以与各工业企业生产流程中的工艺过程的要求相配合,形成有节奏的流水作业运输线。

带式输送机可以用于水平运输或倾斜运输,使用非常方便,广泛应用于现代化的各种工业企业中。在煤矿中,带式输送机主要用于运输平巷及斜井,也常用于地面生产系统和选煤厂中。

本文根据笔者多年的学习经历、社会实践以及

关键词:带式输送机 原理 设计计算 滚筒托辊 安装维护

Abstract

Belt conveyor, also known as" adhesive tape conveyer". Commonly known as the" belt conveyor". Nowadays the most important bulk material transportation equipment, strong conveying capacity, low power consumption, continuous transport capacity, transport small resistance, and stable operation and the like. So, is widely used in mine roadway with belt conveyor for transporting coal, ores and other materials, on the construction of modern mine has an important role in the national economy, the various industry is very common.

Belt conveyor is a kind of friction drive by the continuous mode transportation machinery materials. It is mainly composed of a machine frame, conveying belt, a belt roller, tensioning device, transmission device. It can be the material in certain transportation line, from the initial material to the final point of discharge is formed between a material conveying process. It not only can be broken loose material conveying, can also be carried into pieces of goods transportation. In addition to the pure material handling, but also with various industrial enterprise production process in process requirements are matched, formation of rhythmic flow transport line.

Belt conveyor can be used for horizontal transport or incline transportation, use very convenient, widely used in modern industrial enterprises. In the coal mine, belt conveyor is mainly used for the transport level and inclined shaft, also used in surface production system and coal preparation plant.

In this paper, according to the years of learning experiences, social practice and CAD technology, combined with their own learned in school and related professional knowledge, the related mechanical discipline comprehensive summary, description of the design of a belt conveyor. And introduced the TD belt conveyor drum roller structure, working principle, design process, installation operation and maintenance and related security protection technology.

Key words: principles of design calculation of belt conveyor drum roller installation and maintenance

目 录

摘 要 1

Abstract 2

前 言 5

1. 概述 7

1.2 通用带式输送机的结构 9

1.2.1输送带 10

1.2.2 驱动装置 19

1.2.3 托辊 22

1.2.4 机架 25

1.2.5 拉紧装置 26

2. 带式输送机摩擦传动理论 30

2.1 摩擦传动理论 30

2.2 提高牵引力的途径 31

3 带式输送机的设计计算选型 32

3.1 带式输送机选型设计的依据及要求 32

3.2 带式输送机的工艺布置 32

3.3 零部件设计计算及选择 34

3.3.1 计算标准、符号和单位 34

3.3.2 原始数据及工作条件 35

3.3.3 输送能力和输送带宽度的计算 37

3.3.4 计算圆周驱动力和传动功率计算 40

3.3.5 张力计算 44

3.3.6 输送带选择计算 48

3.3.7 拉紧装置计算 54

3.3.8 托辊的选择 54

4 带式输送机的操作、维护和安装 57

4.1 启动和停机 57

4.2 带式输送机的维护 58

4.3 带式输送机的安装 62

致 谢 64

参考文献 65