设计简介

摘 要

带式输送机是广泛应用于煤炭、港口、建设、电厂等工业领域的连续输送设备,它具有运输效率高、运营成本低等优点。随着国民经济的发展,带式输送机的应用越来越广泛。近年来,随着工业技术的发展,带式输送机也不断朝着大运量、长距离、大倾角、高带速、投资费用少、运营费用低、工作可靠、维护方便等方向发展,对其设计技术的要求也越来越高。 为适应地形的要求,用输送带输送一定高度的带式输送机在很多方面有应用。本文着重讨论了带式输送机的结构原理、传动原理、设计计算法则、运行阻力的计算、各点张力的计算等内容,以及各种计算参数的设计计算和校核,尤其对输送带的选用、托辊的选用进行了详细的分析,使设计更加贴切接近实际问题。本文还分析了国内外带式输送机的现状及发展趋势,说明在现代高科技发展的情况下,带式输送机的发展潜力还是很大的。

本文研究了一般固定式带式输送机的设计理论,并根据所设计的要求再结合目前国内的目前的技术要求组装了一套倾角为0度的固定式带式输送机,说明了这套设计符合设计参数的要求

关键字:输送机 发展 结构原理 计算和校核

Abstract

Taking style to transport machine is broad apply to industry field continuation such as coal , port construction, electric power plant transports equipment , that it has transportation is efficient , is in motion and do business cost low grade merit. The application with the development of national economy, taking style to transport machine is more and more broad. In recent years , with the development of industrial technology,the cost direction such as low , working reliably , defending to go to the lavatory taking style to transport machine bringing speed along also unceasingly to grand fortune amounts , long distance , big dip angle , height , investing in cost stopping being in motion and doing business, develops , designs that the technology request is also more and more high to the person. For the request adapting to landform's, use conveyer belt to transport certain altitude's taking style to transport machine having in many aspects applying. Content such as the main body of a book being emphasized having discussed structure principle , drive principle taking style to transport machine , being designing the calculation calculating a law , running resistance's , every tension calculation, calculating and proofreading the parametric design secretly scheming against as well as various, has carried out detailed analysis on the conveyer belt selecting and using , selecting and using supporting a roller especially , has used the problem designing especially appropriate approximation reality. The main body of a book has been analysed taking style to transport machine current situation and developing trend at home and abroad, the potential taking style to transport is still very big under explanation condition developing in modern high technology.

The general stationary type the main body of a book has been studied takes style to transport the machine design theory , in the light of designed that together request still be tied in wedlock is at present domestic at present the technology has demanded assembling to copy a dip angle once for 14 degree of stationary type takes style to transport machine , the cover having explained this has designed that according with the request designing a parameter's.

Key words: Transport machine Develop Structure principle

Secretly scheme against and school core

目录

前 言 1

1 绪 论 3

1.1 皮带运输机的概况 3

1.1.1 皮带运输机的发展史 3

1.1.2皮带运输机基本结构 4

1.1.3 矿用皮带运输机各机型介绍 5

1.2 皮带运输机的发展趋势 10

1.2.1国外皮带运输机技术的现状 10

1.2.2国内皮带运输机技术的现状 11

1.2.3 国内外皮带运输机技术的差距 12

1.2.4 煤矿皮带运输机技术的发展趋势 16

2 皮带运输机的设计计算 18

2.1已知原始数据及工作条件 18

2.2输送带宽度的确定及核算 19

2.2.1带速的确定 19

2.2.2带宽的确定 20

2.2.3输送带宽度的核算 22

2.3圆周驱动力 23

2.3.1计算公式 23

2.3.2主要阻力计算 24

2.3.3特种主要阻力计算 26

2.3.4特种附加阻力计算 27

2.3.5倾斜阻力计算 28

2.4传动功率计算 29

2.4.1 传动滚筒轴功率( )计算 29

)计算 29

2.4.2 电动机功率计算 29

2.5输送带张力计算 30

2.5.1阻力计算 31

2.5.2 输送带不打滑条件校核 34

2.5.3 输送带下垂度校核 35

2.5.4输送带强度校核计算 36

2.6拉紧力计算 36

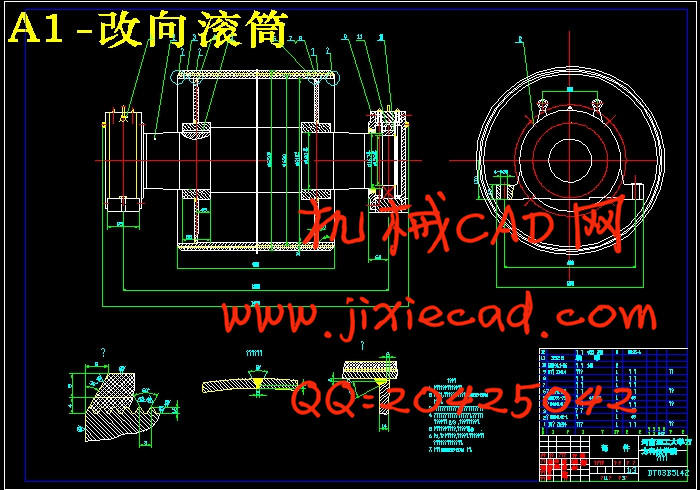

2.7传动滚筒,改向滚筒合张力计算 37

2.7.1改向滚筒合张力计算 37

2.7.2 传动滚筒合张力计算 37

2.8 传动滚筒最大扭矩计算 37

3 皮带运输机的传动原理 38

3.1胶带的摩擦传动原理 38

3.2传动装置的牵引力 41

4 传动装置的选用与设计 43

4.1 电机的选用 43

4.2 减速器的选用 44

4.2.1 传动装置的总传动比 44

4.3 液力偶合器 47

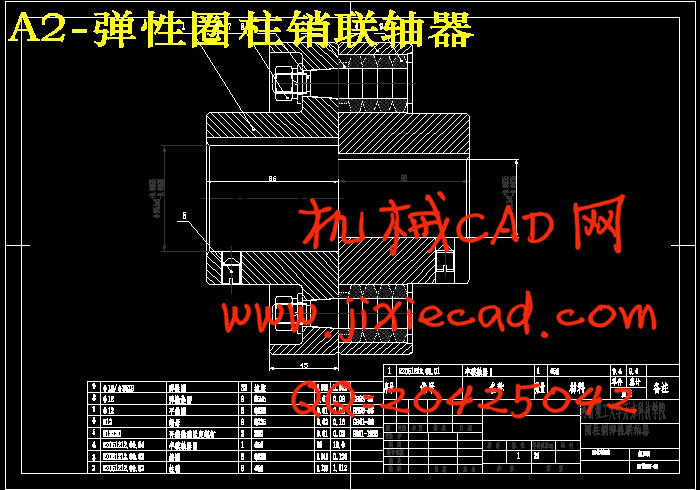

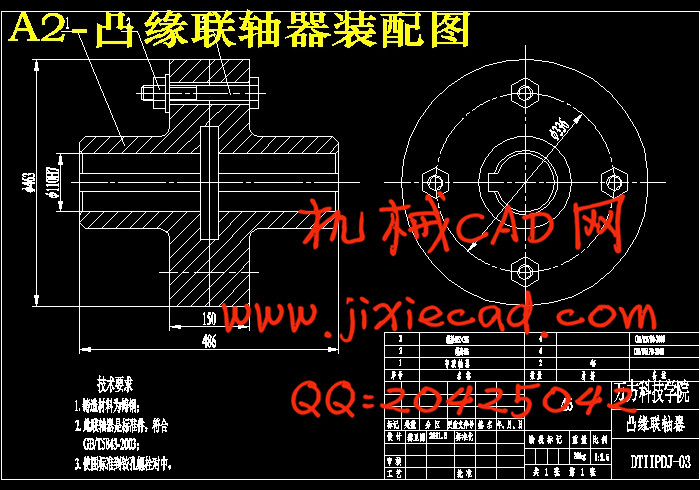

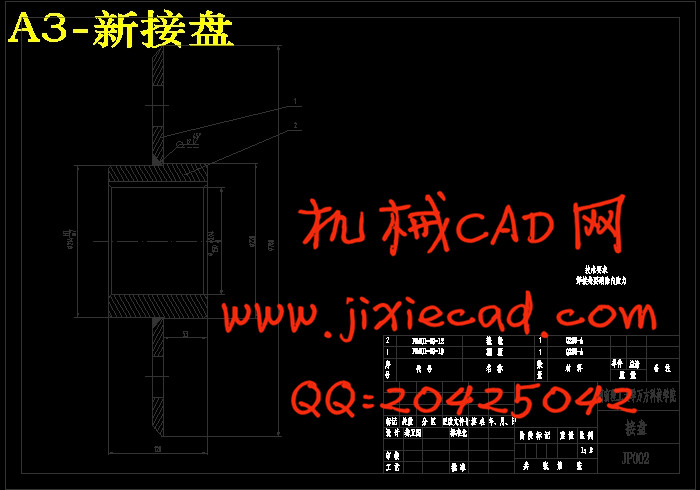

4.4 联轴器 48

5皮带运输机部件的选用 52

5.1 输送带 52

5.1.1 输送带的分类: 54

5.1.2 输送带的连接 56

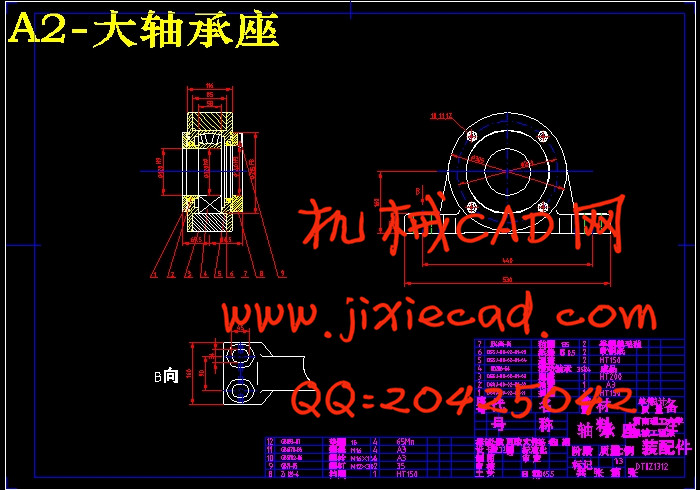

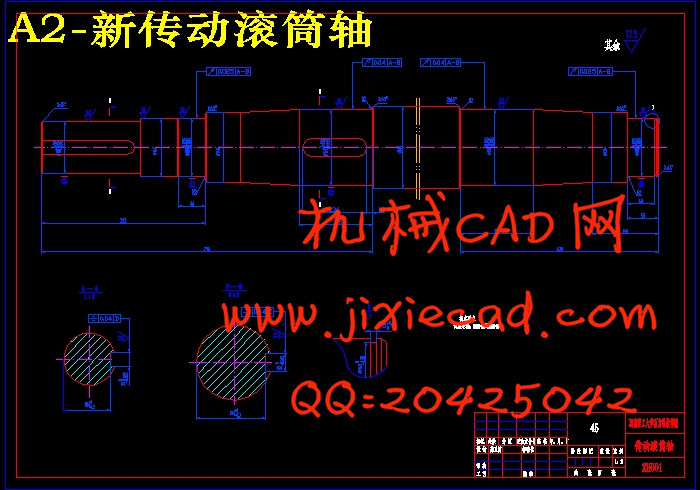

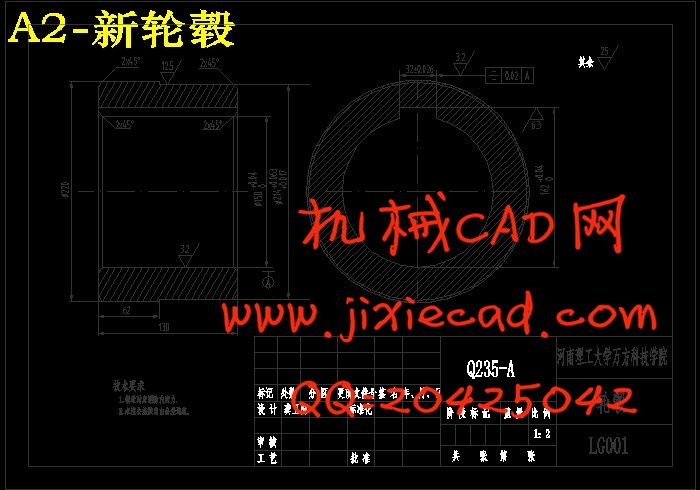

5.2 传动滚筒 57

5.2.1 传动滚筒的作用及类型 57

5.2.2 传动滚筒的选型及设计 58

5.2.3 传动滚筒结构 64

5.2.4传动滚筒的直径验算 65

5.3 拉紧装置 66

5.4 制动装置 69

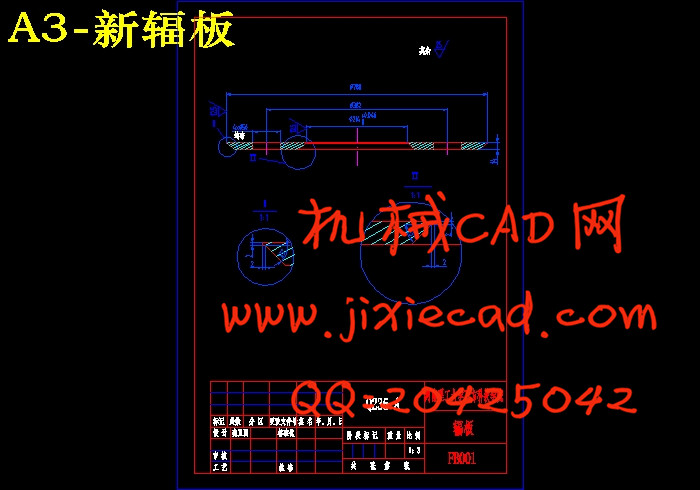

5.5装载装置 71

5.6 清扫装置 72

5.7机架 73

5.8改向滚筒 74

5.9驱动装置架 76

总 结 78

致 谢 79

参考文献 80

带式输送机是广泛应用于煤炭、港口、建设、电厂等工业领域的连续输送设备,它具有运输效率高、运营成本低等优点。随着国民经济的发展,带式输送机的应用越来越广泛。近年来,随着工业技术的发展,带式输送机也不断朝着大运量、长距离、大倾角、高带速、投资费用少、运营费用低、工作可靠、维护方便等方向发展,对其设计技术的要求也越来越高。 为适应地形的要求,用输送带输送一定高度的带式输送机在很多方面有应用。本文着重讨论了带式输送机的结构原理、传动原理、设计计算法则、运行阻力的计算、各点张力的计算等内容,以及各种计算参数的设计计算和校核,尤其对输送带的选用、托辊的选用进行了详细的分析,使设计更加贴切接近实际问题。本文还分析了国内外带式输送机的现状及发展趋势,说明在现代高科技发展的情况下,带式输送机的发展潜力还是很大的。

本文研究了一般固定式带式输送机的设计理论,并根据所设计的要求再结合目前国内的目前的技术要求组装了一套倾角为0度的固定式带式输送机,说明了这套设计符合设计参数的要求

关键字:输送机 发展 结构原理 计算和校核

Abstract

Taking style to transport machine is broad apply to industry field continuation such as coal , port construction, electric power plant transports equipment , that it has transportation is efficient , is in motion and do business cost low grade merit. The application with the development of national economy, taking style to transport machine is more and more broad. In recent years , with the development of industrial technology,the cost direction such as low , working reliably , defending to go to the lavatory taking style to transport machine bringing speed along also unceasingly to grand fortune amounts , long distance , big dip angle , height , investing in cost stopping being in motion and doing business, develops , designs that the technology request is also more and more high to the person. For the request adapting to landform's, use conveyer belt to transport certain altitude's taking style to transport machine having in many aspects applying. Content such as the main body of a book being emphasized having discussed structure principle , drive principle taking style to transport machine , being designing the calculation calculating a law , running resistance's , every tension calculation, calculating and proofreading the parametric design secretly scheming against as well as various, has carried out detailed analysis on the conveyer belt selecting and using , selecting and using supporting a roller especially , has used the problem designing especially appropriate approximation reality. The main body of a book has been analysed taking style to transport machine current situation and developing trend at home and abroad, the potential taking style to transport is still very big under explanation condition developing in modern high technology.

The general stationary type the main body of a book has been studied takes style to transport the machine design theory , in the light of designed that together request still be tied in wedlock is at present domestic at present the technology has demanded assembling to copy a dip angle once for 14 degree of stationary type takes style to transport machine , the cover having explained this has designed that according with the request designing a parameter's.

Key words: Transport machine Develop Structure principle

Secretly scheme against and school core

目录

前 言 1

1 绪 论 3

1.1 皮带运输机的概况 3

1.1.1 皮带运输机的发展史 3

1.1.2皮带运输机基本结构 4

1.1.3 矿用皮带运输机各机型介绍 5

1.2 皮带运输机的发展趋势 10

1.2.1国外皮带运输机技术的现状 10

1.2.2国内皮带运输机技术的现状 11

1.2.3 国内外皮带运输机技术的差距 12

1.2.4 煤矿皮带运输机技术的发展趋势 16

2 皮带运输机的设计计算 18

2.1已知原始数据及工作条件 18

2.2输送带宽度的确定及核算 19

2.2.1带速的确定 19

2.2.2带宽的确定 20

2.2.3输送带宽度的核算 22

2.3圆周驱动力 23

2.3.1计算公式 23

2.3.2主要阻力计算 24

2.3.3特种主要阻力计算 26

2.3.4特种附加阻力计算 27

2.3.5倾斜阻力计算 28

2.4传动功率计算 29

2.4.1 传动滚筒轴功率(

2.4.2 电动机功率计算 29

2.5输送带张力计算 30

2.5.1阻力计算 31

2.5.2 输送带不打滑条件校核 34

2.5.3 输送带下垂度校核 35

2.5.4输送带强度校核计算 36

2.6拉紧力计算 36

2.7传动滚筒,改向滚筒合张力计算 37

2.7.1改向滚筒合张力计算 37

2.7.2 传动滚筒合张力计算 37

2.8 传动滚筒最大扭矩计算 37

3 皮带运输机的传动原理 38

3.1胶带的摩擦传动原理 38

3.2传动装置的牵引力 41

4 传动装置的选用与设计 43

4.1 电机的选用 43

4.2 减速器的选用 44

4.2.1 传动装置的总传动比 44

4.3 液力偶合器 47

4.4 联轴器 48

5皮带运输机部件的选用 52

5.1 输送带 52

5.1.1 输送带的分类: 54

5.1.2 输送带的连接 56

5.2 传动滚筒 57

5.2.1 传动滚筒的作用及类型 57

5.2.2 传动滚筒的选型及设计 58

5.2.3 传动滚筒结构 64

5.2.4传动滚筒的直径验算 65

5.3 拉紧装置 66

5.4 制动装置 69

5.5装载装置 71

5.6 清扫装置 72

5.7机架 73

5.8改向滚筒 74

5.9驱动装置架 76

总 结 78

致 谢 79

参考文献 80