设计简介

摘 要

汽车制动性能检测设备是应用于新车研究开发的实验、新车的出厂检验和交通管理部门对上路车辆定期检验的测试装置。鉴于目前我国汽车工业的迅速发展和有关法规的出台,以及我国汽车检测站设备的落后状况,汽车制动性能检测设备的研究尤其受到关注。

汽车制动性能检测设备的研究是一门综合性应用科学,涉及诸多学科和领域。本论文的主要目标是设计一套汽车制动性能试验台,使之具备功能齐全、性能良好、使用方便、高精度、高可靠性的特点。

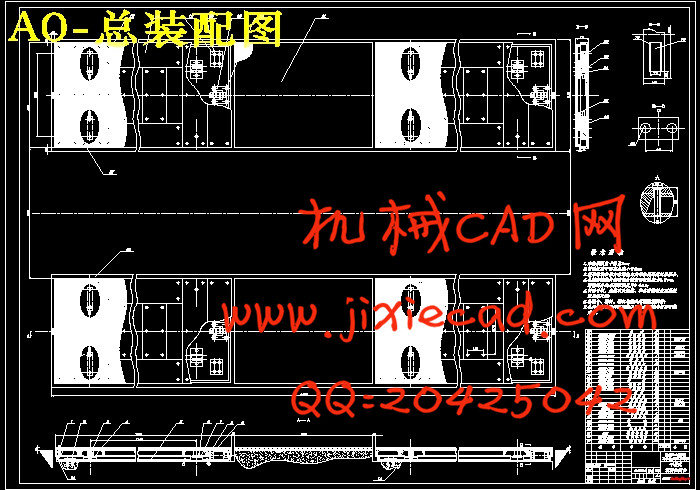

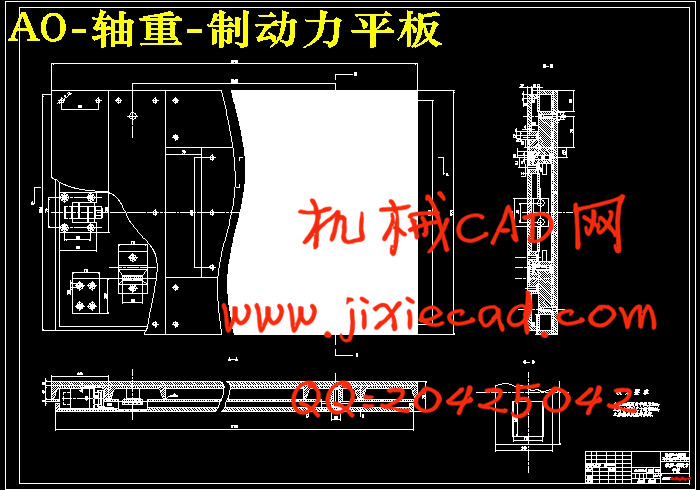

本文介绍了设计对象—平板式制动性能检测台的结构和工作原理,这种试验台能较好地模拟道路检测,采用动态检测方法,对汽车制动性能的检测结果具有真实性。制动板底部采用滚珠滑动、梯形槽定位的方式。这样的设计和以往的滚轮式设计方案相比有一定新意。

关键词:平板式;检测台;制动;动态;结构

ABSTRACT

The automotive braking performance measuring and controlling system is an testing device which is widely used in many fields,such as the test of new car design,the roll-off test of new car and the regular test of automotive which is held by the traffic management department for the automotives on the road. According to the rapid development of automotive industry and the situation that the device of our automotive performance measuring has large distance with dereloped coutries,people have paid more attention to the research of the automotive braking performance measuring and controlling system.

The research of the automotive braking performance measurement and control system is comprehensive application science including many subjects and fields. The main aim of this thesis is to design an automotive braking performance measuring system and make it more multifunctional,good-performance,easy-used and with high precise and reliability.

This thesis introduces the configuration and working principle of brake system. Following the principle and the function requirement. This kind of tester can simulate road detecting better,adopting moving detecting methods. It will make the detecting results more accuracy. The bottom of the brake plate adopts rolling pearl skid,rectangle slut alignment. Compare to past design scheme,such research has more creation.

Keywords:Plate; Station; Brake;Dynamic;Structure

汽车制动性能检测设备是应用于新车研究开发的实验、新车的出厂检验和交通管理部门对上路车辆定期检验的测试装置。鉴于目前我国汽车工业的迅速发展和有关法规的出台,以及我国汽车检测站设备的落后状况,汽车制动性能检测设备的研究尤其受到关注。

汽车制动性能检测设备的研究是一门综合性应用科学,涉及诸多学科和领域。本论文的主要目标是设计一套汽车制动性能试验台,使之具备功能齐全、性能良好、使用方便、高精度、高可靠性的特点。

本文介绍了设计对象—平板式制动性能检测台的结构和工作原理,这种试验台能较好地模拟道路检测,采用动态检测方法,对汽车制动性能的检测结果具有真实性。制动板底部采用滚珠滑动、梯形槽定位的方式。这样的设计和以往的滚轮式设计方案相比有一定新意。

关键词:平板式;检测台;制动;动态;结构

ABSTRACT

The automotive braking performance measuring and controlling system is an testing device which is widely used in many fields,such as the test of new car design,the roll-off test of new car and the regular test of automotive which is held by the traffic management department for the automotives on the road. According to the rapid development of automotive industry and the situation that the device of our automotive performance measuring has large distance with dereloped coutries,people have paid more attention to the research of the automotive braking performance measuring and controlling system.

The research of the automotive braking performance measurement and control system is comprehensive application science including many subjects and fields. The main aim of this thesis is to design an automotive braking performance measuring system and make it more multifunctional,good-performance,easy-used and with high precise and reliability.

This thesis introduces the configuration and working principle of brake system. Following the principle and the function requirement. This kind of tester can simulate road detecting better,adopting moving detecting methods. It will make the detecting results more accuracy. The bottom of the brake plate adopts rolling pearl skid,rectangle slut alignment. Compare to past design scheme,such research has more creation.

Keywords:Plate; Station; Brake;Dynamic;Structure

目 录

摘要 I

ABSTRACT II

第1章 绪论 1

1.1 汽车制动性能检测系统简介 1

1.2 汽车制动性能检测系统研究的意义 2

1.3 汽车制动性能检测技术的发展和国内外目前的状况 2

1.4 主要研究内容及技术途径 3

第2章 汽车制动系统及其性能的评价参数 4

2.1 对汽车制动系统的技术要求 4

2.2 汽车制动系统的常见故障 4

2.3 制动性能评价参数 5

2.3.1 制动效能 6

2.3.2 制动抗热衰退性 7

2.3.3 制动稳定性 8

2.4 地面制动力与制动器制动力及附着力的关系 8

2.5 本章小结 9

第3章 平板式制动性能检测台的设计方案 10

3.1 平板式制动性能试验台的结构 10

3.2 工作原理 12

3.3 设计依据和要求 16

3.3.1设计依据 16

3.3.2 适用范围 16

3.3.3 功能 16

3.4 本章小结 17

第4章 平板式汽车制动检测台设计 18

4.1 总体尺寸确定 18

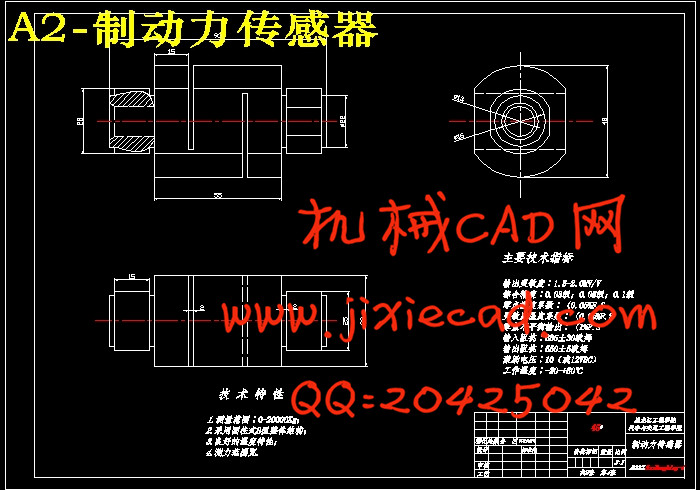

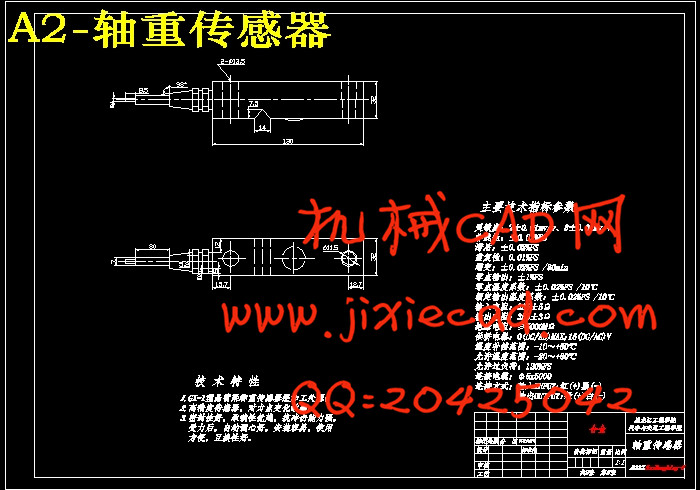

4.2 传感器的选择 20

4.3 材料的选择 24

4.4 制动检测部分结构设计 24

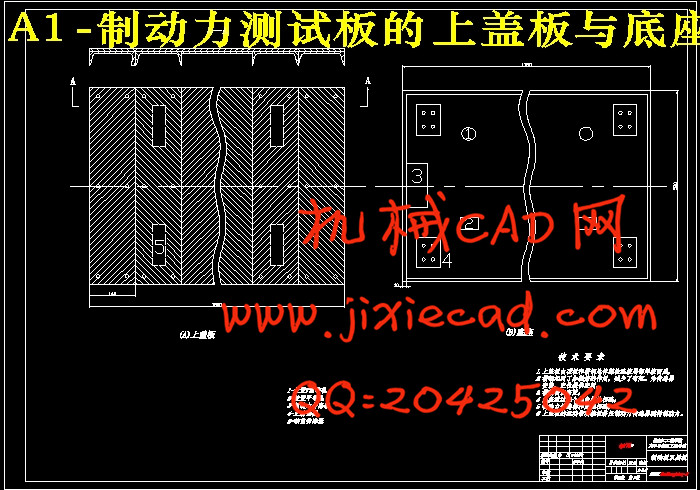

4.4.1 制动板底座的设计 24

4.4.2 制动板上盖板的设计 25

4.4.3 轴重传感器安装 25

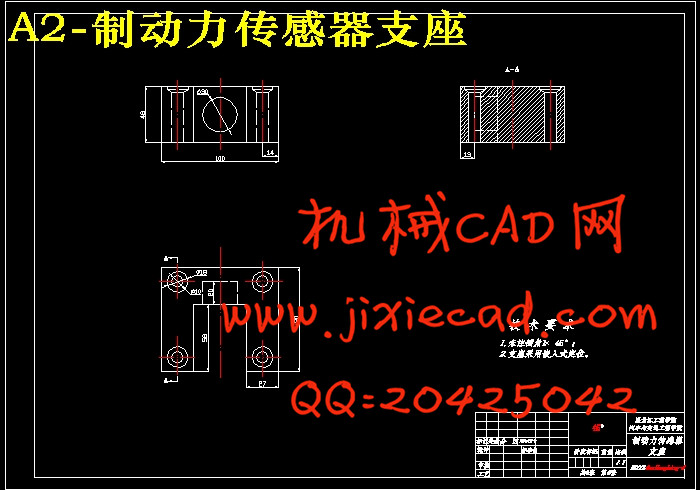

4.4.4 制动力传感器支座设计 26

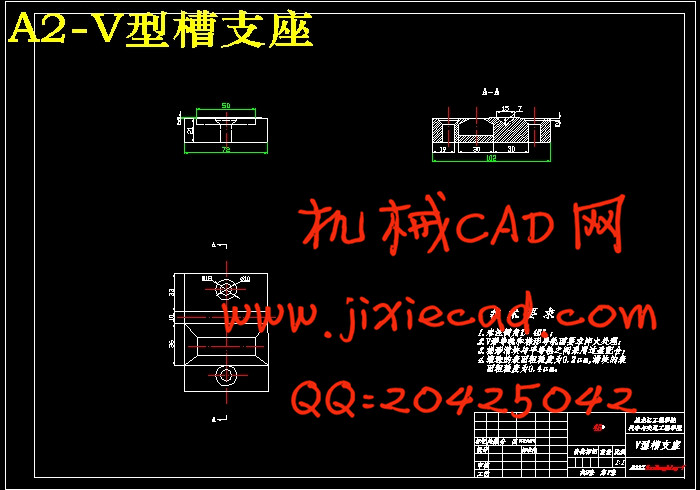

4.4.5 V型槽支座的设计 27

4.5 零件的较核 28

4.6 本章小结 32

结论 33

参考文献 33

致谢 35