设计简介

摘 要

现代汽车的动力装置几乎都是采用往复活塞式内燃机,它具有体积小、质量轻、工作可靠、使用方便等优点,但其性能与汽车的动力性和经济性之间存在着较大的矛盾。汽车需要克服作用在它上面的阻力,才能起步和正常的行驶。汽车变速器和主减速器,它们可以使驱动车轮的扭矩增大为发动机扭矩的若干倍,又可以使其转速减小到发动机转速的若干分之一。

传动系有两个功能:传送发动机到驱动轮之间的动力和改变转矩的大小。由此可见传动系统是汽车非常重要的组成部分,从而对汽车传动系的结构分析与设计计算也就显非常重要了。

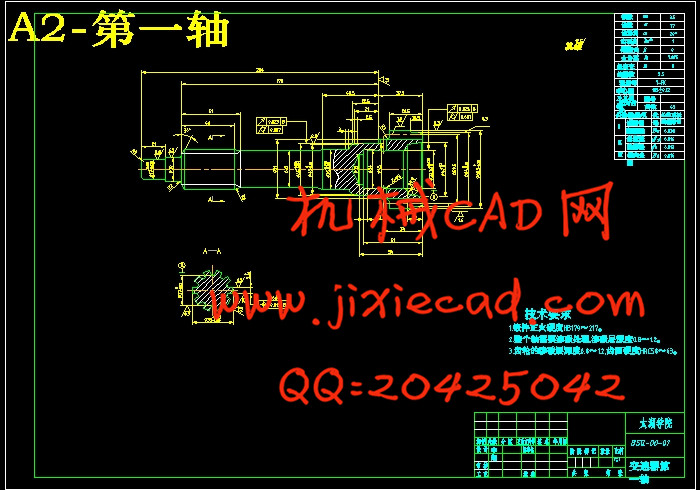

主要设计内容有变速器的布置方案与设计,齿轮的强度计算与校核;主减速器主、从动锥齿轮的支承方案选择,主减速器主要参数选择与计算;差速器的设计。并且用AutoCAD绘出变速器和差速器的装配图还有部分零件图。

通过对微型轿车变速器的设计,不仅满足了现代汽车的动力性,也提高了其经济性,满足了市场现有的需求。

关键词:传动系;变速器;主减速器;差速器

Abstract

The Reciprocating Engine are almost used as the power plant of modern motor, which is advanced in the small volume, light weight, reliability and convenience. However, there is contradiction between the performance and the dynamic and economy of the vehicle.As to start and drive smoothly, the vehicle has to come over the resistance. The torque of the wheels could be increased as several times of the engine or be decreased one of a number of points of the engine speed by the transmission and the main reducer.

The transmission has two function transmit the engine power to the wheels and change the torque. So the transmission is one of the most important parts of the vehicle. The Analysis and design of the transmission are also vital.

The design is consisted of Layout and design of the programme of the transmission, the strength calculation and checking of the gear, the support programme of the final drive active bevel gear and driven bevel gear, the main parameters choosing and calculation of the main reducer and the Differential design. The assembly of the main reducer and the differential and the parts must be drawn with the software AUTOCAD.

According to the transmission design of the mini vehicle, the dynamic ,economy and the market of the modern vehicle are satisfied.

Key words: Power train; Transmission; Final drive; Differential

目 录

摘 要 IIIAbstract III

目 录 V

1 绪论 1

1.1 本课题的研究内容和意义 1

1.2 国内外的发展概况 1

1.3本课题应达到的要求 2

2 变速器传动机构布置方案 3

2.1 传动机构布置方案分析 3

2.1.1 两轴式和中间轴式变速器 3

2.1.2 三轴式 3

2.1.3 倒挡的形式和布置方案 4

2.2 零部件布置方案分析 4

2.2.1 齿轮形式 4

2.2.2 换挡的结构形式 4

2.2.3 防止自动脱档的措施 5

2.2.4 轴承形式 5

2.3 本章小结 5

3 变速器主要参数的选择及设计计算 6

3.1 挡位数确定 6

3.2 传动比 6

3.3 中心距 8

3.4 齿轮参数 8

3.5 各档齿轮齿数的分配 9

3.6 齿轮的设计计算 11

3.7 本章小结 12

4 变速器主要结构元件的校核 13

4.1 齿轮损坏的原因及形式 13

4.2 齿轮材料的选择原则 13

4.3 轮齿强度校核 14

4.3.1 齿轮的接触强度 14

4.3.2 齿轮的接触强度 15

4.4 轴的强度校核 18

4.5 轴承的校核 22

4.5.1 输入轴轴承校核 22

4.5.2 输出轴轴承校核 23

4.6 本章小结 24

5 结论与展望 25

致 谢 26

参考文献 26