设计简介

摘 要

轴承作为汽车的变速器的核心部分,随着汽车工业的发展,其可靠性越发被人们所关注。轴与轴承、轴套的配合为过盈配合,需要较大的压入力,并且随着压入长度的增大而增大,若不能很好的保证轴承的可靠性,很可能会引发交通事故。然而压装过程对轴承的可靠性起着决定性的作用,要将两个轴套均匀地压入无缝钢管两端,并且要保证两轴套间的相对位置,轴套压到底部后,在相应的位置还要钻攻螺纹孔,传统的人为手工压装,其弊端明显,不仅劳动强度大,效率低下,还无法满足精度要求。本次设计的装置采用液压传动,通过电动机带动皮带轮将动力传递至丝杠支承 ,使丝杠转动,从而带动装有螺母的压头移动,将轴套压入至指定位置,同时保证轴套与钻孔之间的相对位置,并通过安全离合器的作用,断开电机完成压装。此装置不仅可以解决在人为进行装配时的大强度、低精度等问题,还能大大地提高了效率。

关键词:汽车变速器;过盈配合;轴、轴承和轴套;轴承压装装置

Abstract

As a core part of the transmission of the car, with the development of the automobile industry, the reliability of bearings are concerned about by more and more people. Shaft bearings, bushings with an interference fit, requires a large amount of pressing force, and increases with the length, if can not ensure the reliability of the bearing, is may lead to accidents . However, the process of pressing plays a decisive role in the bearing reliability , two sleeve pressure evenly into both ends of seamless steel pipe, and to ensure that the relative position between the two bushings the sleeve pressure in the end portion in the corresponding the location but also drilling and tapping threaded holes, traditional press-fit the human hand, its obvious drawbacks, not only labor-intensive, inefficient and unable to meet the accuracy requirements.The design of the device adopts hydraulic transmission, driven by the motor pulley to transmit power to the screw supporting the screw rotation, so as to drive the indenter mobile air-nut pressed into the sleeve to the specified location, at the same time assuring the shaft the relative position between the drilling. This device not only solve the artificial labor intensity when assembly and low positioning accuracy,but also greatly improve efficiency.

Key words: automobile transmission; interference fit ; shaft, bearing and shaft sleeve; bearing pressing device

目 录

摘 要 III

Abstract IV

1 绪论 1

1.1 汽车变速器轴承的专用压机的研究内容和意义 1

1.1.1 设计轴承专用压机的目的和意义 1

1.1.2 轴承专用压机的研究范围 1

1.1.3 轴承专用压机需达到的技术要求 1

1.2 轴承及其压装在国内外的发展概况 2

1.2.1 轴承及其产业在国内外的发展概况 2

1.2.2 轴承压装在国内外的发展概况 3

1.3 本课题应达到的要求 4

1.3.1 液压机的工作原理 4

1.3.2 液压机的组成部分 4

1.3.3 液压机的特点 5

2 汽车变速器的介绍 8

2.1 汽车变速器的工作原理 8

2.2 汽车变速器的分类 8

2.3 汽车变速器的作用 9

2.4 汽车变速器的主要组成部分 9

2.5 轴承的介绍 10

3 设计方案的确定与选择 14

3.1 机械设计步骤 14

3.2 设计思路 14

3.3 设计方案 19

3.3.1 电动机类型的选择 19

3.3.2 传动方式的选择 20

3.3.3 液压机的选择 22

3.3.4 液压缸的设计与选择 22

3.3.5 压板的设计 22

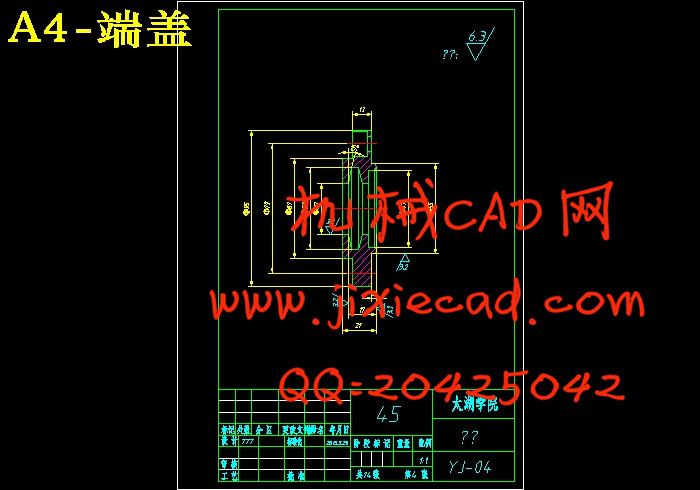

3.3.6 压头的设计 23

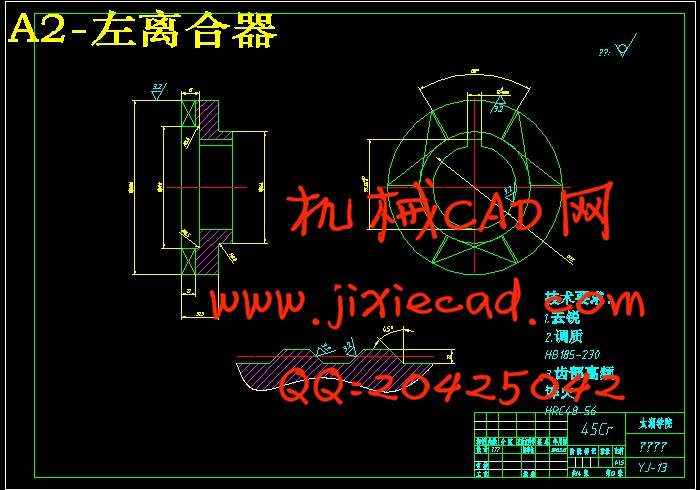

3.3.7 离合器的选择 23

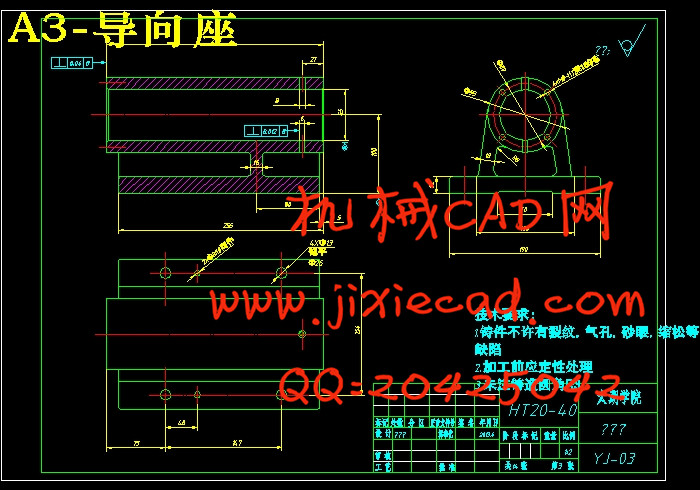

3.4 总体方案的拟定 24

3.5 方案可行性分析及改进 24

4 系统原理及设计计算 26

4.1 系统原理及硬件框图 26

4.2 工作原理 26

4.3 设计计算 26

4.3.1 压入力计算 26

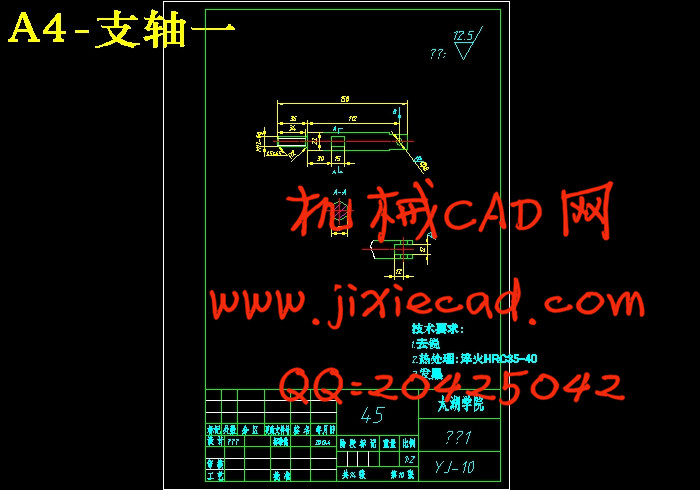

4.3.2 螺杆计算 28

4.3.3 电动机的功率计算 29

4.4 皮带轮的选择 31

4.5 轴承的选择 32

4.6 螺栓强度计算 32

5 结论与展望 33

致 谢 34

参考文献 35