设计简介

摘 要

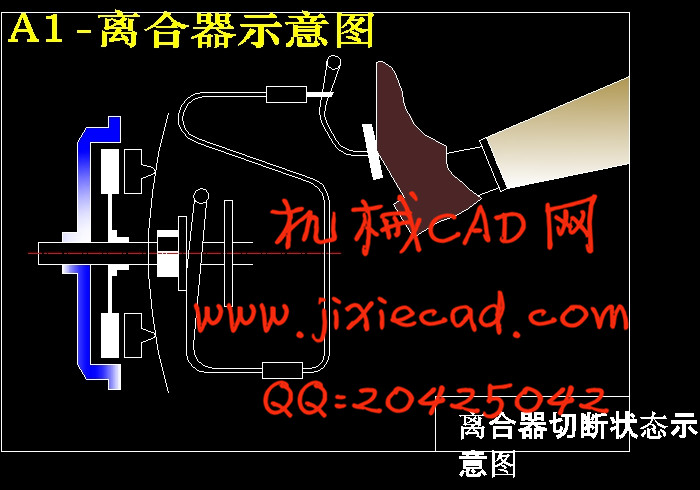

以内燃机在作为动力的机械传动汽车中,离合器是作为一个独立的总成而存在的。离合器通常装在发动机与变速器之间,其主动部分与发动机飞轮相连,从动部分与变速器相连。为各类型汽车所广泛采用的摩擦离合器,实际上是一种依靠其主、从动部分间的摩擦来传递动力且能分离的机构。离合器的主要功用是切断和实现发动机与传动系平顺的接合,确保汽车平稳起步;在换挡时将发动机与传动系分离,减少变速器中换档齿轮间的冲击;在工作中受到较大的动载荷时,能限制传动系所承受的最大转矩,以防止传动系个零部件因过载而损坏;有效地降低传动系中的振动和噪音。

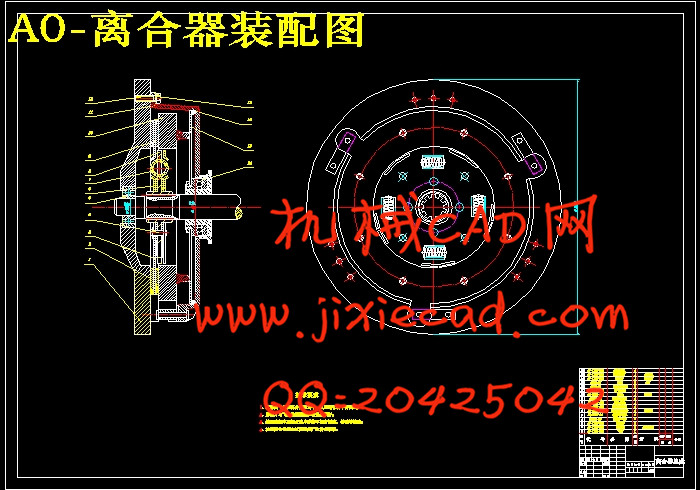

本车设计采用单片螺旋弹簧离合器。本车采用的摩擦式离合器是因为其结构简单,可靠性强,维修方便,目前大多数汽车都采用这种形式的离合器。而采用干式离合器是因为湿式离合器大多是多盘式离合器,用于需要传递较大转矩的离合器,而该车型不在此列。采用螺旋弹簧离合器是因为螺旋弹簧离合器具有很多优点:首先,由于螺旋弹簧具有非线性特性,因此可设计成当摩擦片磨损后,弹簧压力几乎可以保持不变,且可减轻分离离合器时的踏板力,使操纵轻便;其次,螺旋弹簧的安装位置对离合器轴的中心线是对的,因此其压力实际上不受离心力的影响,性能稳定,平衡性也好;再者,螺旋弹簧本身兼起压紧弹簧和分离杠杆的作用,使离合器的结构大为简化,零件数目减少,质量减小并显著地缩短了其轴向尺寸;另外,由于螺旋弹簧与压盘是以整个圆周接触,使压力分布均匀,摩擦片的接触良好,磨损均匀,也易于实现良好的散热通风等。由于螺旋弹簧离合器具有上述一系列的优点,并且制造螺旋弹簧的工艺水平也在不断地提高,因而这种离合器在轿车及微型、轻型客车上已得到广泛的采用,而且逐渐扩展到载货汽车上。从动盘选择单片式从动盘是一位其结构简单,调整方便。压盘驱动方式采用传动片式是因为其没有太明显的缺点且简化了结构,降低了装配要求又有利于压盘定中。选择拉式离合器是因为其较拉式离合器零件数目更少,结构更简化,轴向尺寸更小,质量更小;并且分离杠杆较大,使其踏板操纵力较轻。

关键字:螺旋弹簧离合器 螺旋弹簧 离合器 摩擦片 减振盘

Abstract

To the internal combustion engine as the driving force in the mechanical transmission car, the clutch is the assembly as an independent existence. Clutch is usually packed in between the engine and transmission, the active part connected with the engine flywheel, driven in part connected with the transmission. For various types of motor vehicles is widely used in friction clutch, in fact, is a kind of rely on their owners, driven in part to friction between the transmission power can separate agencies. The main function of the clutch is cut off and the engine and transmission system to achieve smooth joint, to ensure that a smooth start; in the shift will be separated from the engine and power train to reduce the transmission of shocks between the gear shift; in its work by the larger dynamic load when the transmission system to limit the burden of the maximum torque to prevent the powertrain components of the damage due to overload; effectively reduce the transmission lines of the vibration and noise.

The design uses a single car coil spring clutch. The car used clutch friction because of its simple structure, reliability, maintenance convenience, the majority of vehicles currently using this form of clutch. The use of dry-type clutch is because most of the wet clutch is a multi-disc clutch, for the need for greater torque transmission clutch, and the model is not included. The use of coil spring coil spring clutch because the clutch has many advantages: First, the coil spring has nonlinear characteristics, it can be designed to wear when the friction plate, the spring pressure can be maintained almost unchanged, and reduce the separation of the clutch pedal at the time of ability to manipulate light; Secondly, the coil spring on the installation location of the centerline of the clutch shaft is right, so the pressure is not in fact the effects of centrifugal force, stable performance, or balance; In addition, the coil spring itself, and from compress the spring and split the role of leverage, so that greatly simplified the structure of the clutch, spare parts to reduce the number, quality and significantly reduced to reduce the size of its axial; In addition, as a result of coil spring and the pressure plate contacts the entire circumference, so that the pressure distribution, good contacts with friction plate, wear uniform, but also easy to achieve good heat ventilation. As the spiral spring clutch with a series of advantages of the above, and coil spring manufacturing process has been to raise the level, so that the clutch in the car and micro, light bus has been widely used, and gradually extended to the cargo vehicle . Follower plate choice of single-chip set is a follower of its simple structure, convenient adjustment. Platen drive transmission chip used is not too much because of its obvious shortcomings and to simplify the structure, assembly requirements and reduces the pressure plate will be in favor of. Pull-type clutch choice because of its parts than the number of pull-type clutch less, more streamlined structure, the axial size smaller, the quality of even smaller; and a greater separation of the lever so that it is relatively small pedal manipulation.

Keywords: spiral spring clutch coil spring clutch friction plate

vibration plate

目录

第1章 绪论 4

1.1 引言 4

1.2 离合器的发展 4

1.3 螺旋弹簧离合器的结构及其优点 5

1.4 设计内容 7

1.5 PRO/E软件的特点 7

1.6 方案的确定 8

第2章 基本尺寸的选择 9

2.1 离合器基本性能关系式 9

2.2 后背系数的选择 9

2.3摩擦片外径的确定 9

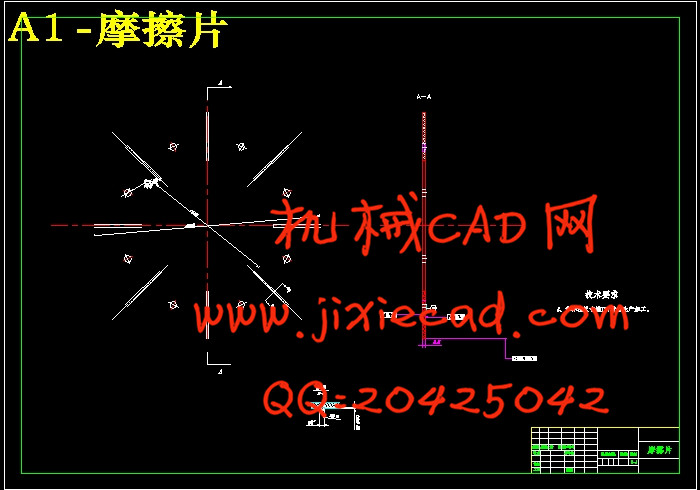

2.4摩擦片pro/E绘图过程 11

2.5本章小结 13

第3章 主动部分设计 14

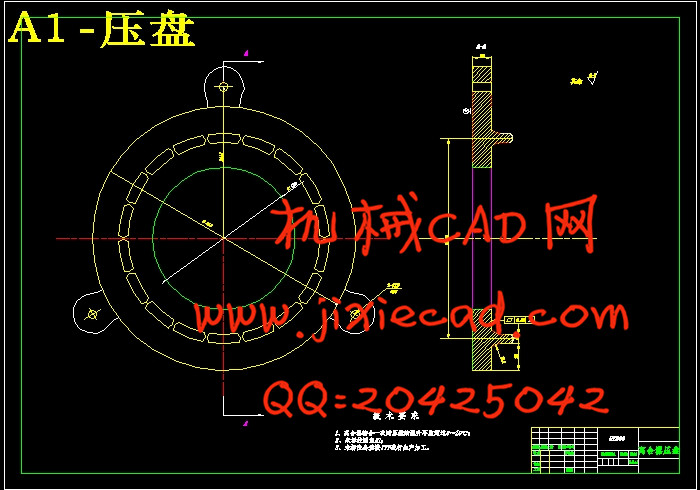

3.1压盘设计 14

3.1.1压盘参数的选择及校核 14

3.1.2压盘pro/E绘图过程 14

3.2 离合器的设计 16

3.3 传动片设计 16

3.4 本章小结 17

第4章 从动盘总成设计 18

4.1摩擦片设计 18

4.2从动盘毂设计 18

4.3从动片设计 20

4.4扭转减震器设计 20

4.4.1扭转减震器的功能 20

4.4.2扭转减震器的结构类型的选择 22

4.4.3扭转减震器的参数确定 23

4.4.4减震弹簧的尺寸确定 24

4.4.4扭转减震器的PRO/E绘图过程 25

4.5本章小结 28

第5章 螺旋弹簧设计 29

5.1螺旋弹簧的概念 29

5.2螺旋弹簧的弹性特性 29

5.3螺旋弹簧的强度计算 31

5.4螺旋弹簧的基本参数的选择 32

5.5螺旋弹簧的PRO/E绘图过程 34

5.6本章小结 36

结论 37

致谢 38

参考文献 39

以内燃机在作为动力的机械传动汽车中,离合器是作为一个独立的总成而存在的。离合器通常装在发动机与变速器之间,其主动部分与发动机飞轮相连,从动部分与变速器相连。为各类型汽车所广泛采用的摩擦离合器,实际上是一种依靠其主、从动部分间的摩擦来传递动力且能分离的机构。离合器的主要功用是切断和实现发动机与传动系平顺的接合,确保汽车平稳起步;在换挡时将发动机与传动系分离,减少变速器中换档齿轮间的冲击;在工作中受到较大的动载荷时,能限制传动系所承受的最大转矩,以防止传动系个零部件因过载而损坏;有效地降低传动系中的振动和噪音。

本车设计采用单片螺旋弹簧离合器。本车采用的摩擦式离合器是因为其结构简单,可靠性强,维修方便,目前大多数汽车都采用这种形式的离合器。而采用干式离合器是因为湿式离合器大多是多盘式离合器,用于需要传递较大转矩的离合器,而该车型不在此列。采用螺旋弹簧离合器是因为螺旋弹簧离合器具有很多优点:首先,由于螺旋弹簧具有非线性特性,因此可设计成当摩擦片磨损后,弹簧压力几乎可以保持不变,且可减轻分离离合器时的踏板力,使操纵轻便;其次,螺旋弹簧的安装位置对离合器轴的中心线是对的,因此其压力实际上不受离心力的影响,性能稳定,平衡性也好;再者,螺旋弹簧本身兼起压紧弹簧和分离杠杆的作用,使离合器的结构大为简化,零件数目减少,质量减小并显著地缩短了其轴向尺寸;另外,由于螺旋弹簧与压盘是以整个圆周接触,使压力分布均匀,摩擦片的接触良好,磨损均匀,也易于实现良好的散热通风等。由于螺旋弹簧离合器具有上述一系列的优点,并且制造螺旋弹簧的工艺水平也在不断地提高,因而这种离合器在轿车及微型、轻型客车上已得到广泛的采用,而且逐渐扩展到载货汽车上。从动盘选择单片式从动盘是一位其结构简单,调整方便。压盘驱动方式采用传动片式是因为其没有太明显的缺点且简化了结构,降低了装配要求又有利于压盘定中。选择拉式离合器是因为其较拉式离合器零件数目更少,结构更简化,轴向尺寸更小,质量更小;并且分离杠杆较大,使其踏板操纵力较轻。

关键字:螺旋弹簧离合器 螺旋弹簧 离合器 摩擦片 减振盘

Abstract

To the internal combustion engine as the driving force in the mechanical transmission car, the clutch is the assembly as an independent existence. Clutch is usually packed in between the engine and transmission, the active part connected with the engine flywheel, driven in part connected with the transmission. For various types of motor vehicles is widely used in friction clutch, in fact, is a kind of rely on their owners, driven in part to friction between the transmission power can separate agencies. The main function of the clutch is cut off and the engine and transmission system to achieve smooth joint, to ensure that a smooth start; in the shift will be separated from the engine and power train to reduce the transmission of shocks between the gear shift; in its work by the larger dynamic load when the transmission system to limit the burden of the maximum torque to prevent the powertrain components of the damage due to overload; effectively reduce the transmission lines of the vibration and noise.

The design uses a single car coil spring clutch. The car used clutch friction because of its simple structure, reliability, maintenance convenience, the majority of vehicles currently using this form of clutch. The use of dry-type clutch is because most of the wet clutch is a multi-disc clutch, for the need for greater torque transmission clutch, and the model is not included. The use of coil spring coil spring clutch because the clutch has many advantages: First, the coil spring has nonlinear characteristics, it can be designed to wear when the friction plate, the spring pressure can be maintained almost unchanged, and reduce the separation of the clutch pedal at the time of ability to manipulate light; Secondly, the coil spring on the installation location of the centerline of the clutch shaft is right, so the pressure is not in fact the effects of centrifugal force, stable performance, or balance; In addition, the coil spring itself, and from compress the spring and split the role of leverage, so that greatly simplified the structure of the clutch, spare parts to reduce the number, quality and significantly reduced to reduce the size of its axial; In addition, as a result of coil spring and the pressure plate contacts the entire circumference, so that the pressure distribution, good contacts with friction plate, wear uniform, but also easy to achieve good heat ventilation. As the spiral spring clutch with a series of advantages of the above, and coil spring manufacturing process has been to raise the level, so that the clutch in the car and micro, light bus has been widely used, and gradually extended to the cargo vehicle . Follower plate choice of single-chip set is a follower of its simple structure, convenient adjustment. Platen drive transmission chip used is not too much because of its obvious shortcomings and to simplify the structure, assembly requirements and reduces the pressure plate will be in favor of. Pull-type clutch choice because of its parts than the number of pull-type clutch less, more streamlined structure, the axial size smaller, the quality of even smaller; and a greater separation of the lever so that it is relatively small pedal manipulation.

Keywords: spiral spring clutch coil spring clutch friction plate

vibration plate

目录

第1章 绪论 4

1.1 引言 4

1.2 离合器的发展 4

1.3 螺旋弹簧离合器的结构及其优点 5

1.4 设计内容 7

1.5 PRO/E软件的特点 7

1.6 方案的确定 8

第2章 基本尺寸的选择 9

2.1 离合器基本性能关系式 9

2.2 后背系数的选择 9

2.3摩擦片外径的确定 9

2.4摩擦片pro/E绘图过程 11

2.5本章小结 13

第3章 主动部分设计 14

3.1压盘设计 14

3.1.1压盘参数的选择及校核 14

3.1.2压盘pro/E绘图过程 14

3.2 离合器的设计 16

3.3 传动片设计 16

3.4 本章小结 17

第4章 从动盘总成设计 18

4.1摩擦片设计 18

4.2从动盘毂设计 18

4.3从动片设计 20

4.4扭转减震器设计 20

4.4.1扭转减震器的功能 20

4.4.2扭转减震器的结构类型的选择 22

4.4.3扭转减震器的参数确定 23

4.4.4减震弹簧的尺寸确定 24

4.4.4扭转减震器的PRO/E绘图过程 25

4.5本章小结 28

第5章 螺旋弹簧设计 29

5.1螺旋弹簧的概念 29

5.2螺旋弹簧的弹性特性 29

5.3螺旋弹簧的强度计算 31

5.4螺旋弹簧的基本参数的选择 32

5.5螺旋弹簧的PRO/E绘图过程 34

5.6本章小结 36

结论 37

致谢 38

参考文献 39