设计简介

摘要

砖混结构的墙体砌筑是工业与民用建筑的主要工作,墙体砌筑的质量直接影响着整个建筑工程的质量。本设计砌筑机械手是墙体砌筑工程中的重要的设备之一,它虽然不能取代工人的体力劳动,但可以改善工人的劳动强度,会大大提高作业的安全性、舒适性和工作效率,也会大大降低劳动成本。

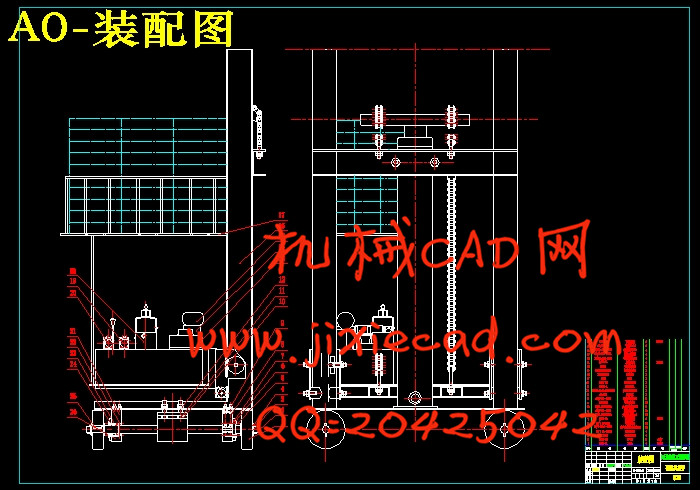

砌筑机械手有四部分组成:平移系统、起升系统、液压系统、灰浆输送系统。

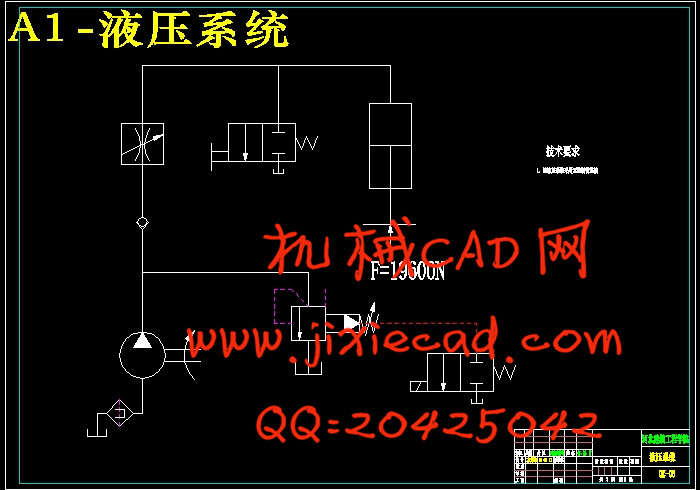

小车长一米,宽零点八米。起升系统采用手动液压堆高车的起升原理,改进后,通过液压泵站来驱动。液压泵站由电瓶,直流电动机,油箱,液压泵,先导式溢流阀,调速阀,手动换向阀,电磁换向阀等组成。平移系统采用双出轴电机直接驱动车轮的方式实现平移。

本设计书主要由四部分组成,第一部分是砌筑机械手的总体设计;第二部分是起升机构和平移机构的设计和校核,第三部分是液压泵站的设计;第四部分是灰浆泵的选型和灰浆钳的设计。

关键词:建筑 砌筑 双出轴

ABSTRACT

Masonry wall brick and concrete structure of industrial and civil building is the main body of work, building directly influences the quality of construction engineering quality. The design of the building project wall lining manipulator is one of the important equipment, although it can't replace manual Labour, but the workers can improve the labor intensity, will greatly improve the operation efficiency and safety, comfort, also can greatly reduce the cost of labor.

Cars have four walls part: translation system, hoisting system and hydraulic system, mortar conveying system.

Car meter long, wide 0.8 meters. Lifting system adopts full hydraulic car manual lifting principle, improvement, through hydraulic pump station to drive. Hydraulic pump station by the battery, dc, tank, pump, polot relief valve, valve, speed manual directional control valves, electromagnetic reversing valves, etc. Translation system adopt dual axis motor driven directly out of wheel translation.

This design mainly consists of four parts, the first part is the overall design of car brick wall, The second part is lifting mechanism and the design and check, the third part is the design of hydraulic pump station, The fourth part is the selection and mortar mortar pump design of pliers.

KEY WORDS:building laying Double the shaft

目录

第1章 概述··········································································1

第2章 总体设计····································································3

2.1 概述············································································3

2.2 确定总体设计方案····························································4

2.2.1选择确定总体参数······················································4

2.2.2总体设计原则····························································4

2.2.砌筑机械手的工作机构···················································5

2.2.4主要技术参数性能·······················································5

第3章 升降工作台设计··························································6

3.1 升降工作台概述·······························································6

3.1.1升降工作台组成························································6

3.2 升降工作台方案确定························································16

3.3 升降工作台材料的选择·····················································18

3.4 液压系统设计································································22

3.5 升降平台校核································································28

3.6 横向传动方案确定···························································29

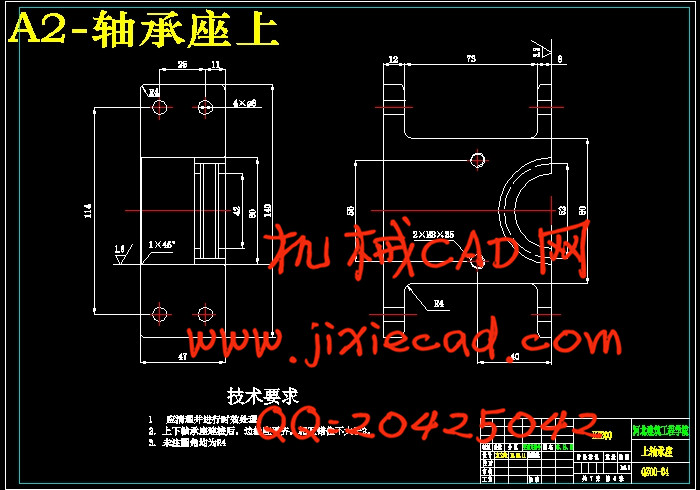

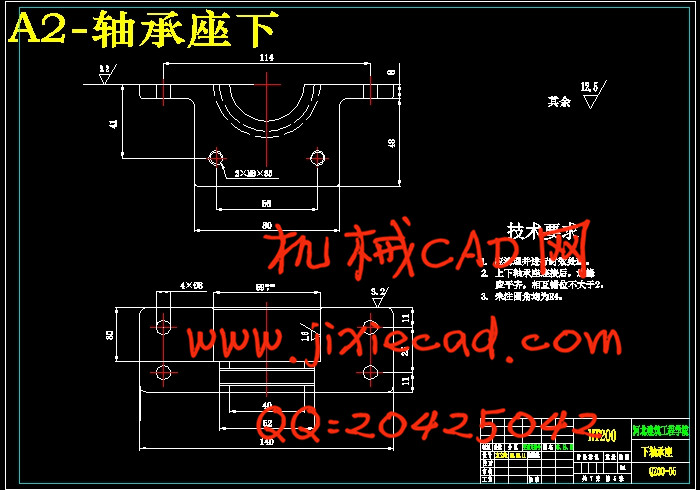

3.7 轴承的选择及校核···························································30

3.8 辅助装置的设计·····························································44

第4章 砖料提升系统设计······················································45

4.1 砖料提升系统概述···························································45

4.2 砖料提升系统方案选择·····················································45

第5章 灰浆输送系统设计·····················································49

第6章 总体布置·································································53

第7章 毕业设计小节···························································53

参考文献············································································55

毕业实习报告······································································01

附录或后记·········································································01

砖混结构的墙体砌筑是工业与民用建筑的主要工作,墙体砌筑的质量直接影响着整个建筑工程的质量。本设计砌筑机械手是墙体砌筑工程中的重要的设备之一,它虽然不能取代工人的体力劳动,但可以改善工人的劳动强度,会大大提高作业的安全性、舒适性和工作效率,也会大大降低劳动成本。

砌筑机械手有四部分组成:平移系统、起升系统、液压系统、灰浆输送系统。

小车长一米,宽零点八米。起升系统采用手动液压堆高车的起升原理,改进后,通过液压泵站来驱动。液压泵站由电瓶,直流电动机,油箱,液压泵,先导式溢流阀,调速阀,手动换向阀,电磁换向阀等组成。平移系统采用双出轴电机直接驱动车轮的方式实现平移。

本设计书主要由四部分组成,第一部分是砌筑机械手的总体设计;第二部分是起升机构和平移机构的设计和校核,第三部分是液压泵站的设计;第四部分是灰浆泵的选型和灰浆钳的设计。

关键词:建筑 砌筑 双出轴

ABSTRACT

Masonry wall brick and concrete structure of industrial and civil building is the main body of work, building directly influences the quality of construction engineering quality. The design of the building project wall lining manipulator is one of the important equipment, although it can't replace manual Labour, but the workers can improve the labor intensity, will greatly improve the operation efficiency and safety, comfort, also can greatly reduce the cost of labor.

Cars have four walls part: translation system, hoisting system and hydraulic system, mortar conveying system.

Car meter long, wide 0.8 meters. Lifting system adopts full hydraulic car manual lifting principle, improvement, through hydraulic pump station to drive. Hydraulic pump station by the battery, dc, tank, pump, polot relief valve, valve, speed manual directional control valves, electromagnetic reversing valves, etc. Translation system adopt dual axis motor driven directly out of wheel translation.

This design mainly consists of four parts, the first part is the overall design of car brick wall, The second part is lifting mechanism and the design and check, the third part is the design of hydraulic pump station, The fourth part is the selection and mortar mortar pump design of pliers.

KEY WORDS:building laying Double the shaft

目录

第1章 概述··········································································1

第2章 总体设计····································································3

2.1 概述············································································3

2.2 确定总体设计方案····························································4

2.2.1选择确定总体参数······················································4

2.2.2总体设计原则····························································4

2.2.砌筑机械手的工作机构···················································5

2.2.4主要技术参数性能·······················································5

第3章 升降工作台设计··························································6

3.1 升降工作台概述·······························································6

3.1.1升降工作台组成························································6

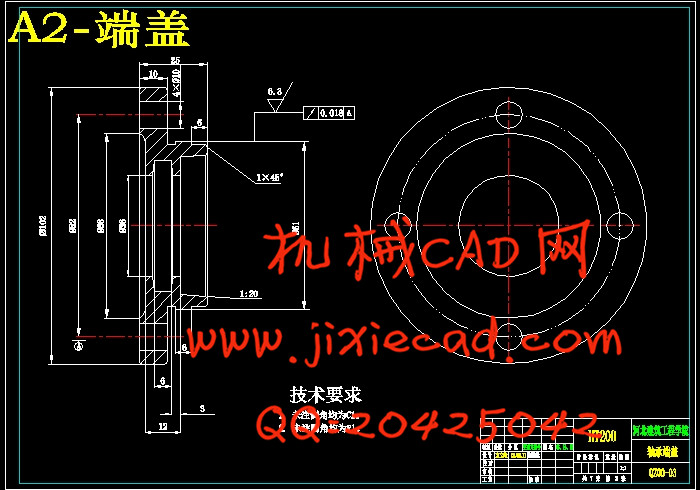

3.2 升降工作台方案确定························································16

3.3 升降工作台材料的选择·····················································18

3.4 液压系统设计································································22

3.5 升降平台校核································································28

3.6 横向传动方案确定···························································29

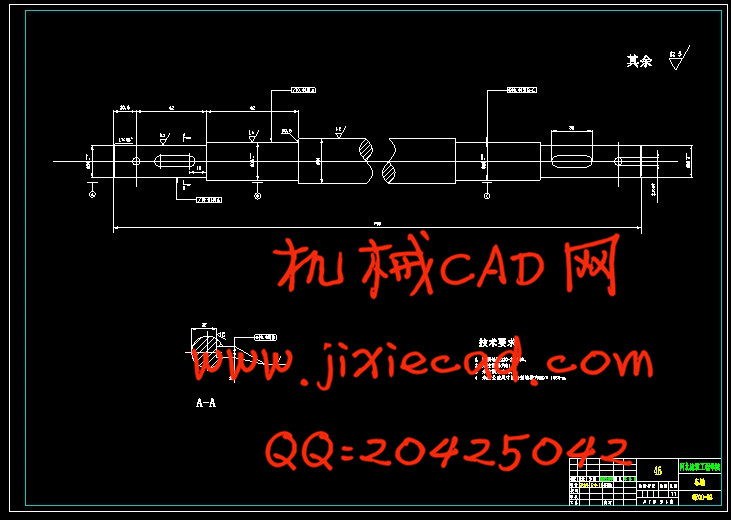

3.7 轴承的选择及校核···························································30

3.8 辅助装置的设计·····························································44

第4章 砖料提升系统设计······················································45

4.1 砖料提升系统概述···························································45

4.2 砖料提升系统方案选择·····················································45

第5章 灰浆输送系统设计·····················································49

第6章 总体布置·································································53

第7章 毕业设计小节···························································53

参考文献············································································55

毕业实习报告······································································01

附录或后记·········································································01