设计简介

目 录

摘要·······················································

Abstract····················································

1 绪论··················································· 1

1.1钳工用液压台虎钳的实际意义···························1

1.2钳工用液压台虎钳的工作原理···························2

1.3钳工用液压台虎钳的优缺点·····························3

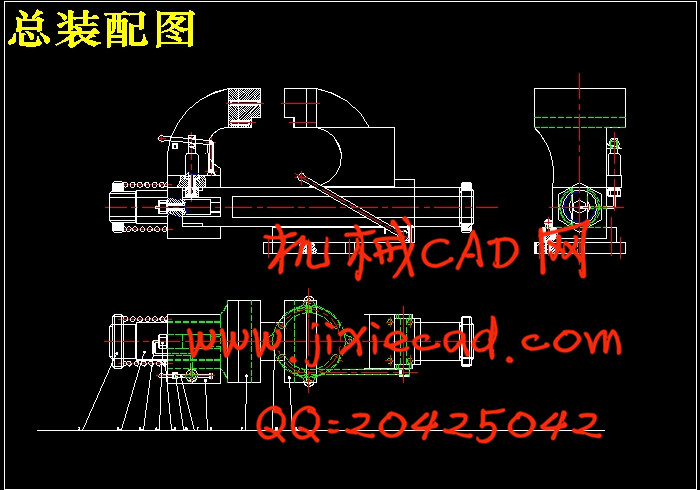

2 钳工用液压台虎钳总体方案的设计··························1

2.1钳工用液压台虎钳几种设计方案及工作原理··············2

2.2设计方案的选择······································3

3液压台虎钳各部分的设计··································4

3.1液压泵的选择········································4

3.2台虎钳身的设计······································8

3.2.1固定钳身的设计·································9

2.4.2 活动钳口的设计································9

2.4.3 台钳与工作台的联接设计·······················10

4 台钳的使用说明书·······································15

5 全文总结···············································36

参考文献················································43

致谢·····················································44

附录

液压台虎钳设计

摘要

液压台虎钳是对现有螺纹传动台虎钳的改进,主要用于成批生产。它能实现快速夹紧与快速松开,且能保证夹紧力大小。这样就可以避免过去要夹紧一个较薄的零件时,因夹紧力没有办法确定调式的时间,同时因能实现快速夹紧与快速松开,从而大大的提高生产效率。

为了实现快速夹紧与快速松开,将传统的螺纹改成液压传动,活动钳身的固定通过刹车手柄来带动钢带刹车块通过摩擦力来抱死活动钳身,从而实现活动钳身的快速移动,而夹紧力则由夹紧弹簧来保证.我们可以通过调整弹簧的张紧程度来保证夹紧力的大小。

液压台虎钳与传统的螺纹台虎钳相比是有不足之处的。一是在成本上要比传统的台虎钳要贵,而且相对来说,制造复杂,操作也复杂一些;二是液压台虎钳的受力方向受到限制,较大的力(如冲击力)只能朝固定钳身方向,给操作者带来不便。这些不足之处是还需改进的,以后要朝这个方向努力。

关键词:液压传动;螺纹传动;夹紧力

Abstract

The hydraulic bench vice is the improvement of the transmission bench vice of existing whorl , mainly used for producing by batch. It can realize clamping and unclamping fast, and can guarantee to clamp the intensity of strength. In this way it can avoid such situation that when clamping a thin part in the past, the time go to the mode cannot confirm, and can make clamping and unclamping fast at the same time , so can improve production efficiency in a high intensity.

In order to make clamping and unclamping fast, make the traditional whorl into hydraulic transmission, the fixation of the activity pincers depend on embracing activity pincers body firmly through frictional force comes by the brake handle driving steel band brake lump. That realizes the fast movement of the activity pincers body, while clamped strength guaranteed by clamping the spring. We can guarantee to clamp the intensity of strength by adjusting the tight intensity of the spring.

Compared with traditional whorl bench vice, the hydraulic bench vice has weak point. The first is more expensive than the traditional bench vice on the cost, and it is a little more complicated in manufacture and operation. The second, the strength direction of hydraulic bench vice is limited, greater strength (such as shock power ) can only be in the body direction of the fixed pincers , bring inconvenience to operator. These weak points are still should be improved, and diligent is needed in this direction later.

Key words: Hydraulic transmission; Transmission of the whorl; Clamp strength

摘要·······················································

Abstract····················································

1 绪论··················································· 1

1.1钳工用液压台虎钳的实际意义···························1

1.2钳工用液压台虎钳的工作原理···························2

1.3钳工用液压台虎钳的优缺点·····························3

2 钳工用液压台虎钳总体方案的设计··························1

2.1钳工用液压台虎钳几种设计方案及工作原理··············2

2.2设计方案的选择······································3

3液压台虎钳各部分的设计··································4

3.1液压泵的选择········································4

3.2台虎钳身的设计······································8

3.2.1固定钳身的设计·································9

2.4.2 活动钳口的设计································9

2.4.3 台钳与工作台的联接设计·······················10

4 台钳的使用说明书·······································15

5 全文总结···············································36

参考文献················································43

致谢·····················································44

附录

液压台虎钳设计

摘要

液压台虎钳是对现有螺纹传动台虎钳的改进,主要用于成批生产。它能实现快速夹紧与快速松开,且能保证夹紧力大小。这样就可以避免过去要夹紧一个较薄的零件时,因夹紧力没有办法确定调式的时间,同时因能实现快速夹紧与快速松开,从而大大的提高生产效率。

为了实现快速夹紧与快速松开,将传统的螺纹改成液压传动,活动钳身的固定通过刹车手柄来带动钢带刹车块通过摩擦力来抱死活动钳身,从而实现活动钳身的快速移动,而夹紧力则由夹紧弹簧来保证.我们可以通过调整弹簧的张紧程度来保证夹紧力的大小。

液压台虎钳与传统的螺纹台虎钳相比是有不足之处的。一是在成本上要比传统的台虎钳要贵,而且相对来说,制造复杂,操作也复杂一些;二是液压台虎钳的受力方向受到限制,较大的力(如冲击力)只能朝固定钳身方向,给操作者带来不便。这些不足之处是还需改进的,以后要朝这个方向努力。

关键词:液压传动;螺纹传动;夹紧力

Abstract

The hydraulic bench vice is the improvement of the transmission bench vice of existing whorl , mainly used for producing by batch. It can realize clamping and unclamping fast, and can guarantee to clamp the intensity of strength. In this way it can avoid such situation that when clamping a thin part in the past, the time go to the mode cannot confirm, and can make clamping and unclamping fast at the same time , so can improve production efficiency in a high intensity.

In order to make clamping and unclamping fast, make the traditional whorl into hydraulic transmission, the fixation of the activity pincers depend on embracing activity pincers body firmly through frictional force comes by the brake handle driving steel band brake lump. That realizes the fast movement of the activity pincers body, while clamped strength guaranteed by clamping the spring. We can guarantee to clamp the intensity of strength by adjusting the tight intensity of the spring.

Compared with traditional whorl bench vice, the hydraulic bench vice has weak point. The first is more expensive than the traditional bench vice on the cost, and it is a little more complicated in manufacture and operation. The second, the strength direction of hydraulic bench vice is limited, greater strength (such as shock power ) can only be in the body direction of the fixed pincers , bring inconvenience to operator. These weak points are still should be improved, and diligent is needed in this direction later.

Key words: Hydraulic transmission; Transmission of the whorl; Clamp strength