设计简介

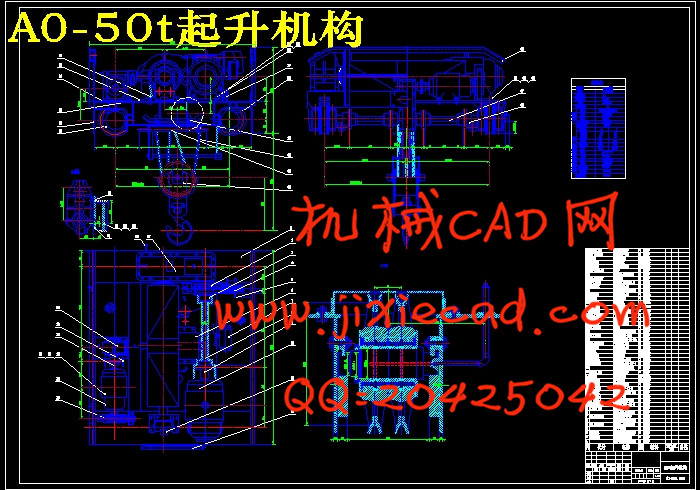

摘 要:本起重机为起重量Q=50t,起升高度H=4.2m,起升速度v=7.5m/min的桥式起重机。本课题主要对起重机的起升机构进行总体设计,该起重机具有一个起升机构,由一台电动机,一台减速器,一台制动器,一套卷筒装置,一套吊钩装置和一套滑轮装置构成。要求起重设备运行平稳, 定位准确, 安全可靠, 技术性能先进。

关键词:起重机,桥式起重机,起升机构设计

Abstract:The crane is bridge crane for lifting weight Q = 50 t, hoisting height H = 4.2 m, lifting speed v = 7.5 m/min . This topic is mainly to the overall design of hoisting mechanism of crane, the crane is consisted of a lifting mechanism, an electric motor, a speed reducer, a brake, a set of drum unit, a set of hook device and a pulley. Required lifting equipment running smooth, accurate, safe, reliable and advanced technical performance.

Key word:Crane;bridge crane; hoisting mechanism design;

目 录

摘要…………………………………………………………………………1

关键词…………………………………………………………………………1

1前言…………………………………………………………………………1

2起升机构的计算…………………………………………………………3

2.1确定起升机构传动方案………………………………………………3

2.2选择钢丝绳…………………………………………………………3

2.3确定滑轮主要尺寸………………………………………………………4

2.4确定卷筒尺寸…………………………………………………………5

2.5选择电动机…………………………………………………………6

2.6验算电动机发热条件……………………………………………………7

2.7选择减速器…………………………………………………………7

2.8验算起升速度和实际所需功率……………………………………7

2.9校核减速器输出强度……………………………………………………7

2.10选择制动器…………………………………………………………8

2.11选择联轴器…………………………………………………………8

2.12验算起动时间………………………………………………………9

2.13验算制动时间………………………………………………………9

2.14高速浮动轴的计算…………………………………………………10

2.14.1疲劳计算………………………………………………………10

2.14.2强度验算………………………………………………………10

3.6.1卷筒心轴计算…………………………………………………14

3.6.2轴承……………………………………………………………16

3.6.3绳端固定装置计算……………………………………………17

4吊钩装置的设计………………………………………………………18

4.2.1确定吊钩装置构造方案……………………………………………18

4.2.2吊钩弯曲部分断面的验算………………………………………19

5结论……………………………………………………………………………22

参考文献……………………………………………………………………22

致谢……………………………………………………………………………23

关键词:起重机,桥式起重机,起升机构设计

Abstract:The crane is bridge crane for lifting weight Q = 50 t, hoisting height H = 4.2 m, lifting speed v = 7.5 m/min . This topic is mainly to the overall design of hoisting mechanism of crane, the crane is consisted of a lifting mechanism, an electric motor, a speed reducer, a brake, a set of drum unit, a set of hook device and a pulley. Required lifting equipment running smooth, accurate, safe, reliable and advanced technical performance.

Key word:Crane;bridge crane; hoisting mechanism design;

目 录

摘要…………………………………………………………………………1

关键词…………………………………………………………………………1

1前言…………………………………………………………………………1

2起升机构的计算…………………………………………………………3

2.1确定起升机构传动方案………………………………………………3

2.2选择钢丝绳…………………………………………………………3

2.3确定滑轮主要尺寸………………………………………………………4

2.4确定卷筒尺寸…………………………………………………………5

2.5选择电动机…………………………………………………………6

2.6验算电动机发热条件……………………………………………………7

2.7选择减速器…………………………………………………………7

2.8验算起升速度和实际所需功率……………………………………7

2.9校核减速器输出强度……………………………………………………7

2.10选择制动器…………………………………………………………8

2.11选择联轴器…………………………………………………………8

2.12验算起动时间………………………………………………………9

2.13验算制动时间………………………………………………………9

2.14高速浮动轴的计算…………………………………………………10

2.14.1疲劳计算………………………………………………………10

2.14.2强度验算………………………………………………………10

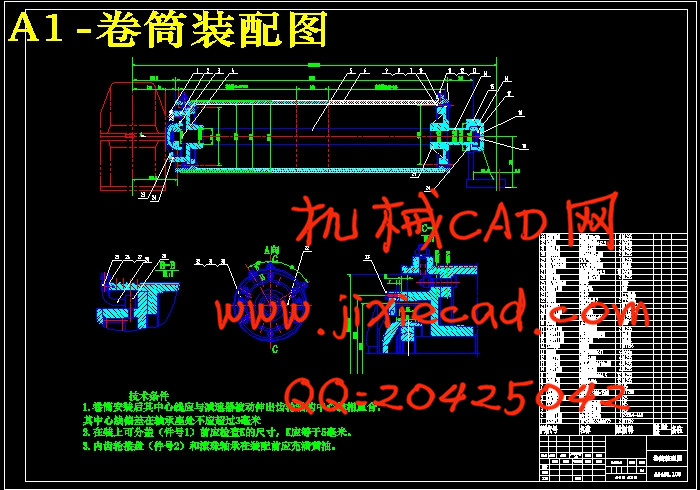

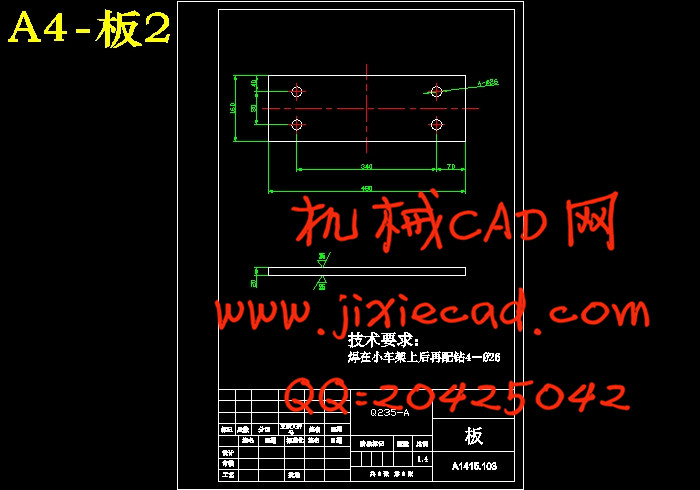

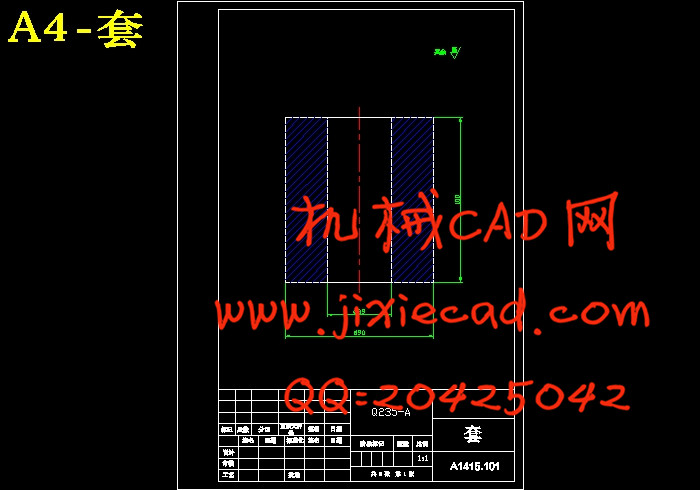

3卷筒部件的设计………………………………………………………11

3.1卷筒……………………………………………………………113.2联接盘……………………………………………………………12

3.3卷筒轮毂………………………………………………………12

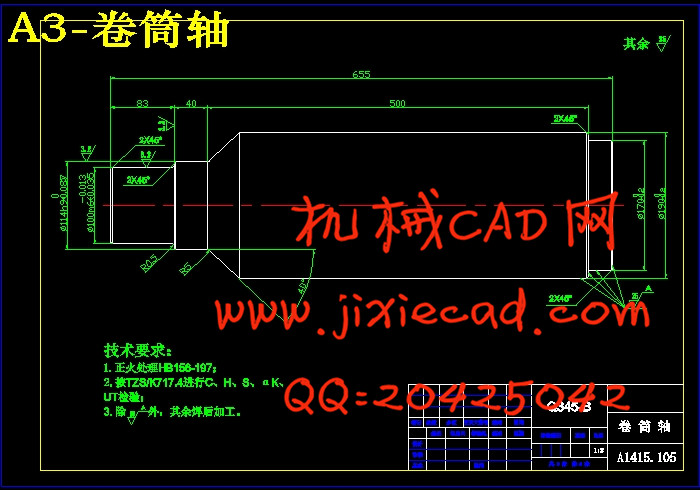

3.4卷筒轴、轴承及轴承座…………………………………………13

3.5钢丝绳在卷筒上的固定装置……………………………………14

3.6卷筒部件计算……………………………………………………143.6.1卷筒心轴计算…………………………………………………14

3.6.2轴承……………………………………………………………16

3.6.3绳端固定装置计算……………………………………………17

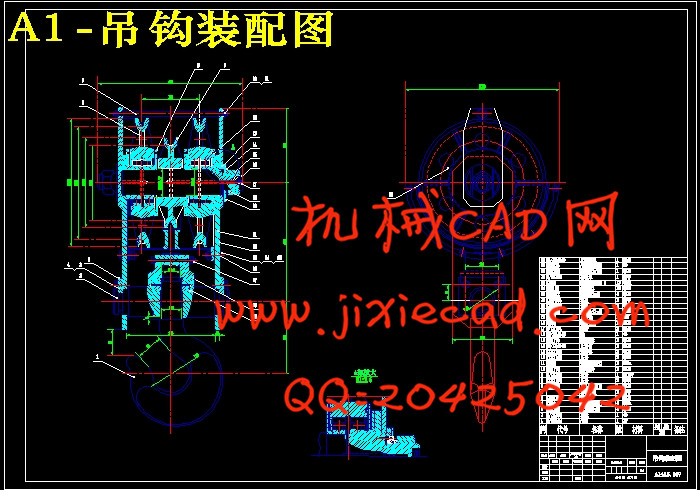

4吊钩装置的设计………………………………………………………18

4.1吊钩装置的构造………………………………………………………18

4.2吊钩装置的计算………………………………………………………184.2.1确定吊钩装置构造方案……………………………………………18

4.2.2吊钩弯曲部分断面的验算………………………………………19

5结论……………………………………………………………………………22

参考文献……………………………………………………………………22

致谢……………………………………………………………………………23