设计简介

摘 要:起重机的出现大大提高了人们的劳动效率,以前需要许多人花长时间才能搬动的大型物件现在用起重机就能轻易达到效果,尤其是在小范围的搬动过程中起重机的作用是相当明显的。在工厂的厂房内搬运大型零件或重型装置桥式起重机是不可获缺的。

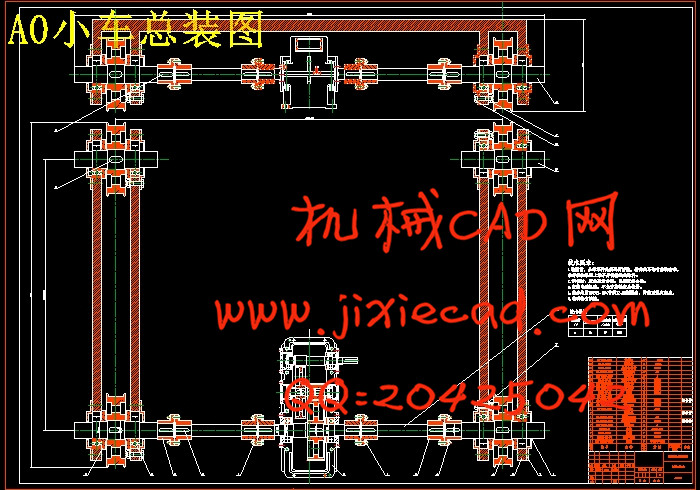

桥式起重机小车主要包括起升机构、小车架、小车运行机构、吊具等部分,其中的小车运行机构主要由减速器、主动轮组、从动轮组、传动轴和一些连接件组成。

本次设计主要从电动机的选择及相关验算、减速器设计及相关校核、小车的布置着手,使其达到所需要求。

关键词:桥式起重机;小车运行机构;减速器;电动机;小车布置;

Abstract: Crane appeares greatly improved people's labor efficiency.That needs a lot of people spend long time to carry large objects with effect of crane can be easily reached now, especially in the small scope in the process of conveying of the role of the crane are quite obvious. At the factory in handling large or heavy equipment parts of the plant of the gantry crane is.

Bridge crane trolley mainly includes lifting mechanism, the trolley, trolley to run institutions, spreader, trolley traveling mechanism is mainly composed of reducer, active wheel, the driven wheel, shaft and some of the fittings.

This design mainly from the choice of the motor and the relevant calculation of the speed reducer design and check the car arrangement in hand, to the necessary requirements

Key words: bridge crane ;trolley running mechanism;the reducer;the motor; trolley arrangement

目 录

摘要……………………………………………………………………………1

关键词……………………………………………………………………………1

1 前言………………………………………………………………………………2

2 桥式起重机的介绍…………………………………………………………………2

2.1 桥式起重机的分类……………………………………………………………2

2.1.1 通用桥式起重机………………………………………………………………2

2.1.2 专用桥式起重机………………………………………………………………3

2.1.3 电动葫芦型桥式起重机………………………………………………………3

2.2 桥式起重机的组成和特点………………………………………………………4

2.3 桥式起重机小车运行机构………………………………………………………4

2.4 本次设计中桥式起重机的主要参数……………………………………………5

3 小车运行机构设计及计算…………………………………………………………5

3.1 小车运行机构的传动方案………………………………………………………5

3.1.1 减速器安装在小车旁边的方案………………………………………………5

3.1.2 减速器安装在两车轮中间的方案……………………………………………6

3.2 小车运行机构计算………………………………………………………………7

3.2.1 确定机构传动方案……………………………………………………………7

3.2.2 选择车轮与轨道并验算其强度………………………………………………7

3.2.3 运行阻力计算……………………………………………………………9

3.2.4 选定电动机并验算电动机发热条件…………………………………………9

3.2.5 验算起动时间……………………………………………………………10

3.2.6 验算起动不打滑条件…………………………………………………………11

3.2.7选择制动器………………………………………………………………12

3.2.8 选择制动轮………………………………………………………………12

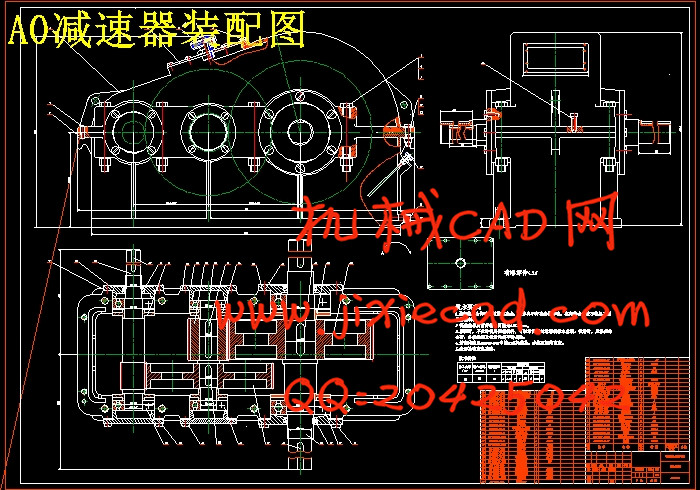

4 减速器的设计及计算……………………………………………………………12

4.1 机构传动效率的选择……………………………………………………………12

4.2 传动比分配………………………………………………………………………13

4.3 运动机动力参数………………………………………………………………13

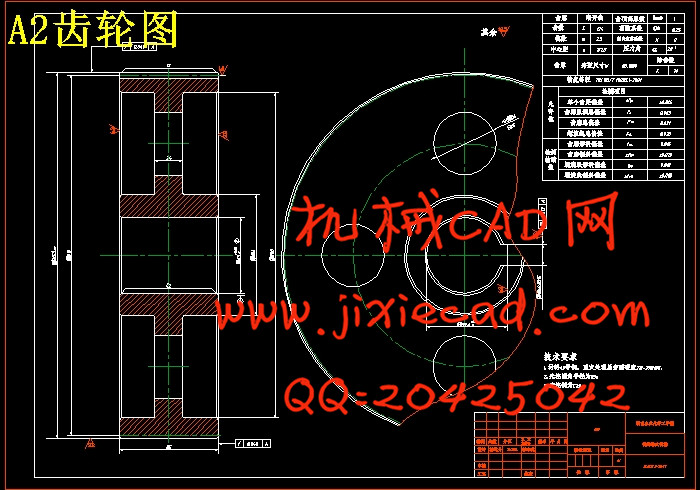

4.4 齿轮传动设计…………………………………………………………………14

4.5 轴的结构设计及计算……………………………………………………………18

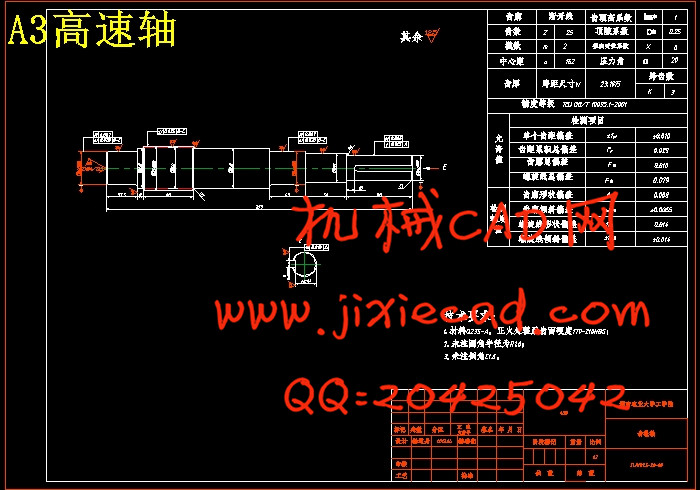

4.5.1 高速轴设计及校核……………………………………………………………18

4.5.2 中间轴的结构设计……………………………………………………………27

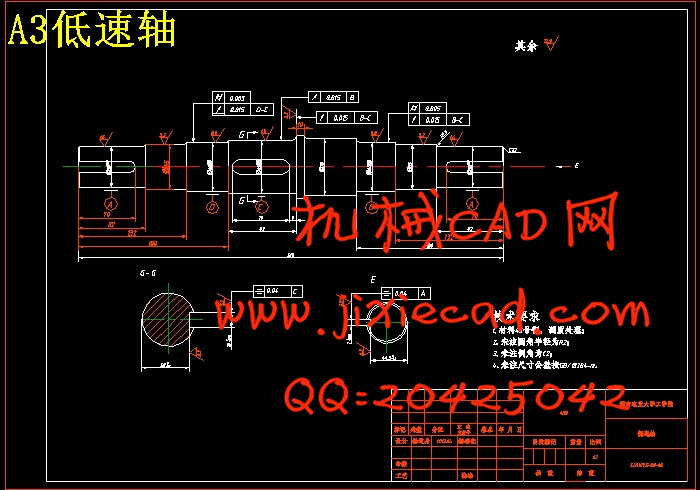

4.5.3 低速轴的结构设计……………………………………………………………28

4.6 滚动轴承的选择与校核…………………………………………………………30

4.7 键连接的选择及校核计算………………………………………………………31

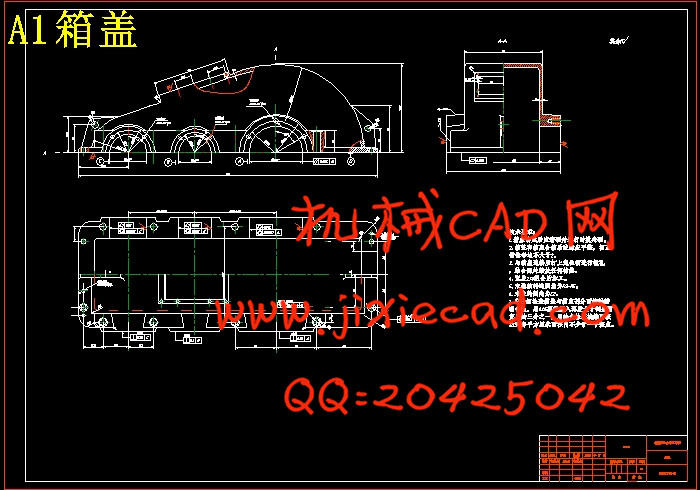

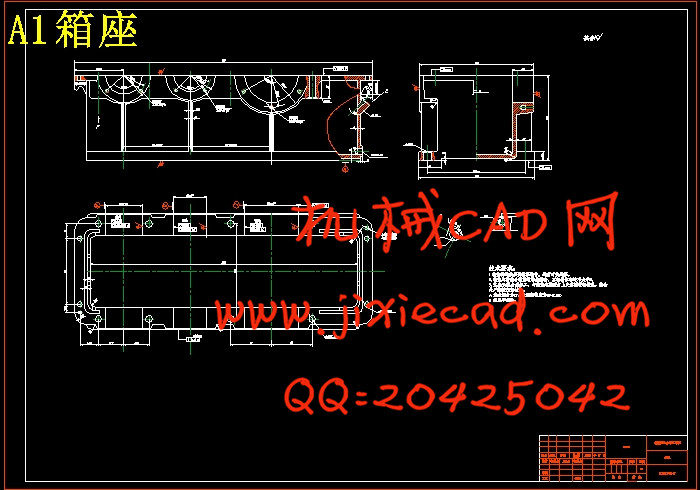

4.8 箱体的结构设计…………………………………………………………………32

5 小车的布置…………………………………………………………………………33

5.1 确定小车轨距和小车轮距………………………………………………………33

5.2 按照选择的小车运行机构方案进行机构布置…………………………………33

6 结论与设计总结……………………………………………………………………33

参考文献…………………………………………………………………………35

致谢…………………………………………………………………………36

附录………………………………………………………………………36

桥式起重机小车主要包括起升机构、小车架、小车运行机构、吊具等部分,其中的小车运行机构主要由减速器、主动轮组、从动轮组、传动轴和一些连接件组成。

本次设计主要从电动机的选择及相关验算、减速器设计及相关校核、小车的布置着手,使其达到所需要求。

关键词:桥式起重机;小车运行机构;减速器;电动机;小车布置;

Abstract: Crane appeares greatly improved people's labor efficiency.That needs a lot of people spend long time to carry large objects with effect of crane can be easily reached now, especially in the small scope in the process of conveying of the role of the crane are quite obvious. At the factory in handling large or heavy equipment parts of the plant of the gantry crane is.

Bridge crane trolley mainly includes lifting mechanism, the trolley, trolley to run institutions, spreader, trolley traveling mechanism is mainly composed of reducer, active wheel, the driven wheel, shaft and some of the fittings.

This design mainly from the choice of the motor and the relevant calculation of the speed reducer design and check the car arrangement in hand, to the necessary requirements

Key words: bridge crane ;trolley running mechanism;the reducer;the motor; trolley arrangement

目 录

摘要……………………………………………………………………………1

关键词……………………………………………………………………………1

1 前言………………………………………………………………………………2

2 桥式起重机的介绍…………………………………………………………………2

2.1 桥式起重机的分类……………………………………………………………2

2.1.1 通用桥式起重机………………………………………………………………2

2.1.2 专用桥式起重机………………………………………………………………3

2.1.3 电动葫芦型桥式起重机………………………………………………………3

2.2 桥式起重机的组成和特点………………………………………………………4

2.3 桥式起重机小车运行机构………………………………………………………4

2.4 本次设计中桥式起重机的主要参数……………………………………………5

3 小车运行机构设计及计算…………………………………………………………5

3.1 小车运行机构的传动方案………………………………………………………5

3.1.1 减速器安装在小车旁边的方案………………………………………………5

3.1.2 减速器安装在两车轮中间的方案……………………………………………6

3.2 小车运行机构计算………………………………………………………………7

3.2.1 确定机构传动方案……………………………………………………………7

3.2.2 选择车轮与轨道并验算其强度………………………………………………7

3.2.3 运行阻力计算……………………………………………………………9

3.2.4 选定电动机并验算电动机发热条件…………………………………………9

3.2.5 验算起动时间……………………………………………………………10

3.2.6 验算起动不打滑条件…………………………………………………………11

3.2.7选择制动器………………………………………………………………12

3.2.8 选择制动轮………………………………………………………………12

4 减速器的设计及计算……………………………………………………………12

4.1 机构传动效率的选择……………………………………………………………12

4.2 传动比分配………………………………………………………………………13

4.3 运动机动力参数………………………………………………………………13

4.4 齿轮传动设计…………………………………………………………………14

4.5 轴的结构设计及计算……………………………………………………………18

4.5.1 高速轴设计及校核……………………………………………………………18

4.5.2 中间轴的结构设计……………………………………………………………27

4.5.3 低速轴的结构设计……………………………………………………………28

4.6 滚动轴承的选择与校核…………………………………………………………30

4.7 键连接的选择及校核计算………………………………………………………31

4.8 箱体的结构设计…………………………………………………………………32

5 小车的布置…………………………………………………………………………33

5.1 确定小车轨距和小车轮距………………………………………………………33

5.2 按照选择的小车运行机构方案进行机构布置…………………………………33

6 结论与设计总结……………………………………………………………………33

参考文献…………………………………………………………………………35

致谢…………………………………………………………………………36

附录………………………………………………………………………36