设计简介

桥式起重机主体结构设计

摘要

起重机的用途是将物品从空间的某一个地点搬运到另一个地点。为了完成这个作业,起重机一般具有使物品沿空间的三个方向运动的机构。桥式类型的起重机是依靠起重机运行机构和小车运行机构的组合运动使所搬运的物品在长方形平面内作运动。

起重机是现代生产不可缺少的组成部分,借助起重机可以实现主要工艺流程和辅助作业的机械化,在流水线和自动线生产车间中,起重机大大提高了生产效率。

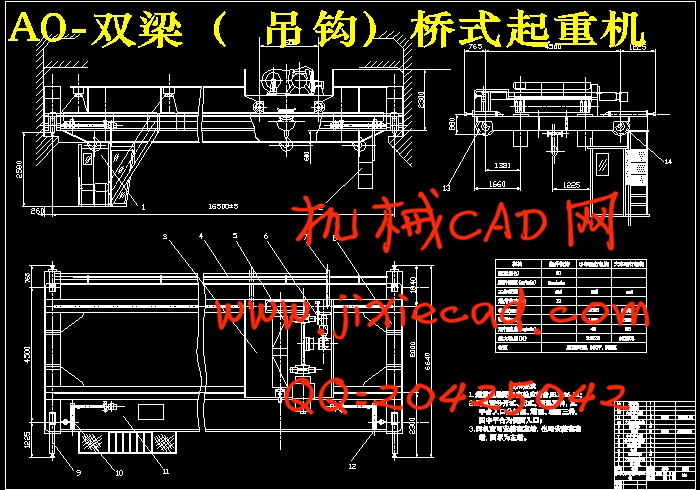

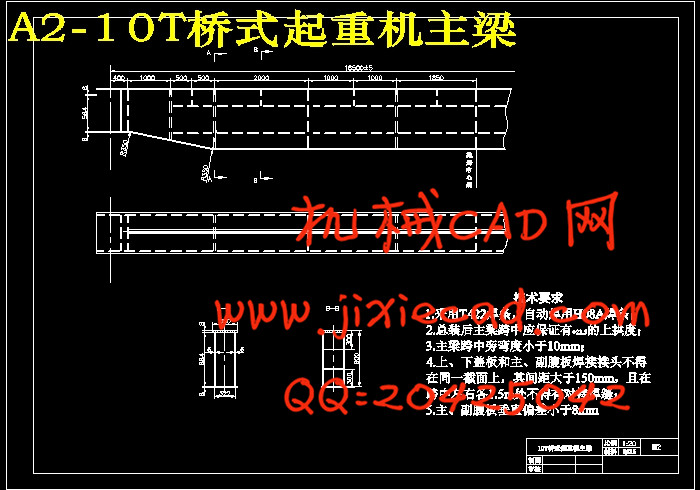

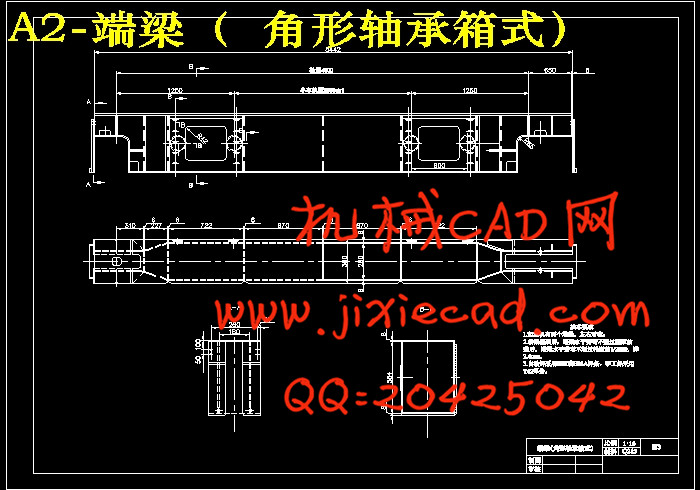

本文主要完成了桥式起重机主体结构部分的设计及主梁和端梁的校核计算。采用正轨箱形梁桥架,正轨箱形梁桥架由两根主梁和端梁构成。主梁外侧分别设有走台,并与端梁通过连接板焊接在一起形成刚性结构。为了运输方便在端梁中间设有接头,通过连接板和角钢使用螺栓连接,这种结构运输方便、安装容易。小车轨道固定于主梁的压板上,压板焊接在盖板的中央。

本文正确选择了起重机桥架钢结构构造形式和构件截面,以保证其在使用过程中的强度、刚度和稳定性。设计时,同时还注意了起重机的结构制造工艺性、省料、安装以及维修方便等问题。

关键词:桥式起重机;主体结构;桥架

Design of main body structure of bridge-type hoist crane

Abstract

The usage of hoist crane is to transport goods from some place to another one. In order to accomplish this job, there is mechanism in the hoist crane which makes the goods move along the space in three directions. The bridge type hoist crane carries the goods to move in the rectangular plane depending upon the combination of the hoist crane movement mechanism and the car movement.

The hoist crane plays an important role in the modern age. It is possible to realize the mechanization of main technical process and assistance work with the help of the hoist crane. The hoist crane can improve the production efficiency greatly in the assembly line and production workshop.

This paper mainly completes the design of main-body structure and checking up calculation of the bridge-type hoist crane. Box-girder bridge type is adopted which is made up of two main beams and end girders. The main beams have walking platform on outside plates and welded with end girders to form rigid structure. For transportation convenience, joints are adopted in the middle of the end girders, and connected together with junction panels, angle-steels and bolts, which brings about transportation convenience and easy fixing. The car rails are fixuped on up-plates of the main beams which are welded in the middle of the up-plates.

The hoist crane bridge types and the structural cross sections are chosen correct to ensure their intensity, the rigidity and the stability in the use process. Meanwhile, the structure manufacture technology capability, materials saving, fixing and convenience of maintenance and so on are paid attention to.

Key word: Bridge-type hoist crane; main body structure; bridge

目 录

目 录

第1章 绪言……………………………………………………………………………………………1

1.1 起重机的概述‥…………………………………………………………………………1

1.2 起重机发展趋势………………………………………………………………………‥1

第2章 起重机总体方案设计……………………………………………………………………3

2.1 起重机参数确定…………………………………………………………………………3

2.2 起重机总体方案……………………………………………………………………………3

2.3 桥架主体结构方案…………………………………………………………………………3

第3章 起重机主体结构设计………………………………………………………………………5

3.1 起重机钢结构载荷情况…………………………………………………………………5

3.2 桥架金属结构计算…………………………………………………………………………5

3.2.1 主梁计算载荷………………………………………………………………………5

3.2.2 主梁截面尺寸的选择………………………………………………………………7

第4章 主体结构各承载部分的计算与校核………………………………………………9

4.1 主梁主要截面计算……………………………………………………………………9

4.2 主梁支承附近截面计算………………………………………………………………10

4.3 端梁计算…………………………………………………………………………………16

总结…………………………………………………………………………………………………………20

参考文献…………………………………………………………………………………………………21

摘要

起重机的用途是将物品从空间的某一个地点搬运到另一个地点。为了完成这个作业,起重机一般具有使物品沿空间的三个方向运动的机构。桥式类型的起重机是依靠起重机运行机构和小车运行机构的组合运动使所搬运的物品在长方形平面内作运动。

起重机是现代生产不可缺少的组成部分,借助起重机可以实现主要工艺流程和辅助作业的机械化,在流水线和自动线生产车间中,起重机大大提高了生产效率。

本文主要完成了桥式起重机主体结构部分的设计及主梁和端梁的校核计算。采用正轨箱形梁桥架,正轨箱形梁桥架由两根主梁和端梁构成。主梁外侧分别设有走台,并与端梁通过连接板焊接在一起形成刚性结构。为了运输方便在端梁中间设有接头,通过连接板和角钢使用螺栓连接,这种结构运输方便、安装容易。小车轨道固定于主梁的压板上,压板焊接在盖板的中央。

本文正确选择了起重机桥架钢结构构造形式和构件截面,以保证其在使用过程中的强度、刚度和稳定性。设计时,同时还注意了起重机的结构制造工艺性、省料、安装以及维修方便等问题。

关键词:桥式起重机;主体结构;桥架

Design of main body structure of bridge-type hoist crane

Abstract

The usage of hoist crane is to transport goods from some place to another one. In order to accomplish this job, there is mechanism in the hoist crane which makes the goods move along the space in three directions. The bridge type hoist crane carries the goods to move in the rectangular plane depending upon the combination of the hoist crane movement mechanism and the car movement.

The hoist crane plays an important role in the modern age. It is possible to realize the mechanization of main technical process and assistance work with the help of the hoist crane. The hoist crane can improve the production efficiency greatly in the assembly line and production workshop.

This paper mainly completes the design of main-body structure and checking up calculation of the bridge-type hoist crane. Box-girder bridge type is adopted which is made up of two main beams and end girders. The main beams have walking platform on outside plates and welded with end girders to form rigid structure. For transportation convenience, joints are adopted in the middle of the end girders, and connected together with junction panels, angle-steels and bolts, which brings about transportation convenience and easy fixing. The car rails are fixuped on up-plates of the main beams which are welded in the middle of the up-plates.

The hoist crane bridge types and the structural cross sections are chosen correct to ensure their intensity, the rigidity and the stability in the use process. Meanwhile, the structure manufacture technology capability, materials saving, fixing and convenience of maintenance and so on are paid attention to.

Key word: Bridge-type hoist crane; main body structure; bridge

第1章 绪言……………………………………………………………………………………………1

1.1 起重机的概述‥…………………………………………………………………………1

1.2 起重机发展趋势………………………………………………………………………‥1

第2章 起重机总体方案设计……………………………………………………………………3

2.1 起重机参数确定…………………………………………………………………………3

2.2 起重机总体方案……………………………………………………………………………3

2.3 桥架主体结构方案…………………………………………………………………………3

第3章 起重机主体结构设计………………………………………………………………………5

3.1 起重机钢结构载荷情况…………………………………………………………………5

3.2 桥架金属结构计算…………………………………………………………………………5

3.2.1 主梁计算载荷………………………………………………………………………5

3.2.2 主梁截面尺寸的选择………………………………………………………………7

第4章 主体结构各承载部分的计算与校核………………………………………………9

4.1 主梁主要截面计算……………………………………………………………………9

4.2 主梁支承附近截面计算………………………………………………………………10

4.3 端梁计算…………………………………………………………………………………16

总结…………………………………………………………………………………………………………20

参考文献…………………………………………………………………………………………………21