设计简介

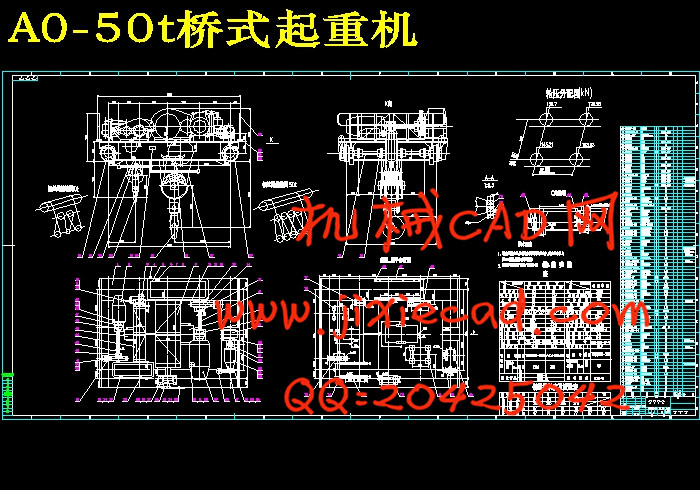

摘 要:本论文课题是设计由电力驱动的50/10t桥式起重机中的机构。这些机构是起重机的主要组成部分。正是这些机构,使起重机能够实现其价值,取代人力搬运货物,既减轻劳动者的劳动强度,降低装卸或搬运的费用,减少货物的破损,又能提高生产率,在生产过程中进行某些特殊的工艺操作,从而提高了经济效益。

桥式起重机主要由金属结构、机械部分(机构)和电气设备三大部分组成。机械部分主要包括起升机构和运行机构等。起升机构是最重要和最基本的机构,没有起升机构就不能称其为起重机,其工作的好坏直接影响整台起重机的工作性能;运行机构包括小车运行机构和大车运行机构,它是实现起重机将货物横向和纵向移动的机构。

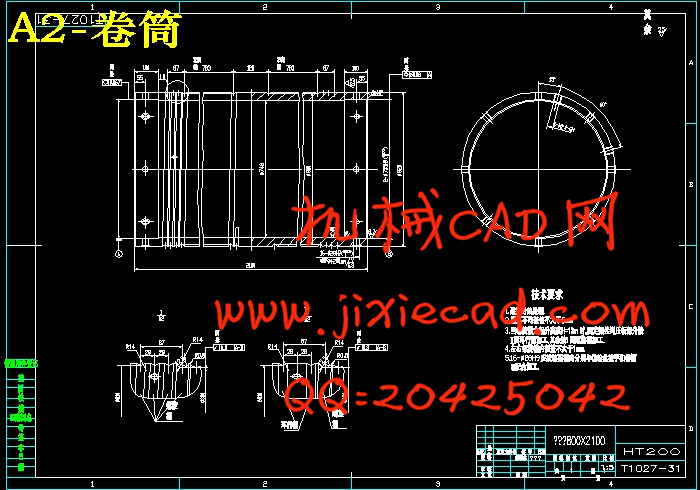

本次设计是按照起升机构部分进行的。起升机构的设计包括起升机构布置方案的选择、卷筒的设计、钢丝绳的选择,以及电动机、减速器、制动器、制动轮和联轴器的选用和设计计算;利用AutoCAD按照确定好的各机构布置方案和设计的尺寸生成装配平面图,可以初步的检查出各个零件设计是否合理,是否影响装配。通过生成装配平面图,可以直观的确定设计的正确性,从而实现当初的设想。

关键词:桥式起重机;起升机构

Abstract :The design of some organizations in the electric drive 50/10t bridge crane is designed in this paper. These organizations are the main constituents of this crane. Because of these organizations, the hoist crane enables to realize its value, instead manpower transporting cargo, both reduces worker's labor intensity, reduces loading and unloading or the transporting expense, reduces the breakage of the cargo, and can enhance the productivity, carries on certain special craft operation in the production process, thus enhanced the economic efficiency.

The bridge crane mainly consists of the metal structure, the machine part (organization) and the electrical equipment. The machine part mainly includes the lifting mechanism and the movement organization. The lifting mechanism is the most important and the most basic organization, if not these organization ,it was not able to call the hoist crane, its work quality direct influence the operating performance of the crane; The movement organization including the car movement organization and the large cart movement organization, which can realizes the cargo crosswise and the longitudinal shift.

This design defers to the lifting mechanism. About designing the lifting mechanism, which includes the organization scheme of arrangement choice, the reel design, the steel wire choice, as well as electric motor, reduction gear, brake, brake pulley and shaft coupling selection with design calculation. According to determined using AutoCAD various organizations scheme of arrangement and the design size production assembly horizontal plan, may preliminary inspection each components design whether reasonably, whether affects the assembly. Through the production assembly horizontal plan, may the direct-viewing determination design accuracy, thus realized the initial tentative plan.

Keywords: Bridge Crane;Hosting Mechanism;Mechanism of Running Car

Signature of Supervisor:

目 录

1 绪论 1

1.1 课题的研究背景 1

1.2国内外桥式起重机发展概况 1

1.3 本论文的主要内容 2

2. 桥式起介绍 4

2.1 桥式起重机的特点和分类 4

2.1.1通用桥式起重机 4

2.1.2专用桥式起重机 5

2.1.3电动葫芦型桥式起重机 6

2.2桥式起重机的组成和特点 7

2.2.1桥式起重机小车 7

3.总体方案设计 8

3.1引言 8

3.2起重机设计的总体方案 8

3.2.1方案一:选择箱形双梁桥式起重机 8

3.2.2方案二:选择通用吊钩桥式起重机 9

3.3方案的确定 10

3.4 小结 10

4起升机构的设计及计算 11

4.1 引言 11

4.2 吊钩电动起升机构的布置方案 11

4.3 主起升机构的计算 14

4.3.1 钢丝绳直径的选取 14

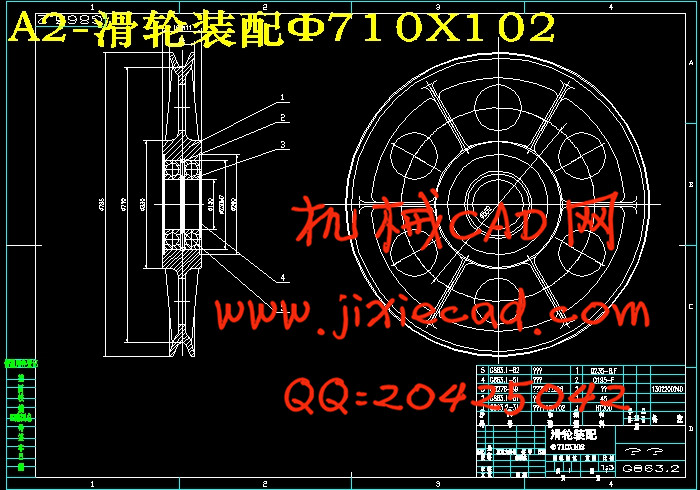

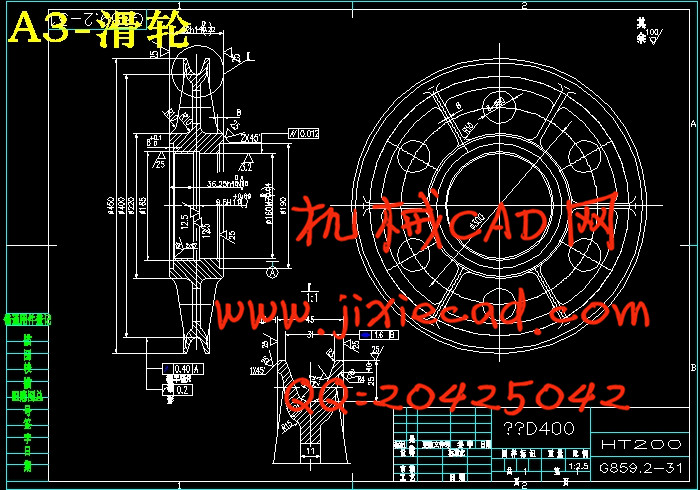

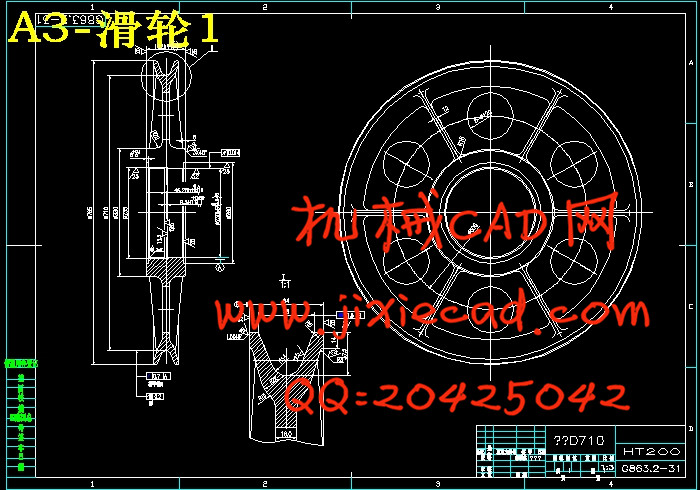

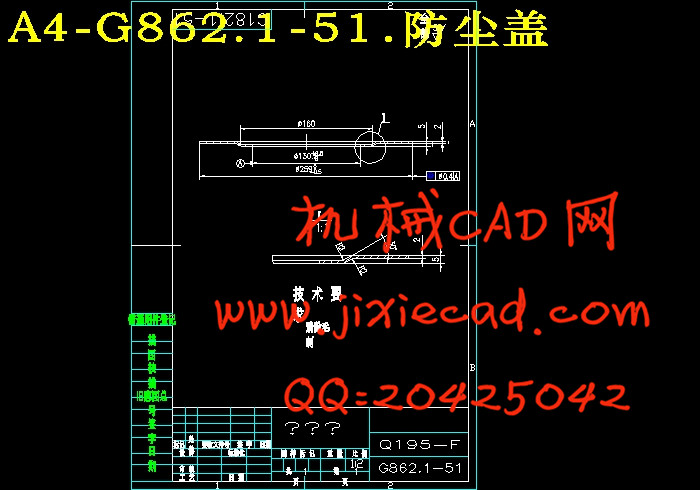

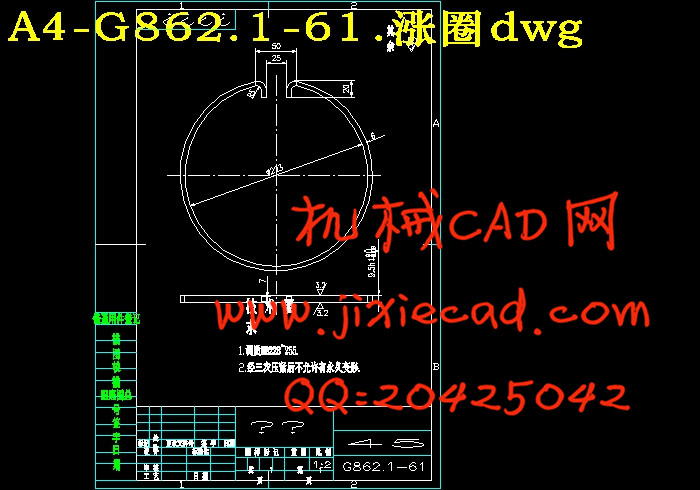

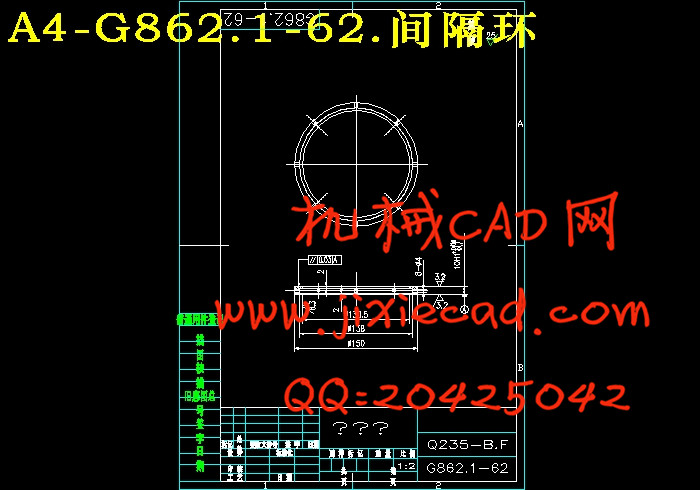

4.3.2 滑轮与卷筒的计算 15

4.3.3 选择电动机 17

4.3.4 减速器的选择 18

4.3.5选择制动器 19

4.3.6选择联轴器 21

4.4 副起升机构的计算 22

4.4.1 钢丝绳直径的选取 22

4.4.2 滑轮、卷筒的计算 23

4.4.3 电动机的选择 24

4.4.4 减速器的选择 25

4.4.5 选择制动器 26

4.4.6 联轴器的选择 28

4.5 小结 29

5 结论 30

5.1全文总结 30

5.2展望 30

参 考 文 献 32

致 谢 33

桥式起重机主要由金属结构、机械部分(机构)和电气设备三大部分组成。机械部分主要包括起升机构和运行机构等。起升机构是最重要和最基本的机构,没有起升机构就不能称其为起重机,其工作的好坏直接影响整台起重机的工作性能;运行机构包括小车运行机构和大车运行机构,它是实现起重机将货物横向和纵向移动的机构。

本次设计是按照起升机构部分进行的。起升机构的设计包括起升机构布置方案的选择、卷筒的设计、钢丝绳的选择,以及电动机、减速器、制动器、制动轮和联轴器的选用和设计计算;利用AutoCAD按照确定好的各机构布置方案和设计的尺寸生成装配平面图,可以初步的检查出各个零件设计是否合理,是否影响装配。通过生成装配平面图,可以直观的确定设计的正确性,从而实现当初的设想。

关键词:桥式起重机;起升机构

Abstract :The design of some organizations in the electric drive 50/10t bridge crane is designed in this paper. These organizations are the main constituents of this crane. Because of these organizations, the hoist crane enables to realize its value, instead manpower transporting cargo, both reduces worker's labor intensity, reduces loading and unloading or the transporting expense, reduces the breakage of the cargo, and can enhance the productivity, carries on certain special craft operation in the production process, thus enhanced the economic efficiency.

The bridge crane mainly consists of the metal structure, the machine part (organization) and the electrical equipment. The machine part mainly includes the lifting mechanism and the movement organization. The lifting mechanism is the most important and the most basic organization, if not these organization ,it was not able to call the hoist crane, its work quality direct influence the operating performance of the crane; The movement organization including the car movement organization and the large cart movement organization, which can realizes the cargo crosswise and the longitudinal shift.

This design defers to the lifting mechanism. About designing the lifting mechanism, which includes the organization scheme of arrangement choice, the reel design, the steel wire choice, as well as electric motor, reduction gear, brake, brake pulley and shaft coupling selection with design calculation. According to determined using AutoCAD various organizations scheme of arrangement and the design size production assembly horizontal plan, may preliminary inspection each components design whether reasonably, whether affects the assembly. Through the production assembly horizontal plan, may the direct-viewing determination design accuracy, thus realized the initial tentative plan.

Keywords: Bridge Crane;Hosting Mechanism;Mechanism of Running Car

Signature of Supervisor:

目 录

1 绪论 1

1.1 课题的研究背景 1

1.2国内外桥式起重机发展概况 1

1.3 本论文的主要内容 2

2. 桥式起介绍 4

2.1 桥式起重机的特点和分类 4

2.1.1通用桥式起重机 4

2.1.2专用桥式起重机 5

2.1.3电动葫芦型桥式起重机 6

2.2桥式起重机的组成和特点 7

2.2.1桥式起重机小车 7

3.总体方案设计 8

3.1引言 8

3.2起重机设计的总体方案 8

3.2.1方案一:选择箱形双梁桥式起重机 8

3.2.2方案二:选择通用吊钩桥式起重机 9

3.3方案的确定 10

3.4 小结 10

4起升机构的设计及计算 11

4.1 引言 11

4.2 吊钩电动起升机构的布置方案 11

4.3 主起升机构的计算 14

4.3.1 钢丝绳直径的选取 14

4.3.2 滑轮与卷筒的计算 15

4.3.3 选择电动机 17

4.3.4 减速器的选择 18

4.3.5选择制动器 19

4.3.6选择联轴器 21

4.4 副起升机构的计算 22

4.4.1 钢丝绳直径的选取 22

4.4.2 滑轮、卷筒的计算 23

4.4.3 电动机的选择 24

4.4.4 减速器的选择 25

4.4.5 选择制动器 26

4.4.6 联轴器的选择 28

4.5 小结 29

5 结论 30

5.1全文总结 30

5.2展望 30

参 考 文 献 32

致 谢 33