设计简介

内容提要

物料搬运机械主要是在企业 ( 包括码头、料场、矿山和商业货仓等 ) 内部进行物料装卸、运输、升降、堆垛和储存的机械设备。一般包括起重机械、输送机、装卸机械、搬运车辆和仓储设备等;习惯上不包括汽车、铁路车辆、飞机和船舶等交通运输工具,以及输送气体和液体的管道。

物料搬运机械按功能大致可分为起重机械、输送机、装卸机械、搬运车辆和仓储设备等五类。一般说来,起重机械用于升降和搬运,但搬运距离较短,它的机构作间歇式运动 ;输送机可连续输送物料,搬运路线一般固定不变,大多用来输送散状物料;装卸机械能自行取物并装卸物料。搬运车辆可灵活安排搬运路线,经济运输距离较长,可在室内或室外作业,具有行驶车轮 ;仓储设备是在仓库中完成堆、取、储存物料的装置,包括料仓装置、高架仓库和给料机等。随着工业的发展,许多机械具有多种功能和用途,例如叉车是搬运车辆,可用以装卸,也可起升重物。

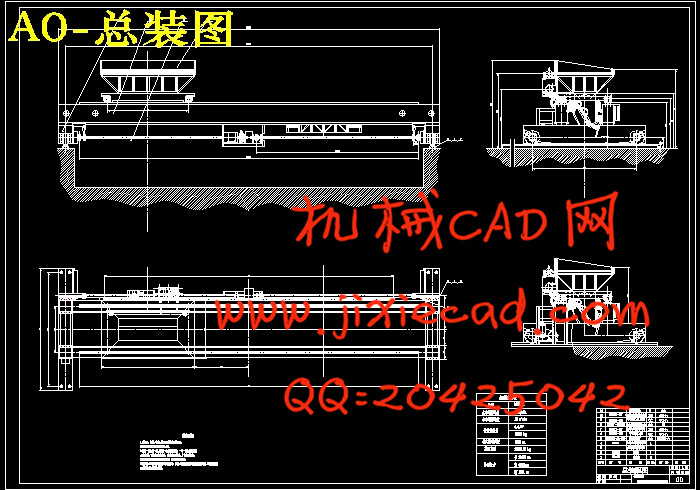

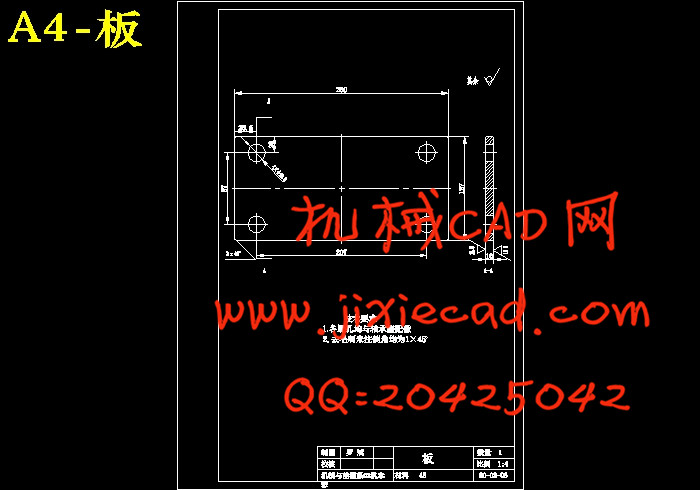

本次毕业设计桥式装卸料机就是一种在生产领域可以广泛应用的物料搬运机械。经过四个多月的努力,终于在指导老师悉心指导下完成了本次毕业设计。本次设计我主要针对该机械的主梁和小车驱动系统进行设计。主梁已经是个成熟的技术项目了,根据不同情况进行不同的选择,按已有的设计准则进行设计。小车驱动系统在参考了传统的方案后,进行了新旧方案的对比分析。最后,对小车驱动系统进行了革新。使它的传动效率和安全性都有了提高,而且制造难度和传统方案差别不大,实现了经济和效益的双丰收。

The material transporting machinery mainly is in the enterprise (including wharf, materials yard, mine and commercial goods warehouse and so on) the interior carries on material loading and unloading, the transportation, the fluctuation, piles up with the storage mechanical device. Includes the hoisting machinery, the conveyer generally, loads and unloads the machinery, transports the vehicles and stores in a storehouse the equipment and so on; In custom not including transportation tool and so on automobile, railroad car, airplane and ships, as well as transportation gas and liquid pipeline.

The material transporting machinery may divide into the hoisting machinery, the conveyer approximately according to the function, loads and unloads the machinery, transports the vehicles and stores in a storehouse the equipment and so on five kinds. In general, the hoisting machinery uses in rising and falling and the transporting, but transports is away from short, its organization makes the intermittent type movement; The conveyer may the streamhandling material, general transport the route fixed to be invariable, mostly uses for to transport disperses the shape material; The loading and unloading mechanical energy takes the thing and the loading and unloading material voluntarily. Transports the vehicles to be possible nimbly to arrange the transporting route, the economical transportation to be away from long, may in the room or outdoor work, has the travel wheel; Stores in a storehouse the equipment is piles to in heaps, takes, the storage material installment in the warehouse, including the bunker installment, the high structure warehouse and gives the material machine and so on. Along with the industry development, many machineries have the many kinds of functions and the use, for example the forklift transports the vehicles, may use by to load and unload, also may lift the heavy item.

This graduation design bridge type installs the unloading device is one kind in the realm of production may the widespread application material transporting machinery. After more than four months endeavors, finally in instructed teacher under the devotedly instruction to complete this graduation project. This time designs me mainly to aim at this machinery the king post and the car actuates the system to carry on the design. The king post already was the mature technical project, carries on the different choice according to the different situation, according to the design criterion which has has carried on the design. The car actuated the system after to refer to the traditional plan, has carried on the new old plan contrast analysis. Finally, actuated the system to the car to carry on the innovation. Caused its transmission efficiency and the security all had the enhancement, moreover the manufacture difficulty and the traditional plan difference was not big, has realized the economical and the benefit double abundant harvest.

目 录

内容提要

Summary

前言………………………………………………………………………...1

1 总体设计……………………………………………………………..….2

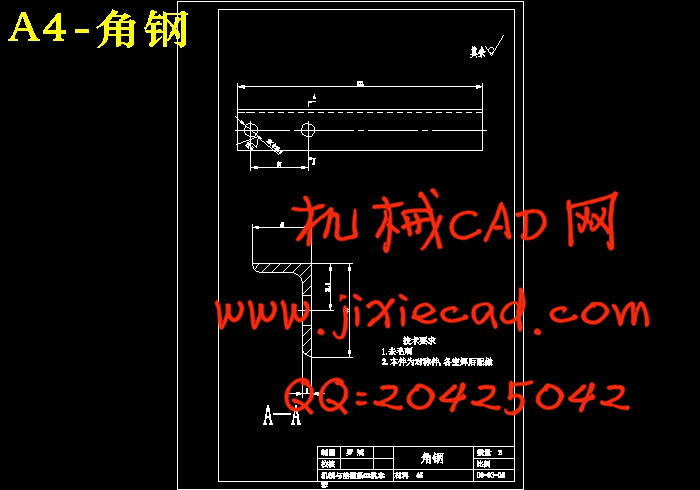

2 主梁的设计……………………………………………………..……….3

2.1 主梁的结构选择…………………………………………………..…..3

2.2 主梁的几何尺寸的确定………………………………….………….3

2.3 载荷计算…………………………………………………………..…..4

2.4 载荷组合…………………………………………………………..…..6

2.5 强度计算………………………………………………………..……..7

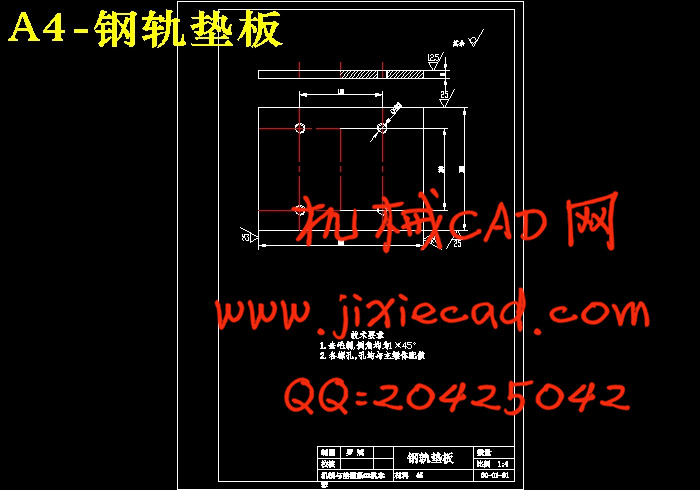

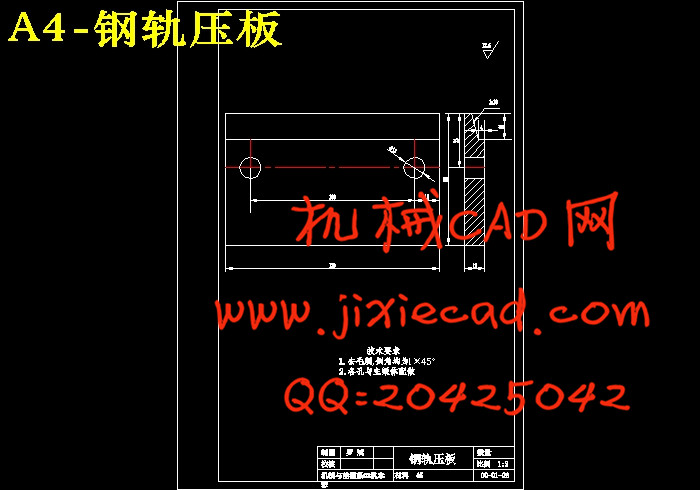

3 小车驱动系统设计………………………………………………..…..17

3.1 确定方案……………………………………………………………...17

3.2 电动机的选择……………………………………………..……….....17

3.3 减速器的选用………………………………………………………...22

3.4 联轴器的选用……………………………………..……………..…...24

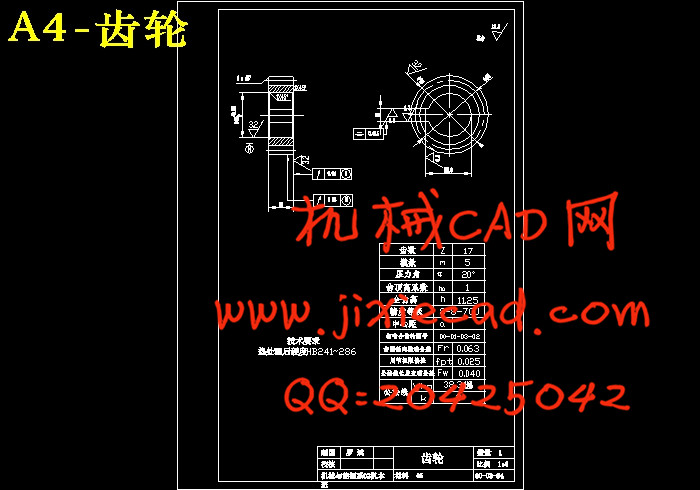

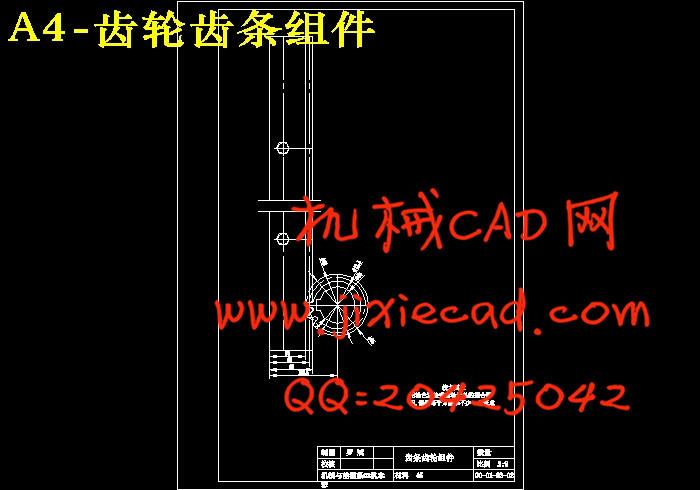

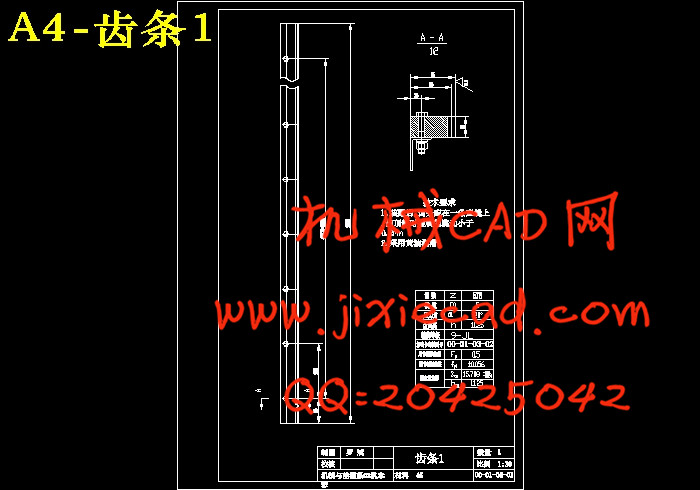

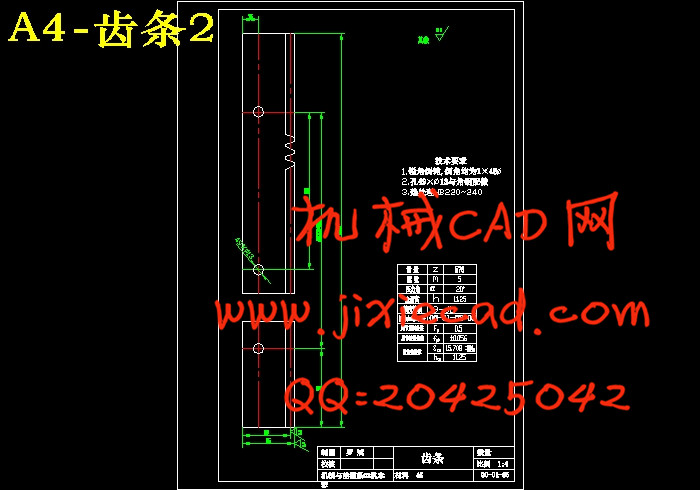

3.5 齿轮的校核……………………………………………………....…...27

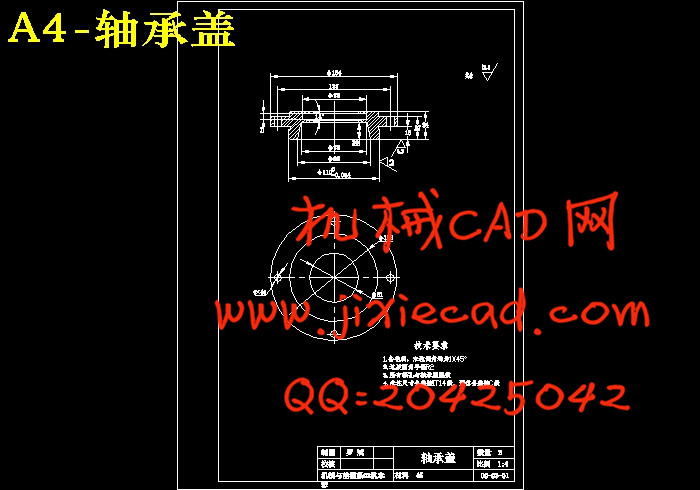

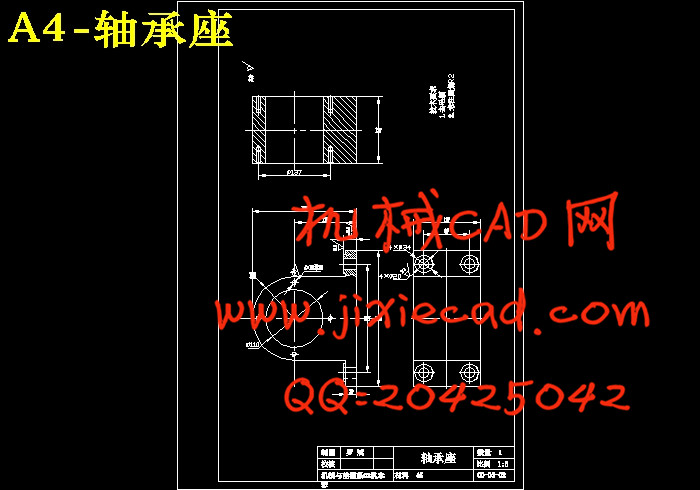

3.6 轴承的选用…………………………………………………………...33

总结………………………………………………………………………..35

参考文献…………………………………………………………………. 36

致谢………………………………………………………………………..37

物料搬运机械主要是在企业 ( 包括码头、料场、矿山和商业货仓等 ) 内部进行物料装卸、运输、升降、堆垛和储存的机械设备。一般包括起重机械、输送机、装卸机械、搬运车辆和仓储设备等;习惯上不包括汽车、铁路车辆、飞机和船舶等交通运输工具,以及输送气体和液体的管道。

物料搬运机械按功能大致可分为起重机械、输送机、装卸机械、搬运车辆和仓储设备等五类。一般说来,起重机械用于升降和搬运,但搬运距离较短,它的机构作间歇式运动 ;输送机可连续输送物料,搬运路线一般固定不变,大多用来输送散状物料;装卸机械能自行取物并装卸物料。搬运车辆可灵活安排搬运路线,经济运输距离较长,可在室内或室外作业,具有行驶车轮 ;仓储设备是在仓库中完成堆、取、储存物料的装置,包括料仓装置、高架仓库和给料机等。随着工业的发展,许多机械具有多种功能和用途,例如叉车是搬运车辆,可用以装卸,也可起升重物。

本次毕业设计桥式装卸料机就是一种在生产领域可以广泛应用的物料搬运机械。经过四个多月的努力,终于在指导老师悉心指导下完成了本次毕业设计。本次设计我主要针对该机械的主梁和小车驱动系统进行设计。主梁已经是个成熟的技术项目了,根据不同情况进行不同的选择,按已有的设计准则进行设计。小车驱动系统在参考了传统的方案后,进行了新旧方案的对比分析。最后,对小车驱动系统进行了革新。使它的传动效率和安全性都有了提高,而且制造难度和传统方案差别不大,实现了经济和效益的双丰收。

he Bridge Type loading and unloading machine main beam and the

car drive system design

Summary

The material transporting machinery mainly is in the enterprise (including wharf, materials yard, mine and commercial goods warehouse and so on) the interior carries on material loading and unloading, the transportation, the fluctuation, piles up with the storage mechanical device. Includes the hoisting machinery, the conveyer generally, loads and unloads the machinery, transports the vehicles and stores in a storehouse the equipment and so on; In custom not including transportation tool and so on automobile, railroad car, airplane and ships, as well as transportation gas and liquid pipeline.

The material transporting machinery may divide into the hoisting machinery, the conveyer approximately according to the function, loads and unloads the machinery, transports the vehicles and stores in a storehouse the equipment and so on five kinds. In general, the hoisting machinery uses in rising and falling and the transporting, but transports is away from short, its organization makes the intermittent type movement; The conveyer may the streamhandling material, general transport the route fixed to be invariable, mostly uses for to transport disperses the shape material; The loading and unloading mechanical energy takes the thing and the loading and unloading material voluntarily. Transports the vehicles to be possible nimbly to arrange the transporting route, the economical transportation to be away from long, may in the room or outdoor work, has the travel wheel; Stores in a storehouse the equipment is piles to in heaps, takes, the storage material installment in the warehouse, including the bunker installment, the high structure warehouse and gives the material machine and so on. Along with the industry development, many machineries have the many kinds of functions and the use, for example the forklift transports the vehicles, may use by to load and unload, also may lift the heavy item.

This graduation design bridge type installs the unloading device is one kind in the realm of production may the widespread application material transporting machinery. After more than four months endeavors, finally in instructed teacher under the devotedly instruction to complete this graduation project. This time designs me mainly to aim at this machinery the king post and the car actuates the system to carry on the design. The king post already was the mature technical project, carries on the different choice according to the different situation, according to the design criterion which has has carried on the design. The car actuated the system after to refer to the traditional plan, has carried on the new old plan contrast analysis. Finally, actuated the system to the car to carry on the innovation. Caused its transmission efficiency and the security all had the enhancement, moreover the manufacture difficulty and the traditional plan difference was not big, has realized the economical and the benefit double abundant harvest.

目 录

内容提要

Summary

前言………………………………………………………………………...1

1 总体设计……………………………………………………………..….2

2 主梁的设计……………………………………………………..……….3

2.1 主梁的结构选择…………………………………………………..…..3

2.2 主梁的几何尺寸的确定………………………………….………….3

2.3 载荷计算…………………………………………………………..…..4

2.4 载荷组合…………………………………………………………..…..6

2.5 强度计算………………………………………………………..……..7

3 小车驱动系统设计………………………………………………..…..17

3.1 确定方案……………………………………………………………...17

3.2 电动机的选择……………………………………………..……….....17

3.3 减速器的选用………………………………………………………...22

3.4 联轴器的选用……………………………………..……………..…...24

3.5 齿轮的校核……………………………………………………....…...27

3.6 轴承的选用…………………………………………………………...33

总结………………………………………………………………………..35

参考文献…………………………………………………………………. 36

致谢………………………………………………………………………..37