设计简介

摘要:切管机主要用于加工各种用途的管件,主要包括各种材料的金属管件,本次设计的切管机所加工的管件主要是直径在3/8″~4″之间。

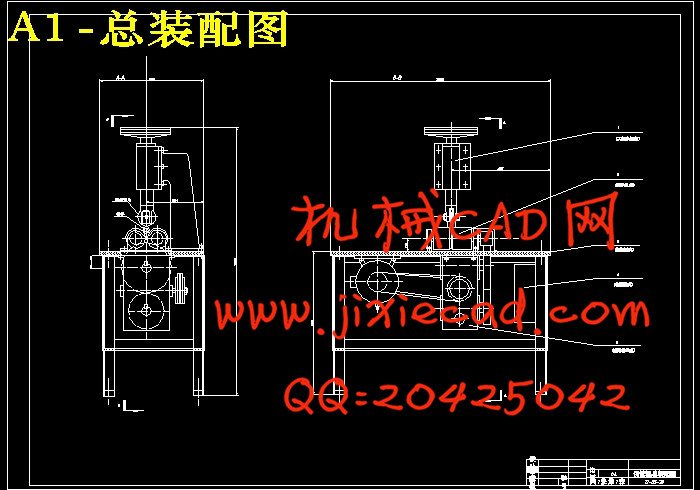

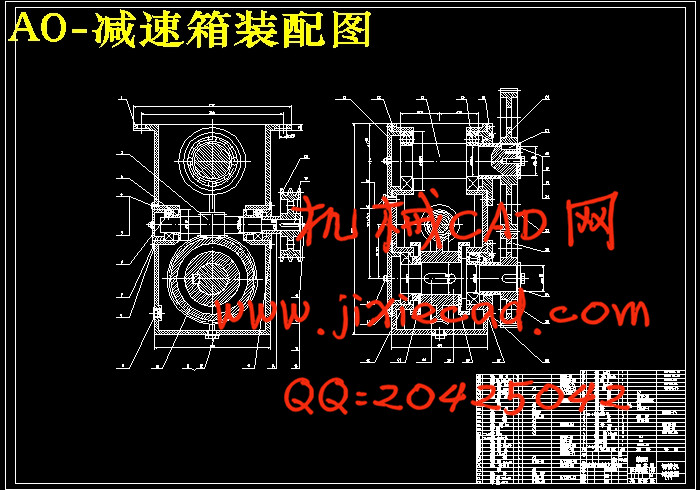

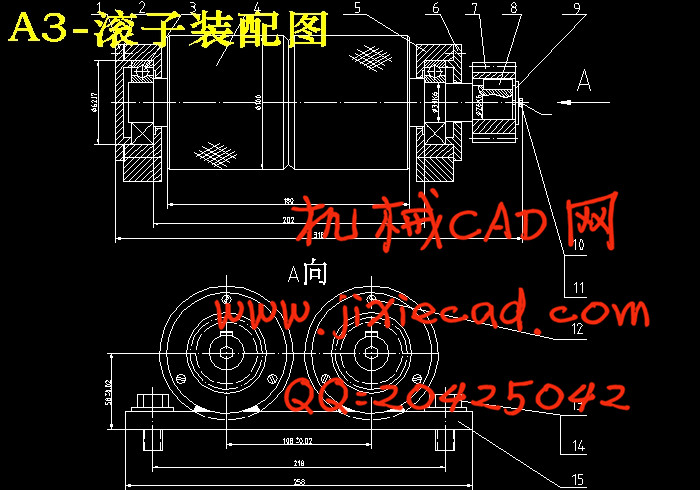

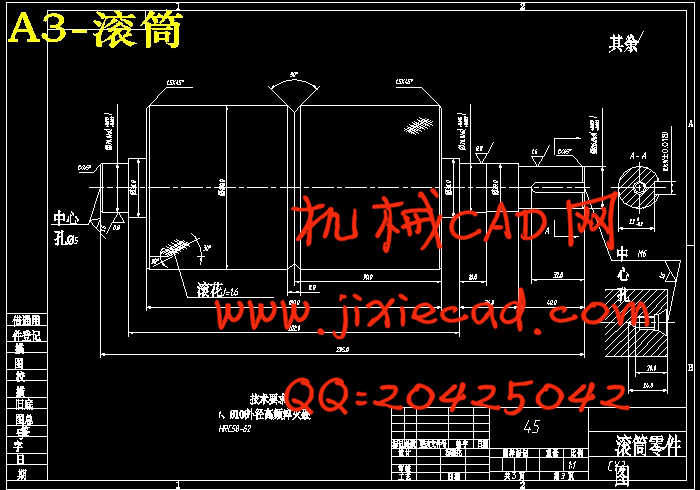

本论文设计的切管机,完成的工作主要是切管机中减速箱、滚子、机体等的设计。其中包括确定工艺方案、传动装置的设计和计算(包括电动机的选择、拟定传动方案、各轴转速、功率和转矩的计算、传动机构的设计与计算等)。在对上述各项进行了详细的强度校核之后,根据已有的经验公式,确定了各个零件之间的相互尺寸。在最后绘制出了装配图、部件图以及部分零件图

本文设计所完成的切管机主要用于车间中对管件的切屑加工,对于提高生产效率,减轻工人的劳动强度有着积极的意义。

关键词:切管机 传动件 设计计算

Abstraction: Tube cutting machine mainly being used in processing various functional tube parts ,primarily includes varieties material`s metals tube parts . This time the designed Tube cutting machine essentially process the tube parts which diameter between 3/8"~4".

The task of this time designed Tube cutting machine is chiefly comprises the design and of deceleration case , roller ,organism, and so on. Besides, the task also includes the others several steps,such as :settle the technology craft program;the design and calculation of transmission installation ; (includes the selection of electric motor ; formulate the transmission program; the rotational speed of each axle; power and the calculation of Torque ; the design and calculaton of the transmission mechanism etc). After detailed intensity proofread for all kinds the above--methioned, according to the already experienced--formula, the mutual dimension among each components being fixed . Finally , draw the assemble chart; components chart as well as portion spare parts chart.

The designed Tube cutting machine mainly used on cutting and processing for tube part in the work shop . To some extent, the design has positive significance in improving productivity and lightening the workers labor intensity.

Key words: tube cutting machine transmission parts design calculation

目 录

引 言 1

1. 确定工艺方案 2

2. 传动装置的设计与计算 4

2.1 电动机的选择 4

2.1.1 类型的选择 4

2.1.2 转速的选择 4

2.1.3 功率的选择 4

2.2 拟订传动方案 5

2.3 计算各轴的转速、功率和转矩 8

2.4 进行传动机构的设计与计算 9

2.4.1 带传动设计 10

2.4.3 蜗轮蜗杆模数的确定 11

2.4.4 齿数的确定 12

2.5 进行总体结构设计,画出总体方案图 13

3. 结构设计 15

3.1 初算各轴的最小直径 15

3.2 计算各主要传动件的结构尺寸 16

3.3 绘制部件的装配草图 20

3.4 绘制设计装配图 25

3.5 绘制零件工作图 28

4. 结论 30

5. 致谢 31

6.参考文献 32

本论文设计的切管机,完成的工作主要是切管机中减速箱、滚子、机体等的设计。其中包括确定工艺方案、传动装置的设计和计算(包括电动机的选择、拟定传动方案、各轴转速、功率和转矩的计算、传动机构的设计与计算等)。在对上述各项进行了详细的强度校核之后,根据已有的经验公式,确定了各个零件之间的相互尺寸。在最后绘制出了装配图、部件图以及部分零件图

本文设计所完成的切管机主要用于车间中对管件的切屑加工,对于提高生产效率,减轻工人的劳动强度有着积极的意义。

关键词:切管机 传动件 设计计算

Abstraction: Tube cutting machine mainly being used in processing various functional tube parts ,primarily includes varieties material`s metals tube parts . This time the designed Tube cutting machine essentially process the tube parts which diameter between 3/8"~4".

The task of this time designed Tube cutting machine is chiefly comprises the design and of deceleration case , roller ,organism, and so on. Besides, the task also includes the others several steps,such as :settle the technology craft program;the design and calculation of transmission installation ; (includes the selection of electric motor ; formulate the transmission program; the rotational speed of each axle; power and the calculation of Torque ; the design and calculaton of the transmission mechanism etc). After detailed intensity proofread for all kinds the above--methioned, according to the already experienced--formula, the mutual dimension among each components being fixed . Finally , draw the assemble chart; components chart as well as portion spare parts chart.

The designed Tube cutting machine mainly used on cutting and processing for tube part in the work shop . To some extent, the design has positive significance in improving productivity and lightening the workers labor intensity.

Key words: tube cutting machine transmission parts design calculation

目 录

引 言 1

1. 确定工艺方案 2

2. 传动装置的设计与计算 4

2.1 电动机的选择 4

2.1.1 类型的选择 4

2.1.2 转速的选择 4

2.1.3 功率的选择 4

2.2 拟订传动方案 5

2.3 计算各轴的转速、功率和转矩 8

2.4 进行传动机构的设计与计算 9

2.4.1 带传动设计 10

2.4.3 蜗轮蜗杆模数的确定 11

2.4.4 齿数的确定 12

2.5 进行总体结构设计,画出总体方案图 13

3. 结构设计 15

3.1 初算各轴的最小直径 15

3.2 计算各主要传动件的结构尺寸 16

3.3 绘制部件的装配草图 20

3.4 绘制设计装配图 25

3.5 绘制零件工作图 28

4. 结论 30

5. 致谢 31

6.参考文献 32