设计简介

芹菜收获机的设计

摘 要

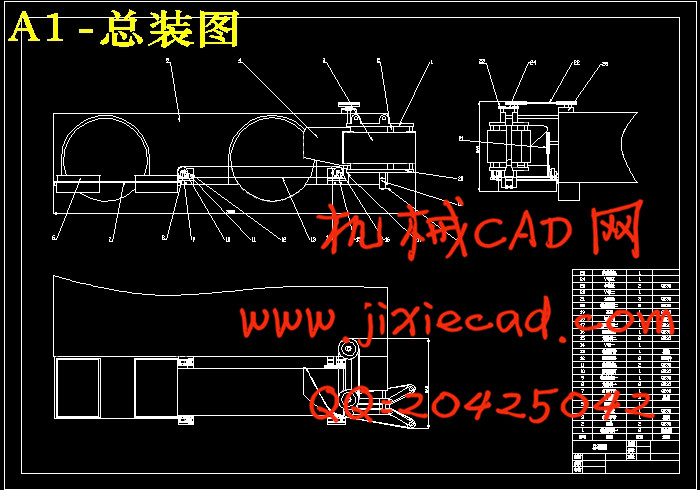

随着新的农业生产模式和新技术的发展与应用,农业机器将成为农业生产的主力军。该文在分析芹菜收获机工作特点的基础上,从芹菜的采摘、转运、装箱等方面进行分析。其中主要对扶茎机构、切削刀、输送机构和装箱机构做了详细的说明。该芹菜收获机适用于家用收割芹菜,结构简单、制造成本低。

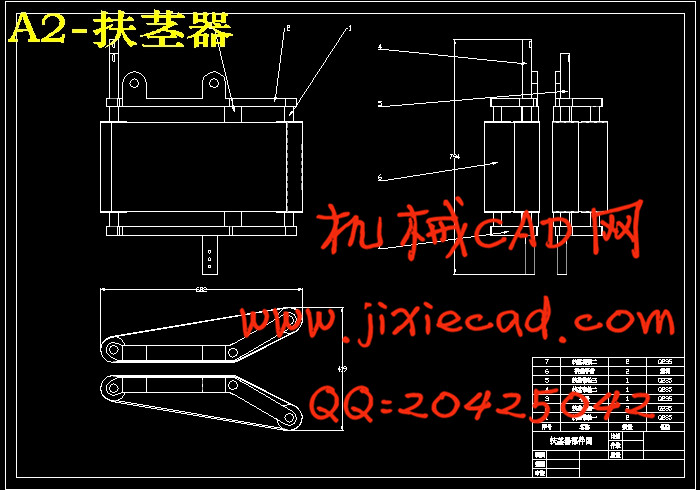

该芹菜收获机的扶茎机构采用喇叭口式结构,切削刀采用固定式切削刀,本文主要介绍了扶茎机构采用喇叭口式结构的设计过程,对它可能出现的松动做了相应的防松措施。对于切削过程中刀具可能出现的状况做了相应的分析。还对其各零件的结构和选材做了详细的分析。整个结构简单、可操作性强、安全可靠。

关键词:芹菜;收获机;固定式切削刀

摘 要

随着新的农业生产模式和新技术的发展与应用,农业机器将成为农业生产的主力军。该文在分析芹菜收获机工作特点的基础上,从芹菜的采摘、转运、装箱等方面进行分析。其中主要对扶茎机构、切削刀、输送机构和装箱机构做了详细的说明。该芹菜收获机适用于家用收割芹菜,结构简单、制造成本低。

该芹菜收获机的扶茎机构采用喇叭口式结构,切削刀采用固定式切削刀,本文主要介绍了扶茎机构采用喇叭口式结构的设计过程,对它可能出现的松动做了相应的防松措施。对于切削过程中刀具可能出现的状况做了相应的分析。还对其各零件的结构和选材做了详细的分析。整个结构简单、可操作性强、安全可靠。

关键词:芹菜;收获机;固定式切削刀

Abstract

With the new model of agricultural production and new technology development and application of agricultural machinery will become a major force in agricultural production. In this paper, the analysis of the characteristics of celery harvesting machine work on the basis of the picking from the celery, transit, packaging, etc. for analysis. The main body of the cutting knife and transporting mechanism part of a detailed description. The celery harvesting machine for celery harvest home, simple structure, low manufacturing costs.

The celery harvesting machine parts Bellbottom type structure, the use of fixed cutting knife cutting knife, the paper introduces the body Wedge Lock design process, it may be loosened so the corresponding relaxation. Tool for cutting the course of the situation that may arise to do the corresponding analysis. Also parts of its structure and material to do a detailed analysis. The entire structure is simple, feasible, safe and reliable.

Keywords: Celery;Harvesting machine;Fixed cutting knife

With the new model of agricultural production and new technology development and application of agricultural machinery will become a major force in agricultural production. In this paper, the analysis of the characteristics of celery harvesting machine work on the basis of the picking from the celery, transit, packaging, etc. for analysis. The main body of the cutting knife and transporting mechanism part of a detailed description. The celery harvesting machine for celery harvest home, simple structure, low manufacturing costs.

The celery harvesting machine parts Bellbottom type structure, the use of fixed cutting knife cutting knife, the paper introduces the body Wedge Lock design process, it may be loosened so the corresponding relaxation. Tool for cutting the course of the situation that may arise to do the corresponding analysis. Also parts of its structure and material to do a detailed analysis. The entire structure is simple, feasible, safe and reliable.

Keywords: Celery;Harvesting machine;Fixed cutting knife

目 录

摘要................................................................I

ABSTRACT...........................................................II

1 绪论.............................................................1

2 芹菜收获机总体方案设计...........................................2

2.1芹菜收获机的工作过程

2.2拖拉机的选择

2.3传动机构的皮带设计

3 收获机切削机构的设计............................................24

3.1切削刀的分析...................................................24

3.1.1切削刀的切削情况.............................................24

3.1.2切削刀的选用.................................................24

3.2切削机构零部件的设计...........................................24

3.2.1刀片的设计...................................................24

3.2.2压刀板和刀杆的设计...........................................25

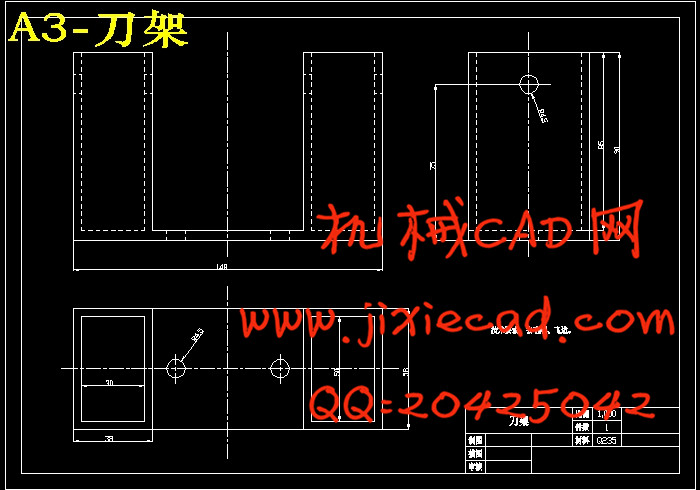

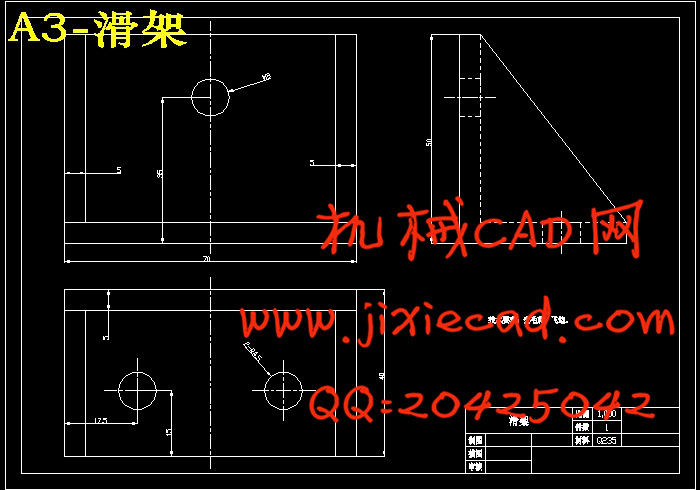

3.2.3刀架的设计...................................................26

四 收获机扶茎机构主要零部件设计.................................6

4.1收获机扶茎机构简介..............................................2

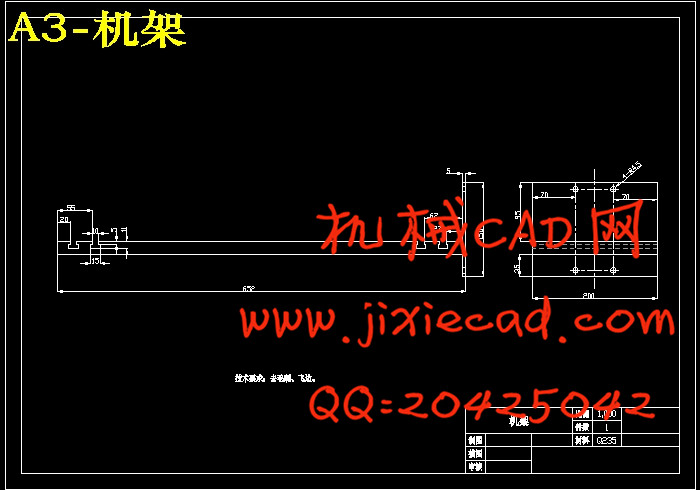

4.2机架的设计......................................................6

4.2.1机架外形......................................................6

4.2.2计算部分......................................................6

4.2.3机架结构的确定................................................7

4.3平带带轮的设计..................................................7

4.3.1尺寸和形状的确定..............................................7

4.3.2主动带轮轴的设计..............................................8

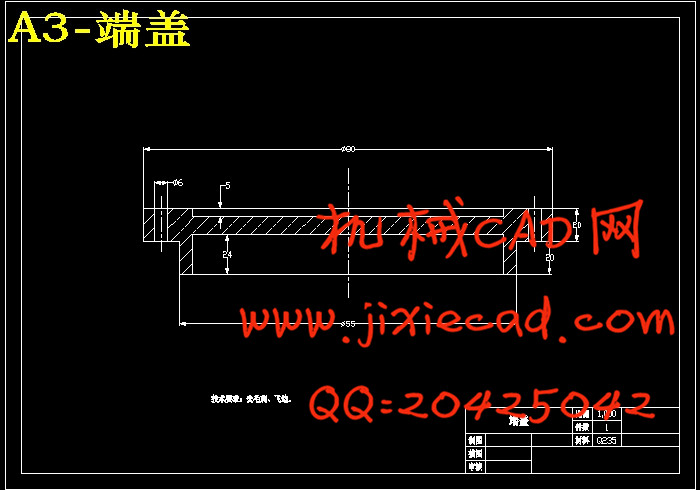

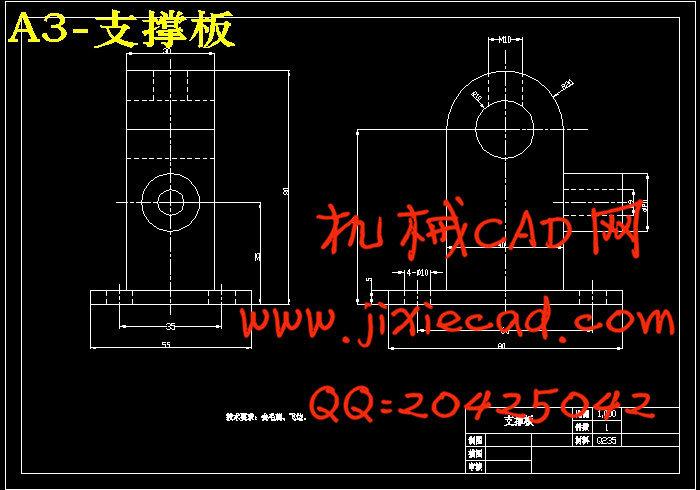

4.3.3端盖的设计...................................................10

4.3.4支撑导论的设计...............................................10

4.3平带的选择.....................................................11

五 收获机输送机构的设计........................................12

5.1收获机输送机构简介..............................................4

5.2输送机构的组成.................................................12

5.3输送机构速度的确定.............................................12

5.4输送机构主要零部件设计.........................................13

5.4.1张紧装置的设计...............................................13

5.4.2输送带的选择.................................................15

5.4.3滚筒的设计...................................................16

5.4.4支撑轴的设计.................................................17

5.4.5其他零部件的设计.............................................20

六 收获机装箱机构的设计

6.1装箱机构的简介

6.2 装箱机构的设计

6.2.1装箱框的设计

6.2.2 装箱平台的设计

6.3 收获机总体方案三维图

七 结论与展望.................................................28

7.1结论...........................................................28

7.2问题与展望.....................................................28

设计心得..........................................................III

参考文献...........................................................IV

致谢................................................................V