设计简介

摘 要

汽车悬架是汽车的车架与车桥或车轮之间的一切传力连接装置的总称,其作用是传递作用在车轮和车架之间的力和力扭,并且缓冲由不平路面传给车架或车身的冲击力,并衰减由此引起的震动,以保证汽车能平顺地行驶。典型的悬架结构由弹性元件、导向机构以及减震器等组成,个别结构则还有缓冲块、横向稳定杆等。弹性元件又有钢板弹簧、空气弹簧、螺旋弹簧以及扭杆弹簧等形式,而现代轿车悬架多采用螺旋弹簧和扭杆弹簧,个别高级轿车则使用空气弹簧。汽车悬架性能是影响汽车行驶平顺性、操纵稳定性和行驶速度的重要因素。因此,研究汽车振动,设计新型悬架系统,将振动控制到最低水平是提高现代汽车质量的重要措施。

本文研究的主要问题如下:

(1)对前、后悬架的结构进行设计,主要是确定减震器的类型。

(2)对悬架的各个尺寸参数进行计算及相关零部件的尺寸进行设计计算。

(3)对减震器和导向机构进行选择计算,确定减震器的类型等。

本文是对轻型货车的前后悬架进行的设计计算,同时兼顾舒适性与运货能力。

关键词:悬架;弹性元件;弹簧;缓冲块 ;减震

ABSTRACT

Automotive vehicle suspension frame and axle or the wheel of all transmission between the general term for connecting devices, and its role is to transfer the role at the wheel and frame and between the torsional force, and uneven pavement from the buffer Biography to the frame or body of the impact, and the attenuation caused by vibration, to ensure the vehicle can travel smoothly. A typical structure of a flexible suspension components, shock absorbers and other agencies, as well as orientation of the individual block structure is also a buffer, such as horizontal Stabilizer. Elastic components and leaf springs, air springs, coil spring, as well as the form of torsion bar spring, and the use of many modern cars suspension coil spring and torsion bar springs, individual car use advanced air springs. Suspension performance is the impact of motor vehicles to motor cars and ride comfort, handling and stability and an important factor in speed. Therefore, the research vehicle vibration, the design of the new suspension system to the minimum level of vibration control is to improve the quality of Hyundai Motor important measures.The main problems discussed in this paper are as follows:

(1)Front and rear suspension design of the structure, primarily determine the type of shock absorber. (2)The various dimensions of the suspension parameters were calculated and related parts of the size of the design calculations

(3)The guiding mechanism of shock absorber selection calculations to determine the types of shock absorbers.

This article is for light goods vehicles, front and rear suspension design and calculation, taking into account the comfort and cargo capacity.

Key words:Suspension;Elastic element;Spring;Block buff;Damping

目 录

摘要………………………………………………………………………………I

Abstract…………………………………………………………………………II

第1章 绪论……………………………………………………………………1

1.1 汽车悬架概述……………………………………………………………………1

1.2 我国汽车悬架发展的现状……………………………………………………2

1.3 研究的背景及意义…………………………………………………………3

1.4 毕业论文研究内容………………………………………………………………4

第2章 悬架的结构形式分析及选择…………………………………………5

2.1 非独立悬架和独立悬架……………………………………………………5

2.2 前、后悬架方案的选择…………………………………………………………6

2.3 辅助元件………………………………………………………………6

2.4 本章总结………………………………………………………………7

第3章 主要参数的选择………………………………………………………………8

3.1 选择的要求及方法……………………………………………………8

3.2 悬架的静绕度……………………………………………………………………8

3.3 悬架动挠度………………………………………………………………………9

3.4 悬架弹性特性………………………………………………………………9

3.5 本章总结……………………………………………………………………10

第4章 弹性元件的计算……………………………………………………11

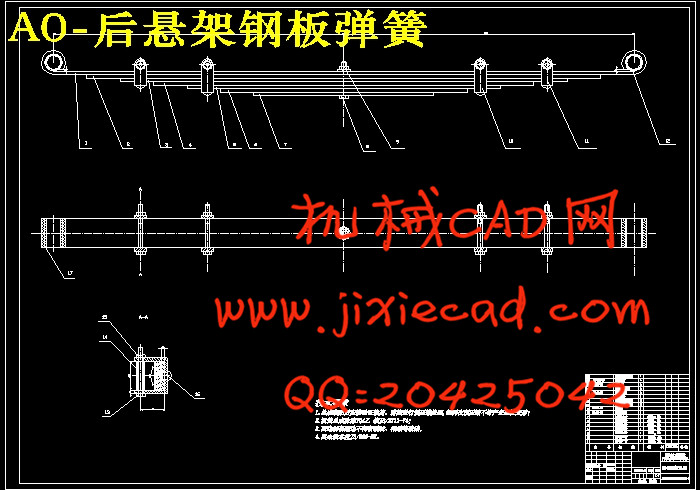

4.1 钢板弹簧的布置方案的选择………………………………………………11

4.2 钢板弹簧主要参数的确定…………………………………………………11

4.2.1 满载弧高…………………………………………………………………11

4.2.2钢板弹簧长度L的确定…………………………………………12

4.3 钢板弹簧总成在自由状态下的弧高及曲率半径计算……………………15

4.4 钢板弹簧的刚度验算…………………………………………………………17

4.5 弹簧的最大应力点及最大应力…………………………………………18

4.6 弹簧卷耳和弹簧销的强度核算…………………………………………19

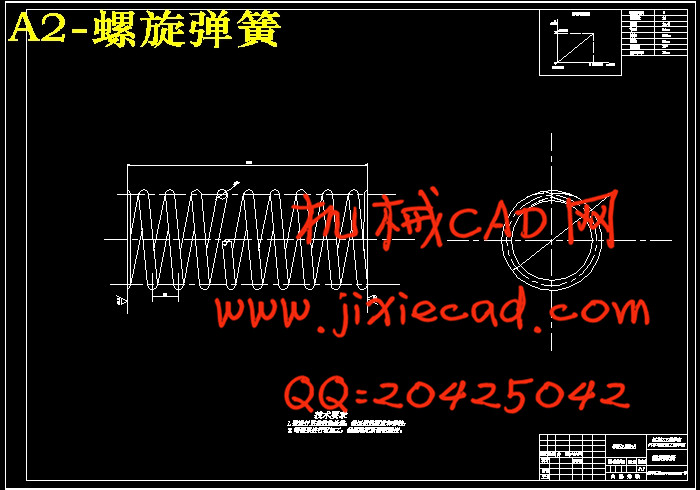

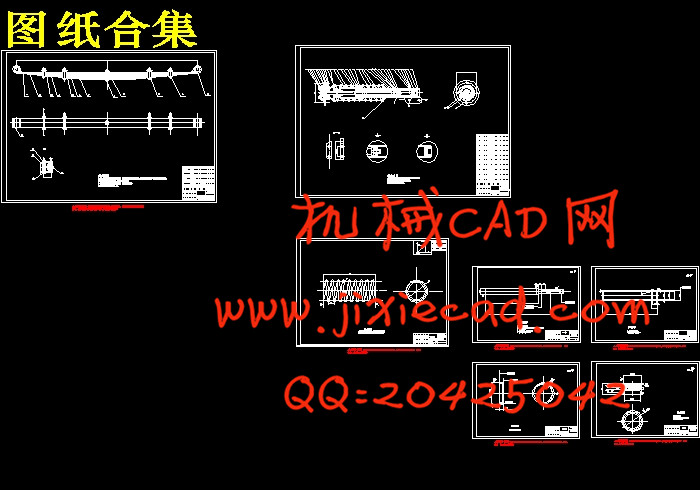

4.7螺旋弹簧的设计计算………………………………………………21

4.7.1螺旋弹簧形式、材料的选择……………………………………21

4.7.2确定弹簧直径及刚度……………………………………………21

4.7.3 其他参数的计算………………………………………………22

4.7.4弹簧的校验……………………………………………………22

4.8 本章总结………………………………………………………………23

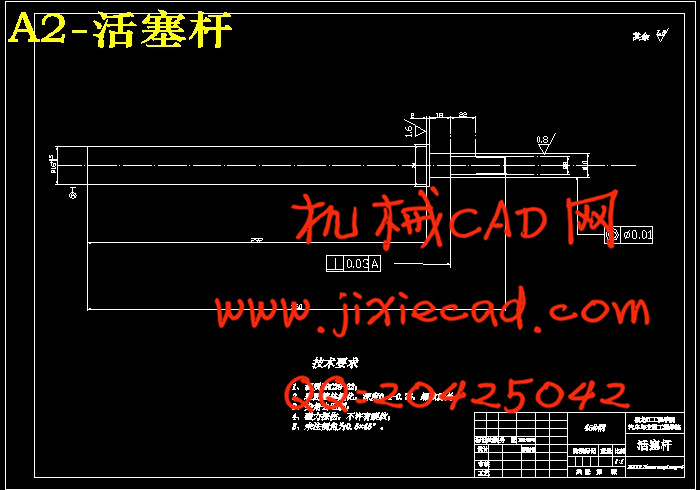

第5章 减振器的设计计算……………………………………………………24

5.1 减振器的分类………………………………………………………24

5. 2 主要性能参数的选择…………………………………………………………24

5.2.1 相对阻尼系数ψ…………………………………………………………24

5.2.2 减振器阻尼系数的确定…………………………………………………25

5.2.3 最大卸荷力的确定………………………………………………………26

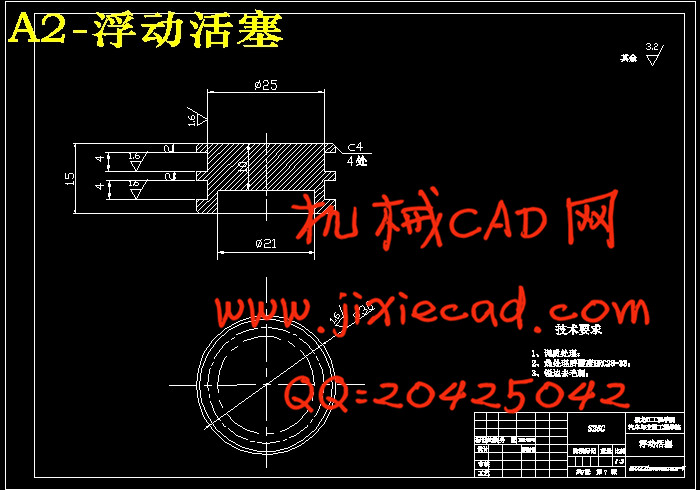

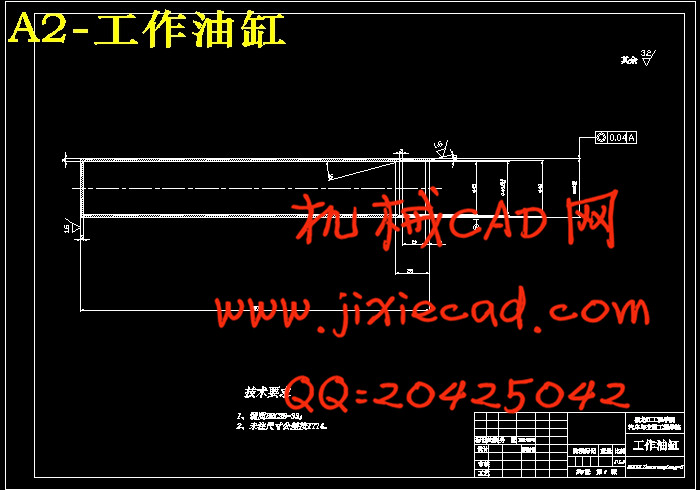

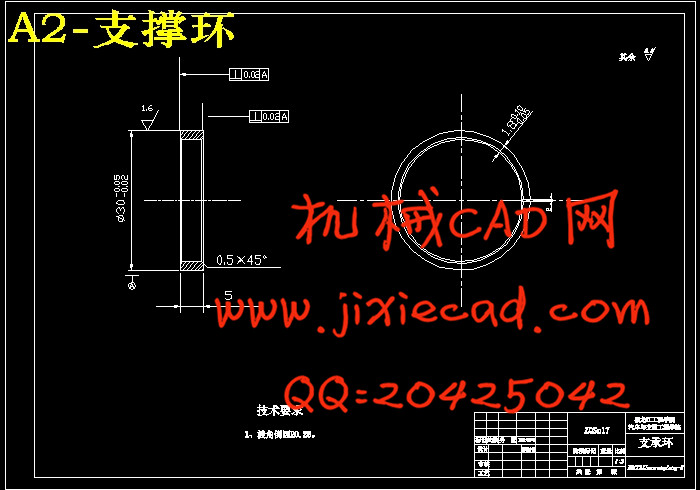

5.3 筒式减振器主要尺寸参数的确定…………………………………………26

5.4 本章总结……………………………………………………………27

第6章 导向机构的设计………………………………………………28

6.1导向机构的布置参数……………………………………………………28

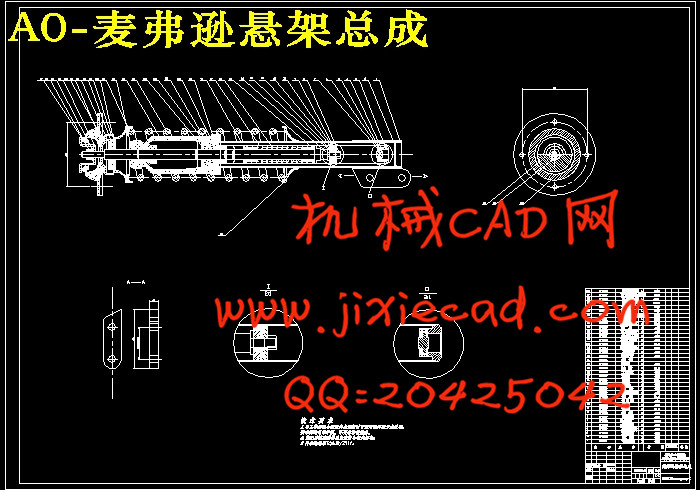

6.2 麦弗逊式悬架导向机构设计………………………………………………29

6.3本章总结…………………………………………………………………32

结 论………………………………………………………………………33

参考文献…………………………………………………………………34

致 谢…………………………………………………………………………35

汽车悬架是汽车的车架与车桥或车轮之间的一切传力连接装置的总称,其作用是传递作用在车轮和车架之间的力和力扭,并且缓冲由不平路面传给车架或车身的冲击力,并衰减由此引起的震动,以保证汽车能平顺地行驶。典型的悬架结构由弹性元件、导向机构以及减震器等组成,个别结构则还有缓冲块、横向稳定杆等。弹性元件又有钢板弹簧、空气弹簧、螺旋弹簧以及扭杆弹簧等形式,而现代轿车悬架多采用螺旋弹簧和扭杆弹簧,个别高级轿车则使用空气弹簧。汽车悬架性能是影响汽车行驶平顺性、操纵稳定性和行驶速度的重要因素。因此,研究汽车振动,设计新型悬架系统,将振动控制到最低水平是提高现代汽车质量的重要措施。

本文研究的主要问题如下:

(1)对前、后悬架的结构进行设计,主要是确定减震器的类型。

(2)对悬架的各个尺寸参数进行计算及相关零部件的尺寸进行设计计算。

(3)对减震器和导向机构进行选择计算,确定减震器的类型等。

本文是对轻型货车的前后悬架进行的设计计算,同时兼顾舒适性与运货能力。

关键词:悬架;弹性元件;弹簧;缓冲块 ;减震

ABSTRACT

Automotive vehicle suspension frame and axle or the wheel of all transmission between the general term for connecting devices, and its role is to transfer the role at the wheel and frame and between the torsional force, and uneven pavement from the buffer Biography to the frame or body of the impact, and the attenuation caused by vibration, to ensure the vehicle can travel smoothly. A typical structure of a flexible suspension components, shock absorbers and other agencies, as well as orientation of the individual block structure is also a buffer, such as horizontal Stabilizer. Elastic components and leaf springs, air springs, coil spring, as well as the form of torsion bar spring, and the use of many modern cars suspension coil spring and torsion bar springs, individual car use advanced air springs. Suspension performance is the impact of motor vehicles to motor cars and ride comfort, handling and stability and an important factor in speed. Therefore, the research vehicle vibration, the design of the new suspension system to the minimum level of vibration control is to improve the quality of Hyundai Motor important measures.The main problems discussed in this paper are as follows:

(1)Front and rear suspension design of the structure, primarily determine the type of shock absorber. (2)The various dimensions of the suspension parameters were calculated and related parts of the size of the design calculations

(3)The guiding mechanism of shock absorber selection calculations to determine the types of shock absorbers.

This article is for light goods vehicles, front and rear suspension design and calculation, taking into account the comfort and cargo capacity.

Key words:Suspension;Elastic element;Spring;Block buff;Damping

目 录

摘要………………………………………………………………………………I

Abstract…………………………………………………………………………II

第1章 绪论……………………………………………………………………1

1.1 汽车悬架概述……………………………………………………………………1

1.2 我国汽车悬架发展的现状……………………………………………………2

1.3 研究的背景及意义…………………………………………………………3

1.4 毕业论文研究内容………………………………………………………………4

第2章 悬架的结构形式分析及选择…………………………………………5

2.1 非独立悬架和独立悬架……………………………………………………5

2.2 前、后悬架方案的选择…………………………………………………………6

2.3 辅助元件………………………………………………………………6

2.4 本章总结………………………………………………………………7

第3章 主要参数的选择………………………………………………………………8

3.1 选择的要求及方法……………………………………………………8

3.2 悬架的静绕度……………………………………………………………………8

3.3 悬架动挠度………………………………………………………………………9

3.4 悬架弹性特性………………………………………………………………9

3.5 本章总结……………………………………………………………………10

第4章 弹性元件的计算……………………………………………………11

4.1 钢板弹簧的布置方案的选择………………………………………………11

4.2 钢板弹簧主要参数的确定…………………………………………………11

4.2.1 满载弧高…………………………………………………………………11

4.2.2钢板弹簧长度L的确定…………………………………………12

4.3 钢板弹簧总成在自由状态下的弧高及曲率半径计算……………………15

4.4 钢板弹簧的刚度验算…………………………………………………………17

4.5 弹簧的最大应力点及最大应力…………………………………………18

4.6 弹簧卷耳和弹簧销的强度核算…………………………………………19

4.7螺旋弹簧的设计计算………………………………………………21

4.7.1螺旋弹簧形式、材料的选择……………………………………21

4.7.2确定弹簧直径及刚度……………………………………………21

4.7.3 其他参数的计算………………………………………………22

4.7.4弹簧的校验……………………………………………………22

4.8 本章总结………………………………………………………………23

第5章 减振器的设计计算……………………………………………………24

5.1 减振器的分类………………………………………………………24

5. 2 主要性能参数的选择…………………………………………………………24

5.2.1 相对阻尼系数ψ…………………………………………………………24

5.2.2 减振器阻尼系数的确定…………………………………………………25

5.2.3 最大卸荷力的确定………………………………………………………26

5.3 筒式减振器主要尺寸参数的确定…………………………………………26

5.4 本章总结……………………………………………………………27

第6章 导向机构的设计………………………………………………28

6.1导向机构的布置参数……………………………………………………28

6.2 麦弗逊式悬架导向机构设计………………………………………………29

6.3本章总结…………………………………………………………………32

结 论………………………………………………………………………33

参考文献…………………………………………………………………34

致 谢…………………………………………………………………………35