设计简介

摘 要:首先明确琼脂压榨机机对液压系统的要求,然后通过给定的技术参数表里的液压系统设计参数,确定液压执行元件的载荷力、系统工作压力以及液压缸的主要结构尺寸,制定系统方案,拟定液压系统图,然后进行液压元件的选择,最后对系统性能进行验算。在具体的结构设计中,主要是针对系统中涉及到的阀类元件的安装,油路板的设计等。

关键词: 琼脂;液压系统;工作压力

Abstract: First ,clear about the hydraulic pressure system request of agar mill, then passes the technique outside and inside fluid department which decides, the definite fluid good part's Dutch strength, the department working strength as well as the fluid cylinder's main construction size, the formulation is a plan, decides the fluid department, however next the fluid part, finally is the performance line calculated. In the concrete construction, is mainly part's peaceful which in the department involves, oil duct board and so on

Key words: agar mill; hydraulic pressure system; working pressure

摘 要 1

关键词 1

1 前言 1

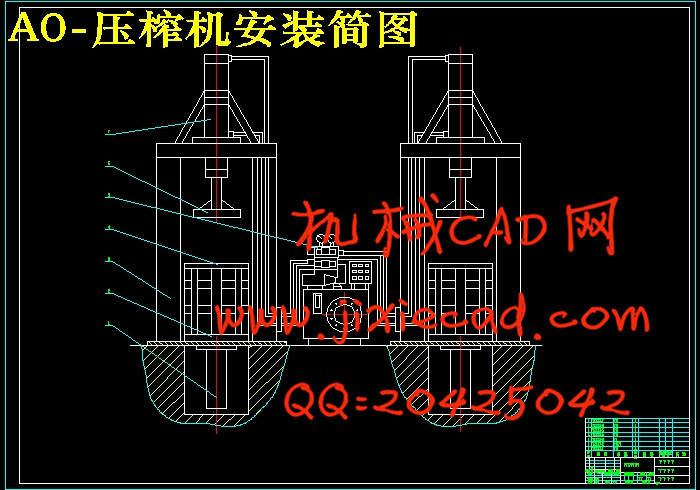

2 琼脂压榨机的组成及液压传动性能特点 2

2.1 琼脂压榨机的组成 2

2.2传动性能特点 3

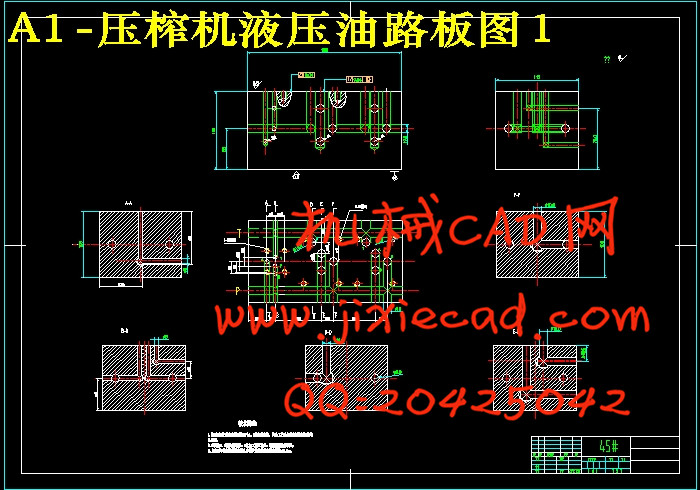

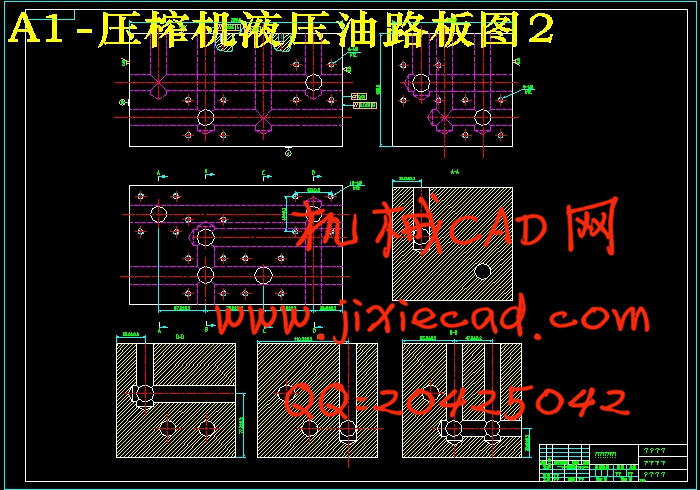

4 液压系统设计 4

4.1 压榨机工作循环 4

4.2 工况分析 4

4.3 拟定液压系统原理图 5

4.3.1 确定供油方式 5

4.3.2 调速方式的选择 5

4.3.3 速度换接方式的选择 5

5 液压执行元件载荷计算及元件的选择 7

5.1 各液压缸的载荷力计算 7

5.1.1 压榨缸的载荷力 7

5.1.2 顶出缸载荷力 7

5.1.3 计算顶出液压缸在工作循环各阶段的压力、流量和功率值 8

5.2 液压缸主要尺寸的确定 9

5.3 确定液压泵的流量、压力和选择泵的规格 11

5.4 液压阀的选择 13

5.5 其它辅助元件及液压油 13

6 液压系统的验算 15

6.1 压力损失计算 15

6.2 估算系统效率、发热和温升 16

7 总结 17

参考文献 18

致 谢 19

关键词: 琼脂;液压系统;工作压力

Abstract: First ,clear about the hydraulic pressure system request of agar mill, then passes the technique outside and inside fluid department which decides, the definite fluid good part's Dutch strength, the department working strength as well as the fluid cylinder's main construction size, the formulation is a plan, decides the fluid department, however next the fluid part, finally is the performance line calculated. In the concrete construction, is mainly part's peaceful which in the department involves, oil duct board and so on

Key words: agar mill; hydraulic pressure system; working pressure

目 录

摘 要 1

关键词 1

1 前言 1

2 琼脂压榨机的组成及液压传动性能特点 2

2.1 琼脂压榨机的组成 2

2.2传动性能特点 3

4 液压系统设计 4

4.1 压榨机工作循环 4

4.2 工况分析 4

4.3 拟定液压系统原理图 5

4.3.1 确定供油方式 5

4.3.2 调速方式的选择 5

4.3.3 速度换接方式的选择 5

5 液压执行元件载荷计算及元件的选择 7

5.1 各液压缸的载荷力计算 7

5.1.1 压榨缸的载荷力 7

5.1.2 顶出缸载荷力 7

5.1.3 计算顶出液压缸在工作循环各阶段的压力、流量和功率值 8

5.2 液压缸主要尺寸的确定 9

5.3 确定液压泵的流量、压力和选择泵的规格 11

5.4 液压阀的选择 13

5.5 其它辅助元件及液压油 13

6 液压系统的验算 15

6.1 压力损失计算 15

6.2 估算系统效率、发热和温升 16

7 总结 17

参考文献 18

致 谢 19