设计简介

汽车后桥是汽车的主要部件之一,其基本的功用是增大由传动轴或直接由变速器传来的转矩,再将转矩分配给左右驱动车轮,并使左右驱动车轮具有汽车行驶运动所要求的差速功能:同时,驱动桥还要承受作用于路面和车架或承载车身之间的铅垂力、纵向力,横向力及其力矩。其质量,性能的好坏直接影响整车的安全性,经济性、舒适性、可靠性。

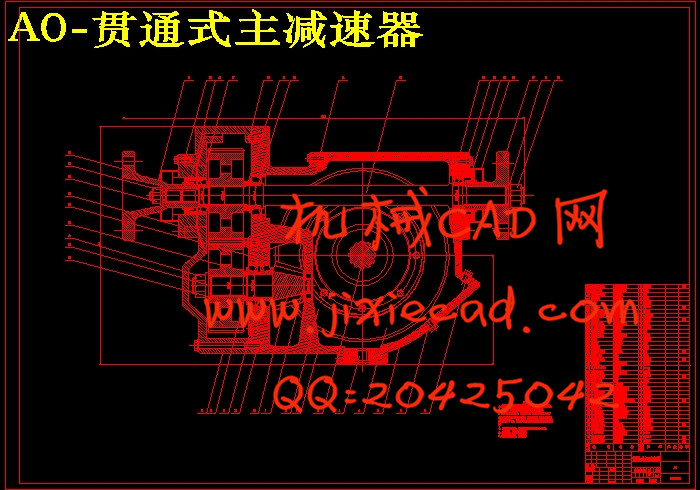

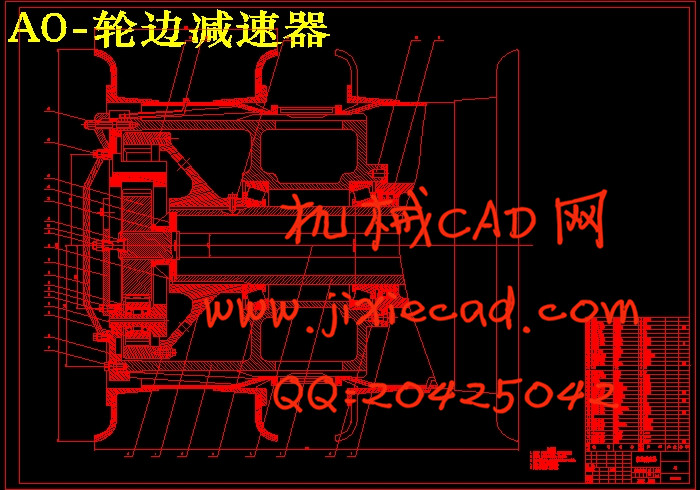

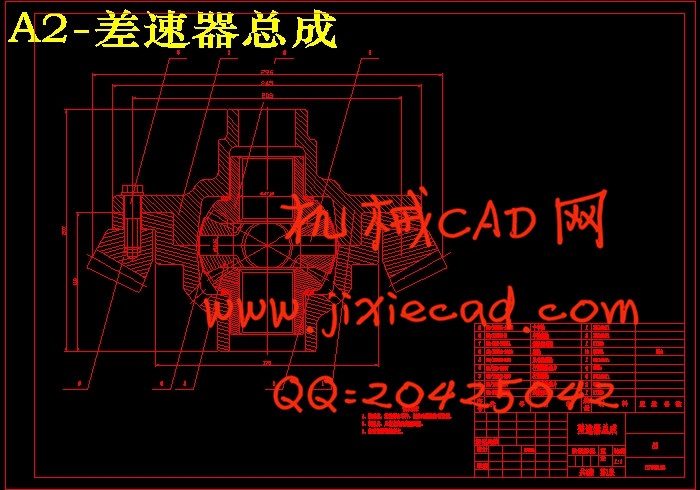

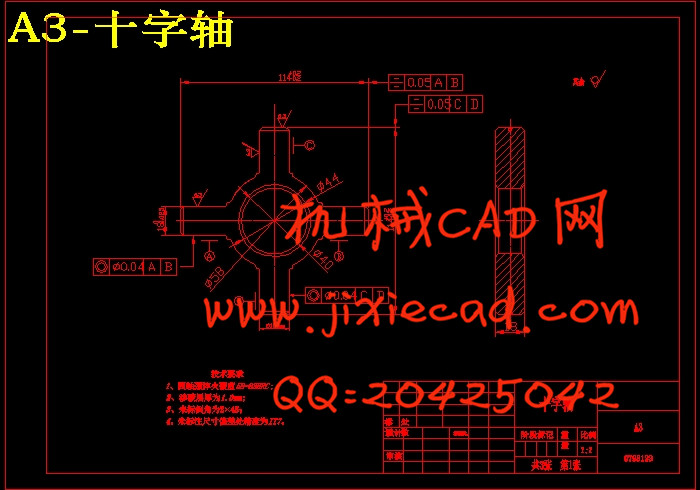

本文认真地分析参考了天龙重卡300双驱动桥,在论述汽车驱动桥运行机理的基础上,提练出了在驱动桥设计中应掌握的满足汽车行驶的平顺性和通过性、降噪技术的应用及零件的标准化、部件的通用化、产品的系列化等三大关键技术;阐述了汽车驱动桥的基本原理并进行了系统分析;根据经济、适用、舒适、安全可靠的设计原则和分析比较,确定了重型卡车驱动桥结构形式、布置方法、主减速器总成、差速器总成、半轴、桥壳及轮边减速器的结构型式;并对制动器以及主要零部件进行了强度校核,完善了驱动桥的整体设计。

通过本课题的研究,开发设计出适用于装置大马力发动机重型货车的双级驱动桥产品,确保设计的重型卡车驱动桥经济、实用、安全、可靠。

关键词: 驱动桥 主减速器 差速器 轮边减速器

Abstract

Drive axle is one of the most important parts of automobile. The function is to increase the torque from drive shaft or from transmission directly, and then distribute it to left and right wheels which have the differential ability automobile needed when driving. And the drive axle has to support the vertical force, longitudinal force, horizontal force and their moments between road and frame or body. Its quality and performance will affect the security, economic, comfortability and reliability.

This article analyzes and refers to the drive axle of Tianlongtruck and the 300 drive axle of Hyundai seriously. Through the study of this topic, we can design the single driving axle devices that apply to the heavy truck with high-powered engine, and make sure the drive axle we design of heavy truck economic, practical, safe and reliable. On talking about the running principal of driving axle ,the three key techno ledge about vehicle traveling on the ride and through, and noise reduction technology applications and the standardization of parts, components of the universal, Products such as the serialization that we should master to meet, it describes and has a systematic analysis on the basic principles of viecle drive axle.

According to the design principles and analysis and comparison of economy, application, comfortability, safety and reliability , the heavy truck drive axle structure, layout ways, and the final drive assembly, differential assembly, the bridge case and axle structure can be determined; and the strength checking of brake parts, as well as major components improves overall design of the driving axle.

Through the study of this topic, we can design the single drive axle devices that apply to the heavy truck with high-powered engine, and make sure the drive axle we design of heavy truck economic, practical, safe and reliable.

Keywords: Heavy truck Drive axle Final drive Differential

目 录

摘 要.............................................................I

Abstract..........................................................II

第1章 绪论........................................................1

第2章 贯通桥主减速器设计.........................................2

2.1 主减速器的结构形式........................................2

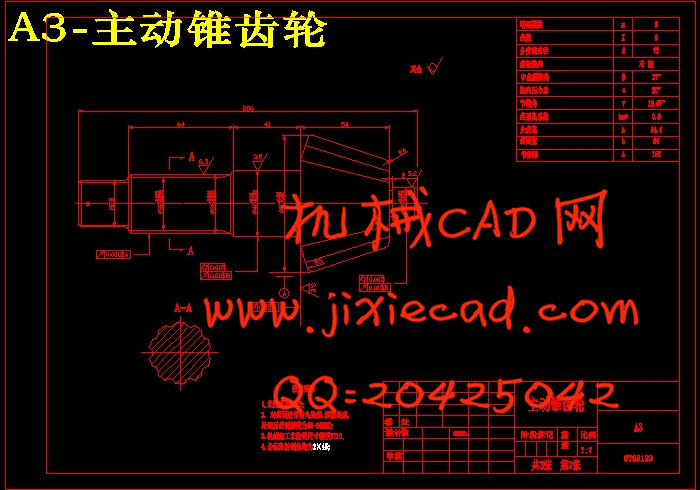

2.1.1 主减速器的齿轮类型...................................2

2.1.2 主减速器的减速形式...................................3

2.1.3 主减速器主从动锥齿轮的支承方案.......................4

2.2 主减速器基本参数选择与计算载荷的确定......................5

2.2.1 主减速器齿轮计算载荷的确定...........................5

2.2.2 锥齿轮主要参数的选择.................................7

2.2.3 主减速器圆弧锥齿轮的几何尺寸计算....................10

2.2.4 主减速器锥齿轮的强度计算............................11

2.2.5 主减速器轴承载荷的计算.............................20

2.3 主减速器齿轮的材料及热处理...............................23

2.4 主减速器的润滑...........................................24

2.5 本章小结..................................................25

第3章 贯通桥差速器设计..........................................26

3.1 对称式圆锥行星齿轮差速器的差速原理.......................26

3.2 对称式圆锥行星齿轮差速器的结构...........................27

3.3 对称式圆锥行星齿轮差速器的设计...........................28

3.3.1 差速器齿轮的基本参数的选择..........................28

3.3.2 差速器直齿锥齿轮的几何尺寸计算......................30

3.3.3 差速器齿轮的强度计算................................32

3.4 差速器齿轮的材料..........................................33

3.5 本章小结..................................................33

第4章 半轴及贯通轴的设计........................................34

4.1 概述.....................................................34

4.2 全浮式半轴的设计与计算....................................34

4.2.1半轴的计算载荷的确定...............................34

4.2.2半轴杆部直径的选择...................................35

4.2.3半轴强度计算.........................................36

4.2.4花键轴的强度计算.....................................36

4.3半轴材料与热处理...........................................38

4.4 本章小结.................................................38

第5章 轮边减速器设计............................................40

5.1 概述......................................................40

5.2 轮边减速器各参数的选择...................................41

5.3 设计参数的优化...........................................42

5.4 轮边减速器各齿轮强度校核.................................43

5.5 本章小结.................................................45

结 论............................................................46

致 谢............................................................47

参考文献..........................................................48