设计简介

摘要

我国是世界上主要的花生产区。多年来,花生收获机械化整体水平较低,极大地影响了花生的发展。随着我国花生种植面积的不断增大,花生摘果压力的不断增大,花生摘果机械在花生生产过程中将起到越来越大的作用。本文通过对我国花生生产现状,摘果方式的调查研究,研制出全喂入式花生摘果机,满足了现阶段花生产区的要求。论文主要内容如下:对全喂入式花生摘果机的结构和工作原理进行了简要分析,总结了该摘果机的主要性能特点重点研究了花生摘果机的喂入,摘果,分选等装置,探索新的工作原理和新的结构设计。

关键词:全喂入式;花生摘果机;摘果

Abstract

Our country is one of the world's major peanuts producing region .For many years, the peanut harvest mechanization level is low, greatly influenced the development of peanuts. Along with our country earthnut cultivates an area to increase ceaselessly, peanut picking pressure increasing, peanut picking machine in the process of peanut production will play a more and more important role. This article through to our country peanut production status, pick the fruit of investigation and study way, develop the feeding type peanuts to pick the fruit machine, meet the requirements of production of the present stage of peanuts. Paper main contents are as follows: On the whole feeding type peanuts to pick the fruit machine structure and working principle are briefly analyzed, This paper summarizes the main properties of picking fruit machine characteristics on the fruit machine peanut pick feeding, pick the fruit, the device such as sorting, explore new working theory and the new structure design.Key word :All the feeding type ;Peanut picking machine ;Pick the fruit.

摘要 I

Abstract II

1. 绪论 1

1.1 研究的目的和意义 1

1.2 国内外花生摘果机械的发展现状 1

2.花生摘果的主要方式及摘果滚筒类型 2

2.1 轴流式钉齿滚筒 4

2.2 蓖梳式圆柱形轴流滚筒 4

2.3 差动式摘果滚筒 5

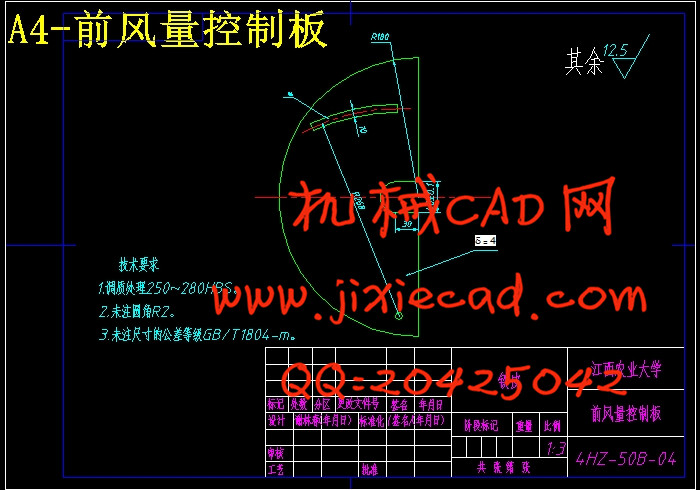

3. 4HZ-50B型全喂入式花生摘果机的结构设计 6

3.1 基本要求 6

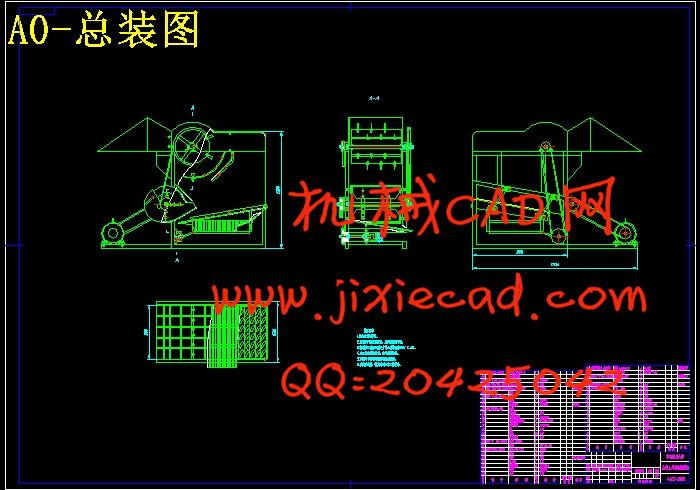

3.2 总体结构 6

3.3工作原理 7

4.摘果装置传动系统的设计 8

4.1 电机与风机V带传动的设计计算 8

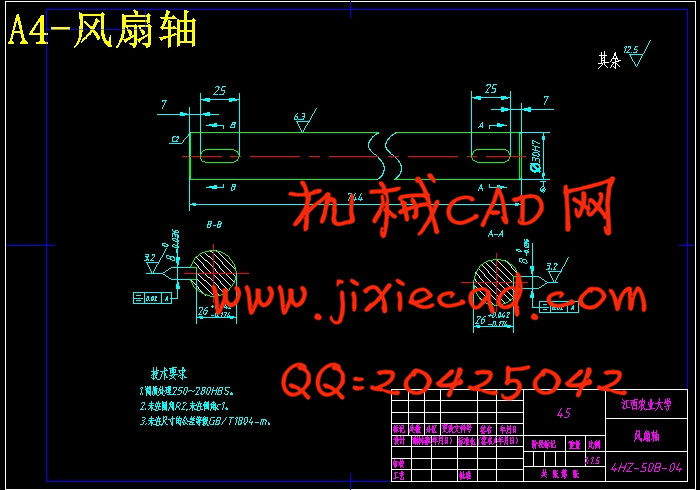

4.2 风机与滚筒V带传动的设计计算 11

4.3 滚筒与筛子V带传动的设计计算 13

5. 主要部件设计 15

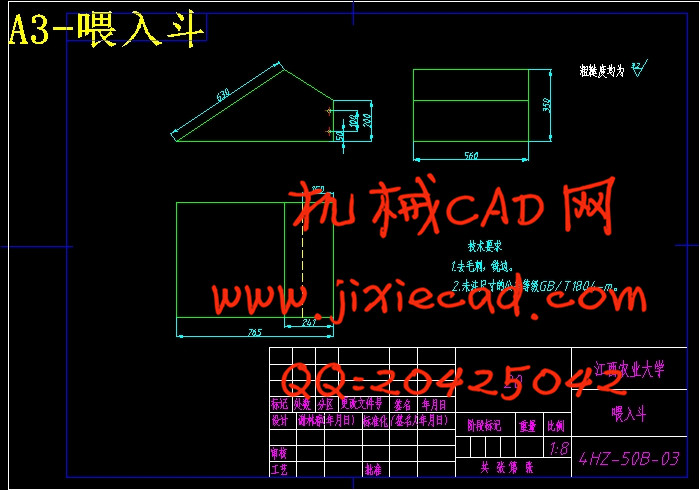

5.1 喂入斗 15

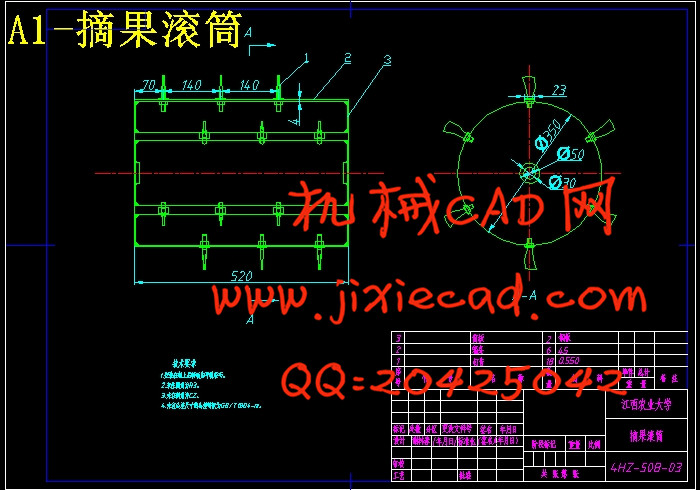

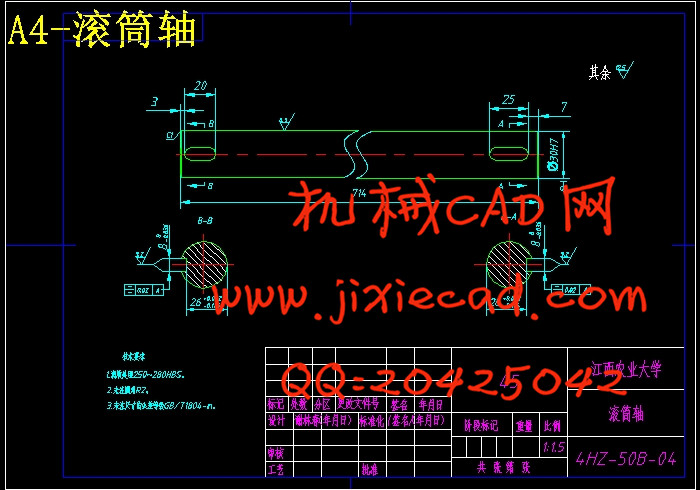

5.2 摘果滚筒设计计算 15

5.2.1 确定滚筒类型 15

5.2.2 滚筒的直径 16

5.2.3滚筒的长度 17

5.2.4滚筒的线速度V 17

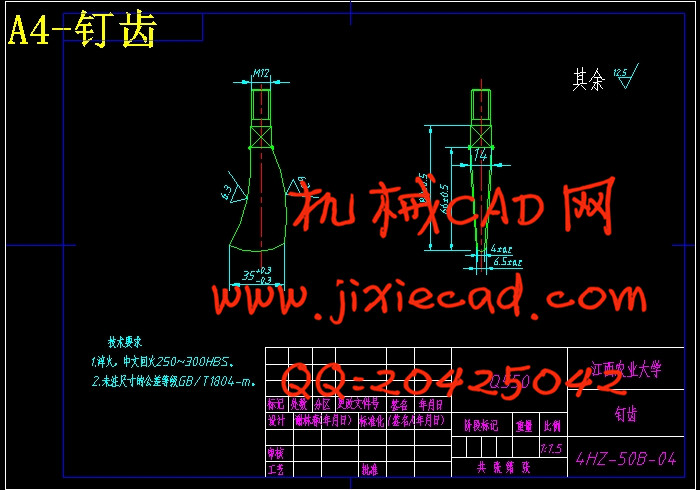

5.3. 滚筒钉齿的设计 18

5.3.1滚筒钉齿的形状的选择 18

5.3.2 滚筒钉齿的排列 18

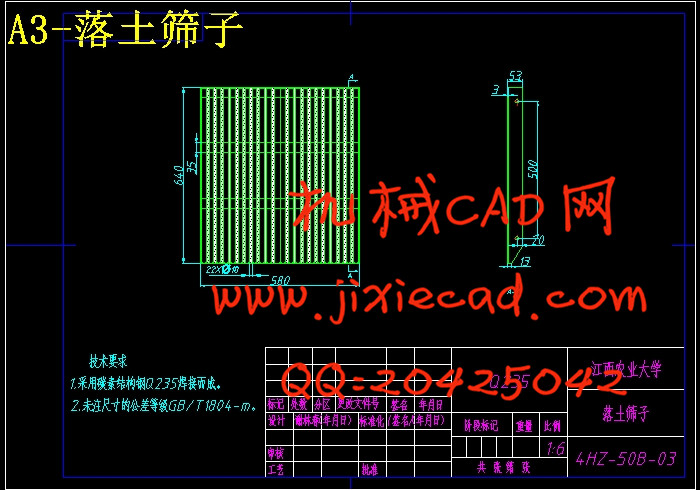

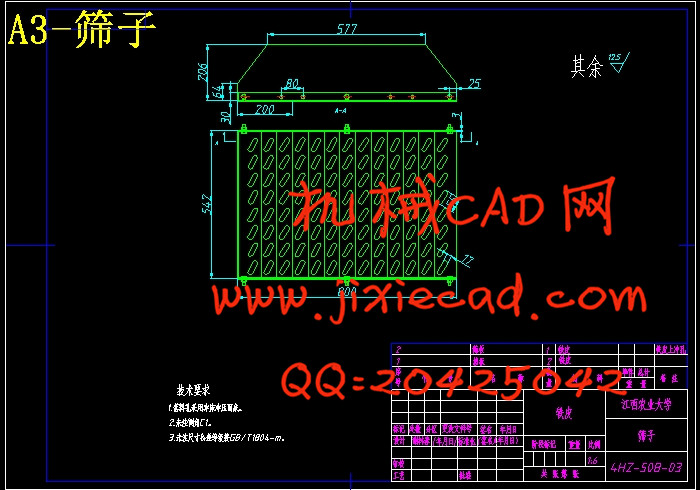

5.4. 凹板筛的设计分析 19

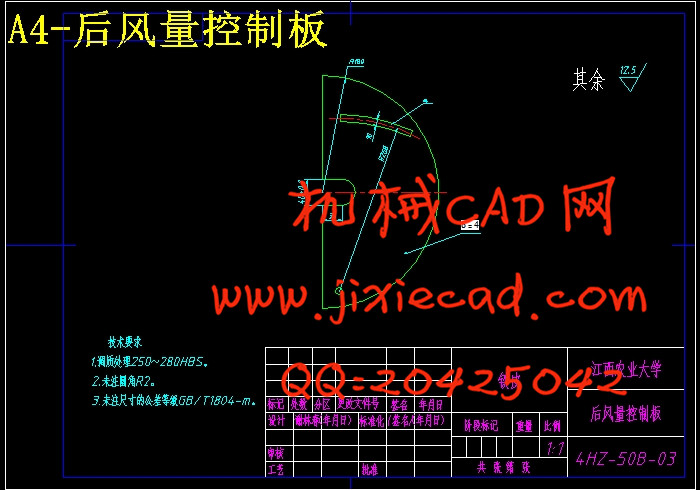

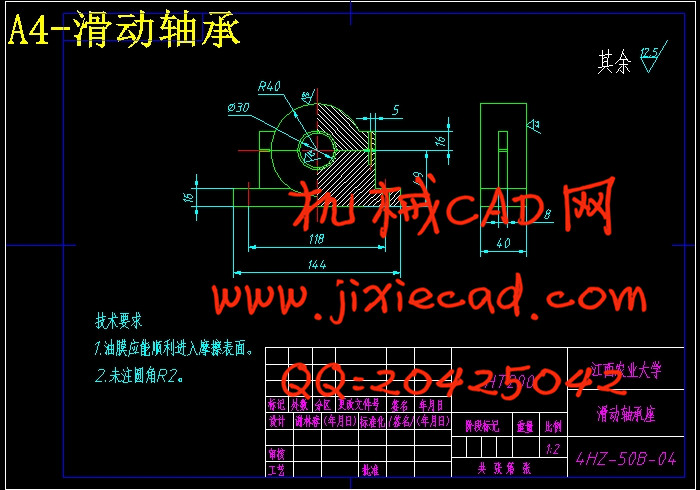

5.5 风机的设计 20

6、花生摘果机的正确使用与养护 21

参考文献 21

谢辞 22