设计简介

摘要

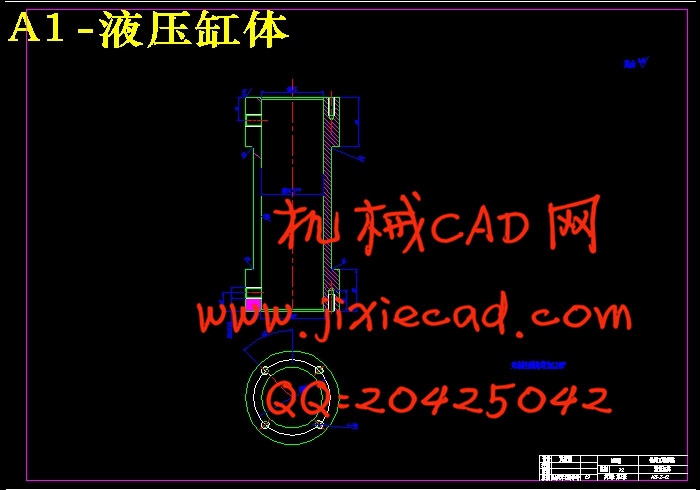

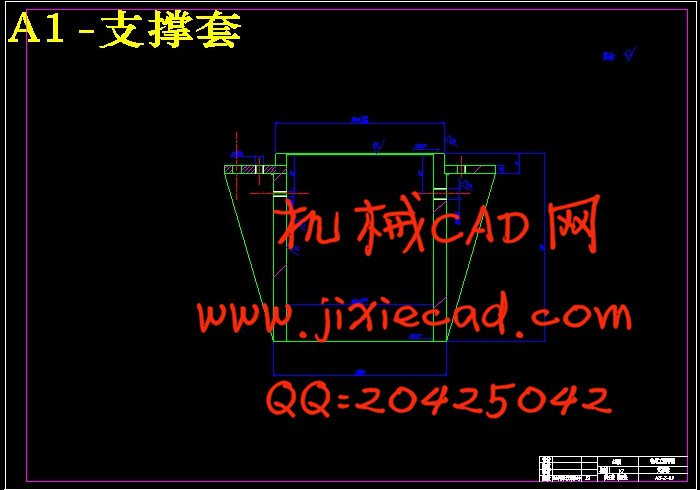

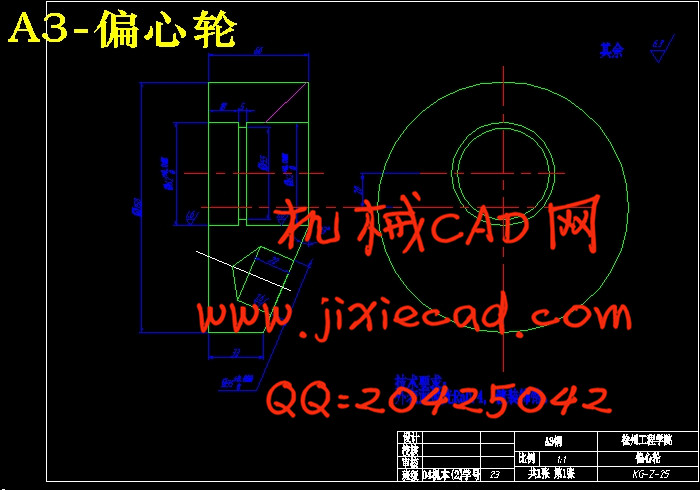

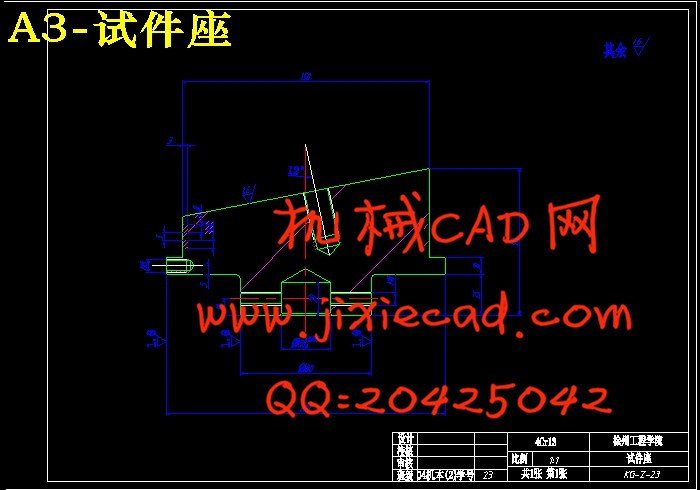

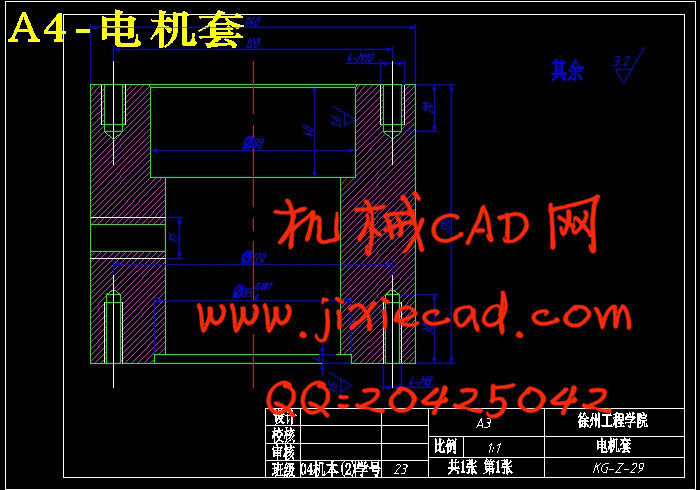

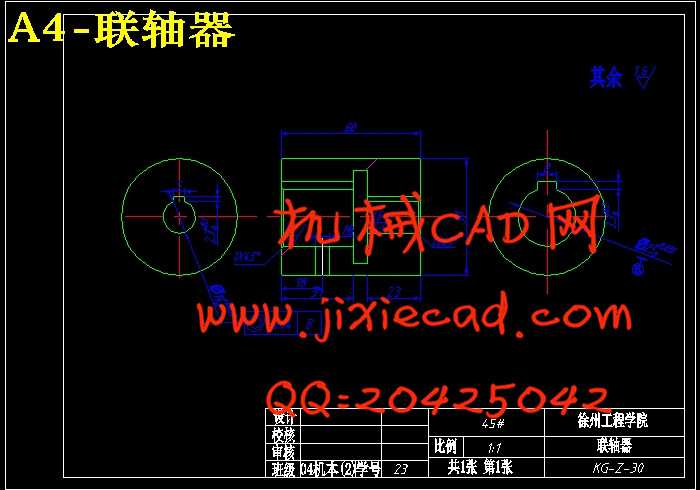

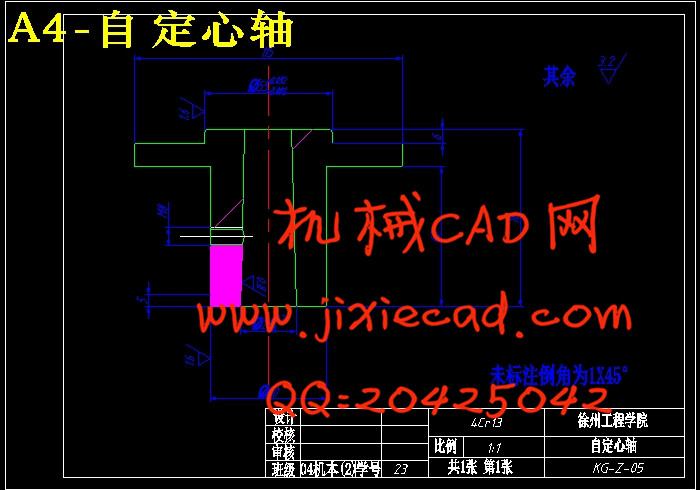

本课题是对人体髋关节模拟试验机机械传动部分的研制。试验机的工作原理是将股骨头和髋臼部件试样按照其正常位置安装于试验台上,通过试验装置使两者之间产生规定的随时间变化的负载及相对角运动。该机械设计时考虑的主要因素是使其在实验室环境中能够正确模拟人体髋关节的实际运动工况,以使试件在试验过程中产生的摩擦机理、磨损形式与实际使用条件下相一致,从而可以准确、可靠地测试人工关节材料的生物摩擦学特性参数,为临床应用提供指导性试验数据。根据以上要求设计出试验机的总装配图。该试验机要求的最大试验载荷为1t,要求主轴转速为60rpm。假设作用在股骨头头部的载荷为1t,则可以算出最大阻力。选则直径为50mm的股骨头,求出最大扭矩,由此确定电机的功率从而计算出最小轴径。根据最小轴径初选各个零件的尺寸。通过校核确认其安全以确保试验机正常运转。电机运转时通过联轴器带动主轴旋转,从而带动固定在主轴轴端的偏心轮转动,试件座安装在摆轴上和摆轴一起饶中心轴线转动。使得由关节球支架固定在试件座上的关节球头和髋臼试件之间产生摩擦,从而达到试验的目的。其中髋臼试件由骨水泥固定在髋臼座上,冲击载荷由液压缸提供作用于自定心轴上,通过髋臼支架最终作用在关节球头上,加上关节球头随试件座绕中心线转动。这样实现模拟人体髋关节的实际运动,使其产生的摩擦机理、磨损形式与实际使用条件下相一致,以达到设计该试验机的初衷。

关键词:关节试验机 ;模拟试验 ;人体髋关节 ;摩擦机理

Abstract

A hip simulator had been designed and manufactured in this study. The principle of the simulator is fit the stock bone and the part test specimen to its normal position in the test platform, causing the variation load changing with the time and the relative angular motion between them through the test equipment. The primary factor which this machine design considered is whether it can simulate the human body coxa correctly in the laboratory environment, so that the friction mechanism, the attrition form of the test sample which produces in the testing with the actual exploitation conditions under consistent, thus may be accurate, reliably test the biological friction of the artificial joint material, provides the guidance tentative data for the clinical practice. Designs the testing machine according to the above request the assembly drawing. The biggest experimental load of this testing machine requests is 1t, the main axle rotational speed is requests 60rpm. The supposition function in the thighbone leader's department load is 1t, then may figure out the biggest resistance. Elects then the diameter is the 50mm stock bone, extracts the maximum torque, from this determines the electrical machinery the power thus to calculate the smallest axle diameter. According to smallest axle diameter primary election each components size. Through the examination confirmed its security by guarantees the testing machine normal work. The electrical machinery revolves when revolves through the shaft coupling impetus main axle, thus leads fixes in the main axle axial-tab terminal eccentric rotation, the test sample place installs on the pendulum shaft and the pendulum shaft forgives the central axis rotation together. Causes to fix by the joint ball support in the test sample place the joint ball and between the acetabulum test sample has the friction, thus achieves experimental the goal. Acetabulum test sample fixes by the bone cement in the acetabulum place, the impact load provides the function by the hydraulic cylinder on the self-centering axis, finally affects through the acetabulum support on joint ball, in addition joint ball circles the middle line rotation along with the test sample place. Like this realizes the simulation human body coxa proper motion, causes the friction mechanism, the attrition form which it produces with the actual exploitation conditions under to be consistent, by achieved designs this testing machine the original intention.

Keywords: hip simulator simulative test hip jiont wear mechanism

目 录本课题是对人体髋关节模拟试验机机械传动部分的研制。试验机的工作原理是将股骨头和髋臼部件试样按照其正常位置安装于试验台上,通过试验装置使两者之间产生规定的随时间变化的负载及相对角运动。该机械设计时考虑的主要因素是使其在实验室环境中能够正确模拟人体髋关节的实际运动工况,以使试件在试验过程中产生的摩擦机理、磨损形式与实际使用条件下相一致,从而可以准确、可靠地测试人工关节材料的生物摩擦学特性参数,为临床应用提供指导性试验数据。根据以上要求设计出试验机的总装配图。该试验机要求的最大试验载荷为1t,要求主轴转速为60rpm。假设作用在股骨头头部的载荷为1t,则可以算出最大阻力。选则直径为50mm的股骨头,求出最大扭矩,由此确定电机的功率从而计算出最小轴径。根据最小轴径初选各个零件的尺寸。通过校核确认其安全以确保试验机正常运转。电机运转时通过联轴器带动主轴旋转,从而带动固定在主轴轴端的偏心轮转动,试件座安装在摆轴上和摆轴一起饶中心轴线转动。使得由关节球支架固定在试件座上的关节球头和髋臼试件之间产生摩擦,从而达到试验的目的。其中髋臼试件由骨水泥固定在髋臼座上,冲击载荷由液压缸提供作用于自定心轴上,通过髋臼支架最终作用在关节球头上,加上关节球头随试件座绕中心线转动。这样实现模拟人体髋关节的实际运动,使其产生的摩擦机理、磨损形式与实际使用条件下相一致,以达到设计该试验机的初衷。

关键词:关节试验机 ;模拟试验 ;人体髋关节 ;摩擦机理

Abstract

A hip simulator had been designed and manufactured in this study. The principle of the simulator is fit the stock bone and the part test specimen to its normal position in the test platform, causing the variation load changing with the time and the relative angular motion between them through the test equipment. The primary factor which this machine design considered is whether it can simulate the human body coxa correctly in the laboratory environment, so that the friction mechanism, the attrition form of the test sample which produces in the testing with the actual exploitation conditions under consistent, thus may be accurate, reliably test the biological friction of the artificial joint material, provides the guidance tentative data for the clinical practice. Designs the testing machine according to the above request the assembly drawing. The biggest experimental load of this testing machine requests is 1t, the main axle rotational speed is requests 60rpm. The supposition function in the thighbone leader's department load is 1t, then may figure out the biggest resistance. Elects then the diameter is the 50mm stock bone, extracts the maximum torque, from this determines the electrical machinery the power thus to calculate the smallest axle diameter. According to smallest axle diameter primary election each components size. Through the examination confirmed its security by guarantees the testing machine normal work. The electrical machinery revolves when revolves through the shaft coupling impetus main axle, thus leads fixes in the main axle axial-tab terminal eccentric rotation, the test sample place installs on the pendulum shaft and the pendulum shaft forgives the central axis rotation together. Causes to fix by the joint ball support in the test sample place the joint ball and between the acetabulum test sample has the friction, thus achieves experimental the goal. Acetabulum test sample fixes by the bone cement in the acetabulum place, the impact load provides the function by the hydraulic cylinder on the self-centering axis, finally affects through the acetabulum support on joint ball, in addition joint ball circles the middle line rotation along with the test sample place. Like this realizes the simulation human body coxa proper motion, causes the friction mechanism, the attrition form which it produces with the actual exploitation conditions under to be consistent, by achieved designs this testing machine the original intention.

Keywords: hip simulator simulative test hip jiont wear mechanism

1 绪论 1

1.1 机械智能 1

1.1.1 机械智能的应用 1

1.1.2 本设计原理 1

1.2 模拟人体关节的发展史 1

1.3 试验机的现实意义 2

2 方案 3

2.1髋关节结构及运动分析 3

2.1.1人体髋关节结构 3

2.1.2 髋关节运动特性分析 4

2.1.3人工髋关节结构 5

2.2 方案的提出 6

2.2.1方案一: 6

2.3方案二 7

2.4 方案的选择: 8

2.5 设计方案 8

2.6 机械传动部分的运动特性分析 10

2.7磨损量的测定及磨损率的计算 12

2.7.1磨损量的测定 12

2.7.2 临床磨损率的计算 13

2.7.3磨损因数的计算 13

2.8温控装置的工作原理 15

3 设计计算过程 16

3.1初选电机功率 16

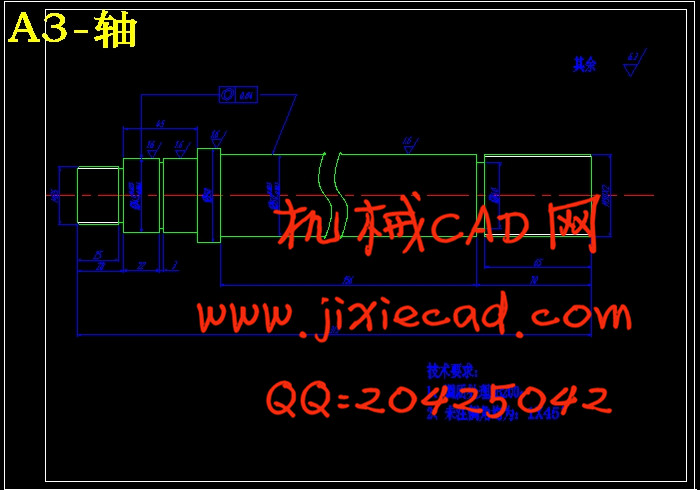

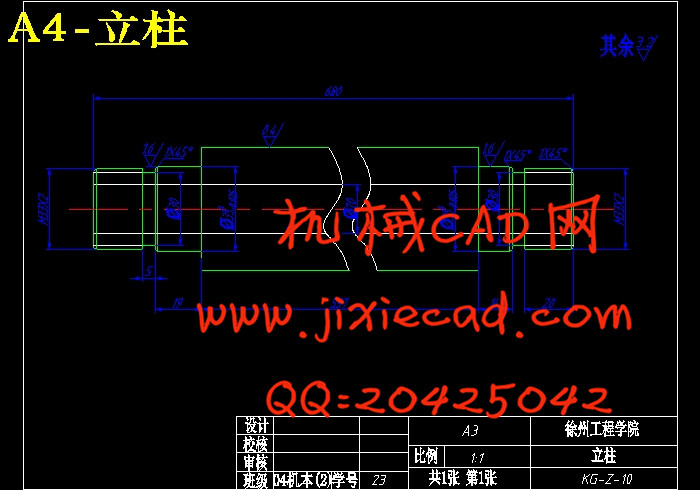

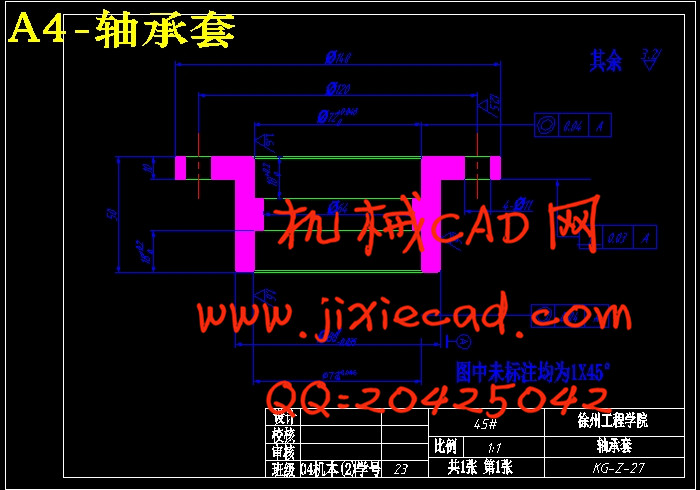

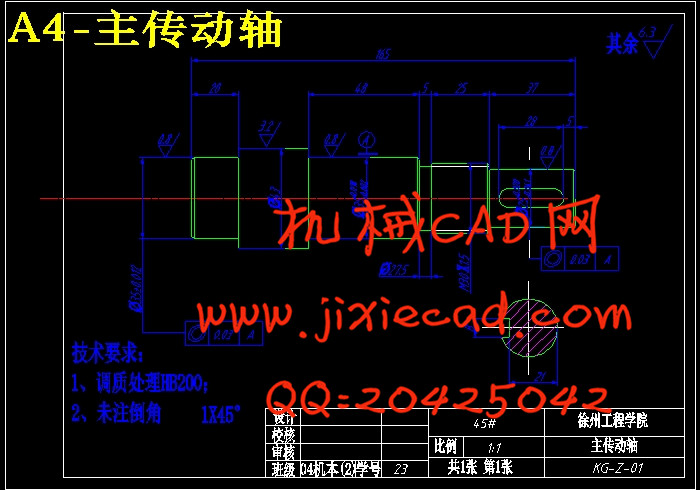

3.2主传动轴的设计 16

3.2.1选择轴的材料 16

3.2.2初步确定轴的最小直径 16

3.2.3轴的结构设计 16

3.2.4轴上零件的周向定位 17

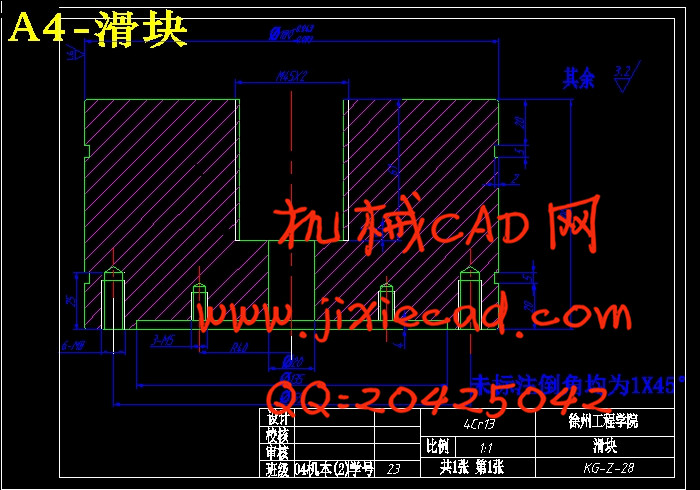

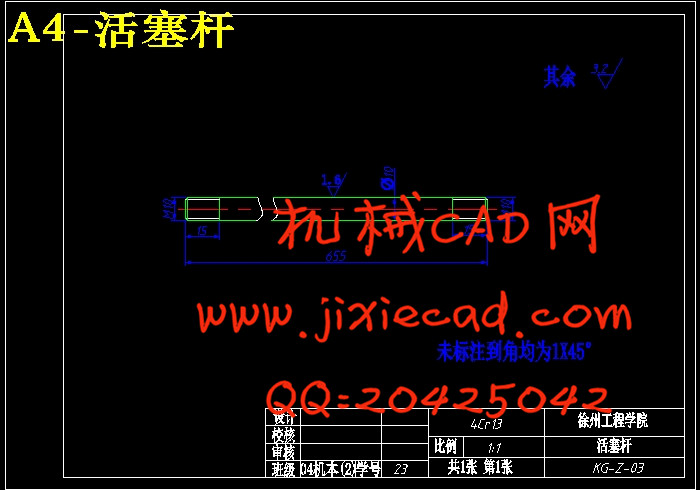

3.2.5确定轴上倒角 17

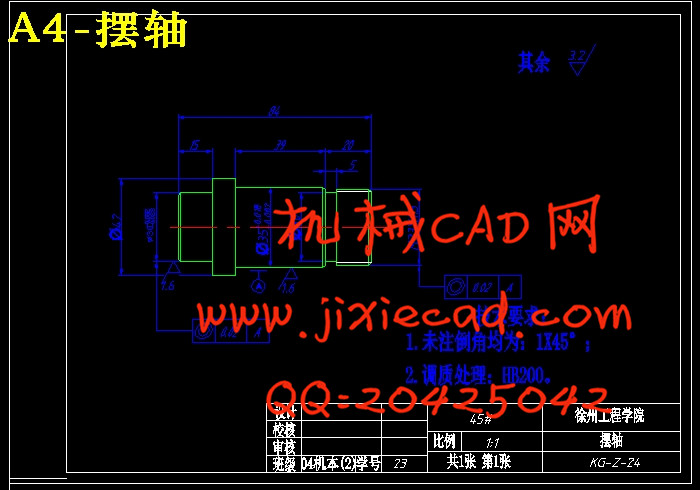

3.3.2初步确定轴的最小直径 18

3.4液压缸的结构尺寸设计 18

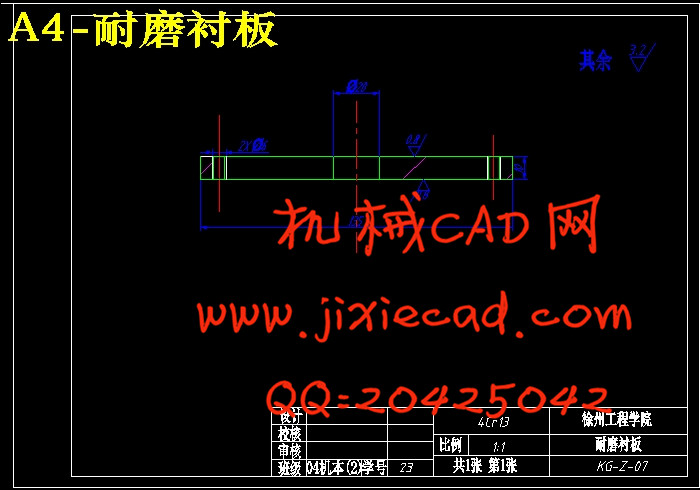

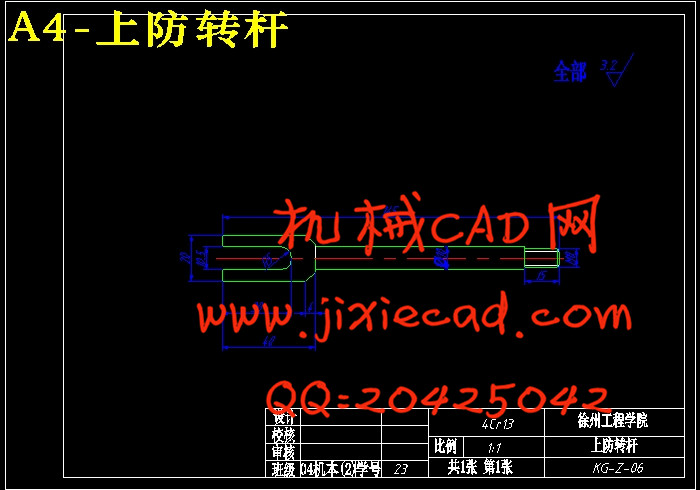

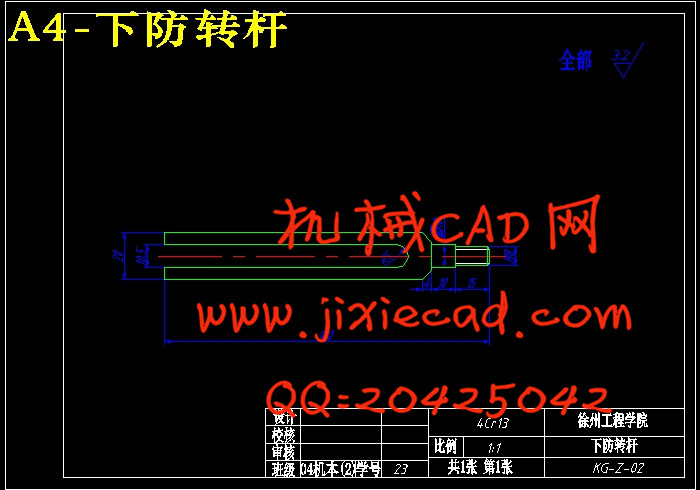

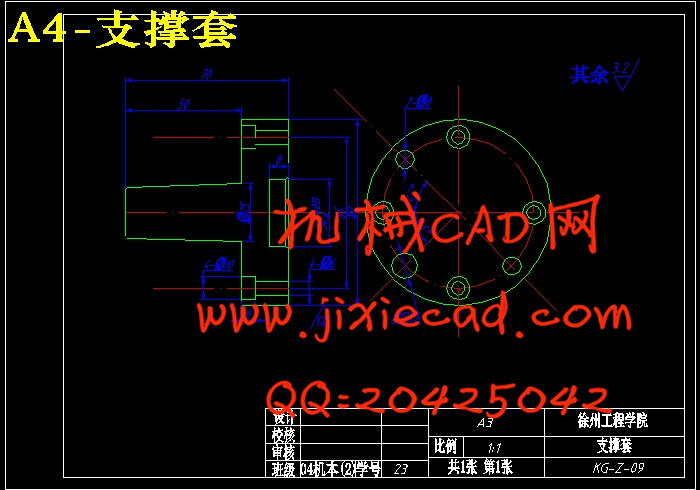

3.5 装配图及主要零件图设计 19

3.5.1 装配图草图 19

3.5.2零件图草图 20

4 零件校核 21

4.1求轴上载荷 22

4.2校核轴的强度 22

4.2.1画受力简图 22

4.2.2求作用在轴上的支反力 22

4.2.3校核轴的强度 23

4.3主动轴上轴承的校核 24

4.4摆轴的校核 25

4.5摆轴上轴承的校核 26

结论 28

致 谢 29

参考文献 30