设计简介

摘 要

人力提升机在我们国家目前还没有申请专利,现代社会上运用最多的是电动机带动的电力提升机,此项设计是传统的结构与创新的思想结合的成果。人力提升机是用于建筑外墙装饰和野外电力设备安装等专用设备,人力在无电源供应的情况下可轻松操纵,从而实现上下输送物料和人员填补该产品系列中的缺失,此项设计结构简单,操作方便。

人力提升机因其安装拆卸方便、结构牢固、安全可靠而广泛应用于采矿、冶炼、码头、建筑等行业中,作提升运输物料及产品之用。本提升机适于输送粉状,粒状及磨琢性小的物料,如:煤、水泥、石块、砂、粘土、矿石等。

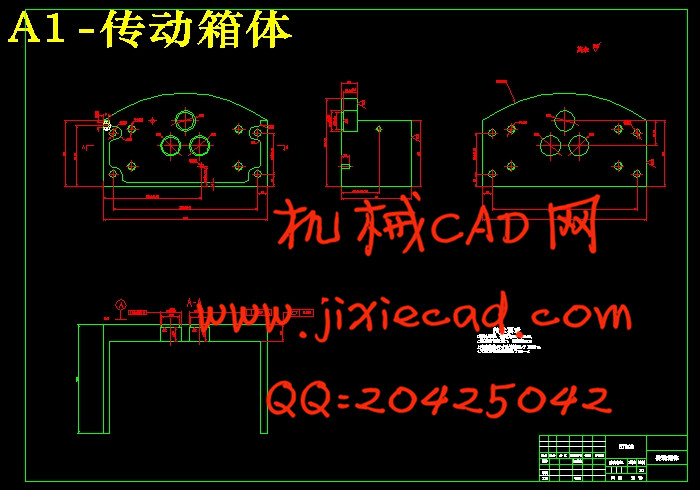

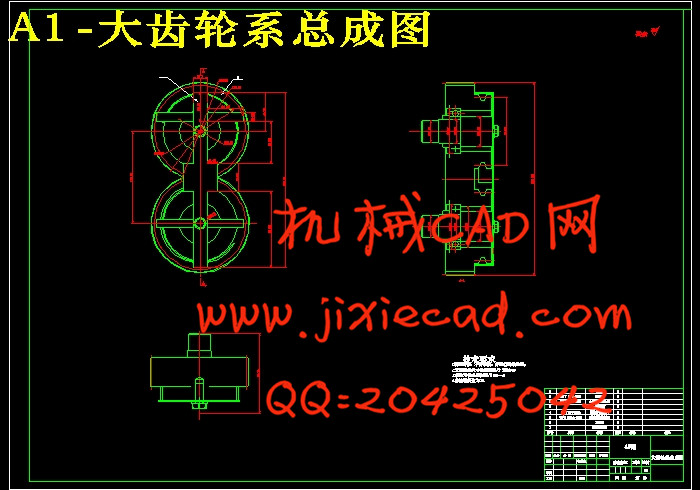

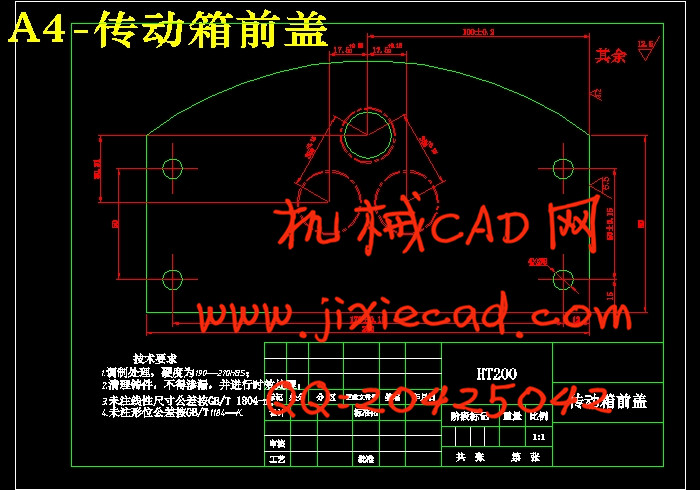

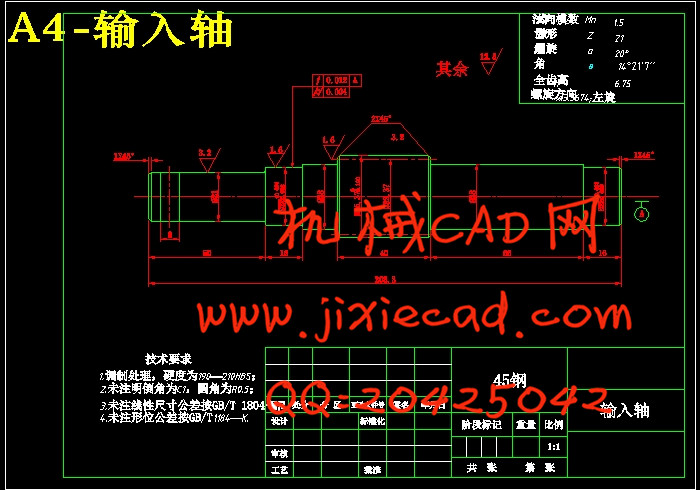

本课题是针对机械原理、机械制造技术、材料力学、理论力学进行设计的,对一级齿轮蜗杆传动机构、二级齿轮传动的优化设计、传动部件装配结构设计,以及其他几种常见机构进行详尽的分析,选择合适的方案进行设计计算。

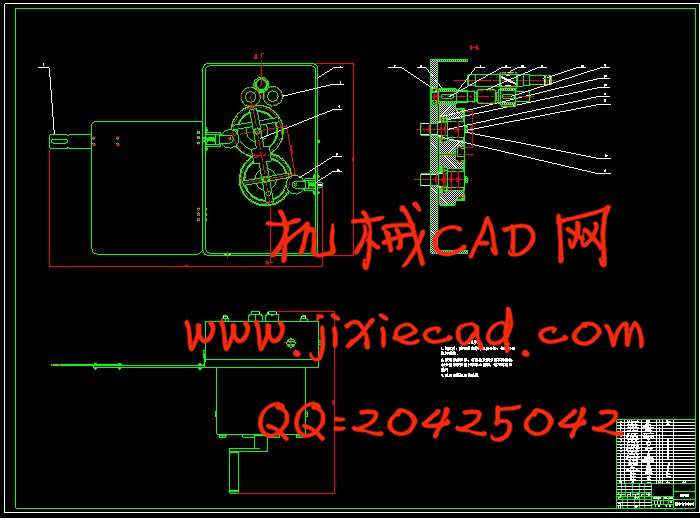

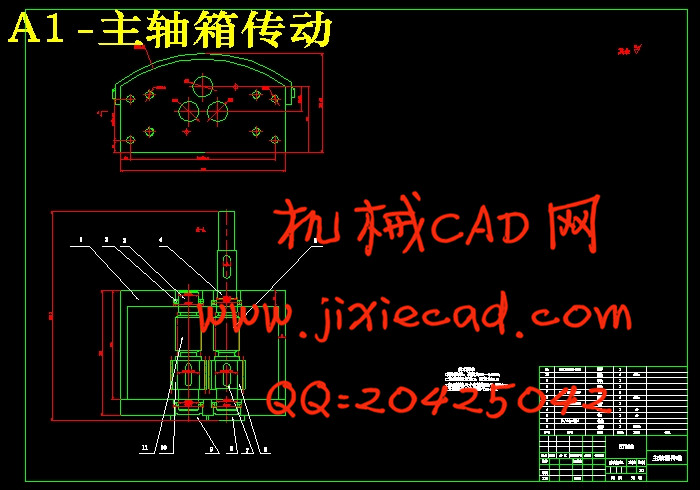

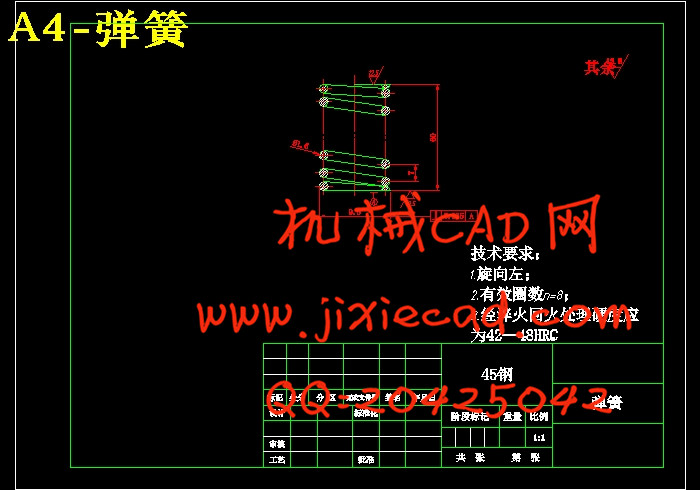

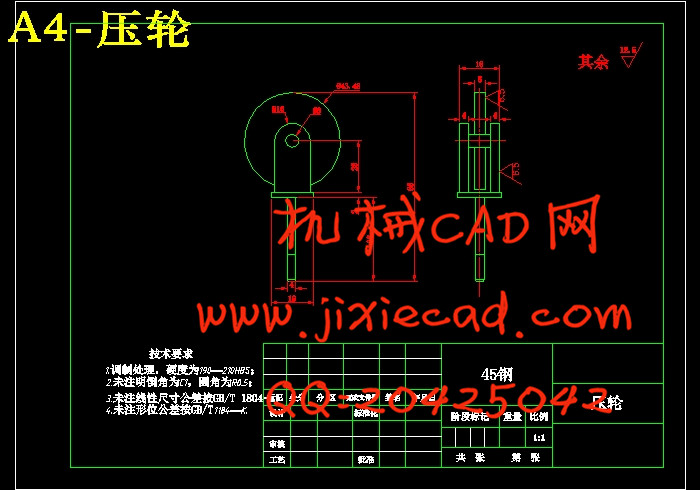

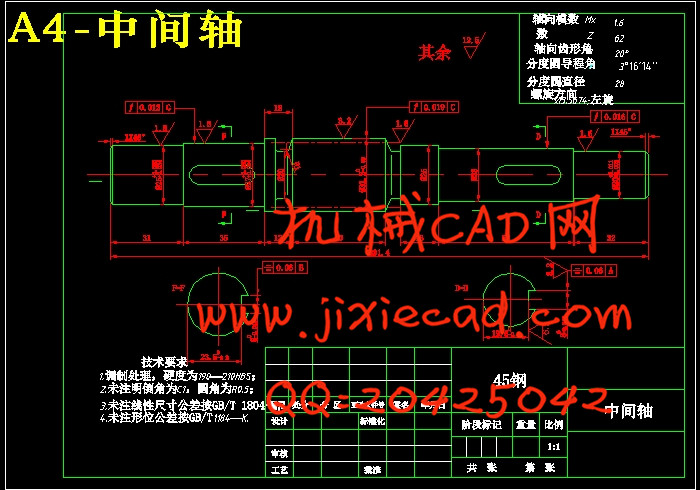

本设计内容包括一级齿轮传动,二级齿轮传动,钢丝绳的绕法,轴的传动,蜗杆的传动。用所学的工程图学和三维制图UG的知识画出装配图,和零件图,实现整个运动。

关键词: 提升机;齿轮;蜗杆;机械设计

Manpower hoist in our country there is no patent application, using the most modern society is the electric hoist motor drive, the design of structure is the traditional and innovative ideas combining with the results. Human hoisting machine is used for building exterior wall decoration and outdoor power equipment installation of special equipment, such as human in the case of no power supply can be easily manipulated, thus conveying material and up and down to fill the absence of the product series, the structure design, simple structure, convenient operation.

Because of its easy installation and removal, the structure solid, safe, reliable and widely used in mining, smelting, docks, and construction industries, to enhance the transport of materials and products for use. The hoist is suitable for conveying powder, granular and non-small-block mill and grinding of small materials, such as: coal, cement, stones, sand, clay, ore and so on。

This topic is in view of the mechanical principle, mechanical manufacturing technology, material mechanics, theoretical mechanics, the level of gear and worm drive, secondary optimization design of gear transmission, transmission parts assembly structure design, and other detailed analysis of several common institutions, choose the right solution for design calculation.

This design content including level gear transmission, the secondary gear transmission, wire rope winding, drive shaft, worm drive. With what they have learned knowledge of engineering graphics and 3 d drawing UG draw assembly drawings, and part drawing, realize the whole movement.

Key words : lifting machine;gear;worm;mechanical design

人力提升机在我们国家目前还没有申请专利,现代社会上运用最多的是电动机带动的电力提升机,此项设计是传统的结构与创新的思想结合的成果。人力提升机是用于建筑外墙装饰和野外电力设备安装等专用设备,人力在无电源供应的情况下可轻松操纵,从而实现上下输送物料和人员填补该产品系列中的缺失,此项设计结构简单,操作方便。

人力提升机因其安装拆卸方便、结构牢固、安全可靠而广泛应用于采矿、冶炼、码头、建筑等行业中,作提升运输物料及产品之用。本提升机适于输送粉状,粒状及磨琢性小的物料,如:煤、水泥、石块、砂、粘土、矿石等。

本课题是针对机械原理、机械制造技术、材料力学、理论力学进行设计的,对一级齿轮蜗杆传动机构、二级齿轮传动的优化设计、传动部件装配结构设计,以及其他几种常见机构进行详尽的分析,选择合适的方案进行设计计算。

本设计内容包括一级齿轮传动,二级齿轮传动,钢丝绳的绕法,轴的传动,蜗杆的传动。用所学的工程图学和三维制图UG的知识画出装配图,和零件图,实现整个运动。

关键词: 提升机;齿轮;蜗杆;机械设计

Abstract

Manpower hoist in our country there is no patent application, using the most modern society is the electric hoist motor drive, the design of structure is the traditional and innovative ideas combining with the results. Human hoisting machine is used for building exterior wall decoration and outdoor power equipment installation of special equipment, such as human in the case of no power supply can be easily manipulated, thus conveying material and up and down to fill the absence of the product series, the structure design, simple structure, convenient operation.

Because of its easy installation and removal, the structure solid, safe, reliable and widely used in mining, smelting, docks, and construction industries, to enhance the transport of materials and products for use. The hoist is suitable for conveying powder, granular and non-small-block mill and grinding of small materials, such as: coal, cement, stones, sand, clay, ore and so on。

This topic is in view of the mechanical principle, mechanical manufacturing technology, material mechanics, theoretical mechanics, the level of gear and worm drive, secondary optimization design of gear transmission, transmission parts assembly structure design, and other detailed analysis of several common institutions, choose the right solution for design calculation.

This design content including level gear transmission, the secondary gear transmission, wire rope winding, drive shaft, worm drive. With what they have learned knowledge of engineering graphics and 3 d drawing UG draw assembly drawings, and part drawing, realize the whole movement.

Key words : lifting machine;gear;worm;mechanical design

目 录

摘 要............................................................................................................ III

ABSTRATE.................................................................................. .IV

目录............................................................................................ V

1 绪论..........................................................................................1

1.1本课题的研究内容和意义..........................................................................1

1.2 国内外的发展概况............................................................................... ..1

1.3 提升机的概述.................................................................................. ......1

1.4 本提升机的构架和原理.................................................................... .......1

2 传动机构的设计计算......................................................................................4

2.1 确定传动装置的总传动比.........................................................................4

2.2 确定传动装置分配传动比........................................................................4

3 齿轮的设计...................................................................................................6

3.1 齿轮设计的一般步骤...............................................................................6

3.2 主动轴齿轮传动的设计计算.....................................................................6

3.3 从动轮齿轮传动的设计计算.....................................................................10

3.4 蜗轮传动...............................................................................................14

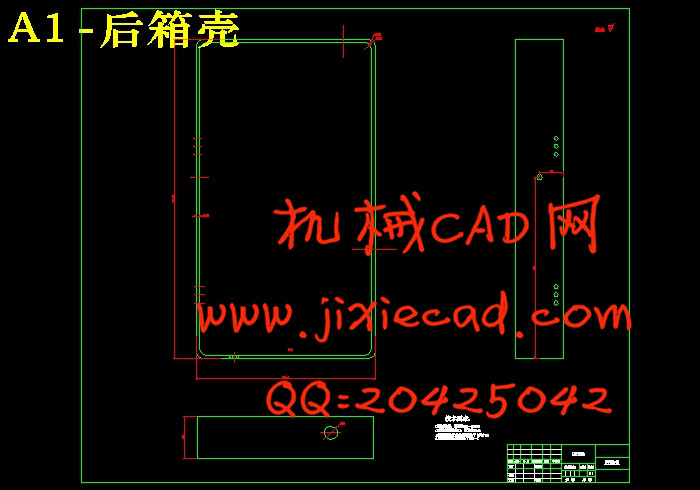

4 箱体的设计...................................................................................................16

5 轴的设计......................................................................................................18

5.1轴的设计过程..........................................................................................18

6 轴承的校核...................................................................................................30

6.1 主动轴上的轴承校核...............................................................................30

6.2 中间轴上的轴承校核............................................................................ ....31

7 润滑密封设计.................................................................................................32

8 联轴器设计..................................................................................... ..............33

9 总结................................................................................................. ...........34

致谢.............................................................................................................35

参考文献.......................................................................................................36