设计简介

摘 要

熔融沉积成型技术(FDM)是目前国内外应用最为广泛的快速成型技术之一。它可以快速、精确地将设计思想从CAD模型物化为具有一定功能的原型或零件,从而实现对产品的快速测评及修改,有效的缩短了产品的开发周期。在熔融沉积快速成型中,成型精度对最终产品的质量起着决定性的作用,但是目前成型机的成型精度往往不高,如何提高成型精度是当今快速成型研究的一个重要方向。

本课题围绕熔融成型机,重点研究了该设备的机械系统,提出一套完整的机械设计方案。具体工作如下:

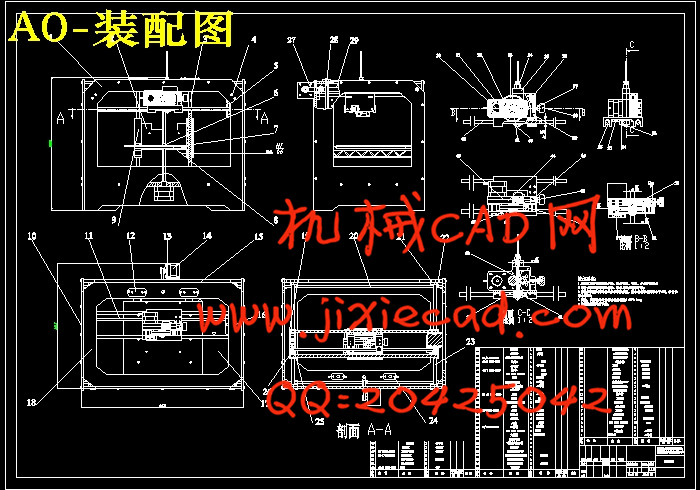

(1)结合传统的FDM熔融沉积成型设备,从整机的外形尺寸、最大成形空间、成形精度、主要运动结构和方式等方面,进行了细致和分析。在吸收了不同机型之间的优点和缺点之后,大致拟定了熔融成型机机械系统总体设计方案中的机械传动结构、三轴运动方式以及加热挤出头结构,确定了机械结构设计中的几个关键技术问题。

(2)以机械设计原理为依据,结合对FDM整个机械系统的几大构件制定的设计方案,按照整机设计需求参数,分别对运动系统、导向系统、机械结构和包装造型进行了具体的参数化选择,着重设计了加热挤出头结构,解决与优化了流涎问题,然后按照机身结构设计原则设计并完成了全部零部件的三维实体建模、装配以及工程图。

关键字:快速成型;FDM;加热挤出头

ABSTRACT

The fused deposition rapid prototyping technology (FDM) is one of the at home and abroad the most widely used rapid prototyping technology. It can quickly and accurately Design ideas from the CAD model materialized as proto types or parts of certain functions in order to achieve the rapid evaluation and modification of the product, effectively shortening the product development cycle. In fused deposition modeling, forming precision on the final product quality plays a decisive role, but the current forming machine precision is not high, how to improve the precision of the rapid prototyping is an important direction of research.

This topic around the molten molding machine, mainly studies the mechanical system of the device, puts forward a complete set of mechanical design.Specific work is as follows:

(1) combined with the traditional FDM fused deposition molding equipment, from the appearance of the whole machine size, maximum forming space, forming precision, main structure and movement mode, are detailed and analyzed.In absorbing the advantages and disadvantages between different models, roughly sketched the melting machine mechanical system overall design scheme of mechanical transmission structure, three axis movement mode and heating extrusion head structure, identified several key technical problems in mechanical structure design.

(2)And in accordance with FDM based on principle of mechanical design, the whole of several major components of design scheme of mechanical system, on the demand of the whole machine design parameters, respectively, on the sports system, guiding system, mechanical structure and packaging for the specific parameterized choice, mainly design the structure of heat extrusion head, solving and optimizing the salivate, then design and completed in accordance with the principle of the fuselage structure design all components of the three-dimensional entity modeling, assembly, and engineering drawing.

Key Words: Rapid Prototyping;Fused Deposition;Heating extrusion head

目录

1 绪论 3

1.1 引言 3

1.2 熔融沉积成型技术概论 3

1.2.1 熔融沉积成型技术的特点 4

1.2.2 熔融沉积成型技术 - 工艺过程 5

1.2.3 熔融沉积成型技术的应用 6

1.3 熔融沉积成型技术存在问题及发展方向 7

1.3.1 熔融沉积成型技术的现状 7

1.3.2 熔融沉积成型技术的发展方向 8

2 总体方案及结构设计 10

2.1 引言 10

2.2 总体设计要求 10

2.3 熔融沉积成型机床的结构运动方案 11

3 电机方案的选择及选型 13

3.1 电机方案的比较 13

3.2 步进电机的选型 13

4 挤出装置的设计 18

4.1 结构尺寸的确定 18

4.2 挤出机构的设计要求 18

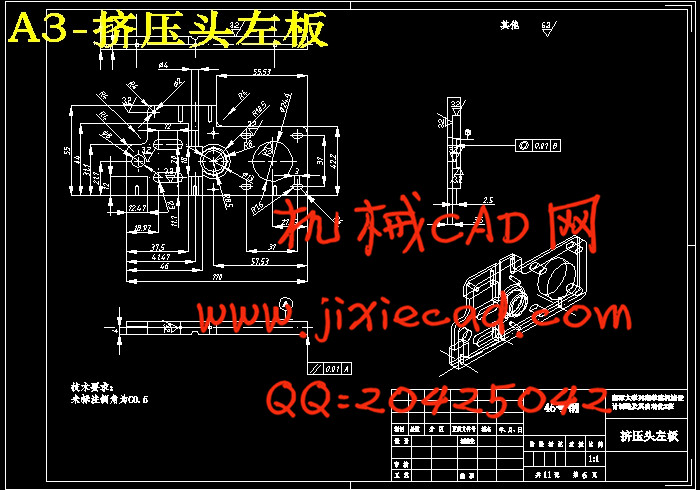

4.3 挤出装置的组成 19

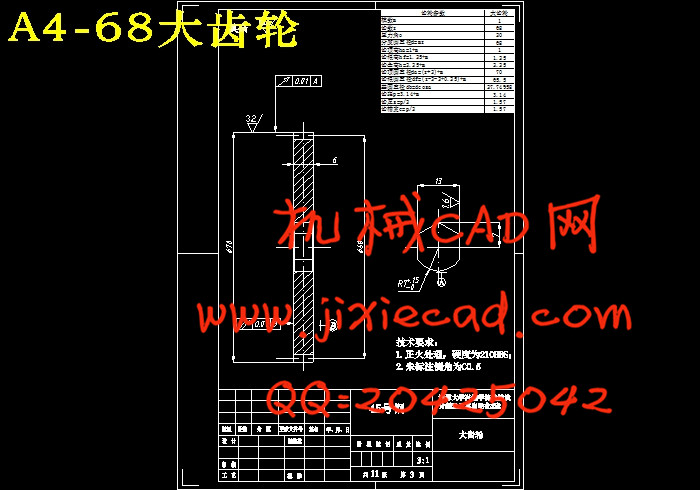

4.4 挤出机构齿轮组设计 20

4.4.1 按齿面接触强度来设计 20

4.4.2 按齿根弯曲强度设计 23

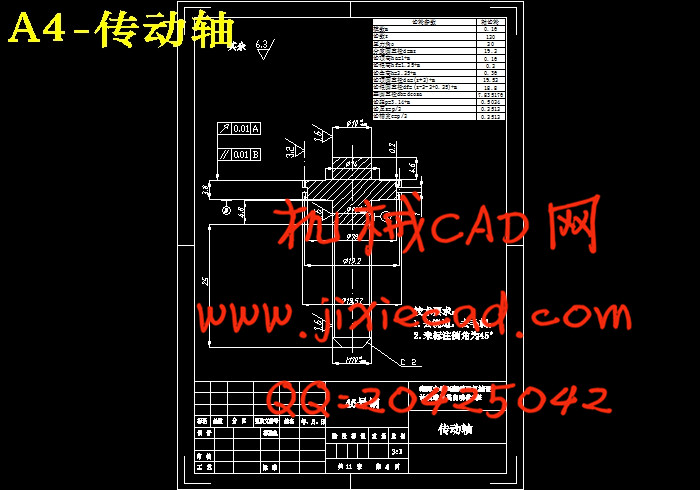

4.5 轴设计 26

4.5.1 作用在齿轮上的力 26

4.5.2 初步确定大齿轮轴的最小直径 26

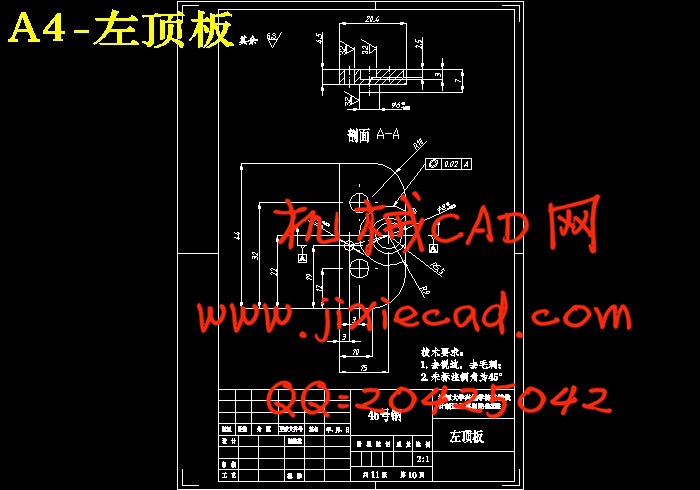

4.5.3 轴的结构设计 27

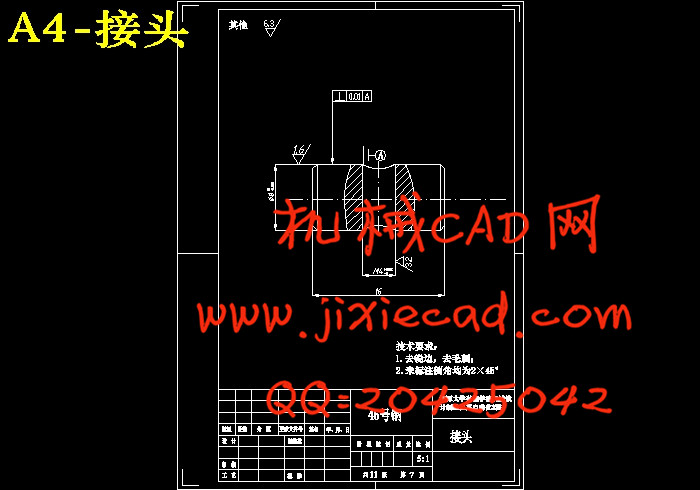

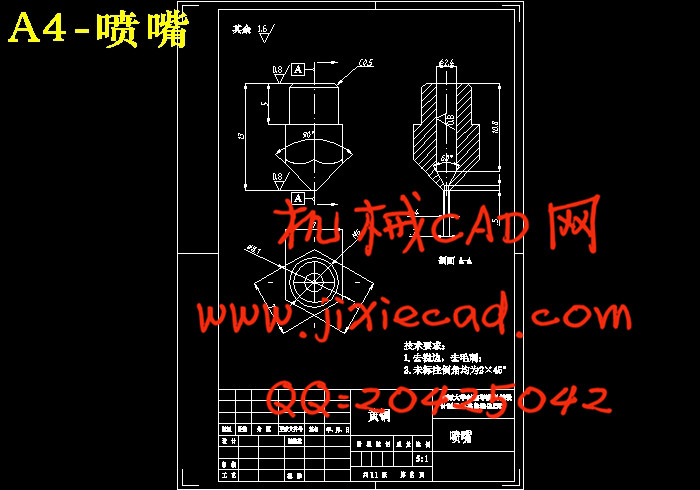

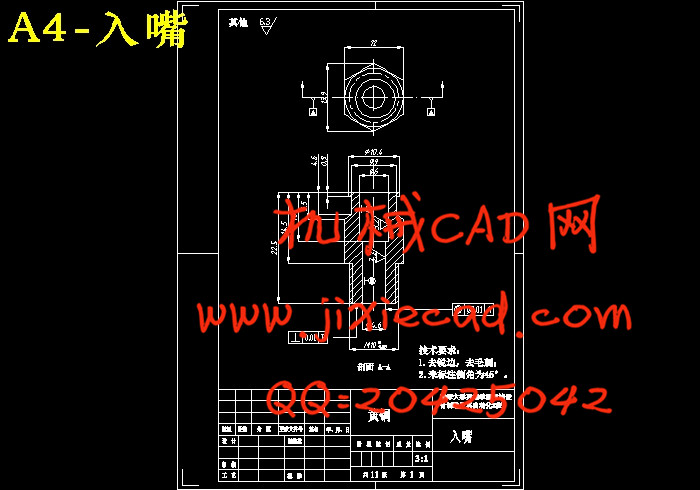

4.6 挤出机构流道口设计 28

4.7 加热腔的设计 30

4.7.1 加热腔入口溢料问题的分析 30

4.7.2 流涎问题的分析 31

4.7.3 解决方案 31

参 考 文 献 33

熔融沉积成型技术(FDM)是目前国内外应用最为广泛的快速成型技术之一。它可以快速、精确地将设计思想从CAD模型物化为具有一定功能的原型或零件,从而实现对产品的快速测评及修改,有效的缩短了产品的开发周期。在熔融沉积快速成型中,成型精度对最终产品的质量起着决定性的作用,但是目前成型机的成型精度往往不高,如何提高成型精度是当今快速成型研究的一个重要方向。

本课题围绕熔融成型机,重点研究了该设备的机械系统,提出一套完整的机械设计方案。具体工作如下:

(1)结合传统的FDM熔融沉积成型设备,从整机的外形尺寸、最大成形空间、成形精度、主要运动结构和方式等方面,进行了细致和分析。在吸收了不同机型之间的优点和缺点之后,大致拟定了熔融成型机机械系统总体设计方案中的机械传动结构、三轴运动方式以及加热挤出头结构,确定了机械结构设计中的几个关键技术问题。

(2)以机械设计原理为依据,结合对FDM整个机械系统的几大构件制定的设计方案,按照整机设计需求参数,分别对运动系统、导向系统、机械结构和包装造型进行了具体的参数化选择,着重设计了加热挤出头结构,解决与优化了流涎问题,然后按照机身结构设计原则设计并完成了全部零部件的三维实体建模、装配以及工程图。

关键字:快速成型;FDM;加热挤出头

ABSTRACT

The fused deposition rapid prototyping technology (FDM) is one of the at home and abroad the most widely used rapid prototyping technology. It can quickly and accurately Design ideas from the CAD model materialized as proto types or parts of certain functions in order to achieve the rapid evaluation and modification of the product, effectively shortening the product development cycle. In fused deposition modeling, forming precision on the final product quality plays a decisive role, but the current forming machine precision is not high, how to improve the precision of the rapid prototyping is an important direction of research.

This topic around the molten molding machine, mainly studies the mechanical system of the device, puts forward a complete set of mechanical design.Specific work is as follows:

(1) combined with the traditional FDM fused deposition molding equipment, from the appearance of the whole machine size, maximum forming space, forming precision, main structure and movement mode, are detailed and analyzed.In absorbing the advantages and disadvantages between different models, roughly sketched the melting machine mechanical system overall design scheme of mechanical transmission structure, three axis movement mode and heating extrusion head structure, identified several key technical problems in mechanical structure design.

(2)And in accordance with FDM based on principle of mechanical design, the whole of several major components of design scheme of mechanical system, on the demand of the whole machine design parameters, respectively, on the sports system, guiding system, mechanical structure and packaging for the specific parameterized choice, mainly design the structure of heat extrusion head, solving and optimizing the salivate, then design and completed in accordance with the principle of the fuselage structure design all components of the three-dimensional entity modeling, assembly, and engineering drawing.

Key Words: Rapid Prototyping;Fused Deposition;Heating extrusion head

目录

1 绪论 3

1.1 引言 3

1.2 熔融沉积成型技术概论 3

1.2.1 熔融沉积成型技术的特点 4

1.2.2 熔融沉积成型技术 - 工艺过程 5

1.2.3 熔融沉积成型技术的应用 6

1.3 熔融沉积成型技术存在问题及发展方向 7

1.3.1 熔融沉积成型技术的现状 7

1.3.2 熔融沉积成型技术的发展方向 8

2 总体方案及结构设计 10

2.1 引言 10

2.2 总体设计要求 10

2.3 熔融沉积成型机床的结构运动方案 11

3 电机方案的选择及选型 13

3.1 电机方案的比较 13

3.2 步进电机的选型 13

4 挤出装置的设计 18

4.1 结构尺寸的确定 18

4.2 挤出机构的设计要求 18

4.3 挤出装置的组成 19

4.4 挤出机构齿轮组设计 20

4.4.1 按齿面接触强度来设计 20

4.4.2 按齿根弯曲强度设计 23

4.5 轴设计 26

4.5.1 作用在齿轮上的力 26

4.5.2 初步确定大齿轮轴的最小直径 26

4.5.3 轴的结构设计 27

4.6 挤出机构流道口设计 28

4.7 加热腔的设计 30

4.7.1 加热腔入口溢料问题的分析 30

4.7.2 流涎问题的分析 31

4.7.3 解决方案 31

参 考 文 献 33