设计简介

摘要

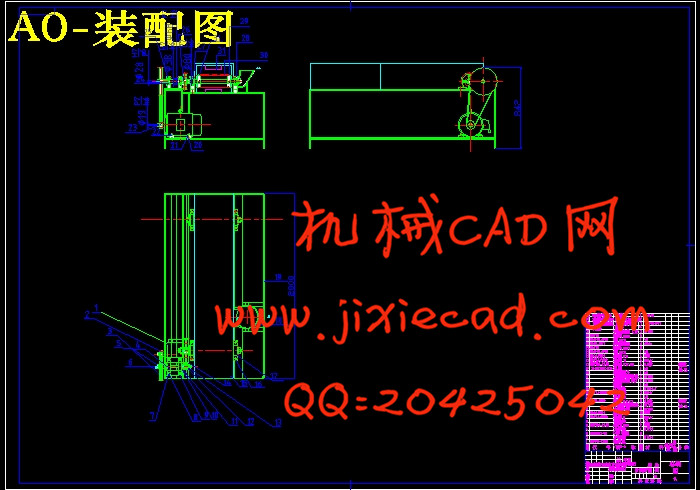

肉类食品链式干燥焙烤机属于肉类加工机械,肉类加工机械是肉类工业发展必须而重要的保证。我国肉类加工设备包括屠宰、分割、肉制品、调理食品、综合利用等方面。随着我国国民经济的迅速发展和人民生活水平的不断提高,我国食品工业得到了飞跃发展,已成为我国国民经济的支柱产业,作为装备食品工业的食品机械发展尤为迅速。肉类食品链式干燥焙烤机研究和设计是通过对肉类食品的送料、干燥、焙烤的一系列加工,达到食品加工的机电一体化,加工生产线的自动,高新技术的广泛运用。通过物料输送机械输送肉类,使肉类加工均匀,干燥器去除原料含有的部分水分,焙烤设备使肉类变熟。对输送速度和温度进行控制。这项设计符合二十一世纪大型化、高速化和提高稳定性的主要要求,运用了高新控制技术、机电一体化技术、智能计算机技术。是我们今后努力的方向。

关键字:肉类食品;干燥;焙烤;链式

Abstract

Meat food chain dry baking machine which belongs to the meat processing machinery, meat processing machinery is the meat industry development must and important guarantee of China's meat processing equipment, including slaughter, segmentation, meat products, food, and other aspects of comprehensive utilization. With the rapid development of our national economy and the improvement of people's living standards, China's food industry got rapid development, has become a pillar industry of our national economy, as the equipment for food industry food machinery development is rapid. Meat food chain dry baking machine research and design is adopted for meat Food feeding, drying, baking, packing and a series of processing, food processing mechanical and electrical integration, processing automatic production line, new and high technology apply extensively. Through the material conveying machinery conveyor dryer to remove meat, raw material containing some water, baking equipment allows the meat to ripen on the finished product packaging, packaging machinery. Through PLC on the conveying velocity and temperature control the designs conforms to the twenty-first Century large-scale, high speed and improve the stability of the main requirements, using the new control technology, electromechanical integration technology, computer technology. The efforts of our future direction

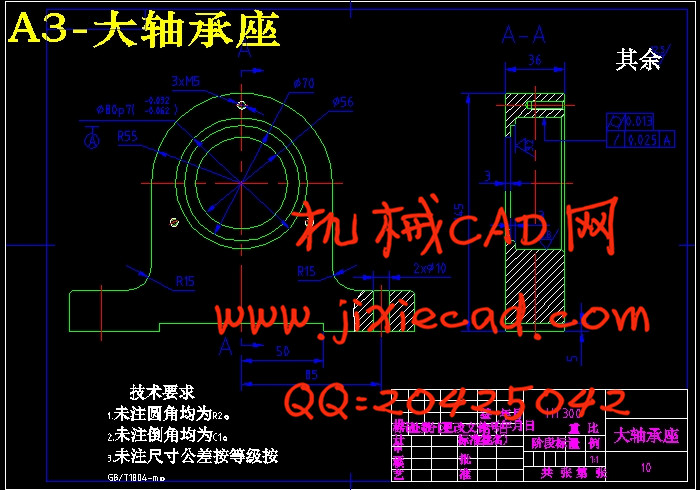

Keywords: meat food; drying; baking; packaging; chain

目录

绪论 …………………………………………………………………6

1 肉类食品链式干燥焙烤机工作过程设计 ……………………………………7

1.1肉类食品链式干燥焙烤机工作原理简述 ……………………………7

1.2 肉类食品链式干燥焙烤机基本设计要求 ……………………………7

1.3各种肉类食品的参数 ………………………………………………7

1.4肉类食品加工耗能计算 ……………………………………………8

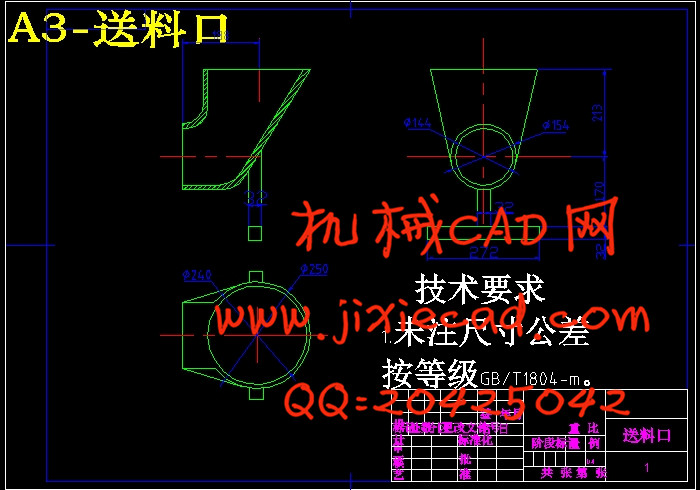

2 送料口的设计 ………………………………………………………8

2.1 送料口的设计要求 ………………………………………………8

2.2各送料口尺寸设计 …………………………………………………8

2.3 材料选择…………………………………………………………8

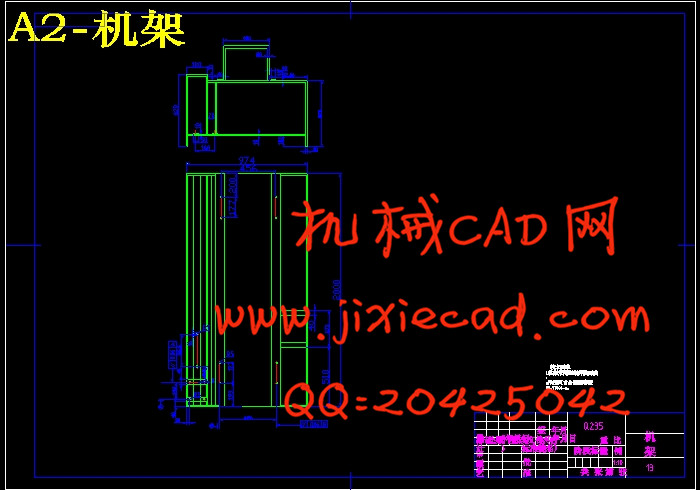

3 干燥室设计 …………………………………………………………8

3.1 输送方式设计 …………………………………………………9

3.1.1传动链设计 ……………………………………………………9

3.1.2 电机的选择 ……………………………………………10

3.1.3 减速机构设计 …………………………………………10

3.2各轴的转速计算……………………………………………………10

3.3各轴输入功率计算 …………………………………………………10

3.4各轴输入扭矩计算 …………………………………………………11

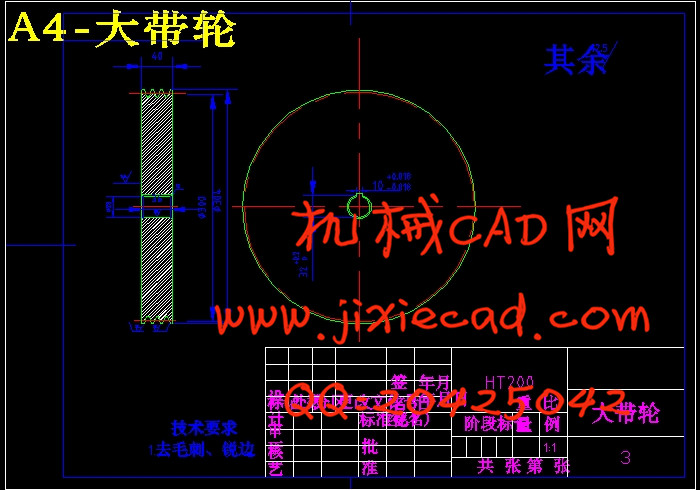

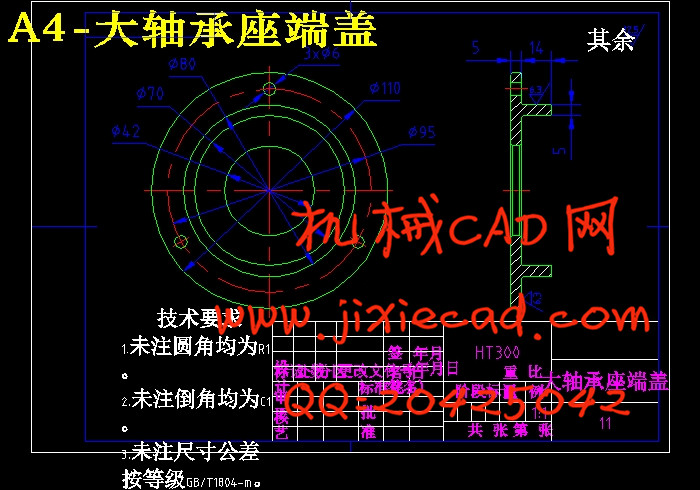

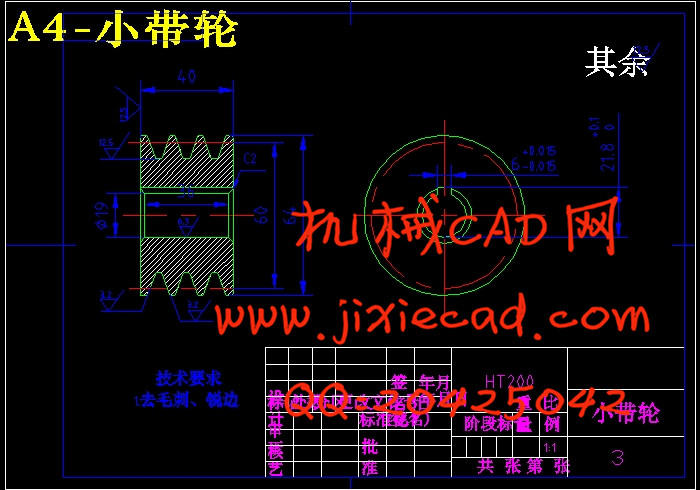

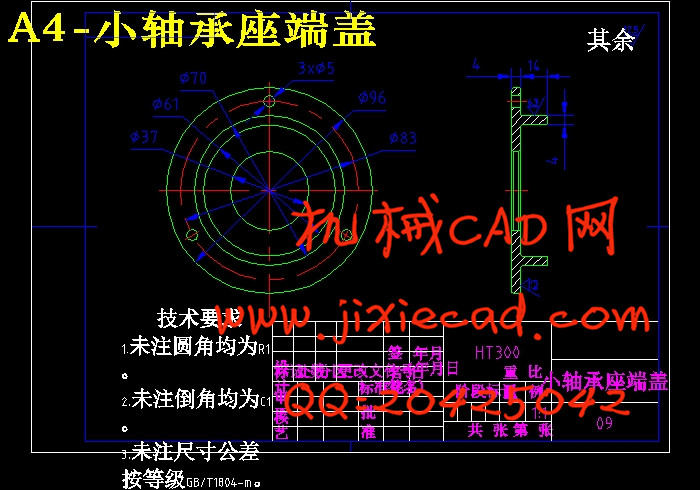

4 ‘V’带传动的设计计算…………………………………………………11

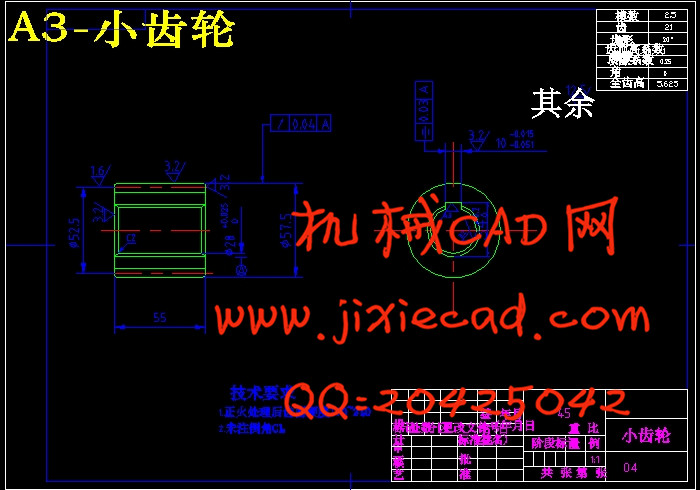

4.1 齿轮设计 ……………………………………………………12

4.1.1设计齿轮的步骤 …………………………………………13

5 链的设计 …………………………………………………………14

5.1条选择 …………………………………………………………15

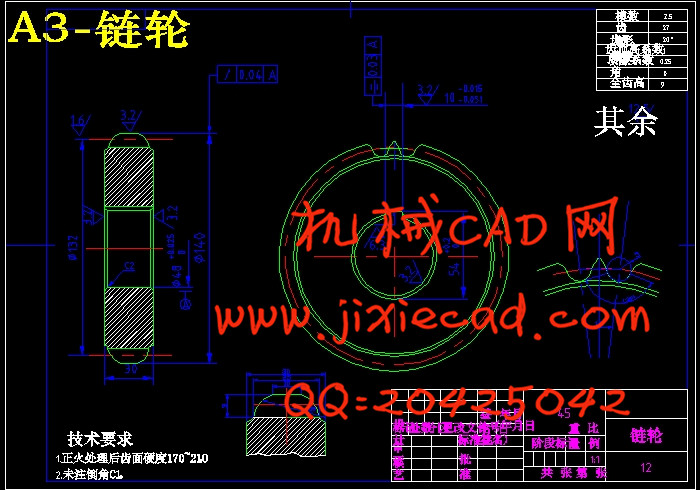

5.2链轮参数计算 …………………………………………………16

5.3轮材料选择 ……………………………………………………17

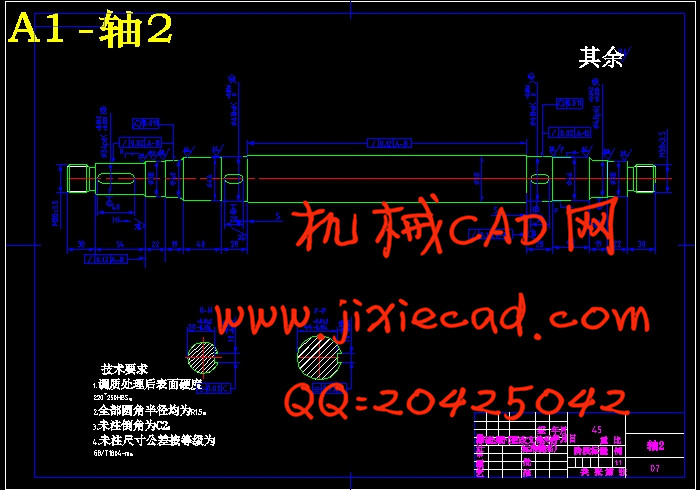

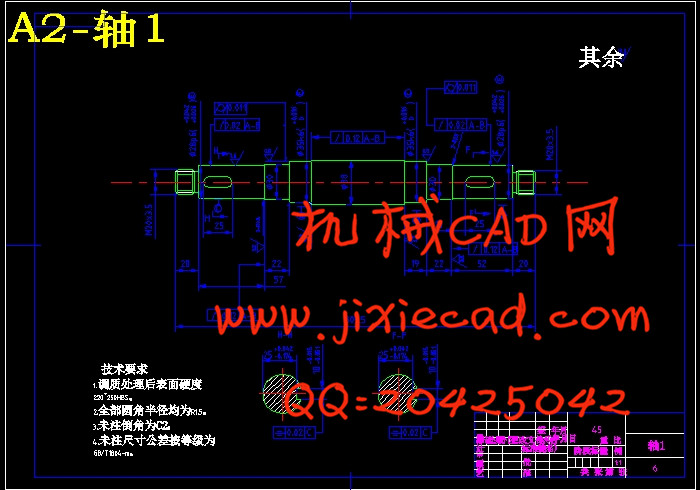

6 轴的设计 …………………………………………………………18

6.1 材料的选择 ………………………………………………………19

6.2 初算轴径d ………………………………………………………20

6.3.绘制轴的弯扭矩图,对危险截面进行校核……………………………21

6.4.轴承的校核 ………………………………………………………22

6.5轴上螺母的选择 ……………………………………………………23

7 干燥焙烤室加工设计 ………………………………………………24

7.1干燥室尺寸设计 ………………………………………………25

7.2 加热方式设计 ………………………………………………25

7.3电烤箱功率确定 …………………………………………………26

7.4加热注意 …………………………………………………………27

8 输送带支撑架 ………………………………………………………27

9 干燥焙烤室内部设计 ………………………………………………27

结论 ……………………………………………………………………28

参考文献著录 ………………………………………………………29

致谢 ……………………………………………………………………30

肉类食品链式干燥焙烤机属于肉类加工机械,肉类加工机械是肉类工业发展必须而重要的保证。我国肉类加工设备包括屠宰、分割、肉制品、调理食品、综合利用等方面。随着我国国民经济的迅速发展和人民生活水平的不断提高,我国食品工业得到了飞跃发展,已成为我国国民经济的支柱产业,作为装备食品工业的食品机械发展尤为迅速。肉类食品链式干燥焙烤机研究和设计是通过对肉类食品的送料、干燥、焙烤的一系列加工,达到食品加工的机电一体化,加工生产线的自动,高新技术的广泛运用。通过物料输送机械输送肉类,使肉类加工均匀,干燥器去除原料含有的部分水分,焙烤设备使肉类变熟。对输送速度和温度进行控制。这项设计符合二十一世纪大型化、高速化和提高稳定性的主要要求,运用了高新控制技术、机电一体化技术、智能计算机技术。是我们今后努力的方向。

关键字:肉类食品;干燥;焙烤;链式

Abstract

Meat food chain dry baking machine which belongs to the meat processing machinery, meat processing machinery is the meat industry development must and important guarantee of China's meat processing equipment, including slaughter, segmentation, meat products, food, and other aspects of comprehensive utilization. With the rapid development of our national economy and the improvement of people's living standards, China's food industry got rapid development, has become a pillar industry of our national economy, as the equipment for food industry food machinery development is rapid. Meat food chain dry baking machine research and design is adopted for meat Food feeding, drying, baking, packing and a series of processing, food processing mechanical and electrical integration, processing automatic production line, new and high technology apply extensively. Through the material conveying machinery conveyor dryer to remove meat, raw material containing some water, baking equipment allows the meat to ripen on the finished product packaging, packaging machinery. Through PLC on the conveying velocity and temperature control the designs conforms to the twenty-first Century large-scale, high speed and improve the stability of the main requirements, using the new control technology, electromechanical integration technology, computer technology. The efforts of our future direction

Keywords: meat food; drying; baking; packaging; chain

目录

绪论 …………………………………………………………………6

1 肉类食品链式干燥焙烤机工作过程设计 ……………………………………7

1.1肉类食品链式干燥焙烤机工作原理简述 ……………………………7

1.2 肉类食品链式干燥焙烤机基本设计要求 ……………………………7

1.3各种肉类食品的参数 ………………………………………………7

1.4肉类食品加工耗能计算 ……………………………………………8

2 送料口的设计 ………………………………………………………8

2.1 送料口的设计要求 ………………………………………………8

2.2各送料口尺寸设计 …………………………………………………8

2.3 材料选择…………………………………………………………8

3 干燥室设计 …………………………………………………………8

3.1 输送方式设计 …………………………………………………9

3.1.1传动链设计 ……………………………………………………9

3.1.2 电机的选择 ……………………………………………10

3.1.3 减速机构设计 …………………………………………10

3.2各轴的转速计算……………………………………………………10

3.3各轴输入功率计算 …………………………………………………10

3.4各轴输入扭矩计算 …………………………………………………11

4 ‘V’带传动的设计计算…………………………………………………11

4.1 齿轮设计 ……………………………………………………12

4.1.1设计齿轮的步骤 …………………………………………13

5 链的设计 …………………………………………………………14

5.1条选择 …………………………………………………………15

5.2链轮参数计算 …………………………………………………16

5.3轮材料选择 ……………………………………………………17

6 轴的设计 …………………………………………………………18

6.1 材料的选择 ………………………………………………………19

6.2 初算轴径d ………………………………………………………20

6.3.绘制轴的弯扭矩图,对危险截面进行校核……………………………21

6.4.轴承的校核 ………………………………………………………22

6.5轴上螺母的选择 ……………………………………………………23

7 干燥焙烤室加工设计 ………………………………………………24

7.1干燥室尺寸设计 ………………………………………………25

7.2 加热方式设计 ………………………………………………25

7.3电烤箱功率确定 …………………………………………………26

7.4加热注意 …………………………………………………………27

8 输送带支撑架 ………………………………………………………27

9 干燥焙烤室内部设计 ………………………………………………27

结论 ……………………………………………………………………28

参考文献著录 ………………………………………………………29

致谢 ……………………………………………………………………30