设计简介

摘 要

本论文对某公司的产品QJR-400/1140(660)矿用隔爆兼本质安全交流软起动器的外壳进行结构优化。

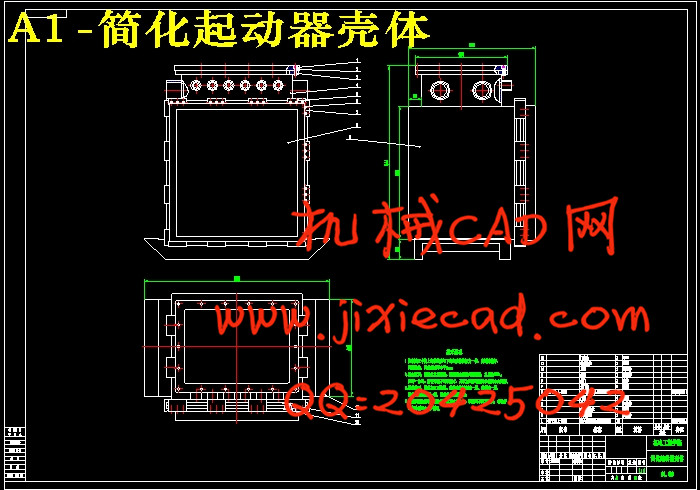

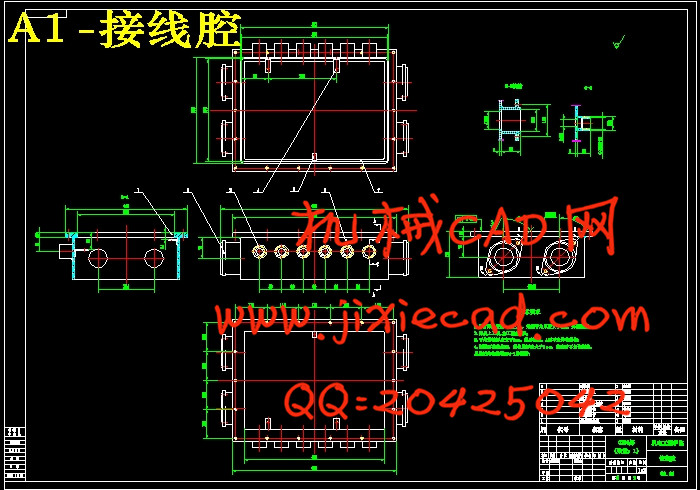

矿用防爆起动器外壳可以有效地接受内部爆炸压力,还能避免内部爆炸时产生的高温而引起外部爆炸性环境的爆炸。矿用隔爆起动器外壳是由两个不同的矩形组成的箱体,首先对它进行结构简化,把非关键部位去除简化,留下各外形面板及关键承力部件。将弹塑性力学引入设计过程中,根据实物的外形尺寸,将壳体的板简化为力学模型,结合小扰度理论,推算出各个面板的理论尺寸;采用比较法,根据理论和实物拟出不同板厚的方案,采用加强筋对其加固;利用隔爆箱和接线腔上的两对法兰满足刚度要求,对法兰的尺寸计算公式进行推导,得出了结果;对其他关键承力部件,如螺钉,进行理论受力分析。分析了起动器的实际试验和受力状况,确定了强度分析时的试验载荷,参考有关标准和资料,提出了起动器外壳变形的允许值。

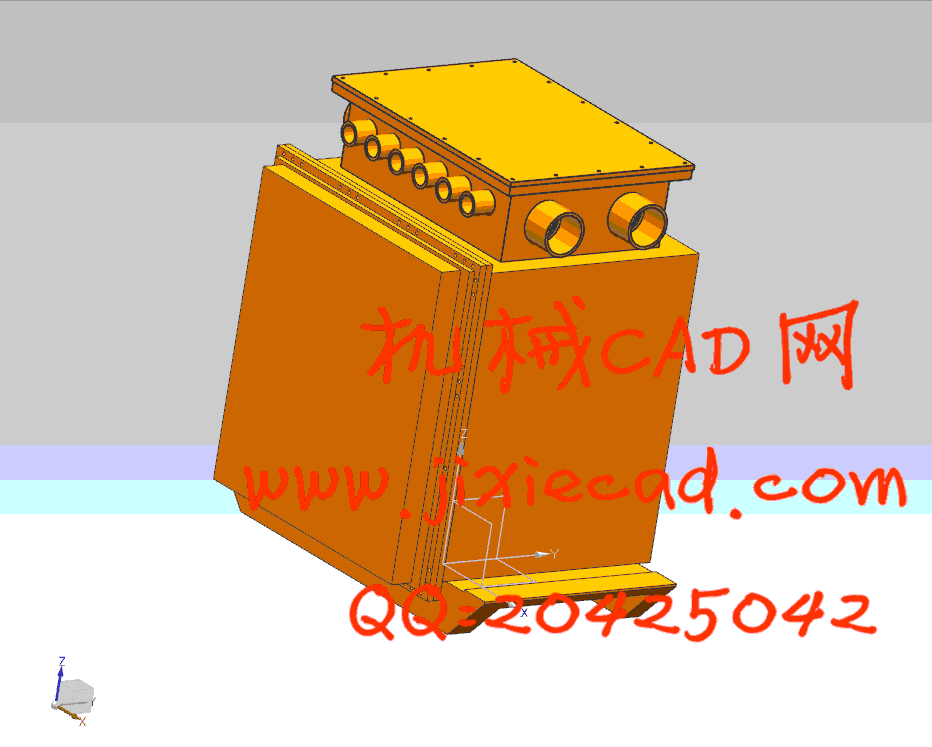

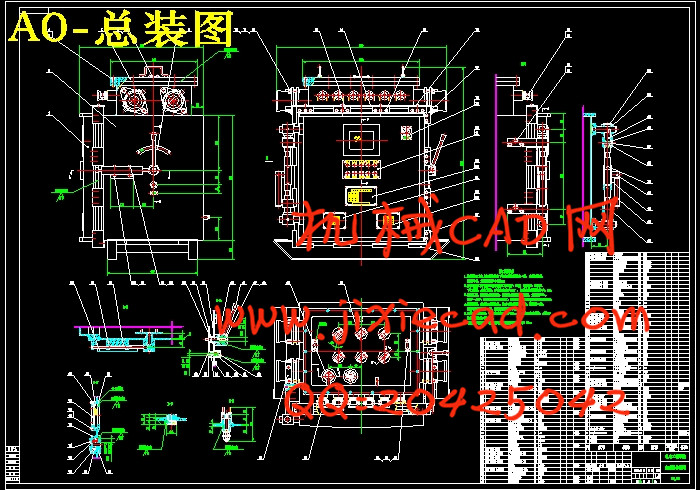

使用UG三维模型软件进行起动器的三维建模,分别作出了关键承力部件的实体模型及简化整体模型。利用Workbench软件,对起动器外壳进行了有限元分析,检验外壳及零部件在1MPa压力测试下产生的应力和位移,获得隔爆箱体、法兰和门等关键部位的位移和应力云图。结合理论数值,来对起动器外壳和关键受力部件进行改进分析,从而达到提高材料的利用率、减轻设备重量和降低成本的目标。

关键词:矿用隔爆起动器;弹塑性力学;有限元分析;三维建模;轻量化。

Abstract

In this paper, the product QJR-400/1140 of a company's (660) mine flameproof and intrinsically safe AC soft starter shell design and research.

Flameproof starter shell can effectively under internal explosion pressure, can avoid high temperature internal explosion caused by the explosion of exterior explosive environment. Flameproof starter shell body is composed of two different rectangular, it first makes structure is simplified, the removal of non key parts of simplified, leaving the outer panel and the key force bearing component. The elastic and plastic mechanics is introduced into the design process, according to the shape size, the shell plate is simplified as a mechanical model, combined with the small disturbance theory, calculate the theoretical size of each panel; by comparison, according to the theory and the real draw up plans of different plate thickness, using reinforced reinforcement on the panel;Two pairs of flanges on flameproof boxes and wiring chamber to meet stiffness requirements, the formula for calculating the size of the flange derivation, And obtained the results; Theoretical stress analysis the bearing on other key components, such as bolts. Analysis of the actual situation of the test and force the starter to determine the test load strength analysis, refer to the relevant standards and information presented launcher shell deformation allowable value.

Three dimensional modeling of starter using UG 3D modeling software, the solid model of the key force bearing components were made and simplified model. Use Workbench software startup shell finite element analysis. Efficacy of displacement and stress in the housing and parts produced under the test pressure 1MPa. Get key parts of the flameproof enclosure, doors and flange stress,According to the theory of value, to improves components of stress analysis on the starter casing and key, so as to improve the material utilization rate, reduce the weight of equipment and cost reductions.

Key words: flameproof starter; The elastoplastic mechanics; Finite Element Analysis; dimensional modeling; lightweight

目 录

1 绪论 1

1.1 课题的提出 1

1.2 本课题研究的主要内容及意义 2

2 矿用隔爆电器设备壳体隔爆要求 3

2.1 爆炸性电气设备的分类 3

2.2 隔爆型电气设备的主要功能 3

2.3 隔爆箱的隔爆原理 4

2.4 外壳的变形允许值 4

2.5 本章小结 5

3 壳体强度刚度的理论计算 6

3.1 隔爆外壳设计概述 6

3.2 箱体结构的设计计算 7

3.2.1 弹塑性力学的理论公式 7

3.2.2 壳体壁厚的设计 9

3.2.3 各面板的最大扰度和应力结果 10

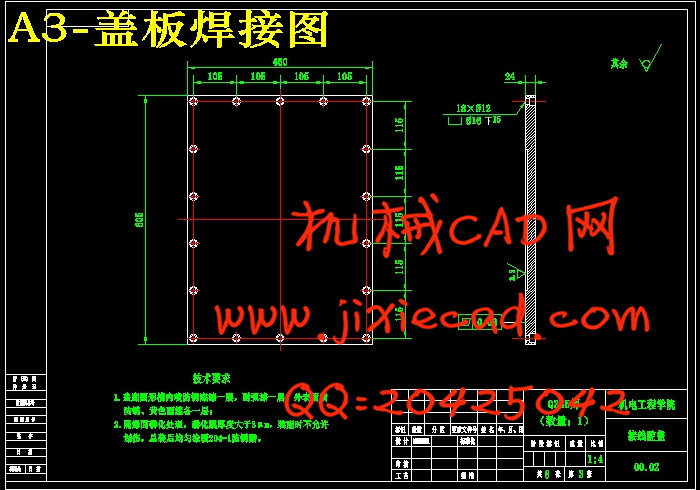

3.2.4 门法兰和盖板法兰变形设计 12

3.2.5 计算结果讨论 13

3.3 连接螺钉的强度及数量 13

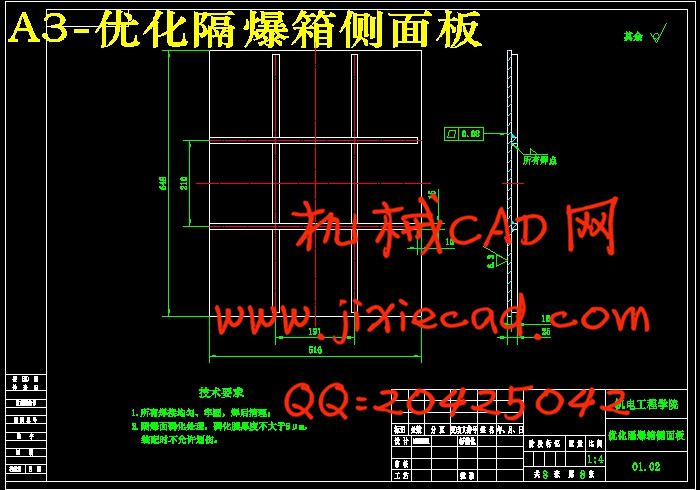

3.4 优化方案设计 16

3.5 本章小结 16

4 基于UG的隔爆箱体外壳的三维建模 17

4.1 UG软件 17

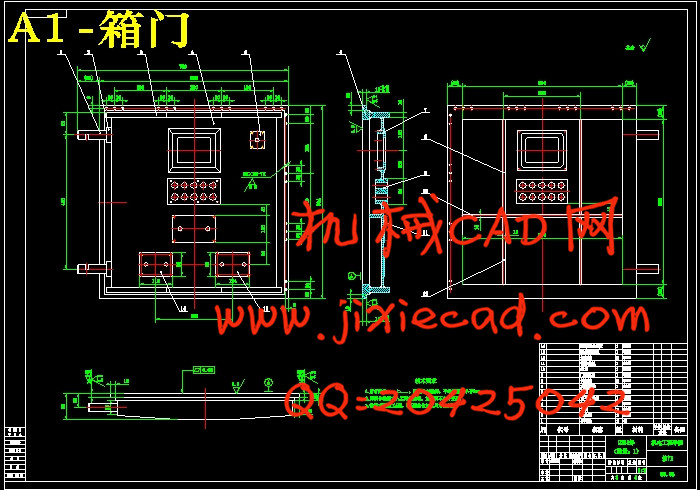

4.2 隔爆软起动器各箱体及组件 18

4.3 三维建模 19

4.4 本章小结 20

5 隔爆软起动器的有限元分析 21

5.1 有限元简介 21

5.2 ANSYS简介 21

5.2.1 技术特点 22

5.2.2 ANSYS Workbench平台 22

5.3 隔爆软起动器的有限元建模 23

5.3.1 几何建模 23

5.3.2 材料的设置 23

5.3.3 网格划分 24

5.3.4 静力分析 25

5.4 分析结果 25

5.4.1 隔爆箱体的静力分析 25

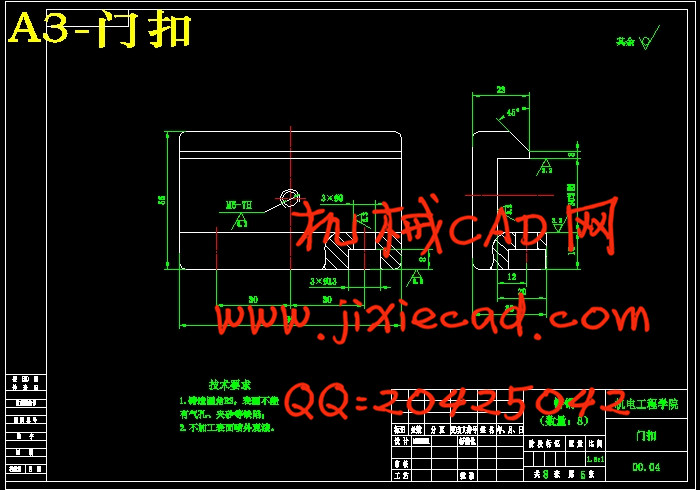

5.4.2 门扣的静力分析 29

5.4.3 门面板的静力分析 30

5.4.4 法兰的静力分析 31

5.5 结果分析与优化 32

5.6 本章小结 34

6 结论 35

谢 辞 36

参考文献 37

本论文对某公司的产品QJR-400/1140(660)矿用隔爆兼本质安全交流软起动器的外壳进行结构优化。

矿用防爆起动器外壳可以有效地接受内部爆炸压力,还能避免内部爆炸时产生的高温而引起外部爆炸性环境的爆炸。矿用隔爆起动器外壳是由两个不同的矩形组成的箱体,首先对它进行结构简化,把非关键部位去除简化,留下各外形面板及关键承力部件。将弹塑性力学引入设计过程中,根据实物的外形尺寸,将壳体的板简化为力学模型,结合小扰度理论,推算出各个面板的理论尺寸;采用比较法,根据理论和实物拟出不同板厚的方案,采用加强筋对其加固;利用隔爆箱和接线腔上的两对法兰满足刚度要求,对法兰的尺寸计算公式进行推导,得出了结果;对其他关键承力部件,如螺钉,进行理论受力分析。分析了起动器的实际试验和受力状况,确定了强度分析时的试验载荷,参考有关标准和资料,提出了起动器外壳变形的允许值。

使用UG三维模型软件进行起动器的三维建模,分别作出了关键承力部件的实体模型及简化整体模型。利用Workbench软件,对起动器外壳进行了有限元分析,检验外壳及零部件在1MPa压力测试下产生的应力和位移,获得隔爆箱体、法兰和门等关键部位的位移和应力云图。结合理论数值,来对起动器外壳和关键受力部件进行改进分析,从而达到提高材料的利用率、减轻设备重量和降低成本的目标。

关键词:矿用隔爆起动器;弹塑性力学;有限元分析;三维建模;轻量化。

Abstract

In this paper, the product QJR-400/1140 of a company's (660) mine flameproof and intrinsically safe AC soft starter shell design and research.

Flameproof starter shell can effectively under internal explosion pressure, can avoid high temperature internal explosion caused by the explosion of exterior explosive environment. Flameproof starter shell body is composed of two different rectangular, it first makes structure is simplified, the removal of non key parts of simplified, leaving the outer panel and the key force bearing component. The elastic and plastic mechanics is introduced into the design process, according to the shape size, the shell plate is simplified as a mechanical model, combined with the small disturbance theory, calculate the theoretical size of each panel; by comparison, according to the theory and the real draw up plans of different plate thickness, using reinforced reinforcement on the panel;Two pairs of flanges on flameproof boxes and wiring chamber to meet stiffness requirements, the formula for calculating the size of the flange derivation, And obtained the results; Theoretical stress analysis the bearing on other key components, such as bolts. Analysis of the actual situation of the test and force the starter to determine the test load strength analysis, refer to the relevant standards and information presented launcher shell deformation allowable value.

Three dimensional modeling of starter using UG 3D modeling software, the solid model of the key force bearing components were made and simplified model. Use Workbench software startup shell finite element analysis. Efficacy of displacement and stress in the housing and parts produced under the test pressure 1MPa. Get key parts of the flameproof enclosure, doors and flange stress,According to the theory of value, to improves components of stress analysis on the starter casing and key, so as to improve the material utilization rate, reduce the weight of equipment and cost reductions.

Key words: flameproof starter; The elastoplastic mechanics; Finite Element Analysis; dimensional modeling; lightweight

目 录

1 绪论 1

1.1 课题的提出 1

1.2 本课题研究的主要内容及意义 2

2 矿用隔爆电器设备壳体隔爆要求 3

2.1 爆炸性电气设备的分类 3

2.2 隔爆型电气设备的主要功能 3

2.3 隔爆箱的隔爆原理 4

2.4 外壳的变形允许值 4

2.5 本章小结 5

3 壳体强度刚度的理论计算 6

3.1 隔爆外壳设计概述 6

3.2 箱体结构的设计计算 7

3.2.1 弹塑性力学的理论公式 7

3.2.2 壳体壁厚的设计 9

3.2.3 各面板的最大扰度和应力结果 10

3.2.4 门法兰和盖板法兰变形设计 12

3.2.5 计算结果讨论 13

3.3 连接螺钉的强度及数量 13

3.4 优化方案设计 16

3.5 本章小结 16

4 基于UG的隔爆箱体外壳的三维建模 17

4.1 UG软件 17

4.2 隔爆软起动器各箱体及组件 18

4.3 三维建模 19

4.4 本章小结 20

5 隔爆软起动器的有限元分析 21

5.1 有限元简介 21

5.2 ANSYS简介 21

5.2.1 技术特点 22

5.2.2 ANSYS Workbench平台 22

5.3 隔爆软起动器的有限元建模 23

5.3.1 几何建模 23

5.3.2 材料的设置 23

5.3.3 网格划分 24

5.3.4 静力分析 25

5.4 分析结果 25

5.4.1 隔爆箱体的静力分析 25

5.4.2 门扣的静力分析 29

5.4.3 门面板的静力分析 30

5.4.4 法兰的静力分析 31

5.5 结果分析与优化 32

5.6 本章小结 34

6 结论 35

谢 辞 36

参考文献 37