设计简介

三自由度微型飞行器模拟转台的设计

摘要:在微型飞行器的研制过程中,飞行仿真实验是必不可少的,飞行仿真实验主要分为测试飞机动力性能的风洞实验和测试飞机动态控制性能。三轴摇摆台是半实物仿真实验系统中的一个关键设备。

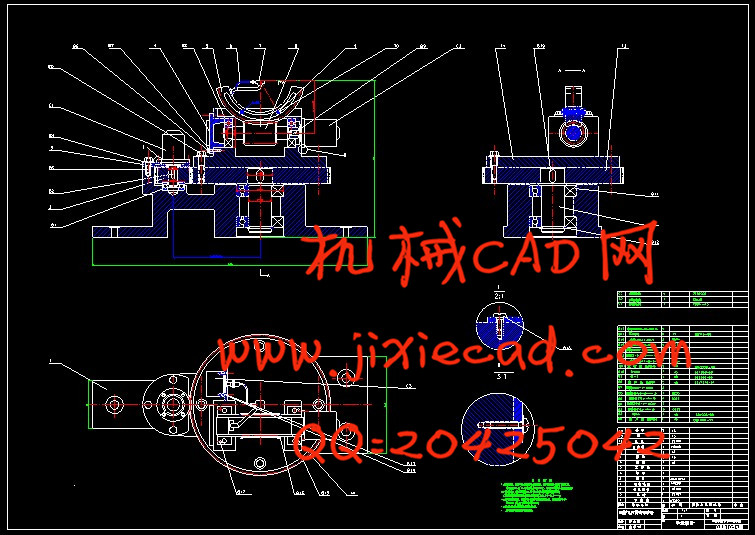

本文设计开发了一种用于微型飞行器半实物仿真实验的多功能飞行模拟转台,转台可作为低速扎的三轴摇摆台,也可以作为高速旋转的一维旋转台使用,转台通过三个独立的轴系来实现所需模拟的三个转角。通过计算机控制系统控制整个转台的转动。设计中采用了齿轮机构、蜗轮蜗杆机构、软轴机构来模拟其三个运动。

本产品的主要功能是在控制系统的作用下,能精确做如下运动:手动步进,手动步退,自动步进,自动步退。所设计的模拟转台具有结构紧凑、操作方便、可控性较好、功能也较强大等优点。

关键字:飞行模拟转台 仿真实验 微型飞行器 摇摆台

A Small Flight Simulator with three-axes

Abstract: In miniature aircraft research and manufacture process, flying imitate experiment is essential , flying imitate experiment primarily includes experiment for check the airplane motive function and check airplane dynamic control fuction.

A semi-substance simulation test system is developed for the text and experiment of micro sensors and micro measuring units used in micro aerial vehicles. The simulator is designed with double functions. The bottom mechanism provides yawing angular motions. The middle mechanism provides pitching angular motion. And the top mechanism provides rolling angular motion. When the bottom mechanism is used individually, the system works as a rotating table. The mechanical system is constructed with three independent axes to fulfill the corresponding three angular motions. It adopted gear organization, worm, soft stalk organization to imitate three movement in the design.

The main function of this product is under the control system, can do movement accurately as follows :step forward as hand control, step backward as hand control, step forward automatically, step backward automatically. The designing turns have advantages such as constructed tightly ,can be manipulated conveniently, is well controled , and have powerful fuction etc.

Key words: Flight simulator Semi-substance simulator

MAV(micro aerial vehicles) Simulator

目 录

1 前言………………………………………………………………………………….............. ( 1)

1.1 模拟转台的简介........................................................................................ ( 1)

1.2 研究概况及发展趋势.......................................................................... .( 2)

1.3 研究内容……………………………………………………………………………... .( 2)

2 转台机械系统方案的选择价…………………………………………………... ( 3)

2.1 控制台的功能分析………………………………………………………... ( 3)

2.2 方案的选择和评价……………………………………………………………................ ( 3)

3 原理设计及评价………………………………………………………............ (13)

3.1 原理一……………………………………………………………......................(13)

3.2 原理二……………………………………………………………......................(15)

3.3 原理三……………………………………………………………......................(17)

3.4 总述方案……………………………………………………………..................(18)

3.5 方案二的介绍……………………………………………………………...........(19)

4 齿轮机构设计……………………………………………………………..........(21)

4.1 失效形式…………………………………………………………....................(21)

4.2 设计准则……………………………………………………………...................(22)

4.3 齿轮设计……………………………………………………………...................(23)

5 蜗杆蜗轮设计…………………………………………………………..........(28)

5.1 蜗杆传动简介…………………………………………………………........... (28)

5.2 蜗杆传动的失效形式…………………………………………………….....(29)

5.3 蜗杆传动的材料选择……………………………………………….......... .(29)

5.4 蜗杆计算…………………………………………………………….................(30)

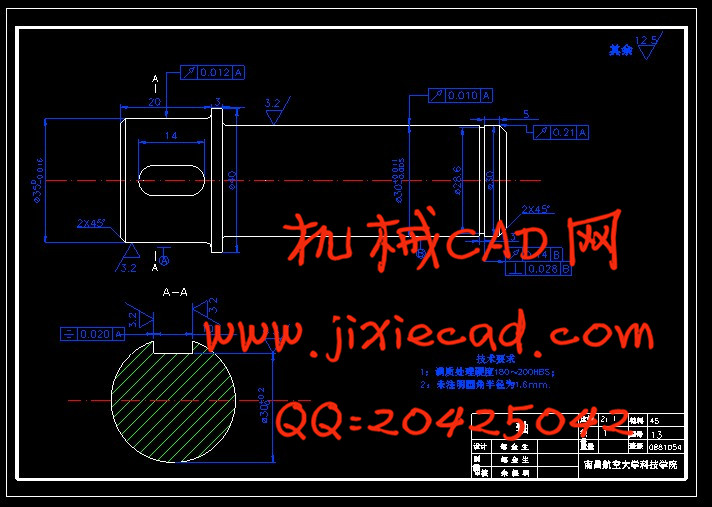

6 软轴设计与计算………………………………………………………........ .(34)

6.1 钢丝软轴的简介…………………………………………………………....(34)

6.2 钢丝软轴的选择与算…………………………………………………...... (36)

7 软轴的校核…………………………………………………………................(37)

7.1 按扭矩强度校核……………………………………………………….....(37)

7.2 按弯扭合成强度条核…………………………………………………...(37)

8 总结……………………………………………………..........................................(39)

参考文献………………………………………………………………...................... (41)

致谢…………………………………………………………………………………………… (42)

摘要:在微型飞行器的研制过程中,飞行仿真实验是必不可少的,飞行仿真实验主要分为测试飞机动力性能的风洞实验和测试飞机动态控制性能。三轴摇摆台是半实物仿真实验系统中的一个关键设备。

本文设计开发了一种用于微型飞行器半实物仿真实验的多功能飞行模拟转台,转台可作为低速扎的三轴摇摆台,也可以作为高速旋转的一维旋转台使用,转台通过三个独立的轴系来实现所需模拟的三个转角。通过计算机控制系统控制整个转台的转动。设计中采用了齿轮机构、蜗轮蜗杆机构、软轴机构来模拟其三个运动。

本产品的主要功能是在控制系统的作用下,能精确做如下运动:手动步进,手动步退,自动步进,自动步退。所设计的模拟转台具有结构紧凑、操作方便、可控性较好、功能也较强大等优点。

关键字:飞行模拟转台 仿真实验 微型飞行器 摇摆台

A Small Flight Simulator with three-axes

Abstract: In miniature aircraft research and manufacture process, flying imitate experiment is essential , flying imitate experiment primarily includes experiment for check the airplane motive function and check airplane dynamic control fuction.

A semi-substance simulation test system is developed for the text and experiment of micro sensors and micro measuring units used in micro aerial vehicles. The simulator is designed with double functions. The bottom mechanism provides yawing angular motions. The middle mechanism provides pitching angular motion. And the top mechanism provides rolling angular motion. When the bottom mechanism is used individually, the system works as a rotating table. The mechanical system is constructed with three independent axes to fulfill the corresponding three angular motions. It adopted gear organization, worm, soft stalk organization to imitate three movement in the design.

The main function of this product is under the control system, can do movement accurately as follows :step forward as hand control, step backward as hand control, step forward automatically, step backward automatically. The designing turns have advantages such as constructed tightly ,can be manipulated conveniently, is well controled , and have powerful fuction etc.

Key words: Flight simulator Semi-substance simulator

MAV(micro aerial vehicles) Simulator

目 录

1 前言………………………………………………………………………………….............. ( 1)

1.1 模拟转台的简介........................................................................................ ( 1)

1.2 研究概况及发展趋势.......................................................................... .( 2)

1.3 研究内容……………………………………………………………………………... .( 2)

2 转台机械系统方案的选择价…………………………………………………... ( 3)

2.1 控制台的功能分析………………………………………………………... ( 3)

2.2 方案的选择和评价……………………………………………………………................ ( 3)

3 原理设计及评价………………………………………………………............ (13)

3.1 原理一……………………………………………………………......................(13)

3.2 原理二……………………………………………………………......................(15)

3.3 原理三……………………………………………………………......................(17)

3.4 总述方案……………………………………………………………..................(18)

3.5 方案二的介绍……………………………………………………………...........(19)

4 齿轮机构设计……………………………………………………………..........(21)

4.1 失效形式…………………………………………………………....................(21)

4.2 设计准则……………………………………………………………...................(22)

4.3 齿轮设计……………………………………………………………...................(23)

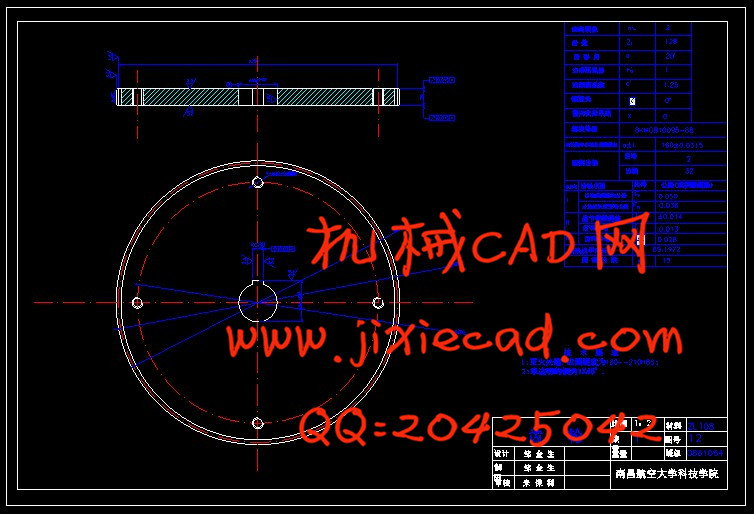

5 蜗杆蜗轮设计…………………………………………………………..........(28)

5.1 蜗杆传动简介…………………………………………………………........... (28)

5.2 蜗杆传动的失效形式…………………………………………………….....(29)

5.3 蜗杆传动的材料选择……………………………………………….......... .(29)

5.4 蜗杆计算…………………………………………………………….................(30)

6 软轴设计与计算………………………………………………………........ .(34)

6.1 钢丝软轴的简介…………………………………………………………....(34)

6.2 钢丝软轴的选择与算…………………………………………………...... (36)

7 软轴的校核…………………………………………………………................(37)

7.1 按扭矩强度校核……………………………………………………….....(37)

7.2 按弯扭合成强度条核…………………………………………………...(37)

8 总结……………………………………………………..........................................(39)

参考文献………………………………………………………………...................... (41)

致谢…………………………………………………………………………………………… (42)