设计简介

扫雪机的设计

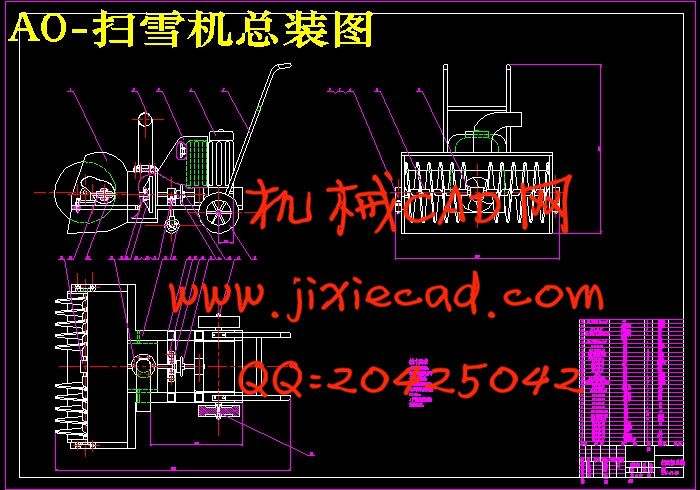

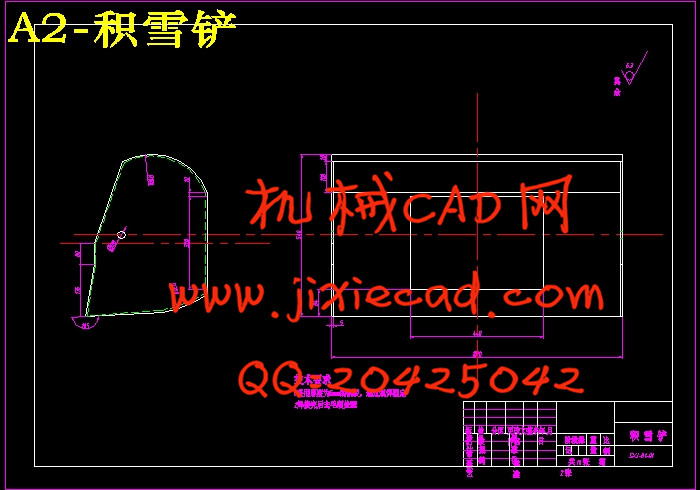

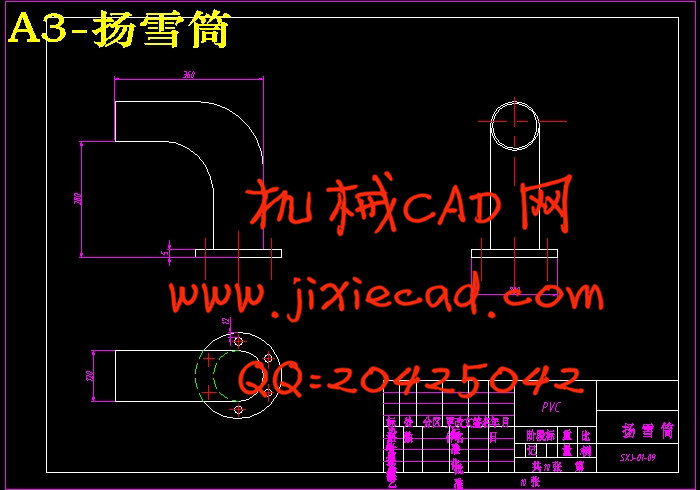

摘 要:本文在分析了目前国内外的主要除雪方法的基础上,提出一种适合中国国

情的小型机械旋转式扫雪机的设计方案。本设计由汽油机提供动力。经输出轴输出动力,通过链传动传递动力,带动其他工作。该扫雪机的工程是利用搅龙旋转将雪集中并向后推送,通过搅龙的向后推力及螺旋桨产生的吸力使其到达螺旋桨。由于螺旋桨高速旋转产生巨大的作用力,雪被高速推向弯管,再通过与弯管壁撞击折射出去。从而达到清除积雪的目的和最佳效果。

关键词:扫雪机 ;搅龙 ;传动轴

The Design of The Snow-blower

Abstract: After analyzing the various means of snow-clearings in the world at present, the project of a sort of snow-blower fit for China is put forward in this paper. Based on the theory study and applied structural design.This designis provided power by the petrol machine. It is outputted power by outputaxis, anddelivering power though a chain transmission, and arousing other work piece operations. Should in addition to the operate process of mini snow bloweris take advantage of stir revolution dragon to concentrate snow and push it backward, pass stir a dragon bckeward the vacuum force of thrust and aerofoil generate make it arrive aerofoil. Because of aerofoil with the top speed revolution generate enormous action force, and snow with top speed is pushed to the conduit bend, then collide with conduit bend wall and project out the conduit bend after refracting, thus hit the purpose

Keywords: Snow-blower; auger;transmission shaft

目 录

摘要 …………………………………………………………………………………1

关键词 ………………………………………………………………………………1

1 引言………………………………………………………………………………2

1.1 研究的目的和意义………………………………………………………3

1.2 国内外研究现状…………………………………………………………3

2 总体方案设计……………………………………………………………………4

2.1 设计任务与要求…………………………………………………………4

2.2 系统工作原理……………………………………………………………4

2.3 主要技术参数……………………………………………………………5

3 具体方案设计及加工……………………………………………………………5

3.1 动力参数…………………………………………………………………5

3.2 链与链轮…………………………………………………………………5

3.2.1 确定链条节数……………………………………………………6

3.2.2 确定节距…………………………………………………………6

3.2.3 确定中心距………………………………………………………6

3.2.4 验算链速…………………………………………………………6

3.2.5 压轴力……………………………………………………………6

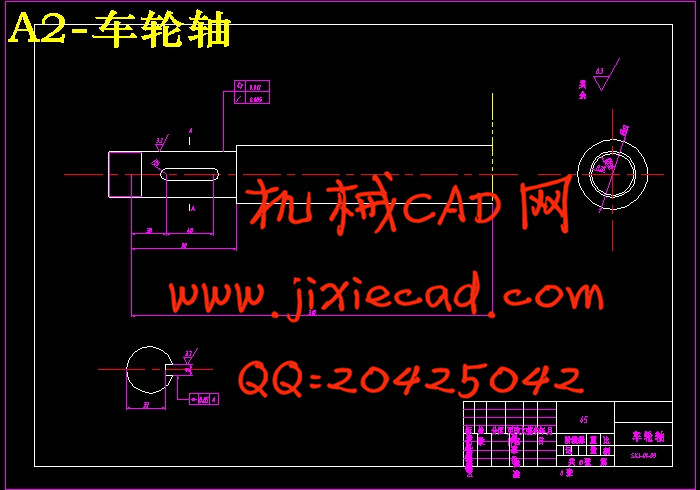

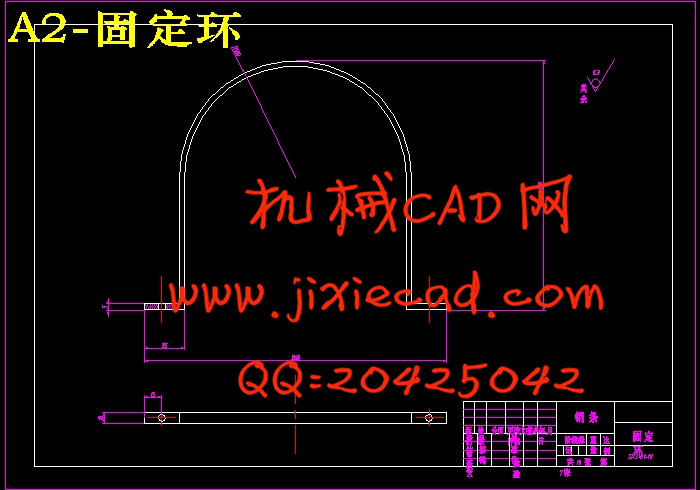

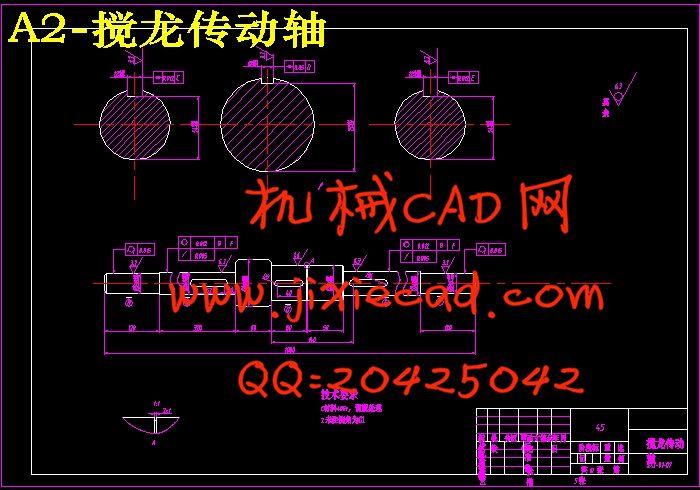

4 传动轴的设计与校核……………………………………………………………7

4.1 轴的设计计算……………………………………………………………7

4.2 确定各轴的直径和长度…………………………………………………7

4.3 轴的校核…………………………………………………………………8

5 涡轮与蜗杆………………………………………………………………………8

5.1 按接触强度计算…………………………………………………………8

5.1.1 确定蜗杆头数、蜗杆齿数………………………………………8

5.1.2 确定涡轮转矩……………………………………………………9

5.1.3 确定条件…………………………………………………………9

5.1.4 初定中心距、模数、倒程角……………………………………9

5.1.5 计算传动效率……………………………………………………9

5.2 验算齿面接触强度………………………………………………………9

5.3 计算传动的主要尺寸……………………………………………………10

5.4 弯曲强度验算……………………………………………………………10

6 搅龙轴设计与校核………………………………………………………………11

6.1 轴的设计计算……………………………………………………………11

6.2 确定各轴段的直径和长度………………………………………………12

6.3 轴的校核…………………………………………………………………12

7 键的选择与校核…………………………………………………………………14

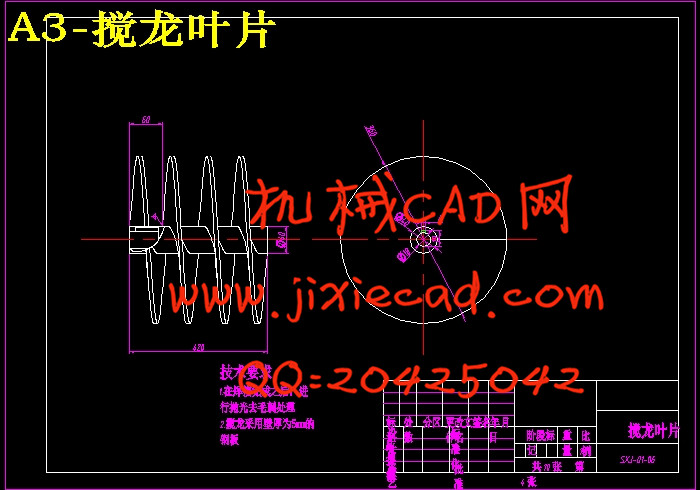

8 螺旋叶片的设计…………………………………………………………………14

9 结论 ……………………………………………………………………………15

9.1 设计完成情况……………………………………………………………15

9.2 结论………………………………………………………………………16

参考文献 ……………………………………………………………………………16

致谢 …………………………………………………………………………………17

摘 要:本文在分析了目前国内外的主要除雪方法的基础上,提出一种适合中国国

情的小型机械旋转式扫雪机的设计方案。本设计由汽油机提供动力。经输出轴输出动力,通过链传动传递动力,带动其他工作。该扫雪机的工程是利用搅龙旋转将雪集中并向后推送,通过搅龙的向后推力及螺旋桨产生的吸力使其到达螺旋桨。由于螺旋桨高速旋转产生巨大的作用力,雪被高速推向弯管,再通过与弯管壁撞击折射出去。从而达到清除积雪的目的和最佳效果。

关键词:扫雪机 ;搅龙 ;传动轴

The Design of The Snow-blower

Abstract: After analyzing the various means of snow-clearings in the world at present, the project of a sort of snow-blower fit for China is put forward in this paper. Based on the theory study and applied structural design.This designis provided power by the petrol machine. It is outputted power by outputaxis, anddelivering power though a chain transmission, and arousing other work piece operations. Should in addition to the operate process of mini snow bloweris take advantage of stir revolution dragon to concentrate snow and push it backward, pass stir a dragon bckeward the vacuum force of thrust and aerofoil generate make it arrive aerofoil. Because of aerofoil with the top speed revolution generate enormous action force, and snow with top speed is pushed to the conduit bend, then collide with conduit bend wall and project out the conduit bend after refracting, thus hit the purpose

Keywords: Snow-blower; auger;transmission shaft

目 录

摘要 …………………………………………………………………………………1

关键词 ………………………………………………………………………………1

1 引言………………………………………………………………………………2

1.1 研究的目的和意义………………………………………………………3

1.2 国内外研究现状…………………………………………………………3

2 总体方案设计……………………………………………………………………4

2.1 设计任务与要求…………………………………………………………4

2.2 系统工作原理……………………………………………………………4

2.3 主要技术参数……………………………………………………………5

3 具体方案设计及加工……………………………………………………………5

3.1 动力参数…………………………………………………………………5

3.2 链与链轮…………………………………………………………………5

3.2.1 确定链条节数……………………………………………………6

3.2.2 确定节距…………………………………………………………6

3.2.3 确定中心距………………………………………………………6

3.2.4 验算链速…………………………………………………………6

3.2.5 压轴力……………………………………………………………6

4 传动轴的设计与校核……………………………………………………………7

4.1 轴的设计计算……………………………………………………………7

4.2 确定各轴的直径和长度…………………………………………………7

4.3 轴的校核…………………………………………………………………8

5 涡轮与蜗杆………………………………………………………………………8

5.1 按接触强度计算…………………………………………………………8

5.1.1 确定蜗杆头数、蜗杆齿数………………………………………8

5.1.2 确定涡轮转矩……………………………………………………9

5.1.3 确定条件…………………………………………………………9

5.1.4 初定中心距、模数、倒程角……………………………………9

5.1.5 计算传动效率……………………………………………………9

5.2 验算齿面接触强度………………………………………………………9

5.3 计算传动的主要尺寸……………………………………………………10

5.4 弯曲强度验算……………………………………………………………10

6 搅龙轴设计与校核………………………………………………………………11

6.1 轴的设计计算……………………………………………………………11

6.2 确定各轴段的直径和长度………………………………………………12

6.3 轴的校核…………………………………………………………………12

7 键的选择与校核…………………………………………………………………14

8 螺旋叶片的设计…………………………………………………………………14

9 结论 ……………………………………………………………………………15

9.1 设计完成情况……………………………………………………………15

9.2 结论………………………………………………………………………16

参考文献 ……………………………………………………………………………16

致谢 …………………………………………………………………………………17