设计简介

沙石振动筛的设计

摘要 十六大明确提出,我国在新世纪头20年经济建设的主要任务之一,是基本实现工业化,并郑重提出“走新型工业化道路”。可是在我省大多数沙石材料厂的沙石筛选过程还是走着最原始的人工运作,工具简单,劳动强度大的老路。本设计正是我们在了解了家乡大部分沙石场的实际情况后,运用我们所学知识为家乡的中小规模的沙石场设计的一种筛分砂石的振动筛。

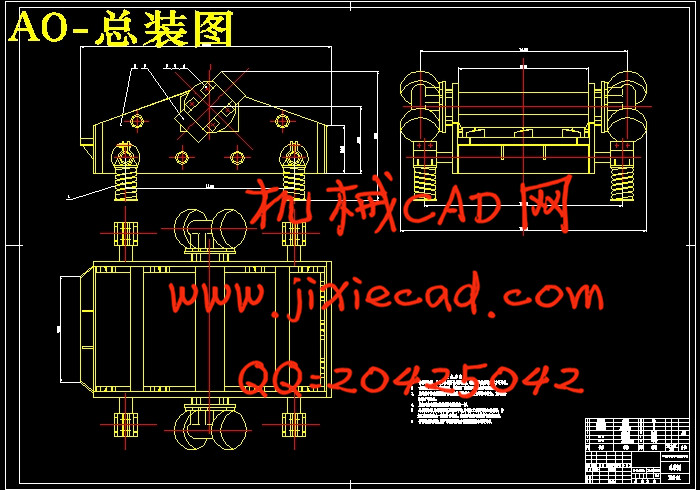

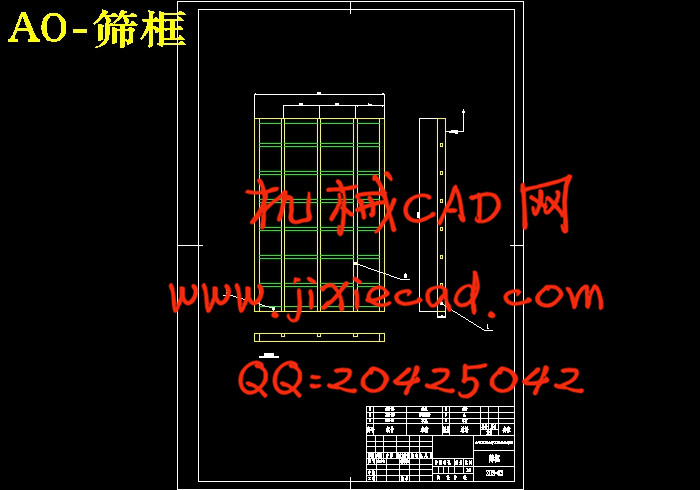

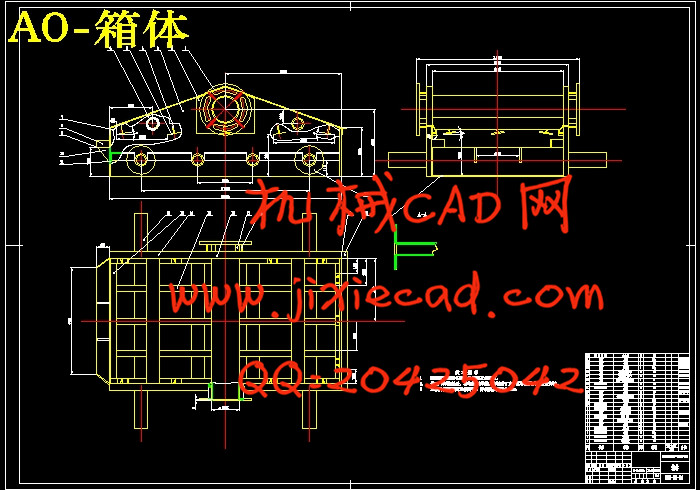

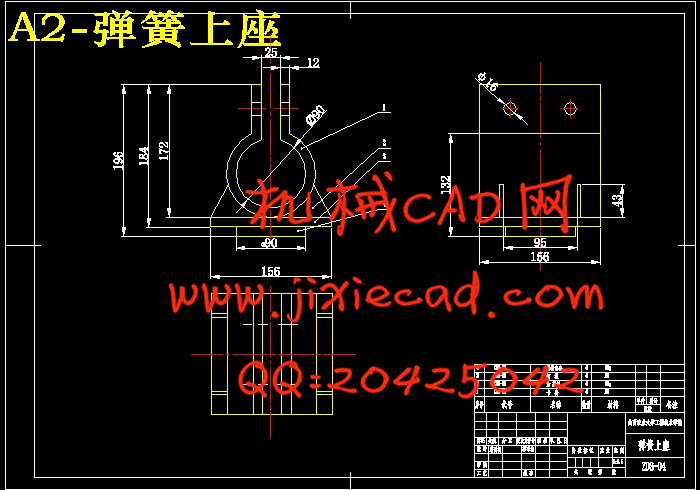

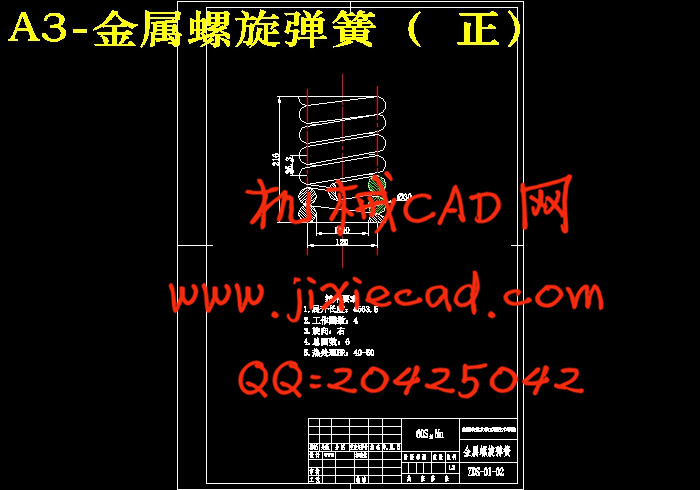

本设计的振动筛为自同步双振动电机驱动的,其特点是结构简单、安装方便、成本低、容易操作及维护等。其筛箱为板梁铆焊组合结构,由主副侧板、管梁、入料挡板、出料板、筛板等组成,侧板选用低合金压力容器钢板,强度高、可焊性好,周边折弯,并在振动方向及沿纵向连接多根角钢,使侧板刚度大大增强,有利于强度的提高和噪音的降低。管梁由法兰盘、无缝钢管、加强槽钢等组成,重量轻、强度大,便于制造安装,具有互换性。加强槽钢上有T形孔,使用T形螺栓,便于筛板的安装维护,消除U形螺栓对管梁的磨损。工作原理:两台振动电机的型号相同,可以产生一种组合的直线振动。这种振动可以使输送槽体中的物料运动,并与筛面发生碰撞,使小于筛孔的物料透过,从而实现物料的几何分级,实现筛分。总体方案为:采用普通筛分法,振动形式为共振,运动轨迹为直线运动,激振方式为惯性式,隔振方式为一级隔振,隔振弹簧为金属螺旋式隔振弹簧。

关键词 振动筛; 筛箱; 振动电机

The design of gravel shaker

Abstract

Congress made it clear that in the new century, China's first 20 years of economic development one of the main tasks is the basic realization of industrialization, and solemnly to "take a new road to industrialization." However, in our province the majority of gravel sand and gravel plant materials selection process is the most primitive artificial walked to operate simple tools, the old labor-intensive. The design is exactly what we learned about the home in the sand most of the actual market situation, we have learned to use his knowledge of small and medium-sized gravel field design of a shaker screen sand and gravel.

This topic shaker for self-synchronizing pair vibration motor-driven, Its characteristic is the structure simple, the installs convenient, the cost low, is easy to operate and the maintenance and so on. It sieves the box is board crossbeam riveting hitch welds built-up section, By host vice- side bar, Hollow beam, Enters the material back plate, Leaves material board, Sieves board and so on composition, The side bar selects the low-alloy pressure vessel steel plate, The intensity is high, The weldability is good, Peripheral knee bend, And in the vibration direction and along longitudinal connects themulti- roots angle steel, Causes the side bar rigidity big enhancement, Is advantageous to the intensity enhancement and noise reducing. Hollow beam by flange plate, Seamless steel pipe, Strengthens composition and so on channel steel, The weight light, the intensity is big, is advantageous for themanufacture installment, Has the interchangeability. Strengthens in the channel steel to have the T shape hole, Uses the T shape bolt, Is advantageous for screen board installs the maintenance, Eliminates the U shape bolt to the hollow beam attrition. Principle of work: Two vibrate the electrical machinery the model to be same, May have one kind of combination straight-line oscillation. This kind of vibration may cause in the transportation trough body thematerial movement, And has the collision with the screening surface, And has the collision with the screening surface, Thus realization material geometry graduation, Realization screening. The overall plan is: Uses the ordinary screening law, The vibration form for resonates, The path is the translation, Stirs up the strength vibration the way is the inertia type, The vibration isolation way is level of vibration isolations, The vibration isolation spring is the metal screw type vibrationisolation spring。

Keywords : Reciprocating coal conveyor Reducer Analysis Strength Check

目录

1 前言 1

1.1课题研究背景及意义 1

1.2振动筛的发展史 1

1.3振动筛在国内的发展现状 3

1.4 振动机械的用途和分类 3

1.4.1 振动机械的组成 4

1.4.2 振动机械的特点 4

1.4.3 振动机械的用途 4

1.4.4 振动机械的分类 5

2技术任务书 7

2.1 直线振动细筛的结构、工作原理及总体方案的比较确定 7

2.1.1结构及工作原理 7

2.1.2直线型振动细筛的特点 7

2.1.3各类筛分方法的比较确定 8

2.1.4 振动形式的确定 10

2.1.5 运动轨迹的确定 10

2.1.6激振方式的比较 11

2.2主要问题及解决方案 12

2.2.1 振动筛降噪措施 12

2.2.2 常见故障及处理措施 12

3 设计计算说明书 15

3.1运动学参数的选择计算 15

3.1.1 物料运动状态的选择 15

3.1.2 安装倾角的选择 15

3.1.3 振动方向角的选择 15

3.1.4 物料的平均速度 16

3.2工艺参数的确定 16

3.3动力学参数的选择计算 17

3.3.1工作机体的质量 17

3.3.2物料的结合质量 17

3.3.3 隔振系统的频率比及隔振弹簧刚度 17

3.4 其它零部件的选择 18

3.4.1隔振系统的选择 18

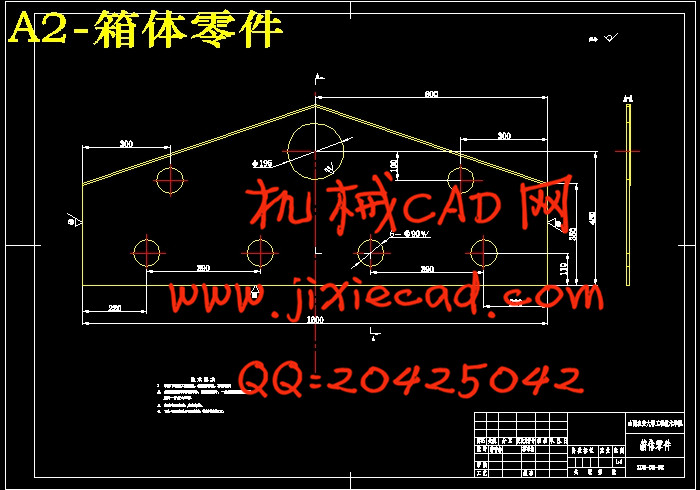

3.4.2筛箱 18

3.4.3筛面的比较选择 19

3.4.4 筛面的压紧装置 20

3.4.5支撑装置的选择 20

4 使用说明书 21

4.1 日常维护保养 21

4.2 检修周期以及大小修 22

4.3故障分析以及排除 22

5 标准化审查报告 24

5.1产品图样的审查 22

5.2产品技术文件审查 22

6 结论 25

参考文献 26

致谢 27

摘要 十六大明确提出,我国在新世纪头20年经济建设的主要任务之一,是基本实现工业化,并郑重提出“走新型工业化道路”。可是在我省大多数沙石材料厂的沙石筛选过程还是走着最原始的人工运作,工具简单,劳动强度大的老路。本设计正是我们在了解了家乡大部分沙石场的实际情况后,运用我们所学知识为家乡的中小规模的沙石场设计的一种筛分砂石的振动筛。

本设计的振动筛为自同步双振动电机驱动的,其特点是结构简单、安装方便、成本低、容易操作及维护等。其筛箱为板梁铆焊组合结构,由主副侧板、管梁、入料挡板、出料板、筛板等组成,侧板选用低合金压力容器钢板,强度高、可焊性好,周边折弯,并在振动方向及沿纵向连接多根角钢,使侧板刚度大大增强,有利于强度的提高和噪音的降低。管梁由法兰盘、无缝钢管、加强槽钢等组成,重量轻、强度大,便于制造安装,具有互换性。加强槽钢上有T形孔,使用T形螺栓,便于筛板的安装维护,消除U形螺栓对管梁的磨损。工作原理:两台振动电机的型号相同,可以产生一种组合的直线振动。这种振动可以使输送槽体中的物料运动,并与筛面发生碰撞,使小于筛孔的物料透过,从而实现物料的几何分级,实现筛分。总体方案为:采用普通筛分法,振动形式为共振,运动轨迹为直线运动,激振方式为惯性式,隔振方式为一级隔振,隔振弹簧为金属螺旋式隔振弹簧。

关键词 振动筛; 筛箱; 振动电机

The design of gravel shaker

Abstract

Congress made it clear that in the new century, China's first 20 years of economic development one of the main tasks is the basic realization of industrialization, and solemnly to "take a new road to industrialization." However, in our province the majority of gravel sand and gravel plant materials selection process is the most primitive artificial walked to operate simple tools, the old labor-intensive. The design is exactly what we learned about the home in the sand most of the actual market situation, we have learned to use his knowledge of small and medium-sized gravel field design of a shaker screen sand and gravel.

This topic shaker for self-synchronizing pair vibration motor-driven, Its characteristic is the structure simple, the installs convenient, the cost low, is easy to operate and the maintenance and so on. It sieves the box is board crossbeam riveting hitch welds built-up section, By host vice- side bar, Hollow beam, Enters the material back plate, Leaves material board, Sieves board and so on composition, The side bar selects the low-alloy pressure vessel steel plate, The intensity is high, The weldability is good, Peripheral knee bend, And in the vibration direction and along longitudinal connects themulti- roots angle steel, Causes the side bar rigidity big enhancement, Is advantageous to the intensity enhancement and noise reducing. Hollow beam by flange plate, Seamless steel pipe, Strengthens composition and so on channel steel, The weight light, the intensity is big, is advantageous for themanufacture installment, Has the interchangeability. Strengthens in the channel steel to have the T shape hole, Uses the T shape bolt, Is advantageous for screen board installs the maintenance, Eliminates the U shape bolt to the hollow beam attrition. Principle of work: Two vibrate the electrical machinery the model to be same, May have one kind of combination straight-line oscillation. This kind of vibration may cause in the transportation trough body thematerial movement, And has the collision with the screening surface, And has the collision with the screening surface, Thus realization material geometry graduation, Realization screening. The overall plan is: Uses the ordinary screening law, The vibration form for resonates, The path is the translation, Stirs up the strength vibration the way is the inertia type, The vibration isolation way is level of vibration isolations, The vibration isolation spring is the metal screw type vibrationisolation spring。

Keywords : Reciprocating coal conveyor Reducer Analysis Strength Check

目录

1 前言 1

1.1课题研究背景及意义 1

1.2振动筛的发展史 1

1.3振动筛在国内的发展现状 3

1.4 振动机械的用途和分类 3

1.4.1 振动机械的组成 4

1.4.2 振动机械的特点 4

1.4.3 振动机械的用途 4

1.4.4 振动机械的分类 5

2技术任务书 7

2.1 直线振动细筛的结构、工作原理及总体方案的比较确定 7

2.1.1结构及工作原理 7

2.1.2直线型振动细筛的特点 7

2.1.3各类筛分方法的比较确定 8

2.1.4 振动形式的确定 10

2.1.5 运动轨迹的确定 10

2.1.6激振方式的比较 11

2.2主要问题及解决方案 12

2.2.1 振动筛降噪措施 12

2.2.2 常见故障及处理措施 12

3 设计计算说明书 15

3.1运动学参数的选择计算 15

3.1.1 物料运动状态的选择 15

3.1.2 安装倾角的选择 15

3.1.3 振动方向角的选择 15

3.1.4 物料的平均速度 16

3.2工艺参数的确定 16

3.3动力学参数的选择计算 17

3.3.1工作机体的质量 17

3.3.2物料的结合质量 17

3.3.3 隔振系统的频率比及隔振弹簧刚度 17

3.4 其它零部件的选择 18

3.4.1隔振系统的选择 18

3.4.2筛箱 18

3.4.3筛面的比较选择 19

3.4.4 筛面的压紧装置 20

3.4.5支撑装置的选择 20

4 使用说明书 21

4.1 日常维护保养 21

4.2 检修周期以及大小修 22

4.3故障分析以及排除 22

5 标准化审查报告 24

5.1产品图样的审查 22

5.2产品技术文件审查 22

6 结论 25

参考文献 26

致谢 27