设计简介

砂轮回转试验机设计

摘要

随着我国加入WTO 和机械行业的振兴,特别是汽车行业的发展,对曲轴磨等大直径砂轮的需求迅速增长,因而生产大直径砂轮厂家的数量增多,致使砂轮的发展也趋于高速化,而高速砂轮的出厂又必需经过强度检验。砂轮回转强度是衡量砂轮质量的最重要指标之一,直接影响到人身及设备的安全,回转机是检测砂轮回转强度的专用设备。回转试验机由于适用的砂轮规格较多,相关标准对砂轮试验时的速度精度要求严格,所以要求回转试验机有很好的调速和稳速性能,调速范围从几百转/分到数千转/分。

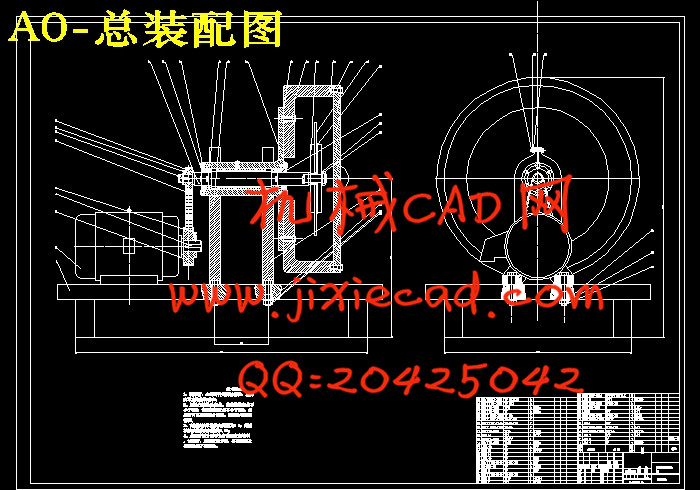

该设计包括机械设计和控制电路设计两部分,机械设计部分主要包括电机的型号选择、同步带的设轴的设计、轴承的选择以及法兰盘和砂轮防护罩的设计。电路设计部分主要是变频器的设计。本设计是通过电机带动同步带传递到轴上带动砂轮旋转,电机的速度通过变频器来控制,从而实现验证砂轮的强度是否合格。

关键词:砂轮,同步带,变频器

The grinding wheel rotation testing machine design

Abstract

With China's accession to the WTO and the revitalization of mechanical industry, especially the development of automobile industry, large diameter of crankshaft grinding wheel demand growth, thus producing big diameter the growing number of grinding wheel manufacturer, the development of the grinding wheel, tend to be fast pace, and high speed grinding wheel factory and necessary after strength test. The grinding wheel turn strength is the most important measure of grinding wheel quality indexes, directly affect the person and the safety equipment, back to the turn of the strength of the grinding wheel is used to test the return of special equipment. Because of the grinding wheel rotation testing machine for specifications, so relevant standards to the grinding wheel speed test accuracy requirement strictly, so the requirement rotation testing machine have very good control performance and steady speed, speed range from hundreds of thousands to turn/turn/points.

This design including mechanical design and control circuit design two parts, mechanical design part mainly includes the motor model selection, synchronous belt of the design, bearing a shaft of choice and flange constructed and the design of the grinding wheel cover. Circuit design is the design of the main part of the frequency converter. This design is driven by motor synchronous belt transmission shaft grinding wheel rotation to drive, motor speed through the frequency converter to control, so as to realize the strength of the grinding wheel validation if they are qualified.

Key words: grinding wheel, synchronous belt, inverter

目录

1绪 论 1

1.1砂轮回转试验机概述 1

1.2回转试验机工艺要求分析 1

1.3回转试验机的拖动方式 2

1.4砂轮机操作规程 3

1.5砂轮的保养 4

1.5.1砂轮的检查 4

1.5.2砂轮的安装 4

1.5.3砂轮的平衡试验 5

1.5.4砂轮的修整 5

2 机械设计 6

2.1电机功率的确定 6

2.2步进电机同步齿形带的设计 6

2.2.1选择带的带型 6

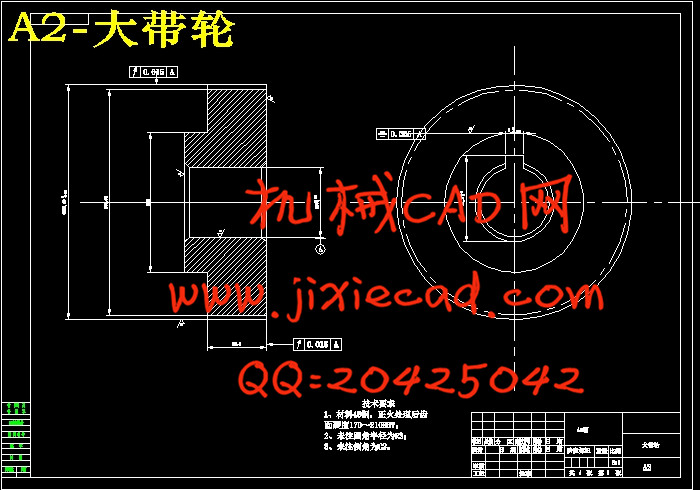

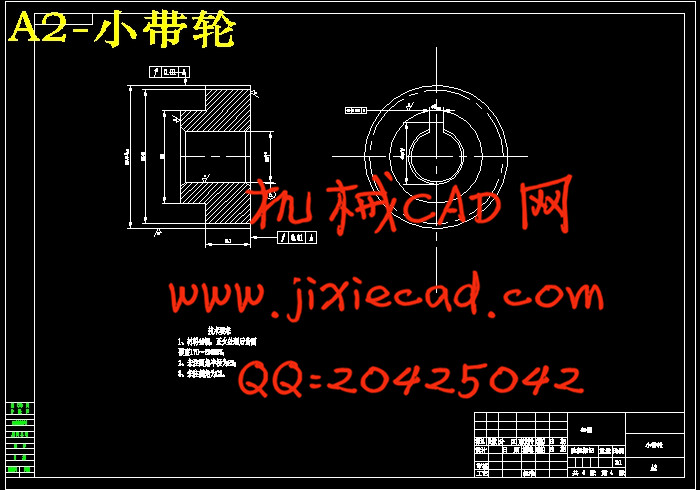

2.2.2 确定带轮直径及带速 6

2.2.3确定中心距及带长 7

2.2.4 确定带宽 7

2.2.5确定带轮的宽度 8

2.2.6结果整理 8

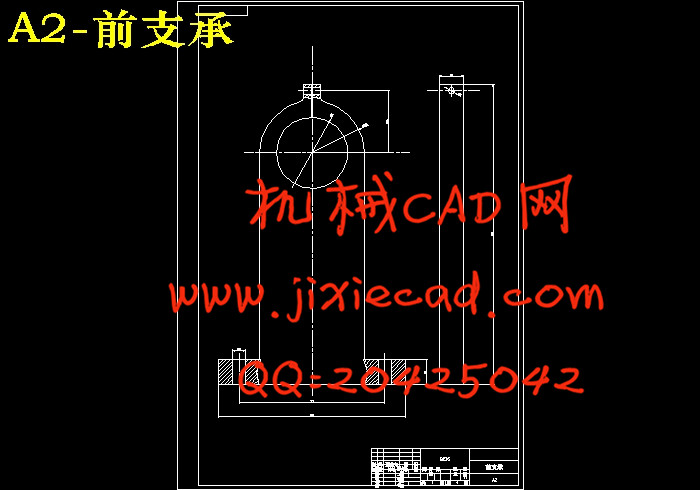

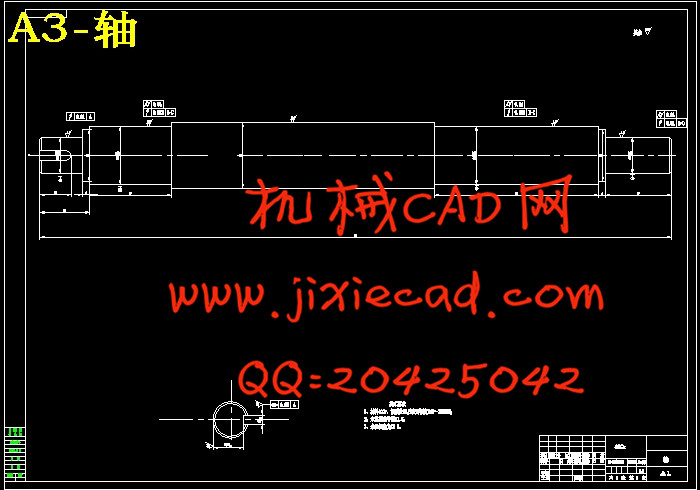

2.3 轴的结构设计 9

2.4 轴的强度校核 10

2.5 轴承的选择 10

2.6 轴承寿命校核 11

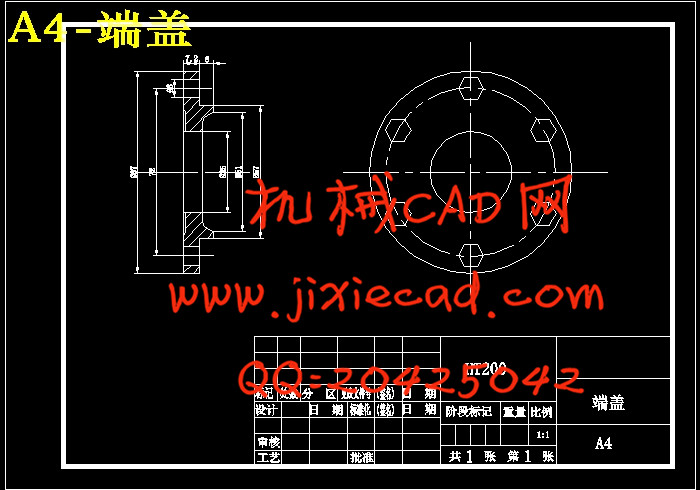

2.7 设计新结构的砂轮卡盘 12

2.8 设计新结构的防护罩 12

结 论 13

致 谢 14

参考文献 15

摘要

随着我国加入WTO 和机械行业的振兴,特别是汽车行业的发展,对曲轴磨等大直径砂轮的需求迅速增长,因而生产大直径砂轮厂家的数量增多,致使砂轮的发展也趋于高速化,而高速砂轮的出厂又必需经过强度检验。砂轮回转强度是衡量砂轮质量的最重要指标之一,直接影响到人身及设备的安全,回转机是检测砂轮回转强度的专用设备。回转试验机由于适用的砂轮规格较多,相关标准对砂轮试验时的速度精度要求严格,所以要求回转试验机有很好的调速和稳速性能,调速范围从几百转/分到数千转/分。

该设计包括机械设计和控制电路设计两部分,机械设计部分主要包括电机的型号选择、同步带的设轴的设计、轴承的选择以及法兰盘和砂轮防护罩的设计。电路设计部分主要是变频器的设计。本设计是通过电机带动同步带传递到轴上带动砂轮旋转,电机的速度通过变频器来控制,从而实现验证砂轮的强度是否合格。

关键词:砂轮,同步带,变频器

The grinding wheel rotation testing machine design

Abstract

With China's accession to the WTO and the revitalization of mechanical industry, especially the development of automobile industry, large diameter of crankshaft grinding wheel demand growth, thus producing big diameter the growing number of grinding wheel manufacturer, the development of the grinding wheel, tend to be fast pace, and high speed grinding wheel factory and necessary after strength test. The grinding wheel turn strength is the most important measure of grinding wheel quality indexes, directly affect the person and the safety equipment, back to the turn of the strength of the grinding wheel is used to test the return of special equipment. Because of the grinding wheel rotation testing machine for specifications, so relevant standards to the grinding wheel speed test accuracy requirement strictly, so the requirement rotation testing machine have very good control performance and steady speed, speed range from hundreds of thousands to turn/turn/points.

This design including mechanical design and control circuit design two parts, mechanical design part mainly includes the motor model selection, synchronous belt of the design, bearing a shaft of choice and flange constructed and the design of the grinding wheel cover. Circuit design is the design of the main part of the frequency converter. This design is driven by motor synchronous belt transmission shaft grinding wheel rotation to drive, motor speed through the frequency converter to control, so as to realize the strength of the grinding wheel validation if they are qualified.

Key words: grinding wheel, synchronous belt, inverter

目录

1绪 论 1

1.1砂轮回转试验机概述 1

1.2回转试验机工艺要求分析 1

1.3回转试验机的拖动方式 2

1.4砂轮机操作规程 3

1.5砂轮的保养 4

1.5.1砂轮的检查 4

1.5.2砂轮的安装 4

1.5.3砂轮的平衡试验 5

1.5.4砂轮的修整 5

2 机械设计 6

2.1电机功率的确定 6

2.2步进电机同步齿形带的设计 6

2.2.1选择带的带型 6

2.2.2 确定带轮直径及带速 6

2.2.3确定中心距及带长 7

2.2.4 确定带宽 7

2.2.5确定带轮的宽度 8

2.2.6结果整理 8

2.3 轴的结构设计 9

2.4 轴的强度校核 10

2.5 轴承的选择 10

2.6 轴承寿命校核 11

2.7 设计新结构的砂轮卡盘 12

2.8 设计新结构的防护罩 12

结 论 13

致 谢 14

参考文献 15