设计简介

摘要

我国目前的山楂山楂机械的发展情况比较落后,由于缺少良好的设备,加工手段落后,生产效率低,致使一些地区出现水果积压腐烂现象,给果农造成很大的经济损失。山楂去核手工作业现在在中国仍然是主要的加工手段,不仅占用大量的劳动力、劳动强度大、生产率低,而且卫生安全也得不到有效保障。去核作业是山楂加工工序中十分重要的前处理工序。以往的手工操作远不能满足现代山楂加工的需求,不仅占用大量的劳力,劳动强度大,生产效率低,且产品质量难以控制。本设计主要是为了解决山楂去核作业的劳动强度大,安全卫生,提高生产效率,降低山楂果实破损率,保证山楂产品的质量。因此,小型山楂山楂机有非常好的应用前景。

关键词:山楂;山楂机;设计

Abstract

Development situation of China's current Hawthorn nuclear machinery is relatively backward, due to the lack of good equipment, processing methods are backward, low production efficiency, resulting in some areas appear fruit backlog rotten phenomenon, caused great economic losses to farmers. Hawthorn nuclear manual operation now in China is still the main means of processing, not only takes up a lot of labor, high labor intensity, low productivity, and health and safety are not effectively guarantee. Pitted pretreatment procedure is very important in the process of hawthorn processing. The old manual operation cannot meet the modern Hawthorn processing requirements, not only takes up a lot of labor, labor intensity is high, the production efficiency is low, and the product quality is difficult to control. This design is mainly to solve the Hawthorn nuclear operation labor intensity, safety and health, improve production efficiency, reduce the damage rate of hawthorn hawthorn fruit, guarantee the quality of the products. Therefore, application prospect of small Hawthorn nuclear machine has a very good.

Keywords: haw;stoner;design

目录

摘要 1

Abstract 2

1 前言 3

1.1本论文研究的目的和意义 3

1.2国内外果核类山楂机械的发展情况 3

1.3山楂的特性和山楂山楂机的应用前景 5

2 山楂山楂机的设计 5

2.1 马达的选择 6

2.1.1 选择马达系列 6

2.1.2 选择马达功率 7

2.2 传动装置的选择 7

2.2.1 传动的选择 7

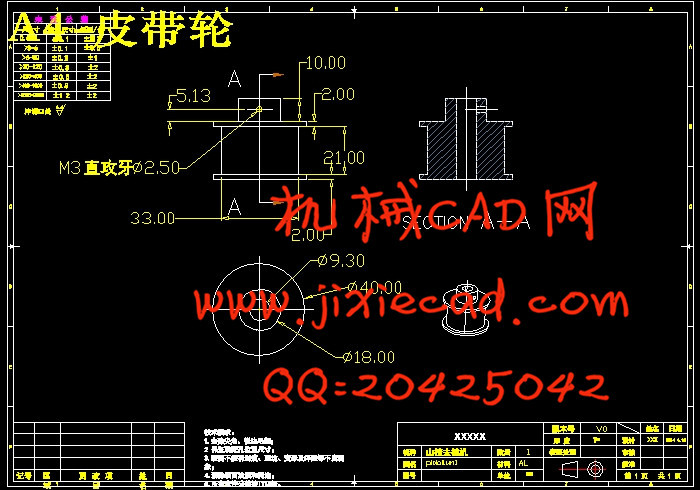

2.2.2 V带传动的设计 8

3 山楂山楂机关键部件设计 10

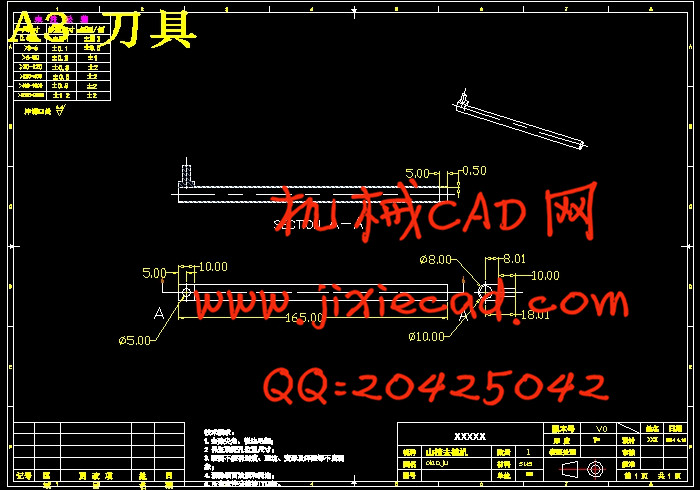

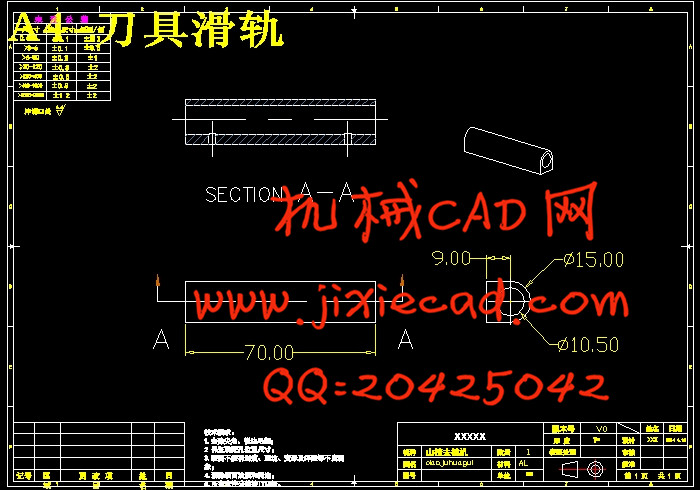

3.1 去核的刀具 10

3.1.1 去核的刀具材料及尺寸 10

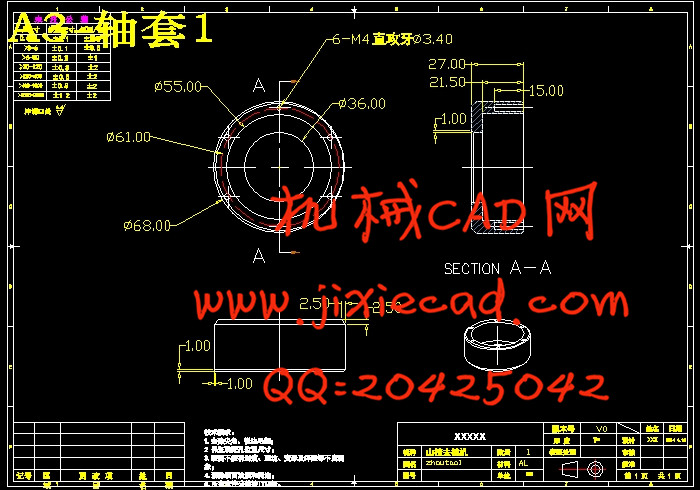

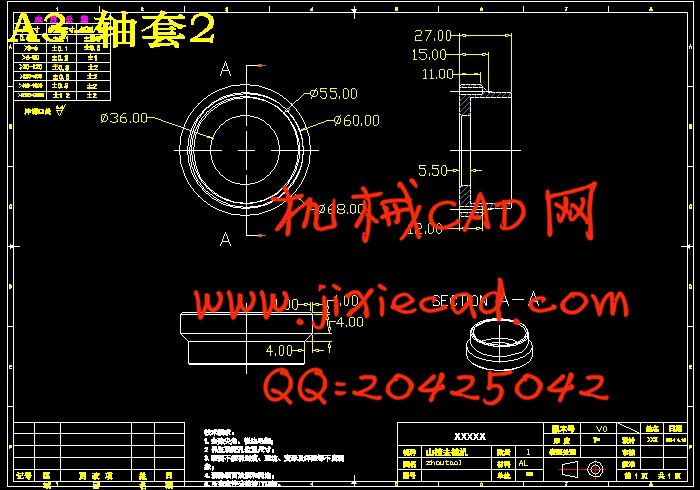

3.2 山楂定位盘 10

3.2.1 山楂定位盘材料 10

3.2.2 山楂定位盘尺寸 10

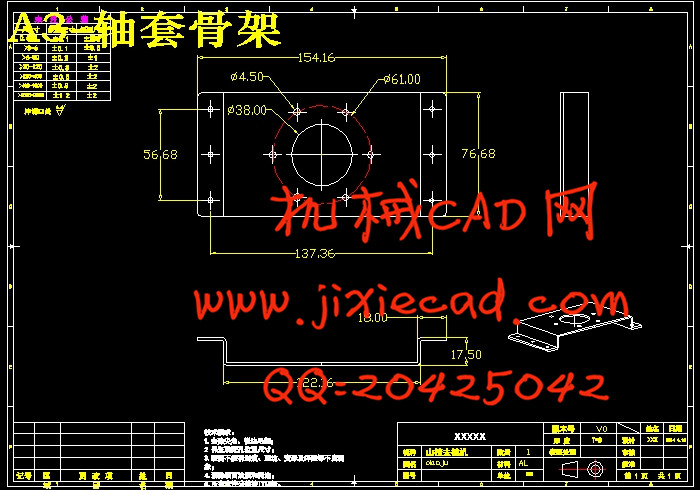

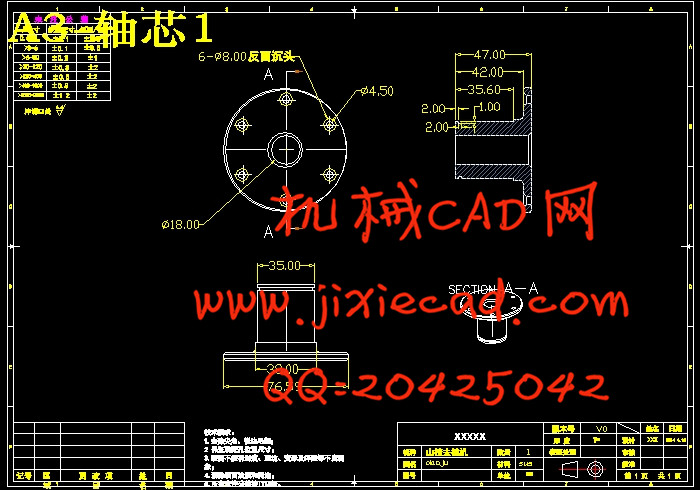

3.3 山楂机定位盘主轴 11

3.3.1 轴的材料选择 11

3.3.2 初步估算轴径 11

3.3.3 轴的结构设计 11

3.3.4 轴的强度验算 12

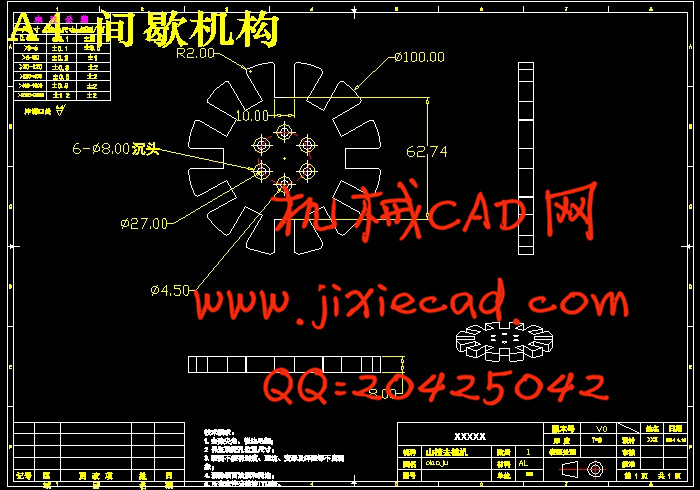

3.4 山楂机主轴间歇轮 13

3.5 山楂机传动圆盘 13

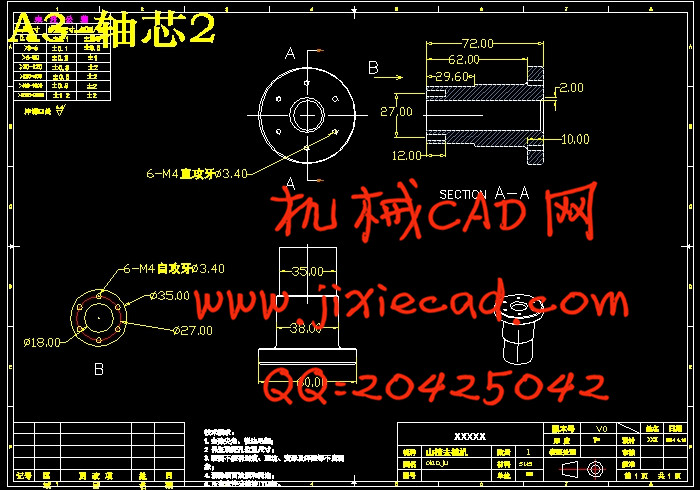

3.6 山楂机传动轴 14

3.6.1 轴的材料选择 14

3.6.2 初步估算轴径 14

3.6.3 轴的结构设计 14

3.6.4 轴的强度验算 14

3.7 轴承的选择 15

3.7.1 载荷条件 16

3.7.2 轴承转速 16

3.7.3 调心性能 16

3.7.4 轴承刚度 16

3.7.5 安装及拆卸要求 16

3.7.6 经济性 16

3.7.7 轴承寿命 16

3.8 连杆设计 18

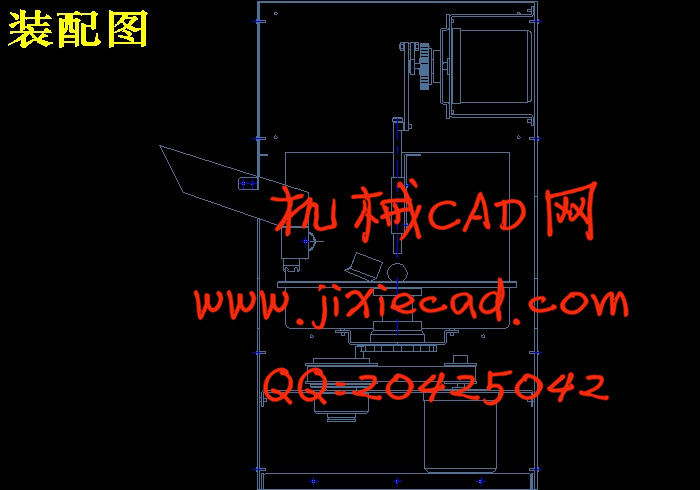

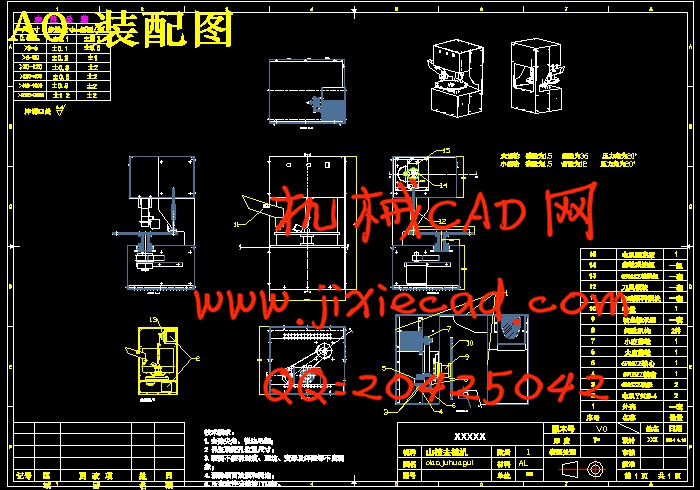

3.9 山楂去核机装配图 18

4 总结 20

参考文献 21

致谢 23

我国目前的山楂山楂机械的发展情况比较落后,由于缺少良好的设备,加工手段落后,生产效率低,致使一些地区出现水果积压腐烂现象,给果农造成很大的经济损失。山楂去核手工作业现在在中国仍然是主要的加工手段,不仅占用大量的劳动力、劳动强度大、生产率低,而且卫生安全也得不到有效保障。去核作业是山楂加工工序中十分重要的前处理工序。以往的手工操作远不能满足现代山楂加工的需求,不仅占用大量的劳力,劳动强度大,生产效率低,且产品质量难以控制。本设计主要是为了解决山楂去核作业的劳动强度大,安全卫生,提高生产效率,降低山楂果实破损率,保证山楂产品的质量。因此,小型山楂山楂机有非常好的应用前景。

关键词:山楂;山楂机;设计

Abstract

Development situation of China's current Hawthorn nuclear machinery is relatively backward, due to the lack of good equipment, processing methods are backward, low production efficiency, resulting in some areas appear fruit backlog rotten phenomenon, caused great economic losses to farmers. Hawthorn nuclear manual operation now in China is still the main means of processing, not only takes up a lot of labor, high labor intensity, low productivity, and health and safety are not effectively guarantee. Pitted pretreatment procedure is very important in the process of hawthorn processing. The old manual operation cannot meet the modern Hawthorn processing requirements, not only takes up a lot of labor, labor intensity is high, the production efficiency is low, and the product quality is difficult to control. This design is mainly to solve the Hawthorn nuclear operation labor intensity, safety and health, improve production efficiency, reduce the damage rate of hawthorn hawthorn fruit, guarantee the quality of the products. Therefore, application prospect of small Hawthorn nuclear machine has a very good.

Keywords: haw;stoner;design

目录

摘要 1

Abstract 2

1 前言 3

1.1本论文研究的目的和意义 3

1.2国内外果核类山楂机械的发展情况 3

1.3山楂的特性和山楂山楂机的应用前景 5

2 山楂山楂机的设计 5

2.1 马达的选择 6

2.1.1 选择马达系列 6

2.1.2 选择马达功率 7

2.2 传动装置的选择 7

2.2.1 传动的选择 7

2.2.2 V带传动的设计 8

3 山楂山楂机关键部件设计 10

3.1 去核的刀具 10

3.1.1 去核的刀具材料及尺寸 10

3.2 山楂定位盘 10

3.2.1 山楂定位盘材料 10

3.2.2 山楂定位盘尺寸 10

3.3 山楂机定位盘主轴 11

3.3.1 轴的材料选择 11

3.3.2 初步估算轴径 11

3.3.3 轴的结构设计 11

3.3.4 轴的强度验算 12

3.4 山楂机主轴间歇轮 13

3.5 山楂机传动圆盘 13

3.6 山楂机传动轴 14

3.6.1 轴的材料选择 14

3.6.2 初步估算轴径 14

3.6.3 轴的结构设计 14

3.6.4 轴的强度验算 14

3.7 轴承的选择 15

3.7.1 载荷条件 16

3.7.2 轴承转速 16

3.7.3 调心性能 16

3.7.4 轴承刚度 16

3.7.5 安装及拆卸要求 16

3.7.6 经济性 16

3.7.7 轴承寿命 16

3.8 连杆设计 18

3.9 山楂去核机装配图 18

4 总结 20

参考文献 21

致谢 23