设计简介

摘要

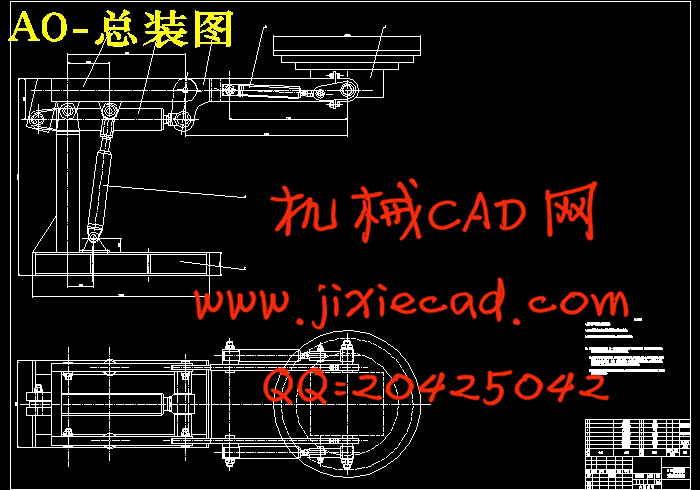

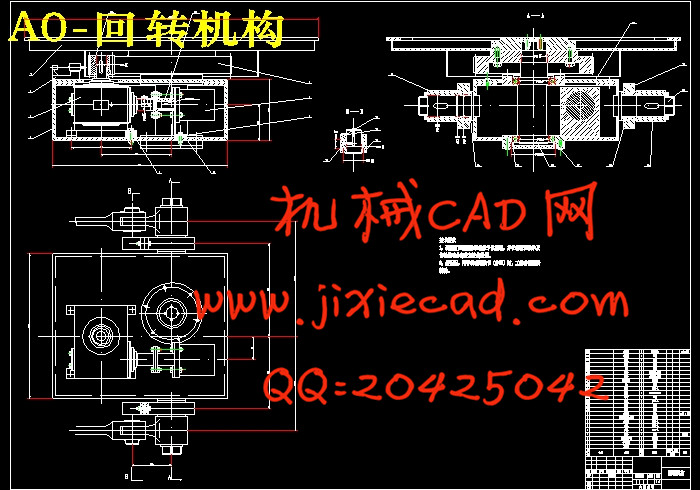

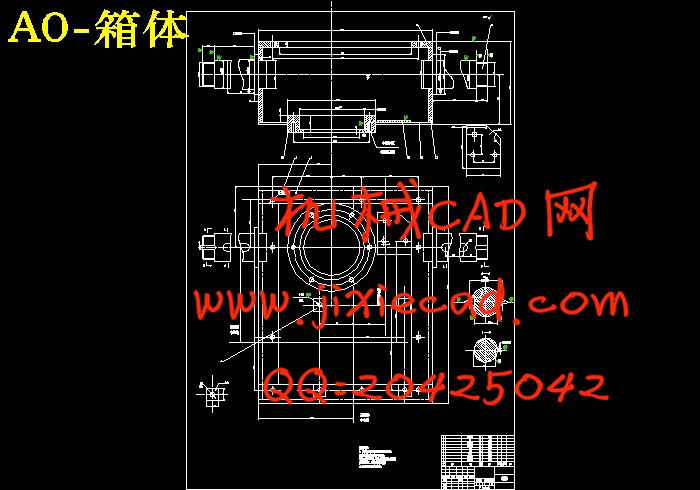

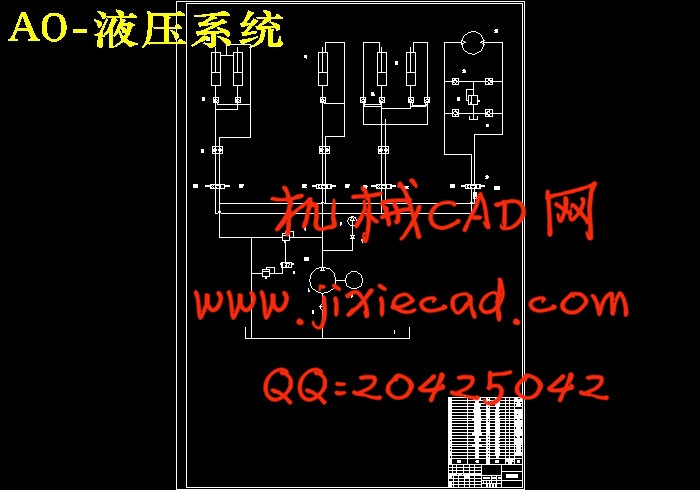

焊接作为一种工艺手段,已经成为很重要的热处理加工技术。焊接技术是随着金属的应用出现的,金属焊接的方法有很多种,各种压焊方法的共同特点是在焊接过程中施加压力而不加填充材料。焊接产品质量的好坏不仅取决于焊接工艺质量,与备料、装配等工序也有密切联系。因此,在整个焊接生产过程中,不论产品的质量要求和批量的大小,均应考虑采用生产工艺装备。焊接质量与生产装备工业密不可分,其中装载工件的工作台是在焊接过程中利用自身的各部分完成焊接变位的机械。本次设计的主要内容是:已知工作台的装载能力,焊接时要求的工作台的变位各种参数,设计出利用液压系统传动的0.5t液压焊接变位机械,其中包括液压系统的设计,对液压元件的选用,和工作台中回转机构的计算设计。再根据总体上对轴、轴承、联轴器等的刚度、寿命要求、综合位移要求等等,确定其余零部件。

关键词:液压;变位;焊接;传动

Abstract

With the high level of modern industrial development and the continuous advancement of welding technology, welding metal as a way to connect the technology in the production of metal structures has basically replaced the rivets connecting process. The quality of welding quality depends not only on the quality of welding technology, but also on the preparation and assembly processes are closely linked. Hence, throughout the welding process, regardless of the quality of the product requirements and batch size,we should consider the use of production technology and equipment. Among them, the wheel frame is welding driving wheel with the workpiece by means of friction between the cylindrical workpiece driven welding positioner rotating machinery, mainly used in the cylindrical workpiece and welding assembly. This paper studys the following:

Cylindrical workpiece in a known weight and rotation speed under the premise of the process of taking into account the transmission efficiency of the existence of friction and, ultimately, the output power to determine the motor type. Then selected based on speed, calculated the transmission gear ratio, so as to further determine the selection of the drive reducer form, quantity, and so on. The quality of welding quality depends not only on the quality of welding technology, but also on the preparation and assembly processes are closely linked. On the basis of the whole shaft, bearings, couplings, such as stiffness, longevity requirements,

integrated displacement requirements. we could determine the remaining components.

Key words: hydradulic ; pressure,; jointing,; changing ,; drive

目录

摘要 IAbstract II

目录 IV

第1章 绪论 1

1.1液压传动系统的发展概况 1

1.2焊接结构生产现状及发展方向 1

第2章 液压系统的设计计算 2

2.1液压缸负载分析2

2.2初选系统工作压力6

2.3计算液压缸的主要结构尺寸和液压马达排量7

2.4 计算液压元件实际工作压力10

2.5 计算液压元件实际所需流量10

2.6 制定系统方案和拟订液压系统图图11

2.7 液压元件的选择16.

第3章 传动部分设计计算 18

3.1齿轮的设计计算 18

3.2轴的设计计算 21

结论 26

参考文献 27

后记 28