设计简介

摘 要

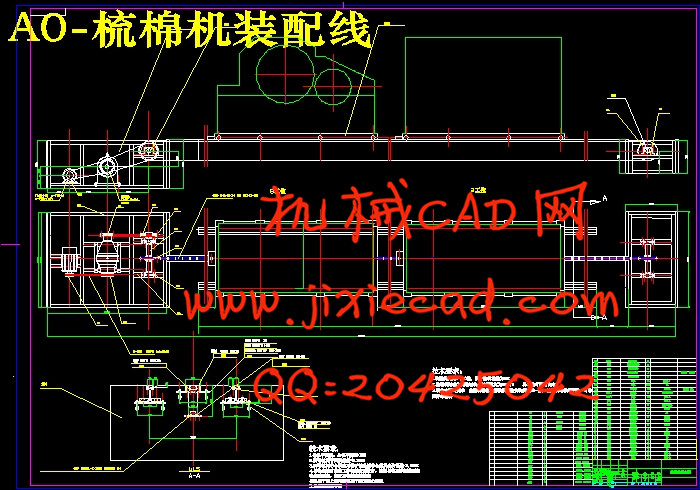

目前,大多数梳棉机生产厂家在生产梳棉机时,基本上采用普通装配,精度较低,效率比较低下,辅助时间长。为了减少工人的劳动量和缩短时间定额,实现自动装配与人工装配相结合,从而引出本次毕业设计的课题——梳棉机装配线承载装置、梳棉机的装配线有关主要部件的传动机构设计,为大批量而且高效率生产优质梳棉机服务。

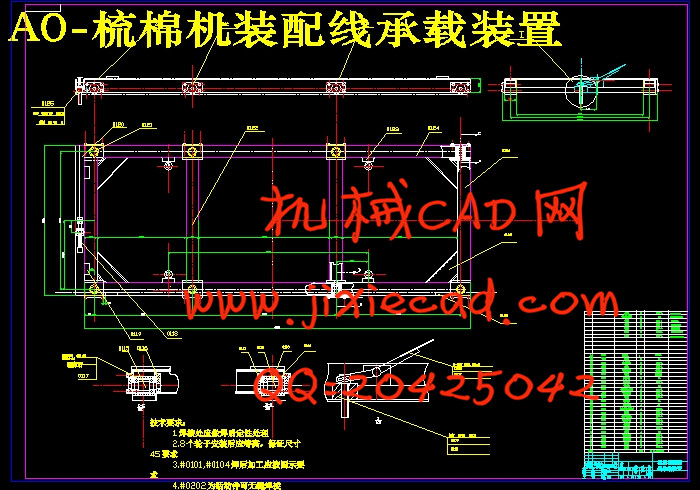

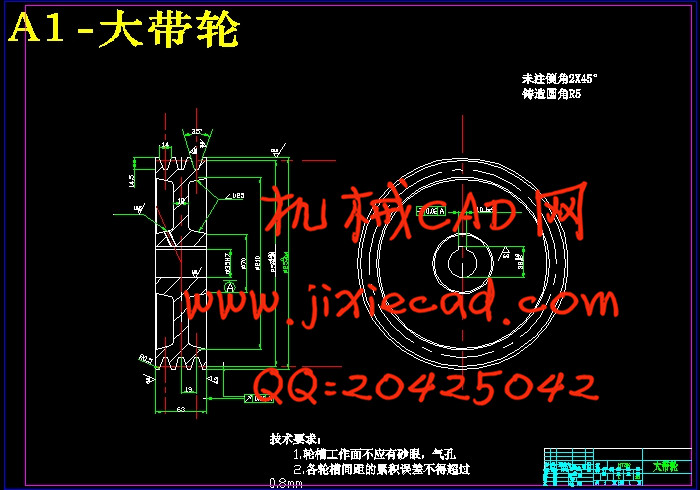

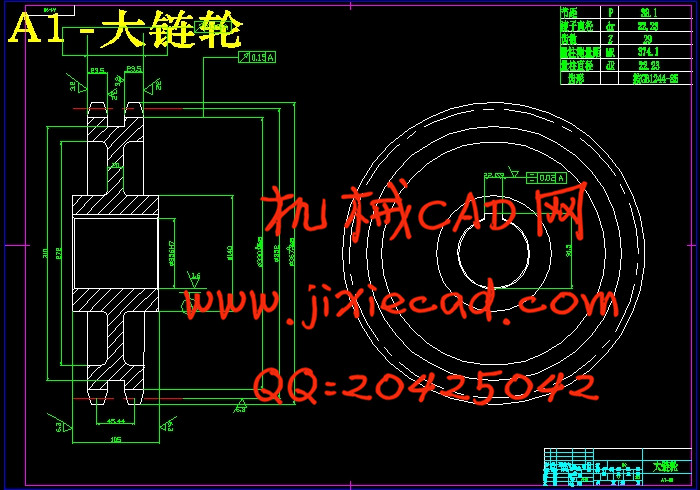

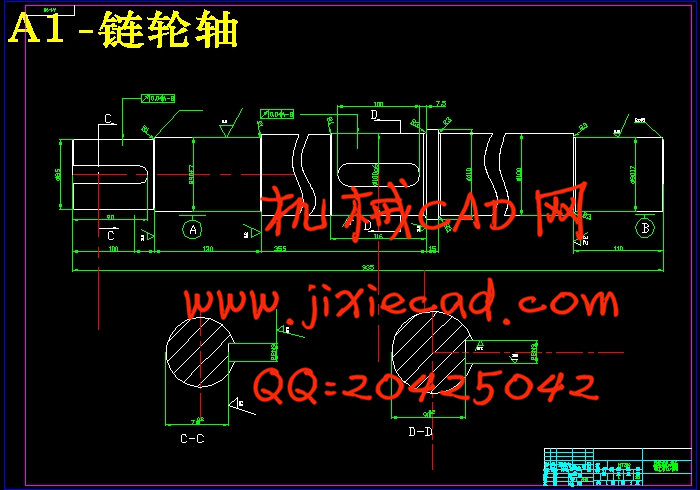

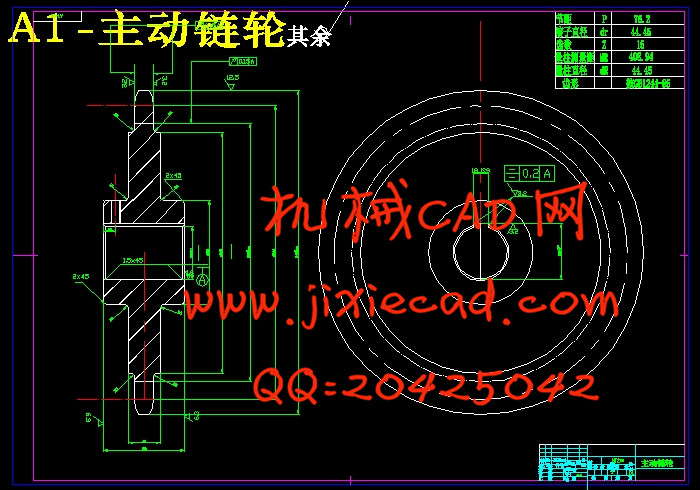

本次设计的重点是梳棉机的承载装置及输送方式,传动机构,主要装配工艺方案设计,以及部装流程设计的确定,就此本文主要进行了总体方案论证和主要构件设计。经过方案论证,最终确定采用间歇式链传动装配线。它与同样实现产品的出现的普装相比,无论是装配精度,还是效率(普通装配两天装一台机器,而本次设计的装配线可在一天8个工时装6-7台产品,而且可实现试车调试),都远远优化了传统的结构。主要构件包括承载装置和传动机构,其中传动通过无电机与减速器的带传动和各级链传动组合,实现低转速进给的功能,速度为0~30MM /s。

关键词:主要传动机构;承载装置;装配工艺。

Abstract

At present, most bearing manufacturers load and unload workpiece manually during grinding bearing inner-outer circle double endings, and auxiliary time is long. In order to reduce the amount of labor, shorten the time fixed and realize automation,lead to the subject of this graduation project: Special purpose Machine Tools design on small scaled bearing inner-outer circle end-grind processing, and the main purpose of the design is servicing for high-volume production of quality of bearing inner-outer circle.

The design focuses on carding machine carrying devices and transmission, transmission mechanism, the main assembly process design, process design and install the determination of the Department, this paper mainly to the overall scheme analysis and design of the main components.After the program demonstration, ultimately determine the use of intermittent chain drive assembly.It is the appearance of their products with the same equipment than the universal, whether it is assembly accuracy, or efficiency (two-day general assembly installed on one machine, but this design of assembly line workers at the day 8 6-7 sets fashion products, andenables test debug), optimized far the traditional structure.Major components including bearing devices and transmission, which drive motor and the reducer through the non-belt drive and chain drive at all levels combined, low-speed function of feed speed is 0 ~ 30MM / s

Keywords: The main transmission mechanism; bearing device; assembly process

目 录

1 引 言 1

2 装配线装配工艺总体设计 2

2.1 用途分析 3

2.2 装配线特点及装配工艺分析与制定 3

2.2.1 装配线的特点 3

2.2.2 装配线的工艺制定原则 5

2.2.3 装配线的工艺分析及设计 6

2.2.4 工序集中与分散................................................................................................7

3 装配最佳部装流程设计..............................................................................................8

3.1 承载装置确定.....................................................................................................8

3.2.对工位的编排......................................................................................................9

4 装配线的保证精度设计............................................................................................10

4.1 隔距的设计..........................................................................................................10

42工位等待时间设计...............................................................................................11

4.3 节拍的选择..........................................................................................................12

5 装配的传动设计.........................................................................................................12

5.1 有关传动机构的设计制定原则.......................................................................... 13

5.2 带传动的设计计算 26

5.3. 链传动的设计计算 26

5.4 减速器的设计计算..............................................................................................25

6承载装置设计 27

7 总 结 28

参考文献 31

致 谢 32

目前,大多数梳棉机生产厂家在生产梳棉机时,基本上采用普通装配,精度较低,效率比较低下,辅助时间长。为了减少工人的劳动量和缩短时间定额,实现自动装配与人工装配相结合,从而引出本次毕业设计的课题——梳棉机装配线承载装置、梳棉机的装配线有关主要部件的传动机构设计,为大批量而且高效率生产优质梳棉机服务。

本次设计的重点是梳棉机的承载装置及输送方式,传动机构,主要装配工艺方案设计,以及部装流程设计的确定,就此本文主要进行了总体方案论证和主要构件设计。经过方案论证,最终确定采用间歇式链传动装配线。它与同样实现产品的出现的普装相比,无论是装配精度,还是效率(普通装配两天装一台机器,而本次设计的装配线可在一天8个工时装6-7台产品,而且可实现试车调试),都远远优化了传统的结构。主要构件包括承载装置和传动机构,其中传动通过无电机与减速器的带传动和各级链传动组合,实现低转速进给的功能,速度为0~30MM /s。

关键词:主要传动机构;承载装置;装配工艺。

Abstract

At present, most bearing manufacturers load and unload workpiece manually during grinding bearing inner-outer circle double endings, and auxiliary time is long. In order to reduce the amount of labor, shorten the time fixed and realize automation,lead to the subject of this graduation project: Special purpose Machine Tools design on small scaled bearing inner-outer circle end-grind processing, and the main purpose of the design is servicing for high-volume production of quality of bearing inner-outer circle.

The design focuses on carding machine carrying devices and transmission, transmission mechanism, the main assembly process design, process design and install the determination of the Department, this paper mainly to the overall scheme analysis and design of the main components.After the program demonstration, ultimately determine the use of intermittent chain drive assembly.It is the appearance of their products with the same equipment than the universal, whether it is assembly accuracy, or efficiency (two-day general assembly installed on one machine, but this design of assembly line workers at the day 8 6-7 sets fashion products, andenables test debug), optimized far the traditional structure.Major components including bearing devices and transmission, which drive motor and the reducer through the non-belt drive and chain drive at all levels combined, low-speed function of feed speed is 0 ~ 30MM / s

Keywords: The main transmission mechanism; bearing device; assembly process

目 录

1 引 言 1

2 装配线装配工艺总体设计 2

2.1 用途分析 3

2.2 装配线特点及装配工艺分析与制定 3

2.2.1 装配线的特点 3

2.2.2 装配线的工艺制定原则 5

2.2.3 装配线的工艺分析及设计 6

2.2.4 工序集中与分散................................................................................................7

3 装配最佳部装流程设计..............................................................................................8

3.1 承载装置确定.....................................................................................................8

3.2.对工位的编排......................................................................................................9

4 装配线的保证精度设计............................................................................................10

4.1 隔距的设计..........................................................................................................10

42工位等待时间设计...............................................................................................11

4.3 节拍的选择..........................................................................................................12

5 装配的传动设计.........................................................................................................12

5.1 有关传动机构的设计制定原则.......................................................................... 13

5.2 带传动的设计计算 26

5.3. 链传动的设计计算 26

5.4 减速器的设计计算..............................................................................................25

6承载装置设计 27

7 总 结 28

参考文献 31

致 谢 32