设计简介

摘 要

输送机是在一定的线路上连续输送物料的物料搬运机械,又称连续输送机,是现代化生产和物流运输不可缺少的重要机械设备之一。它的广泛应用对于提高劳动生产率,实现物料输送过程的机械化和自动化,都具有重要的现实意义。

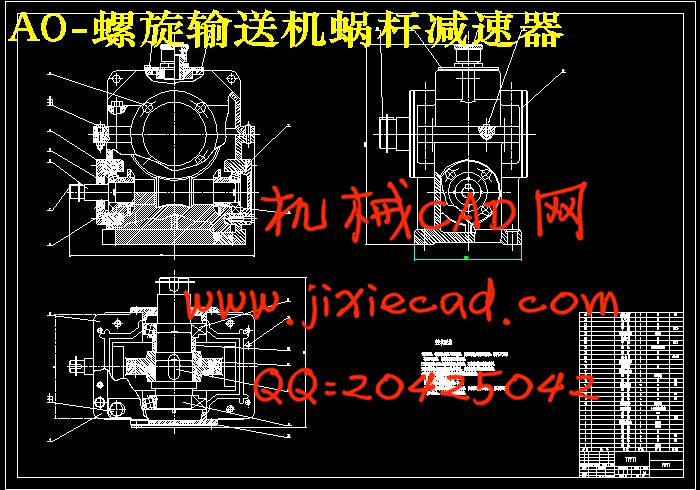

本次设计主要以螺旋输送机为例。本文查阅了许多国内外文献,详尽地了解国内外关于螺旋输送机优化的研究现状和发展动态。文中对螺旋输送机进行了较全面论述,阐明了螺旋输送机的工作原理。根据设计准则和设计理论,通过蜗轮蜗杆的设计计算及校验,各轴的结构设计,轴承的选择及其他部件的设计,最终完成了环面蜗轮蜗杆减速器设计。该设计体现了传动装置设计的一般过程,也可适用于其他类型输送机传动装置的设计。具有代表性,对其他类似设计有参考价值和借鉴意义。

关键词:螺旋输送机,传动装置,蜗轮蜗杆减速器

Abstract

The conveyor is a handling machine in a certain line on the continuously transported material, also named continuous conveyors. The conveyor is the necessary device of modern manufacturing and material fluid transportation. In order to reduce people's heavy physical work, to raise working productivity, to achieve material-conveying automation and mechanization, it possesses very important practical significance. it has already widely used in many country departments. Conveyors are used extensively in industry for conveying and elevating bulk materials over relatively short distances. They are very effective conveying devices for relatively free flowing bulk solids.

The design is for screw conveyor as example. This paper access to a number of domestic and foreign literatures, understanding of the status and developments at home and abroad on the screw conveyor detailed. Paper is a more comprehensive discussion of the screw conveyor and clarifies the working principle of the screw conveyor. According to the design criteria and design theory, though the design calculation and verification of the worm, the structural design of the shaft, bearing selection and design of the other components, complete the torus worm gear reducer design finally. The design reflects the general process, also has applicable to other types of conveyor gear design. It has representative and the reference value and reference to other similar design.

Key words: Screw conveyor, Gearing, Worm gear reducer

目 录输送机是在一定的线路上连续输送物料的物料搬运机械,又称连续输送机,是现代化生产和物流运输不可缺少的重要机械设备之一。它的广泛应用对于提高劳动生产率,实现物料输送过程的机械化和自动化,都具有重要的现实意义。

本次设计主要以螺旋输送机为例。本文查阅了许多国内外文献,详尽地了解国内外关于螺旋输送机优化的研究现状和发展动态。文中对螺旋输送机进行了较全面论述,阐明了螺旋输送机的工作原理。根据设计准则和设计理论,通过蜗轮蜗杆的设计计算及校验,各轴的结构设计,轴承的选择及其他部件的设计,最终完成了环面蜗轮蜗杆减速器设计。该设计体现了传动装置设计的一般过程,也可适用于其他类型输送机传动装置的设计。具有代表性,对其他类似设计有参考价值和借鉴意义。

关键词:螺旋输送机,传动装置,蜗轮蜗杆减速器

Abstract

The conveyor is a handling machine in a certain line on the continuously transported material, also named continuous conveyors. The conveyor is the necessary device of modern manufacturing and material fluid transportation. In order to reduce people's heavy physical work, to raise working productivity, to achieve material-conveying automation and mechanization, it possesses very important practical significance. it has already widely used in many country departments. Conveyors are used extensively in industry for conveying and elevating bulk materials over relatively short distances. They are very effective conveying devices for relatively free flowing bulk solids.

The design is for screw conveyor as example. This paper access to a number of domestic and foreign literatures, understanding of the status and developments at home and abroad on the screw conveyor detailed. Paper is a more comprehensive discussion of the screw conveyor and clarifies the working principle of the screw conveyor. According to the design criteria and design theory, though the design calculation and verification of the worm, the structural design of the shaft, bearing selection and design of the other components, complete the torus worm gear reducer design finally. The design reflects the general process, also has applicable to other types of conveyor gear design. It has representative and the reference value and reference to other similar design.

Key words: Screw conveyor, Gearing, Worm gear reducer

绪 论 1

第一章 设计方案的选定 6

第二章 电动机的选择与计算 7

2.1 初选电动机类型和结构型式 7

2.2 电动机基本参数 7

2.2.1 确定传送机所需的功率

2.2.2 确定传动总效率

2.2.3 电动机的输出功率 8

2.2.4 选择电动机及主要参数 8

第三章 传动装置的传动比及运动参数计算 10

3.1 传动装置的传动比 10

3.2 传动装置运动参数的计算 10

3.2.1 各轴功率计算 10

3.2.2 各轴转速的计算 10

3.2.3 各轴输入扭矩的计算 10

第四章 减速器部件的设计计算 11

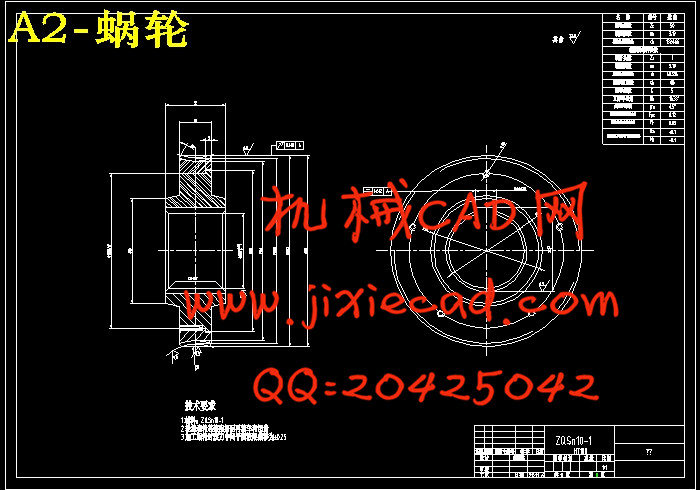

4.1 蜗轮蜗杆传动设计计算及校核 11

4.1.1 选择蜗杆、蜗轮材料 11

4.1.2 确定蜗杆头数Z1及蜗轮齿数Z2 11

4.1.3 验算滚筒的速度 11

4.1.4 确定蜗杆蜗轮中心距a 及传动几何参数设计 12

4.1.5 蜗轮蜗杆校核计算 14

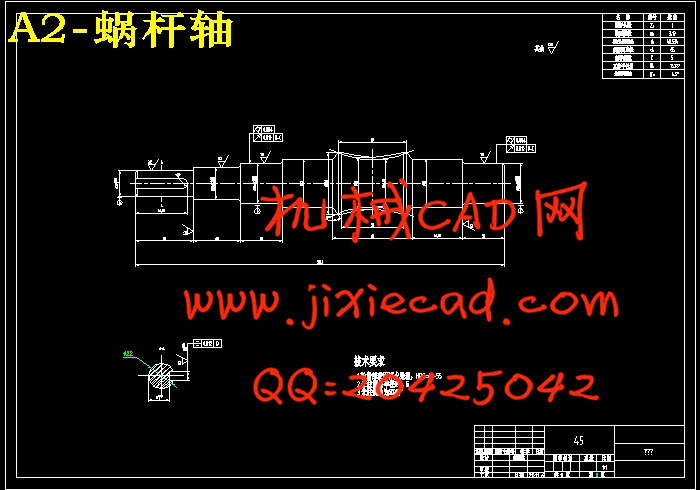

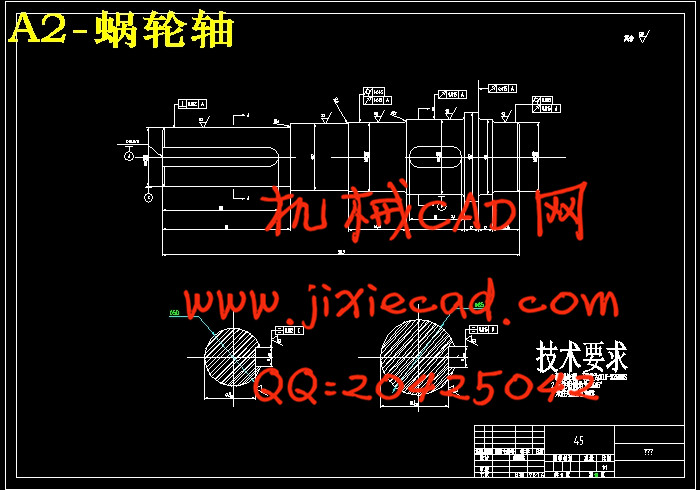

4.2 轴的设计及校核 15

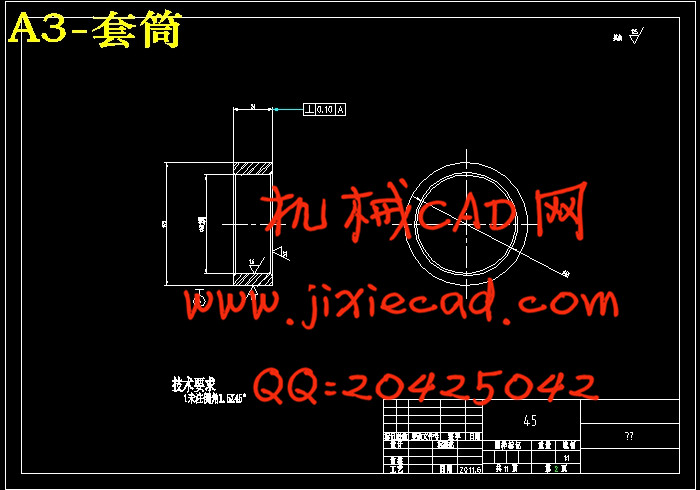

4.2.1各轴的结构设计 15

4.2.2各轴的强度校核 19

4.3 轴承的选择及校核 23

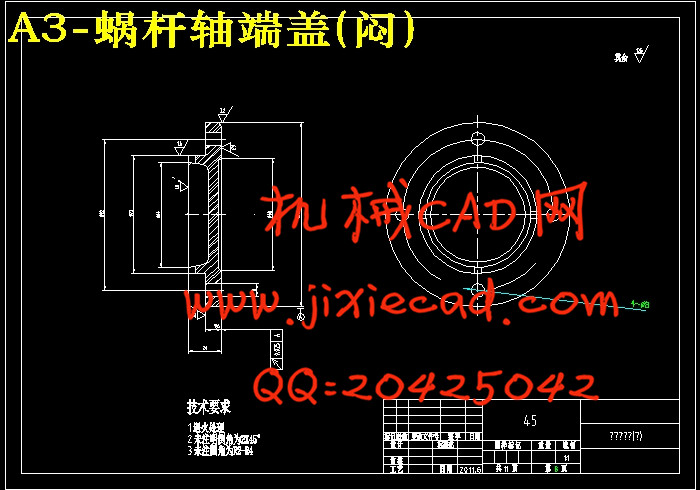

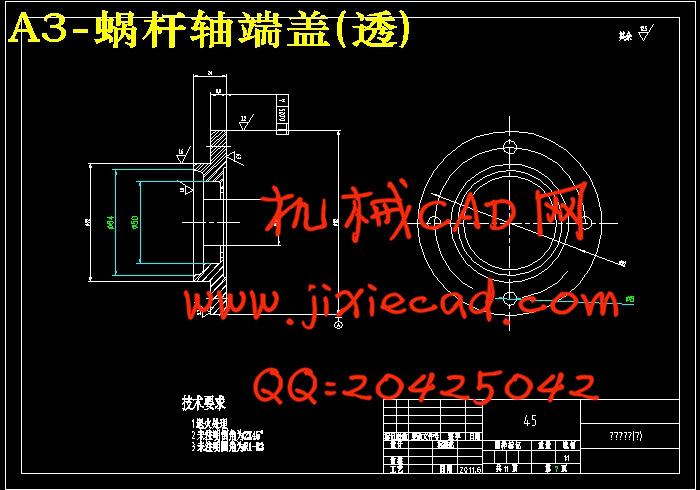

4.3.1 蜗杆轴轴承的选择及寿命校核 23

4.3.2 蜗轮轴轴承的寿命校核 25

4.4 键的选择及强度校核 26

4.4.1 蜗杆轴上安装联轴器处的键联接 26

4.4.2 蜗杆轴上装蜗轮处的键联接 26

4.4.3 蜗轮轴上装联轴器处的键联接 26

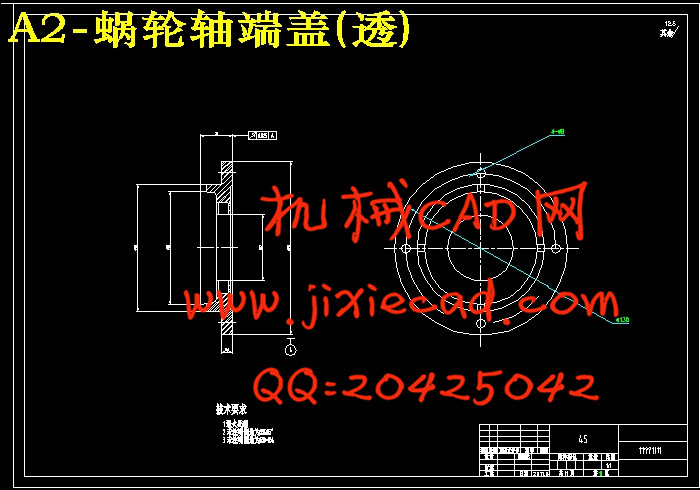

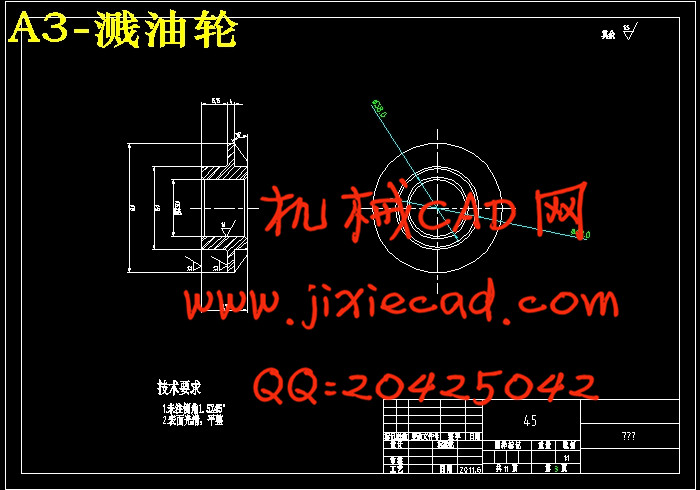

4.5 减速器的其他部件设计 27

4.5.1 窥视孔和视孔盖 27

4.5.2 通气器 28

4.5.3 定位销 28

4.5.4 起盖螺钉 28

4.5.5 起吊装置 29

4.5.6 放油孔及螺塞 29

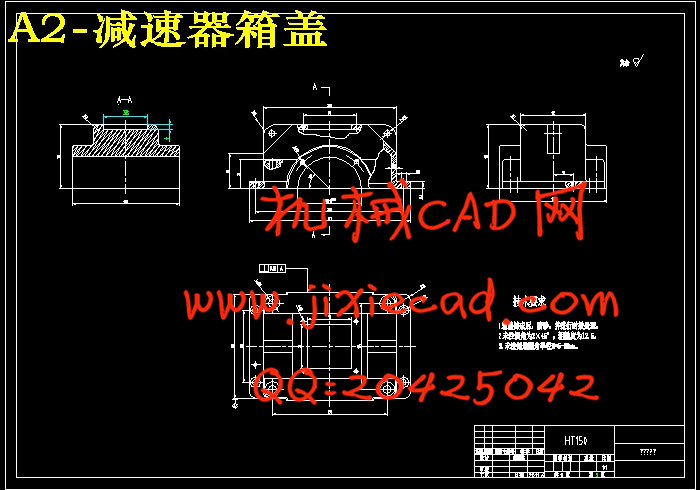

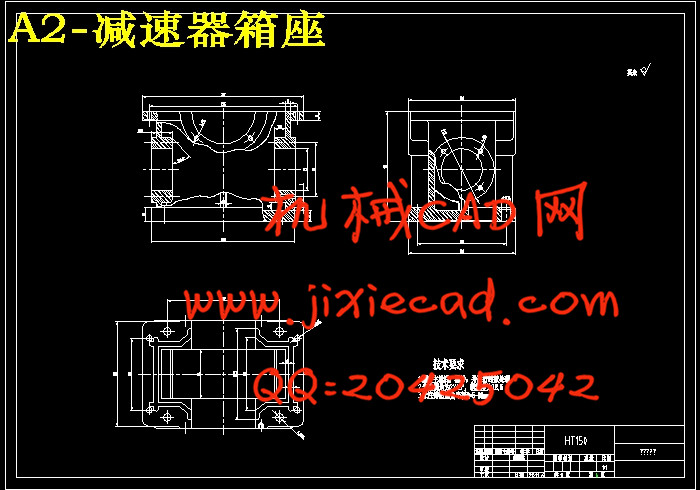

4.6 箱体结构设计及其他技术说明 30

4.6.1 箱体结构设计 30

4.6.2 减速器其他技术说明 30

结 论 32

致 谢 33

参考文献 34