设计简介

摘要

该薯类打浆制粉、干燥机可连续完成对薯类(主要指马铃薯、甘薯和木薯)

的粉碎打浆、搅拌、离心分离和脱水干燥功能。该机一定程度上解决了淀粉生产过程中的淀粉纯度低和生产速度不够快捷的难题。采用离心分离,提高了淀粉的纯度;接喷雾干燥,省却了耗时较长的淀粉沉降过程。该机生产速度快捷,适用于工厂生产。

目前,我国大型的机械化薯类淀粉厂并不多,大多数工厂采用落后的开放式工艺,手工操作或部分机械化操作,因此存在着设备简陋、不定型、不配套、收粉率低(50-60%)、卫生条件差、产量小、劳动量大、综合利用差等问题。

本设计进行改进,满足现代设计要求。该机一定程度上解决了淀粉生产过程中的淀粉纯度低和生产速度不够快捷的难题。

关键词:薯类;淀粉;干燥

Abstract

The potato pulp dryer can be completed for milling, the potato (mainly refers to the potato, sweet potato and cassava).The crushing and beating, stirring, centrifugal separation and dewatering and drying function.The machine was solved on certain level starch production starch in process of low purity and production rate is not fast problem.Centrifugal separation, improved starch purity; by spray drying, obviates the time-consuming starch settling process.The machine production speed is quick, is suitable for factory production.

At present, China's large-scale mechanization of potato starch factory is not much, most factories use backward open process, manual operation or partially-mechanized operations, therefore the existence of simple equipment, not stereotypes, not matching, low powder collecting rate (5060%), poor hygiene, output is little, large amount of labor, comprehensive utilization the problem such as difference.

This design was improved, meet the modern design requirements.The machine was solved on certain level starch production starch in process of low purity and production rate is not fast problem.

Key words: potato; starch; dry

目录

1 绪论

1.1 课题背景

1.1.1 薯类作物......................................................1

1.1.2 甘薯的简介....................................................1

1.1.3 马铃薯的简介..................................................1

1.1.4 我国薯类加工设备现状..........................................2

1.2 薯类加工工序介绍..................................................3

1.3 淀粉及其制品深加工工业的市场前景..................................4

1.4 设计的主要内容 ...................................................4

2 薯类打浆制粉、干燥机的总体设计........................................4

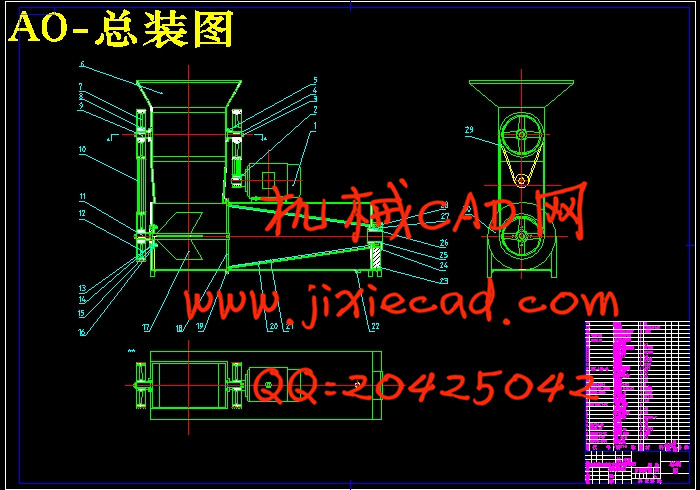

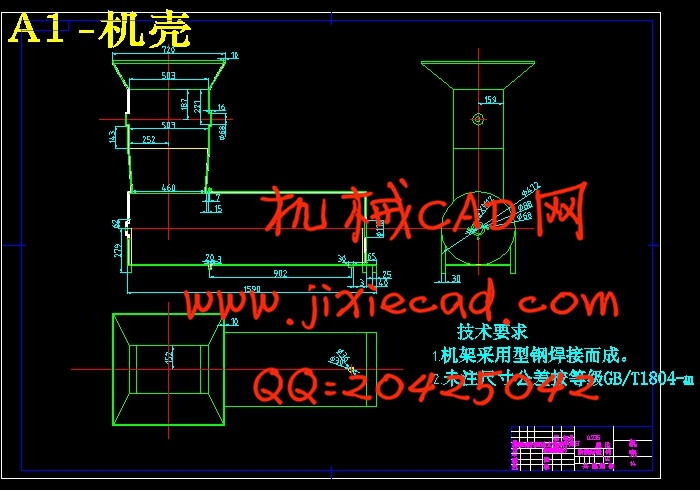

2.1 整体设计预览图及其原理介绍........................................5

2.2 薯类粉碎方式的选择与设计..........................................5

2.2.1 粉碎的方式....................................................5

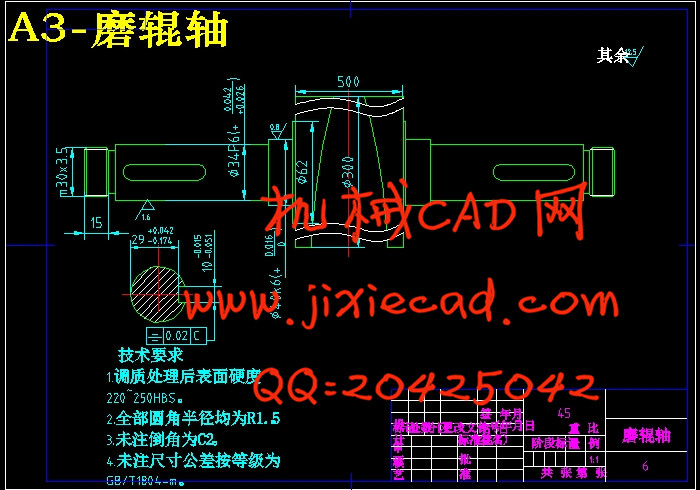

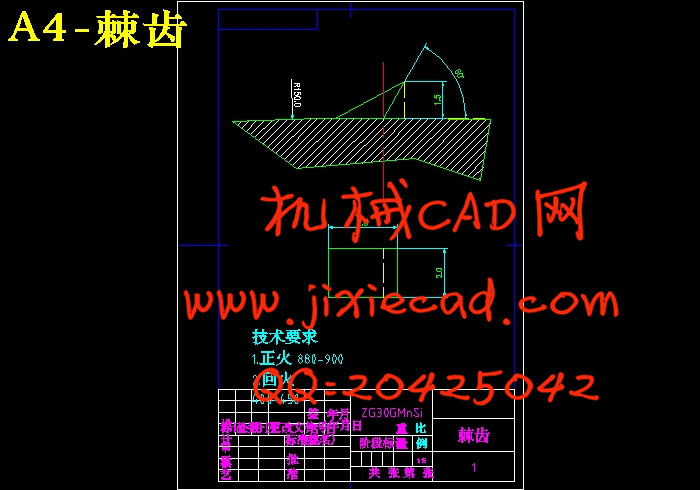

2.2.2 粉碎磨辊的棘齿设计............................................5

2.2.2.1 棘齿大小对淀粉提取率的影响................................6

2.2.2.2 棘齿的大小与受力..........................................6

2.2.2.3 棘齿的排布图..............................................7

2.2.3 电机的选择....................................................7

2.2.4 传动比的分配..................................................7

2.2.5 转速的计算....................................................7

2.2.6 磨辊尺寸及其轴上轴承尺寸的选择................................8

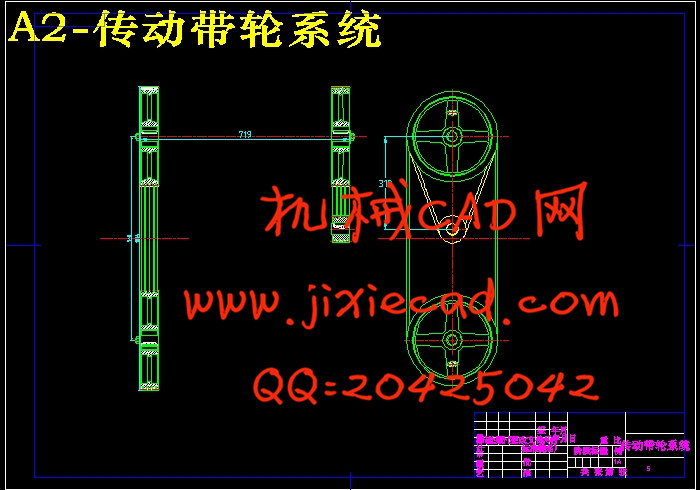

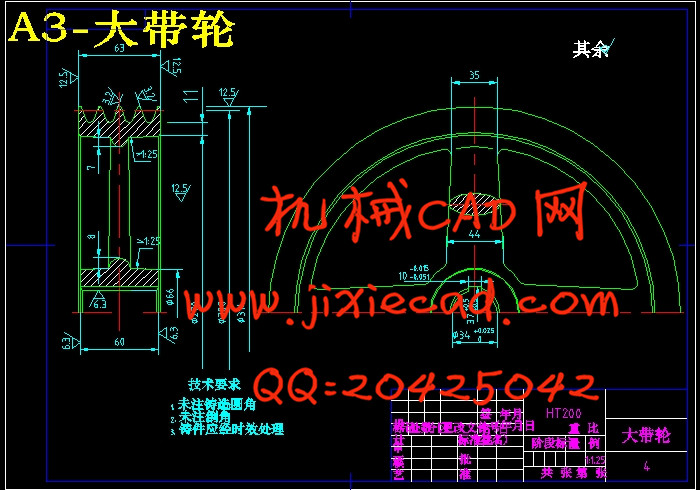

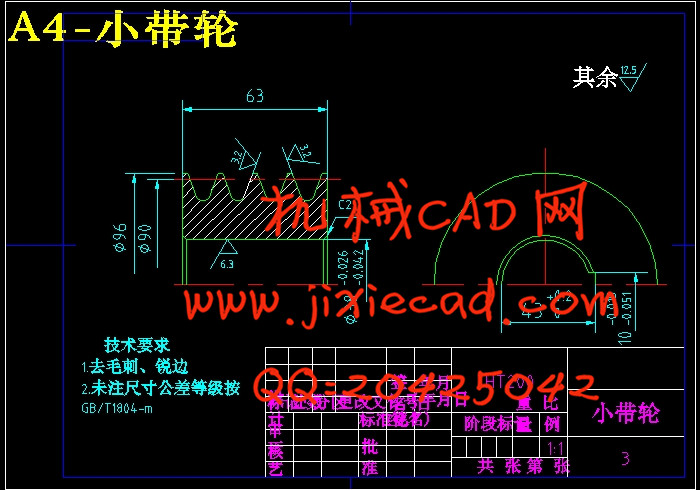

2.3 带轮的选择与计算..................................................9

2.4 搅拌与离心分离装置的设计.........................................11

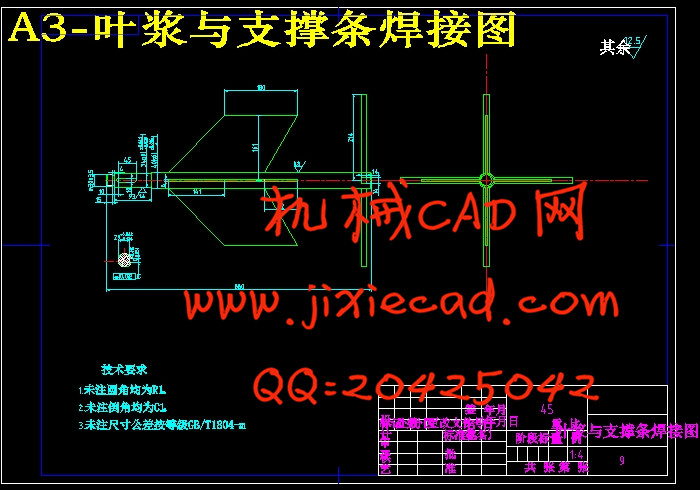

2.4.1 搅拌叶片的设计...............................................11

2.4.2 过滤设备的分类...............................................12

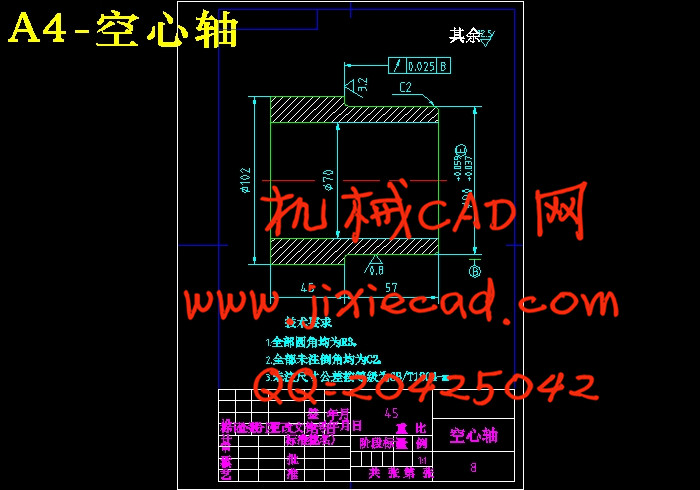

2.4.3 离心滚筒的相关组件及其设计...................................12

2.4.3.1 离心滚筒的离心原理.....................................12

2.4.3.2 筛网的选择.............................................13

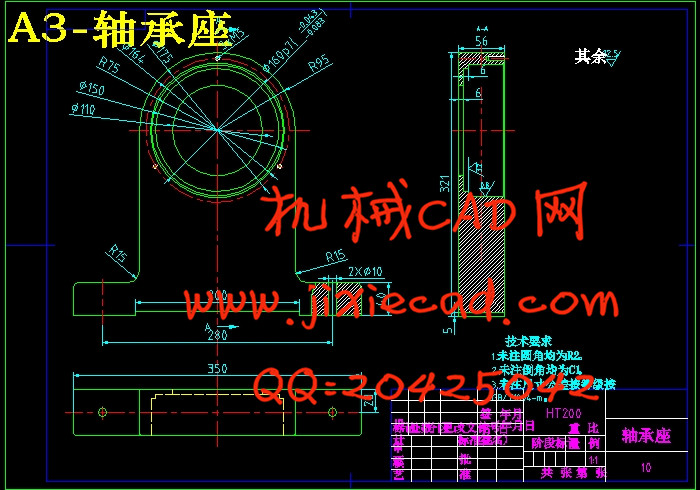

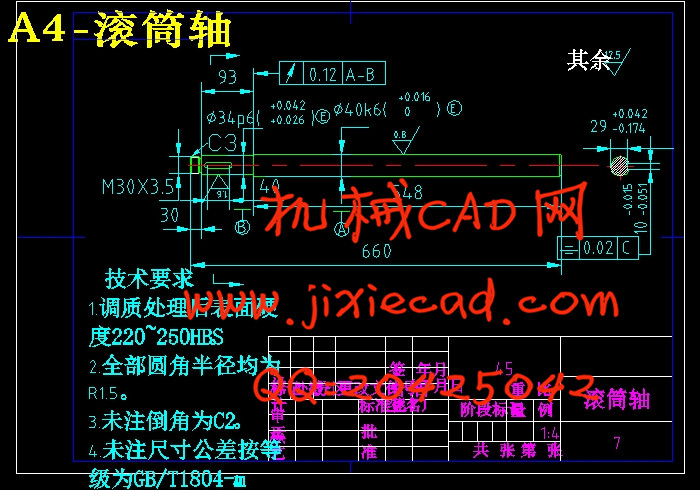

2.4.4 滚筒轴的设计...............................................14

2.5 轴系零件的设计计算.............................................14

2.5.1 初算轴径d................................................. 14

2.5.2 轴承的校核.................................................14

2.6 喷雾干燥.......................................................15

2.6.1 干燥原理...................................................15

2.6.2 干燥的优缺点...............................................15

2.6.3 喷雾干燥对设备的要求.......................................16

2.6.4 喷雾干燥工艺流程图.........................................16

参考文献................................................. 18

设计总结 ............................................... 19

该薯类打浆制粉、干燥机可连续完成对薯类(主要指马铃薯、甘薯和木薯)

的粉碎打浆、搅拌、离心分离和脱水干燥功能。该机一定程度上解决了淀粉生产过程中的淀粉纯度低和生产速度不够快捷的难题。采用离心分离,提高了淀粉的纯度;接喷雾干燥,省却了耗时较长的淀粉沉降过程。该机生产速度快捷,适用于工厂生产。

目前,我国大型的机械化薯类淀粉厂并不多,大多数工厂采用落后的开放式工艺,手工操作或部分机械化操作,因此存在着设备简陋、不定型、不配套、收粉率低(50-60%)、卫生条件差、产量小、劳动量大、综合利用差等问题。

本设计进行改进,满足现代设计要求。该机一定程度上解决了淀粉生产过程中的淀粉纯度低和生产速度不够快捷的难题。

关键词:薯类;淀粉;干燥

Abstract

The potato pulp dryer can be completed for milling, the potato (mainly refers to the potato, sweet potato and cassava).The crushing and beating, stirring, centrifugal separation and dewatering and drying function.The machine was solved on certain level starch production starch in process of low purity and production rate is not fast problem.Centrifugal separation, improved starch purity; by spray drying, obviates the time-consuming starch settling process.The machine production speed is quick, is suitable for factory production.

At present, China's large-scale mechanization of potato starch factory is not much, most factories use backward open process, manual operation or partially-mechanized operations, therefore the existence of simple equipment, not stereotypes, not matching, low powder collecting rate (5060%), poor hygiene, output is little, large amount of labor, comprehensive utilization the problem such as difference.

This design was improved, meet the modern design requirements.The machine was solved on certain level starch production starch in process of low purity and production rate is not fast problem.

Key words: potato; starch; dry

目录

1 绪论

1.1 课题背景

1.1.1 薯类作物......................................................1

1.1.2 甘薯的简介....................................................1

1.1.3 马铃薯的简介..................................................1

1.1.4 我国薯类加工设备现状..........................................2

1.2 薯类加工工序介绍..................................................3

1.3 淀粉及其制品深加工工业的市场前景..................................4

1.4 设计的主要内容 ...................................................4

2 薯类打浆制粉、干燥机的总体设计........................................4

2.1 整体设计预览图及其原理介绍........................................5

2.2 薯类粉碎方式的选择与设计..........................................5

2.2.1 粉碎的方式....................................................5

2.2.2 粉碎磨辊的棘齿设计............................................5

2.2.2.1 棘齿大小对淀粉提取率的影响................................6

2.2.2.2 棘齿的大小与受力..........................................6

2.2.2.3 棘齿的排布图..............................................7

2.2.3 电机的选择....................................................7

2.2.4 传动比的分配..................................................7

2.2.5 转速的计算....................................................7

2.2.6 磨辊尺寸及其轴上轴承尺寸的选择................................8

2.3 带轮的选择与计算..................................................9

2.4 搅拌与离心分离装置的设计.........................................11

2.4.1 搅拌叶片的设计...............................................11

2.4.2 过滤设备的分类...............................................12

2.4.3 离心滚筒的相关组件及其设计...................................12

2.4.3.1 离心滚筒的离心原理.....................................12

2.4.3.2 筛网的选择.............................................13

2.4.4 滚筒轴的设计...............................................14

2.5 轴系零件的设计计算.............................................14

2.5.1 初算轴径d................................................. 14

2.5.2 轴承的校核.................................................14

2.6 喷雾干燥.......................................................15

2.6.1 干燥原理...................................................15

2.6.2 干燥的优缺点...............................................15

2.6.3 喷雾干燥对设备的要求.......................................16

2.6.4 喷雾干燥工艺流程图.........................................16

参考文献................................................. 18

设计总结 ............................................... 19