设计简介

摘要

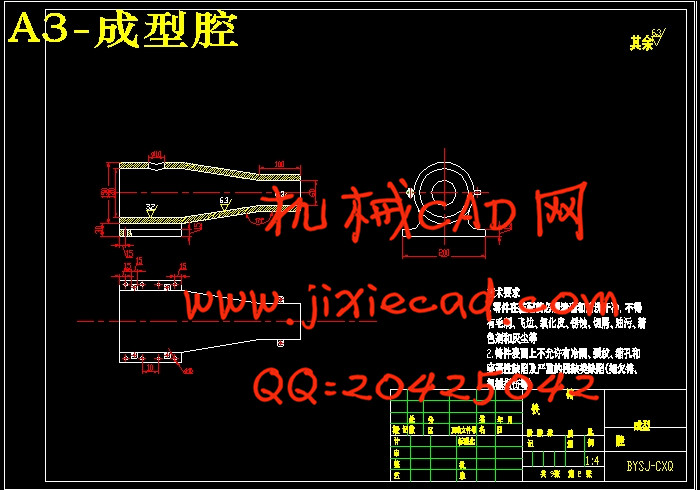

成型机是树枝剪碎成型机的成型部分,作为树枝剪碎成型机的最终输出部分,成型机参数的选择对整个机械的功耗,成型效果等,起着决定性的作用。影响成型机效果的主要因素有:成型颗粒的含水率,成型颗粒大小,成型压力大小等。通过查阅相关文献,选定成型方式为机械往复式活塞冲压成型机。确定适当的成型压力,含水率,颗粒大小等。再在实际需求的基础上,确定成型直径的大小,在此基础上,建立适当的模型,设计出成型筒的具体参数,再进行缸体,轴等的校核,从而最终确定相关参数。

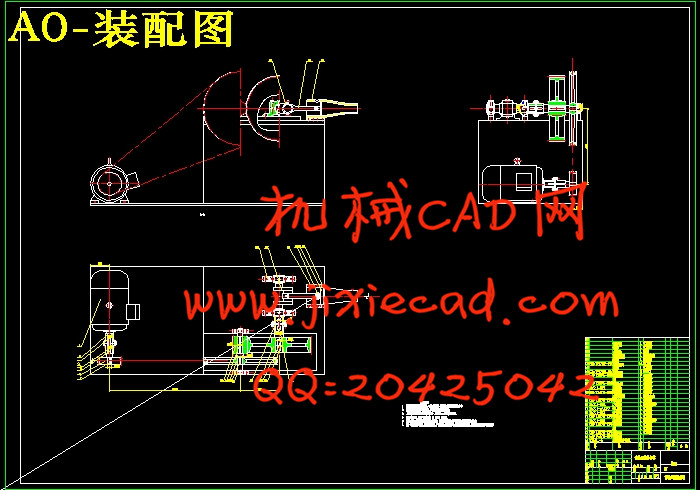

本方案选择的曲柄压力成型机是通过曲柄滑块机构将电动机的旋转运动转换为滑块的直线往复运动,对坯料进行加工的机械。曲柄压力机动作平稳,结构简单,操作方便,性能可靠。

关键词:成型机,曲柄机构,机械制造

ABSTRACT

Molding machine branches to cut it into pieces forming part of the molding machine, was cut to the final output part of the molding machine, molding machine parameter selection on the power consumption of the whole machinery, molding effect plays a decisive role as branches. The main factors affecting the effect of molding machines: the moisture of the forming particles, forming particle size, forming pressure and size. Through the relevant literature, selected molding methods for mechanical reciprocating piston stamping molding machine. To determine the appropriate molding pressure, moisture content, particle size. And then determine the size of the diameter of the molding on the basis of actual demand, and on this basis, the establishment of an appropriate model to design the specific parameters of the forming tube, cylinder, axis, etc. check, which ultimately determine the relevant parameters.

Crank pressure machine is pass crank a slippery piece organization to revolve electric motor conversion for slippery piece of straight line back and forth sport ,Carries the formed processing to the compression materials the forging and stamping machinery The crank press is steady ,the work is reliable ,Its structure is simple ,the ease of operation ,the performance is reliable ,the coupling uses the rigidity to trans the key type coupling, the use service is convenient

Keyword:molding machine;crank organization; machine manufacturing

成型机是树枝剪碎成型机的成型部分,作为树枝剪碎成型机的最终输出部分,成型机参数的选择对整个机械的功耗,成型效果等,起着决定性的作用。影响成型机效果的主要因素有:成型颗粒的含水率,成型颗粒大小,成型压力大小等。通过查阅相关文献,选定成型方式为机械往复式活塞冲压成型机。确定适当的成型压力,含水率,颗粒大小等。再在实际需求的基础上,确定成型直径的大小,在此基础上,建立适当的模型,设计出成型筒的具体参数,再进行缸体,轴等的校核,从而最终确定相关参数。

本方案选择的曲柄压力成型机是通过曲柄滑块机构将电动机的旋转运动转换为滑块的直线往复运动,对坯料进行加工的机械。曲柄压力机动作平稳,结构简单,操作方便,性能可靠。

关键词:成型机,曲柄机构,机械制造

ABSTRACT

Molding machine branches to cut it into pieces forming part of the molding machine, was cut to the final output part of the molding machine, molding machine parameter selection on the power consumption of the whole machinery, molding effect plays a decisive role as branches. The main factors affecting the effect of molding machines: the moisture of the forming particles, forming particle size, forming pressure and size. Through the relevant literature, selected molding methods for mechanical reciprocating piston stamping molding machine. To determine the appropriate molding pressure, moisture content, particle size. And then determine the size of the diameter of the molding on the basis of actual demand, and on this basis, the establishment of an appropriate model to design the specific parameters of the forming tube, cylinder, axis, etc. check, which ultimately determine the relevant parameters.

Crank pressure machine is pass crank a slippery piece organization to revolve electric motor conversion for slippery piece of straight line back and forth sport ,Carries the formed processing to the compression materials the forging and stamping machinery The crank press is steady ,the work is reliable ,Its structure is simple ,the ease of operation ,the performance is reliable ,the coupling uses the rigidity to trans the key type coupling, the use service is convenient

Keyword:molding machine;crank organization; machine manufacturing

目录

摘要 1

ABSTRACT 2

第一章.绪论 3

1.1课题的目的和意义 3

1.2国内外发展情况 3

第二章.压缩成型方式的选择及相关参数的计算 7

2.1压缩成型方式的分类 7

2.2成型方式选择 9

2.3颗粒参数的选择 10

2.4相关数值的选择 11

2.5电动机的选择 14

第三章.传动系统设计 17

3.1传动系统的类型及系统分析 17

3.1.1传动系统的类型 17

3.1.2传动系统的布置方式 17

3.1.3传动级数和各级传动比的分配 18

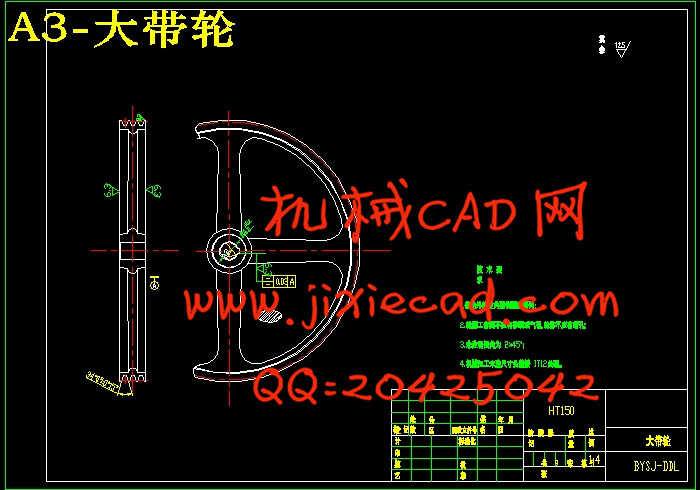

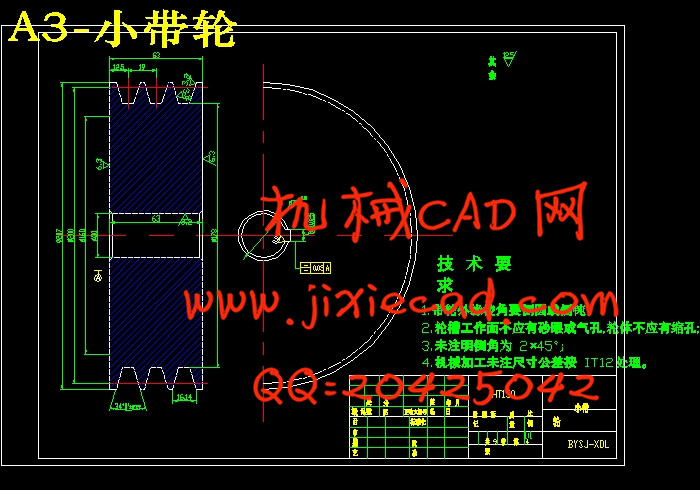

3.2带轮传动设计 18

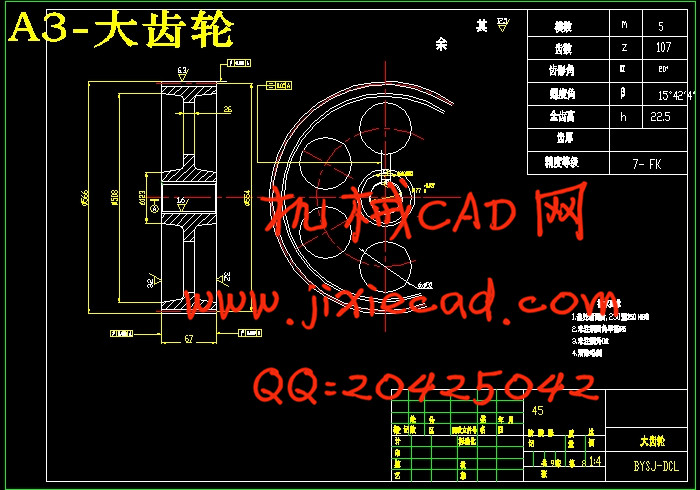

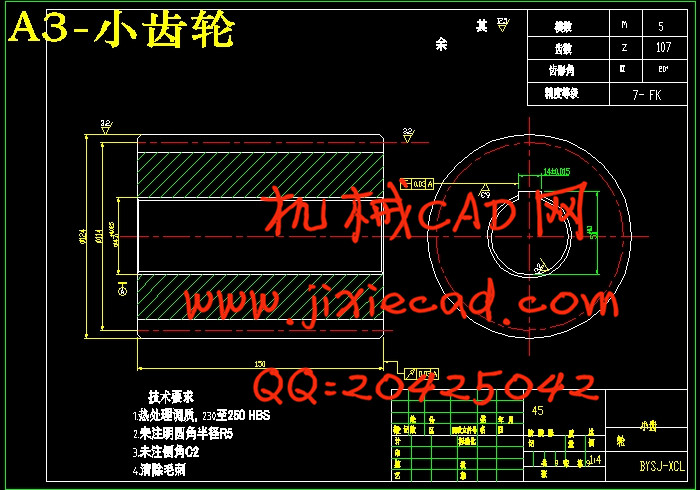

3.3 齿轮传动的设计 20

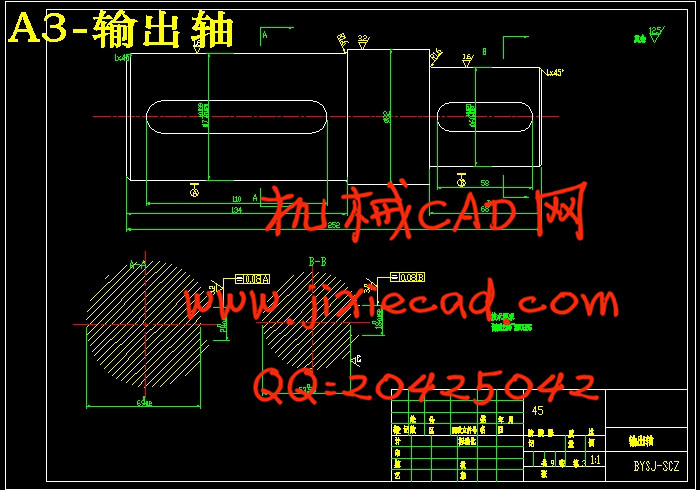

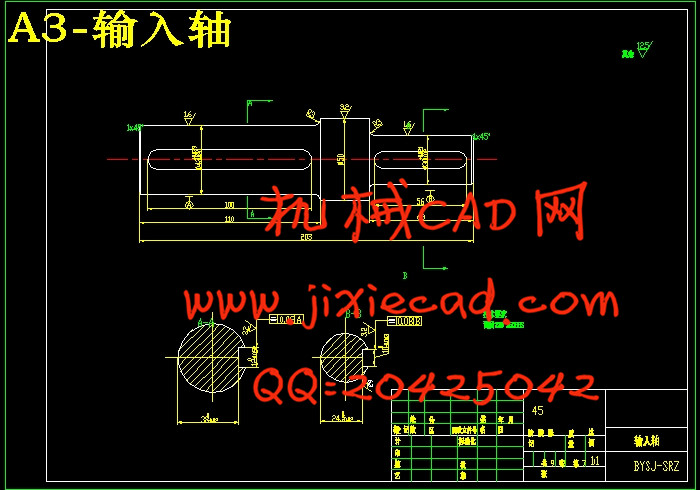

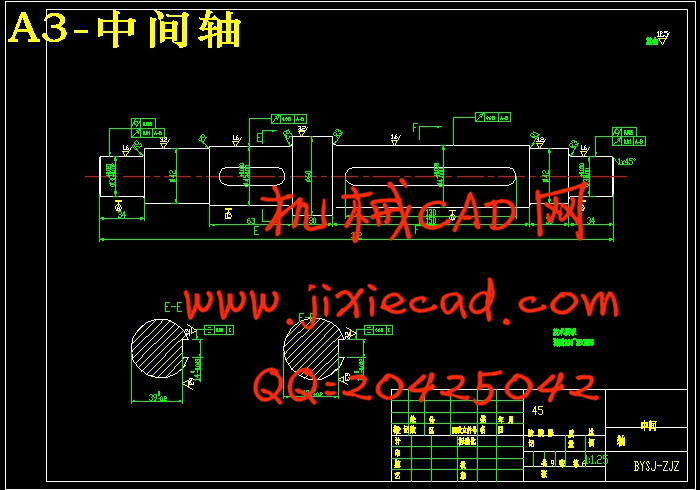

3.4轴的设计 22

3.4.1轴的概述 22

3.5曲柄滑块机构 25

3.6曲柄轴的设计计算 27

3.7滑动轴承座的选择 28

第四章.机身的设计 30

结束语 31

参考文献 32

致谢 33

摘要 1

ABSTRACT 2

第一章.绪论 3

1.1课题的目的和意义 3

1.2国内外发展情况 3

第二章.压缩成型方式的选择及相关参数的计算 7

2.1压缩成型方式的分类 7

2.2成型方式选择 9

2.3颗粒参数的选择 10

2.4相关数值的选择 11

2.5电动机的选择 14

第三章.传动系统设计 17

3.1传动系统的类型及系统分析 17

3.1.1传动系统的类型 17

3.1.2传动系统的布置方式 17

3.1.3传动级数和各级传动比的分配 18

3.2带轮传动设计 18

3.3 齿轮传动的设计 20

3.4轴的设计 22

3.4.1轴的概述 22

3.5曲柄滑块机构 25

3.6曲柄轴的设计计算 27

3.7滑动轴承座的选择 28

第四章.机身的设计 30

结束语 31

参考文献 32

致谢 33