设计简介

摘要:近年来,随着我国经济建设的发展,在很多领域的生产实际中,对各种木质物料粉碎机的需求越来越大。根据木质物料粉碎机用途的不同,研制出满足各种要求的木质物料粉碎机已成为目前迫在眉睫的紧要任务。

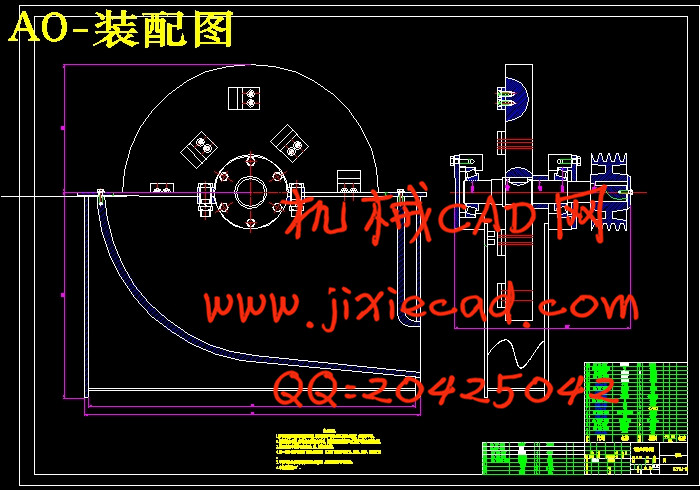

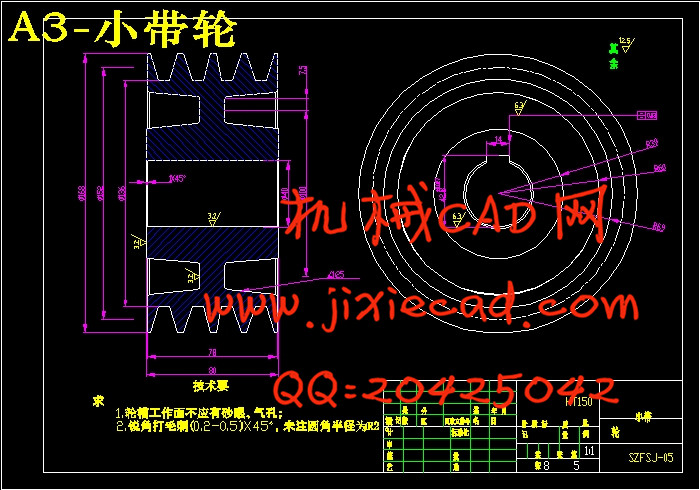

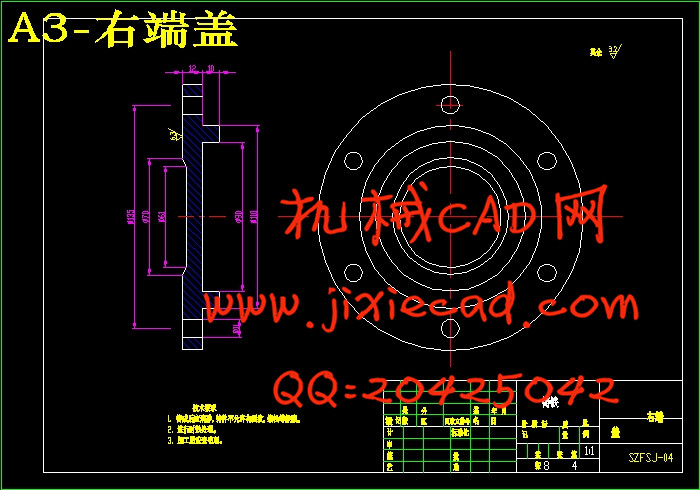

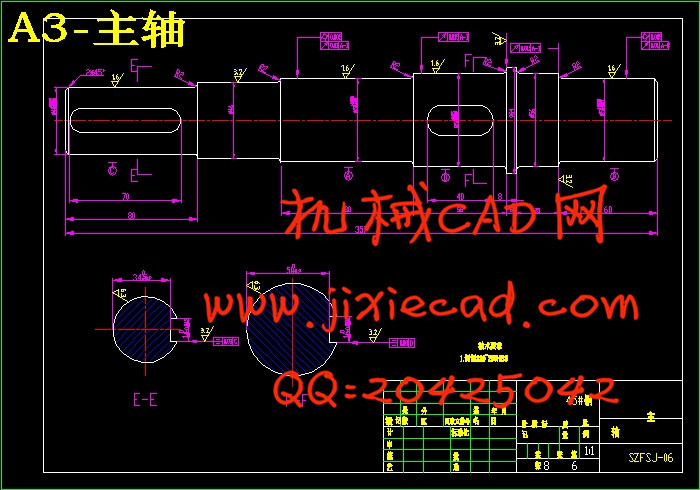

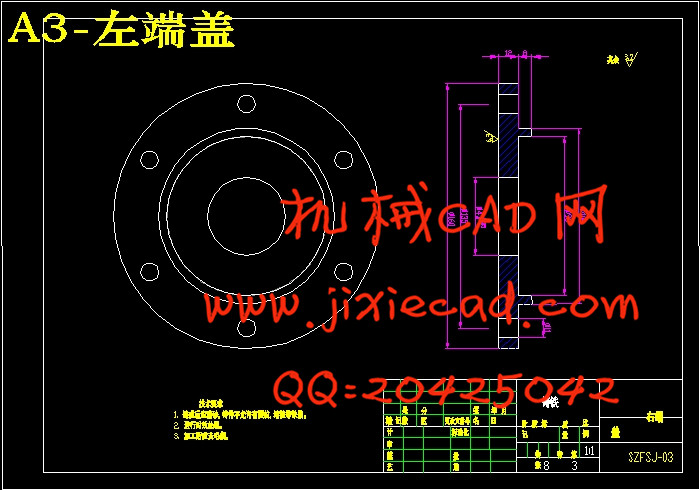

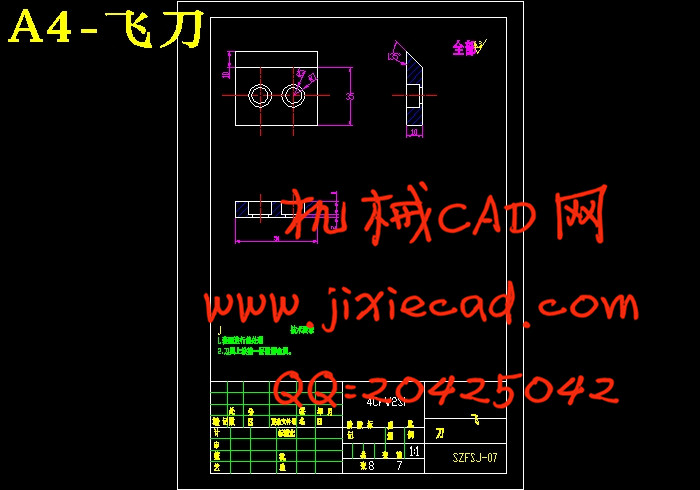

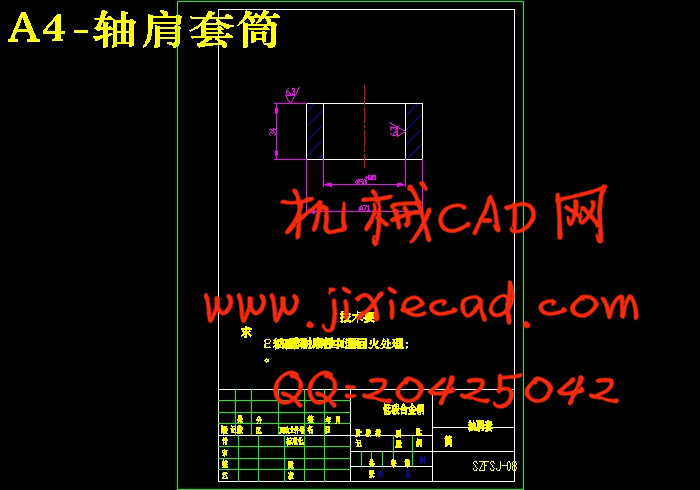

本机的机架、上盖都采用了铸件,降低了整机的重心;发动机和主轴之间通过皮带传动,缓和了载荷冲击;主轴通过两个圆锥滚子轴承与机架连接;刀盘和主轴之间采用平键联接;飞刀用垫块和螺栓固定。飞刀采用螺旋曲面方式依次摆放多把短刀。

关键词:树枝粉碎机,园林绿化,削片机,木材加工The Design of branch chipper

Abstract:In recent years, with the economic development in our country, and in many fields in the actual production, for a variety of wooden material grinder increasing demand. According to the wooden material grinder of different applications, developed to meet the various requirements of the wooden material grinder has become the urgent task for current imminent.

The machine's rack, about the top head has used the casting to reduce the machine's center of gravity, Strengthened the stability of complete machine effectively; Between the engine and the main axle adopts the belt transmission to relax the load impact, reduced the harm of overload which brings for the major component such as fly cutter;The connection of main axle and rack is two circular cone roller, to prevent the main axle have great beating; The connection of cutter head and main axle is flat key, Coordinates closely;The fly cutter uses the bolt and cushion to be fixed, Reliable and stable, The fly cutter stretches out the quantity to be able to adjust,And advantageous for disassembling and the replacement. Rack is equipped with wheels, can be driven by the traction machine,Suitable to use in the urban green residues and the trail level lumber processing.

Key words: branch chipper, landscaping, chipper, wood processing目录

摘要 1

Abstract 2

1 绪论 3

1.1课题研究背景,目的及其意义 3

1.2 枝桠粉碎机的分类特点及其工作原理 3

1.3 国内外枝桠粉碎机的发展现状和趋势 5

1.4 选题的设计思想,设计方法及改进 6

1.5 预期结果 6

2 移动式枝桠粉碎机的总体设计 7

2.1 枝桠粉碎机设计任务 7

2.2 普通盘式枝桠粉碎机的结构 7

2.3盘式枝桠粉碎机的削片原理 9

2.4本章小结 11

3 主要技术参数的确定和计算 12

3.1 生产能力的确定 12

3.2 飞刀数量的确定 12

3.3切削力的计算 13

3.3.1主切削力的理论分析与计算 13

3.3.2主切削力的经验公式 15

3.4切削功率的计算 19

3.4.1 切削功率的计算 19

3.5飞刀伸出量的确定 21

4 主要部件的设计计算 22

4.1盘式短刀与长刀削片机比较 22

4.2飞刀平面布置 24

4.3.2轴的结构设计 27

4.4滚动轴承的选择 28

4.5 键连接的设计 28

4.5.1带轮与输入轴间键的选择及校核 28

4.5.2输出轴与齿轮间键的选择及校核 28

4.6飞刀的设计 29

4.7本章小结 29

5 主要部件的校核和验算 30

5.1 主轴强度的校核 30

5.1.1求轴上的载荷 30

5.1.2按弯扭合成应力校核轴的强度 31

5.1.3 精确校核轴的疲劳强度 31

5.2 滚动轴承的校核 34

5.3本章小结 35

5.4最后完成图 35

结论 36

致谢 37

参考文献 38